Proper upkeep of small marine engines is essential for ensuring their longevity and optimal performance. Understanding the intricacies of these machines can greatly enhance their functionality, allowing for a smoother operation on the water. This section aims to provide valuable insights into the various aspects of engine care, ensuring users can navigate potential issues with confidence.

Essential Procedures for maintaining these engines include routine checks, troubleshooting common problems, and performing necessary adjustments. By familiarizing oneself with the components and functions of the engine, users can effectively address minor complications before they escalate into significant challenges.

In addition, awareness of safety measures during maintenance is crucial. Proper handling of tools and components will not only protect the engine but also ensure the safety of the operator. With the right knowledge and techniques, maintaining a small marine engine can be both straightforward and rewarding.

Overview of Mercury 9.9 Engine

This section provides an insight into a popular model of outboard motors known for its reliability and performance. Designed for various watercraft, this engine is appreciated for its efficient power delivery and ease of use. With a focus on innovation, this model stands out in the boating community for its robust construction and user-friendly features.

Key Features

One of the standout attributes of this engine is its lightweight design, which contributes to enhanced maneuverability on the water. The engineering incorporates advanced technology that ensures optimal fuel efficiency, making it a cost-effective choice for long outings. Additionally, the quiet operation of the motor allows for a more pleasant experience while navigating through serene waters.

Maintenance Considerations

Regular upkeep is essential to maintain the performance of this outboard motor. Simple tasks such as checking fluid levels and inspecting the propeller can significantly extend the lifespan of the engine. Adhering to maintenance schedules and following guidelines will ensure that the motor remains in peak condition, ready for any adventure.

Common Issues and Solutions

When operating a small outboard engine, various challenges may arise that can affect performance and reliability. Identifying these common problems early on can save time and ensure a smoother boating experience.

One frequent issue is difficulty starting the engine. This can often be attributed to a faulty ignition system or fuel delivery problems. Checking the spark plugs and ensuring the fuel lines are clear can help address this concern.

Another common challenge is overheating. This is usually caused by a clogged cooling system or a malfunctioning thermostat. Regular maintenance, including flushing the cooling system and inspecting the water pump, can prevent overheating and prolong engine life.

Additionally, unusual noises during operation may indicate internal wear or damage. It’s essential to inspect components like bearings and gaskets promptly to avoid more severe issues.

By staying aware of these typical problems and implementing preventive measures, you can enhance the longevity and efficiency of your outboard engine.

Routine Maintenance Procedures

Regular upkeep is essential for ensuring the longevity and optimal performance of your marine engine. Following a systematic approach to maintenance can help prevent unexpected issues and extend the lifespan of the equipment.

Inspection of Key Components

Frequent examination of critical parts, such as the fuel system, cooling system, and ignition components, is vital. Look for signs of wear or damage, and address any abnormalities promptly. Checking fluid levels and ensuring cleanliness can significantly enhance operational reliability.

Cleaning and Lubrication

Maintaining cleanliness is crucial for performance. Regularly clean the exterior surfaces to prevent corrosion and buildup. Additionally, applying the appropriate lubricants to moving parts minimizes friction and reduces wear, contributing to smoother operation.

Essential Tools for Repair

Having the right instruments is crucial for performing maintenance on watercraft engines. These tools not only facilitate efficient work but also ensure that every task is executed with precision. In this section, we will explore the must-have equipment for effective servicing.

Basic Hand Tools

Basic hand tools are indispensable for any maintenance project. They allow for easy access to various components and make the process smoother. Here’s a list of essential hand tools:

| Tool | Purpose |

|---|---|

| Wrenches | For tightening and loosening bolts and nuts. |

| Screwdrivers | To remove and secure screws in place. |

| Pliers | For gripping and bending materials. |

| Socket Set | To work with various sizes of nuts and bolts efficiently. |

Specialized Equipment

In addition to standard hand tools, some specialized equipment can greatly enhance the maintenance experience. These tools are designed for specific tasks and can significantly reduce time and effort.

| Tool | Purpose |

|---|---|

| Compression Tester | To check the compression of engine cylinders. |

| Fuel Pressure Gauge | To measure the fuel system’s pressure. |

| Multimeter | For testing electrical systems and diagnosing issues. |

| Torque Wrench | To apply specific torque settings on fasteners. |

Troubleshooting Electrical Problems

Electrical issues in outboard motors can often be complex, yet identifying the root cause is essential for effective resolution. Common symptoms include difficulty starting, intermittent power loss, or malfunctioning components. A systematic approach to diagnosing these problems can save time and resources.

Begin by examining the battery, ensuring it is fully charged and the terminals are clean and securely connected. A weak or dead battery is a frequent culprit for electrical failures. If the battery appears functional, inspect the wiring harness for any signs of wear, corrosion, or loose connections, which can disrupt the flow of electricity.

