Enthusiasts of classic collectibles often find joy in breathing new life into beloved artifacts from the past. Working with older models requires patience, a careful hand, and an appreciation for both the materials and techniques of a bygone era. This section provides insights for anyone looking to delve into restoration, from first-time hobbyists to seasoned collectors. Our aim is to assist readers in preserving the integrity and charm of these items while ensuring they stand the test of time.

In the following segments, we will explore essential steps and practices, providing an accessible approach to tackling each stage. You’ll gain a clear understanding of common issues that may arise with aging mechanisms, as well as detailed advice on how to address them. From replacing worn parts to fine-tuning intricate features, this guide is designed to help you achieve satisfying and durable results.

Whether you’re aiming to enhance functionality or simply retain the nostalgic aesthetic, restoring these pieces offers a rewarding experience. Dive in to discover the skills, tools, and expertise needed to keep these timeless creations running smoothly, making them ready to en

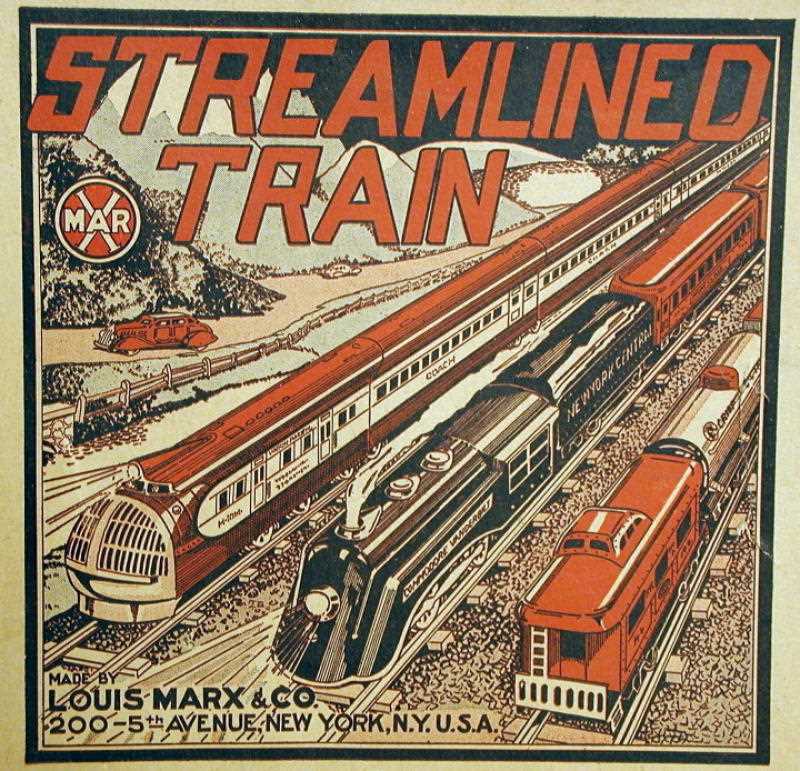

Marx Trains Repair Manual

In this guide, enthusiasts will find practical insights into rejuvenating beloved models from past eras. Whether dealing with minor malfunctions or looking to enhance performance, this section provides essential techniques and knowledge to restore functionality and extend the lifespan of cherished collectibles.