Next, check the fuses in the system. A blown fuse can prevent certain functions from operating properly. Replacing a faulty fuse is a straightforward task, but it’s important to determine why the fuse failed initially. If the issue persists, further investigation into the electrical components may be necessary.

Finally, consider the ignition system. Problems here can lead to starting difficulties or erratic engine behavior. Ensure that the spark plugs are in good condition and replace them if needed. Additionally, testing the ignition coil and other related components can help pinpoint the source of the issue.

Fuel System Inspection Techniques

Ensuring the optimal performance of the fuel delivery mechanism is crucial for the longevity and efficiency of your marine engine. This section outlines effective methods for assessing the integrity and functionality of the fuel system, which is essential for maintaining reliable operation.

Visual Examination

Begin by visually inspecting the components of the fuel system, including lines, connectors, and filters. Look for signs of wear, leaks, or corrosion that may affect performance. A thorough inspection helps identify potential issues before they escalate.

Pressure Testing

Utilizing a pressure gauge can provide valuable insights into the fuel system’s functionality. By measuring the pressure during operation, you can determine if the system is delivering fuel at the required levels. Abnormal pressure readings may indicate blockages or malfunctions that need attention.

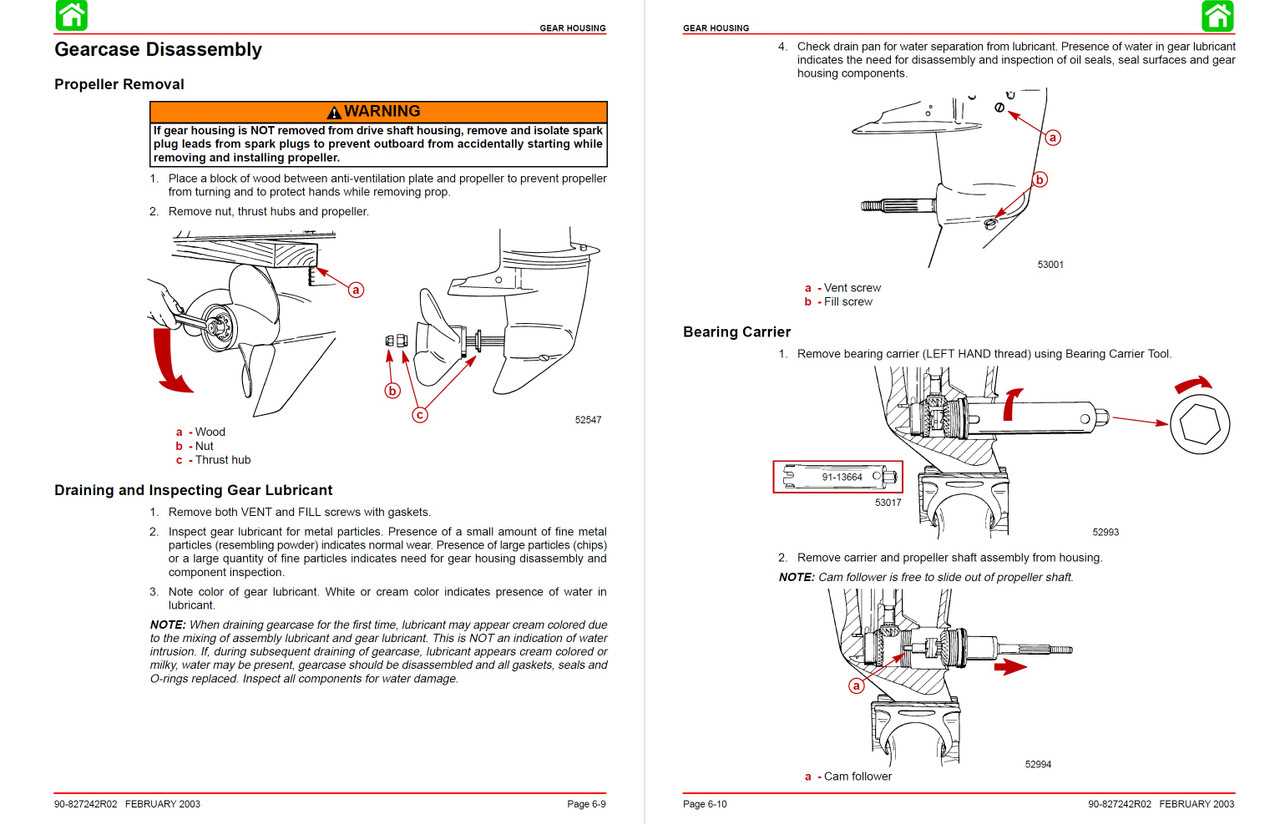

Replacing Propeller and Shaft

Ensuring the optimal performance of your watercraft often involves the replacement of essential components like the propeller and drive shaft. This process not only enhances efficiency but also improves overall handling. A proper understanding of the procedures involved is crucial for a successful replacement.