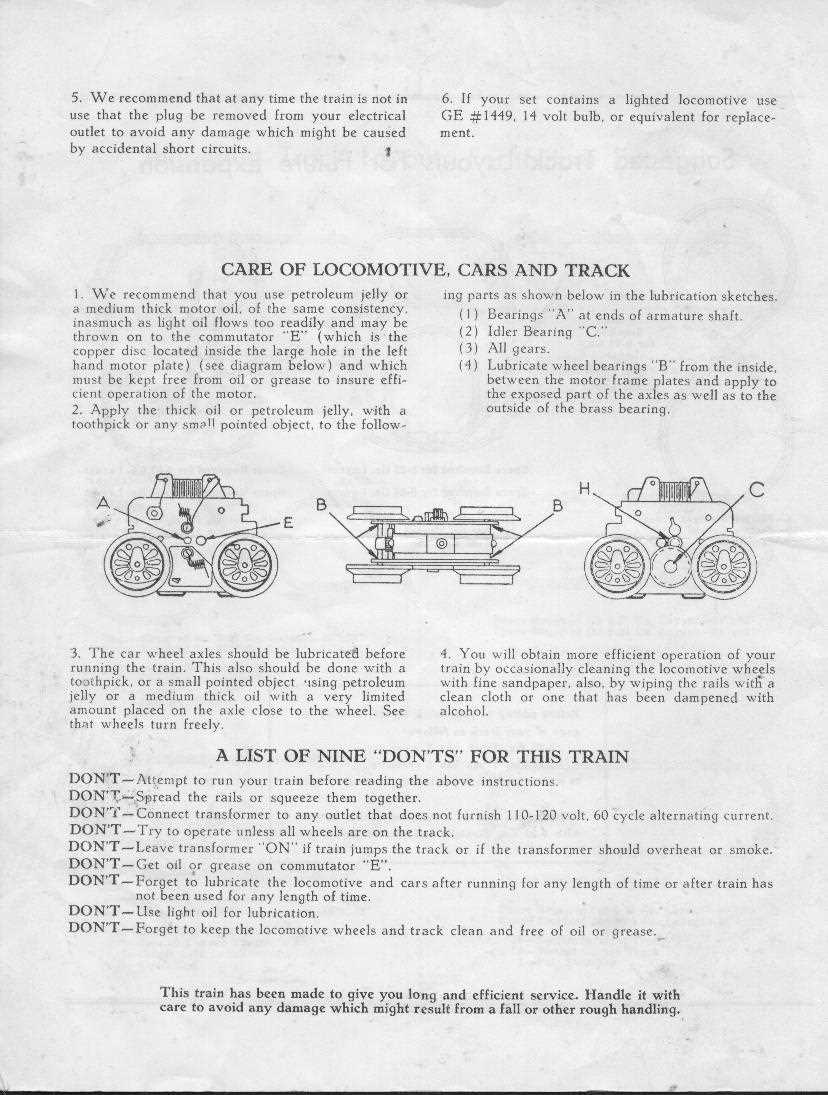

Basic Maintenance Tips

Proper upkeep is essential to preserve these models’ charm and ensure they run smoothly. Regular cleaning, careful lubrication, and inspection of mechanical parts can prevent common issues and keep the components in peak condition. Periodic checks help in identifying wear and tear early, allowing for timely adjustments.