Preparation and Tools Required

Before beginning, gather the necessary tools such as a socket set, wrenches, and a propeller puller. Make sure to also have safety gear on hand to protect yourself during the process. Verify that the vessel is securely positioned and stable to prevent any accidents while working.

Step-by-Step Replacement Process

Start by removing the retaining nut and carefully extracting the propeller from the shaft. Inspect the components for wear and damage, replacing them as needed. Once the old parts are removed, align the new propeller with the shaft, ensuring a snug fit. Reattach the retaining nut, tightening it to the manufacturer’s specifications for optimal security.

Cooling System Care and Repair

Maintaining the efficiency of the cooling mechanism is essential for optimal performance and longevity of any watercraft engine. Proper attention to this system helps prevent overheating and ensures smooth operation. Regular inspections and timely interventions are key to keeping the cooling components functioning effectively.

Routine Maintenance

Conducting routine checks on the cooling system is vital. This includes inspecting hoses for cracks, ensuring connections are secure, and examining the coolant levels. Flushing the system periodically can also help remove any debris or buildup that may hinder performance.

Common Issues and Solutions

Overheating is a prevalent issue that can arise due to various factors, such as blocked passages or low fluid levels. If overheating occurs, it is crucial to investigate and address the root cause immediately. Replacing worn-out components and clearing obstructions can restore the system’s efficiency and prevent future problems.

Best Practices for Engine Storage

Proper storage of an engine is crucial to ensure its longevity and optimal performance. By following certain guidelines, you can prevent potential damage and maintain the condition of your equipment during periods of inactivity.

- Clean Thoroughly: Before storing, remove any dirt, debris, and fuel residue from the engine’s exterior. This helps prevent corrosion and buildup over time.

- Drain Fluids: Empty all fuel and oil from the engine to avoid degradation and contamination. Use fresh fluids upon reactivation.

- Protect Against Moisture: Store in a dry location to minimize exposure to humidity. Consider using desiccants or moisture-absorbing products.

- Cover the Engine: Use a protective cover to shield from dust and environmental factors that could cause wear.

- Inspect and Maintain: Regularly check stored engines for any signs of damage or wear. Perform necessary maintenance before the next use.

By adhering to these practices, you can enhance the reliability and readiness of your engine for future use.

Understanding Warranty and Support

When purchasing a marine engine, it’s essential to comprehend the protection and assistance offered by the manufacturer. This understanding ensures that you are aware of your rights and the resources available should issues arise during the lifecycle of the product.

Typically, the warranty covers various aspects, including:

- Defects in materials and workmanship

- Coverage duration, often spanning several years

- Exclusions for specific damages or misuse

To maximize the benefits of your warranty, consider the following:

- Keep all purchase receipts and documentation.

- Follow maintenance guidelines as outlined by the manufacturer.

- Register your product if required.

In addition to the warranty, support services are crucial. These may include:

- Access to customer service representatives for inquiries

- Availability of repair centers or authorized service providers

- Online resources such as troubleshooting guides and FAQs

By understanding both the warranty and available support options, you can ensure a smoother experience with your marine engine, enhancing your overall satisfaction.

Performance Enhancements and Modifications

Improving the capabilities of an outboard engine involves various strategies that can significantly boost power and efficiency. By focusing on specific upgrades and adjustments, enthusiasts can achieve better performance tailored to their needs.

One effective approach is to enhance the intake and exhaust systems. Upgrading these components allows for increased airflow, which can lead to improved combustion and overall output. Additionally, tuning the fuel delivery system can optimize the air-fuel mixture for enhanced efficiency.

| Modification | Description |

|---|---|

| Intake Upgrade | Installing a high-performance air filter can enhance airflow into the engine. |

| Exhaust System | Replacing the stock exhaust with a performance model reduces back pressure, improving efficiency. |

| Fuel System Tuning | Adjusting the fuel injectors can ensure the optimal air-fuel mixture for better performance. |

| Propeller Selection | Choosing the right propeller can enhance acceleration and top speed based on intended use. |

Incorporating these enhancements not only boosts performance but also contributes to a more enjoyable experience on the water. Careful consideration of each modification will ensure that the engine operates at its best.

Safety Precautions During Repairs

When performing maintenance on marine engines, adhering to safety protocols is essential to prevent accidents and ensure a smooth workflow. Understanding the potential hazards and preparing adequately can help avoid injuries and equipment damage.

- Personal Protective Equipment: Always wear appropriate gear such as gloves, goggles, and sturdy footwear to safeguard against injuries.

- Ventilation: Ensure the workspace is well-ventilated to avoid inhaling harmful fumes from fuel or lubricants.

- Fire Safety: Keep a fire extinguisher nearby, and be aware of flammable materials in the vicinity.

- Stability: Ensure that the engine is securely positioned to prevent any movement during maintenance tasks.

- Electrical Safety: Disconnect the battery before working on electrical components to minimize the risk of shock or short circuits.

By following these guidelines, individuals can create a safer environment and reduce the likelihood of accidents during maintenance tasks.