Key Components to Inspect

Each model’s inner workings include various moving parts that may

Understanding Model Rail Designs

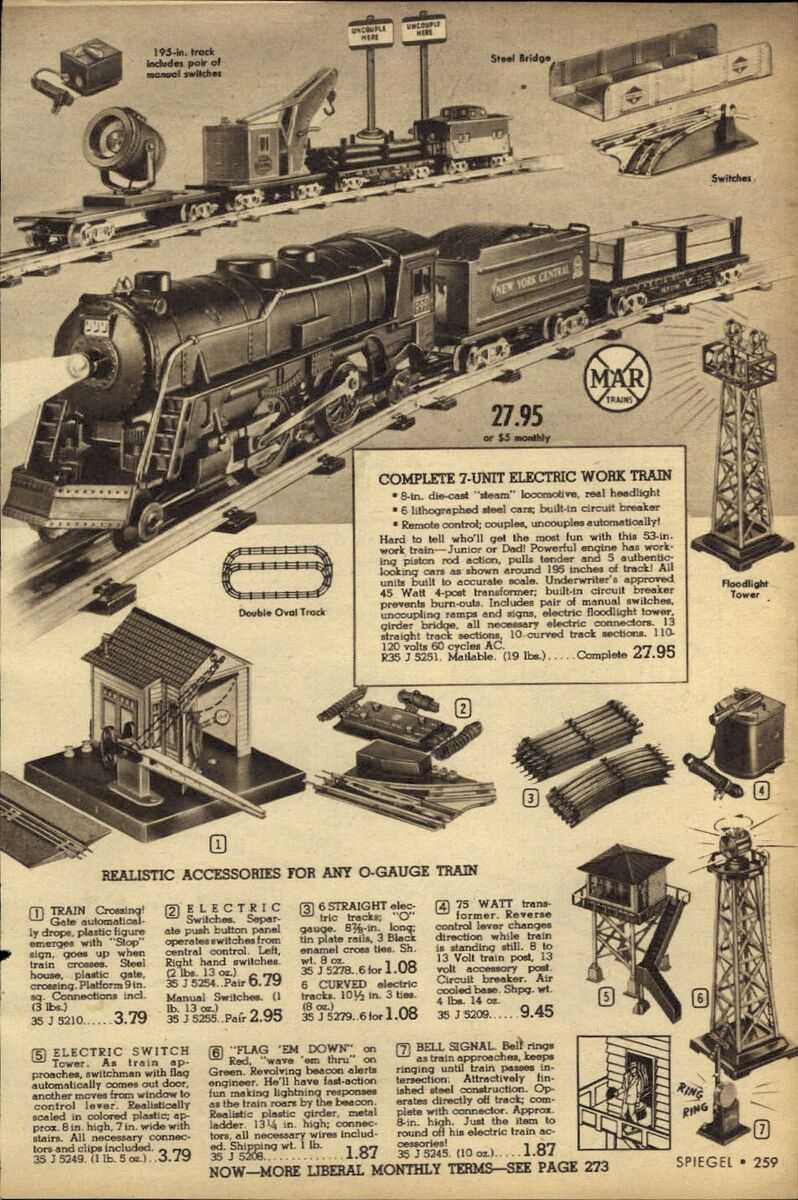

Exploring various types of vintage miniature rail designs unveils an intricate world of detailed craftsmanship and engineering marvels. With origins spanning decades, these pieces reflect distinct styles, materials, and mechanisms that captivate enthusiasts and collectors alike. Each design series embodies unique aspects of the era it represents, adding both aesthetic and historical value to any collection.

Identifying Series and Editions

Many classic miniature rail models are categorized by production series and specific editions, each with unique features and recognizable characteristics. Understanding these details helps enthusiasts distinguish one model from another and appreciate the unique traits that make each piece special.

- Era-Based Design Elements – Some pieces are easily identified by the stylistic and structural traits specific to their time period.

- Material Composition – Different metals, plastics, and paints were often used in particular editions, marking distinct prod

Tools Needed for Train Repairs

When working on model train maintenance, having the right selection of tools can streamline the process, ensuring efficiency and precision. A well-prepared toolkit supports smooth operation and reliable adjustments, reducing wear and prolonging the lifetime of each component. Here is a guide to essential equipment, organized by purpose and function, for optimal maintenance.

Basic Instruments

Basic instruments help manage smaller components and delicate mechanisms, providing precision without causing damage to sensitive parts.

Tool Description Small Screwdrivers Useful for handling tiny screws without stripping or damaging them. Needle-nose Pliers Ideal Diagnosing Common Train Issues

Identifying potential mechanical challenges can help ensure smooth operation and prevent extensive wear. Recognizing signs early can make troubleshooting more effective, allowing for swift adjustments and maintenance. Below is an overview of typical issues and practical guidance for their resolution.

Issue Possible Cause Suggested Solution Power Loss Dirty contacts or connectors Clean contacts and inspect connectors for dust or corrosion buildup Unusual Noise Insufficient lubrication Apply appropriate lubricant to moving parts and check for loose components Erratic Movement Track Step-by-Step Motor Restoration

Restoring a vintage motor involves carefully bringing back its original functionality and improving its durability. This process requires attention to each component to ensure smooth operation and longevity. Below is a structured approach to systematically revive and enhance the motor’s performance.

1. Disassembly and Cleaning

Begin by carefully disassembling the motor, taking note of each part’s position. Use a gentle cleanser to remove accumulated dirt and residue from all components, as cleanliness is essential for optimal reassembly and functioning. Be cautious with delicate parts to prevent any damage during cleaning.

2. Inspecting Components

Examine each piece for wear, especially gears, bushings, and wiring. Parts showing significant damage or corrosion should be either repaired or replaced. Inspect connections thoroughly to ensure they are intact and can conduct efficiently.

3. Lubricating Moving Parts

Apply appropriate lubricant to all moving parts, focusing on gears, bearings, and axles. Proper lubrication reduces friction, extends compone

Repairing Damaged Train Wheels

The process of restoring compromised wheel structures is essential for ensuring operational safety and efficiency. When the integrity of these components is threatened, timely intervention is crucial to prevent further complications.

Identifying Issues: The first step involves a thorough inspection to ascertain the extent of the damage. Look for visible cracks, excessive wear, or any deformation that may compromise functionality.

Cleaning and Preparation: Once the issues are identified, the next phase is to meticulously clean the affected areas. Removing debris and contaminants is vital for effective repairs.

Repair Techniques: Depending on the damage, various methods can be employed. For minor surface issues, grinding may suffice to restore the wheel’s shape. In cases of deeper cracks, welding can be utilized to mend the material. It is crucial to ensure that any repair technique used meets the required safety standards.

Finishing Touches: After repairs, a final inspection is necessary to confirm the restoration’s integrity. Once approved, a protective coating can be applied to enhance durability and prevent future deterioration.

Replacing Worn-Out Gears

When components become excessively worn, it is essential to address the issue promptly to maintain optimal performance. This section focuses on the process of swapping out deteriorated parts to ensure smooth operation.

Identifying when replacements are necessary can prevent further complications. Consider the following indicators:

- Unusual noises during operation

- Slippage or hesitation in movement

- Visible signs of wear or damage

Once you have determined that a replacement is needed, follow these general steps:

- Gather the necessary tools and replacement parts.

- Carefully disassemble the assembly to access the worn components.

- Remove the damaged parts, taking note of their orientation.

- Install the new components, ensuring they are properly aligned.

- Reassemble the unit, double-checking for any loose fittings.

After completing the replacement, it is advisable to conduct a thorough inspection and test the system to confirm everything operates as intended. Regular maintenance and timely replacements can significantly extend the lifespan of the equipment.

Fixing Electrical Wiring Problems

Issues related to electrical connections can often disrupt functionality, leading to various complications. Identifying and addressing these concerns is crucial for ensuring smooth operations and safety. This section will explore common challenges associated with wiring and provide guidance on how to effectively resolve them.

Start by assessing the situation. Check for visible signs of wear or damage in the wiring. Discoloration, frayed edges, or exposed wires can indicate serious problems that require immediate attention. Ensure that the power supply is turned off before proceeding with any inspection or repairs.

Next, test the connections. Utilize a multimeter to check for continuity and voltage. If a particular section shows no connectivity, it may require reconnection or replacement. Pay close attention to any loose terminals, as these can lead to inconsistent power flow.

In cases of faulty components, consider replacing the damaged parts. Always use components that meet the required specifications to maintain the integrity of the system. Secure all connections tightly to prevent future issues.

Finally, after making necessary adjustments, restore power and conduct thorough testing. Monitor the system for any signs of malfunction. Addressing wiring concerns promptly can significantly enhance the reliability and longevity of your equipment.

Maintaining Track Connections

Proper upkeep of track joints is essential for ensuring smooth operations and preventing disruptions. Regular attention to these connections helps maintain optimal performance and extends the lifespan of the entire system. This section outlines key practices to keep in mind for effective maintenance.

Regular Inspection

Routine checks are crucial for identifying potential issues early. Consider the following points during your inspections:

- Look for signs of wear or damage on the connections.

- Ensure that all fasteners are secure and intact.

- Check for any debris or obstructions that may interfere with alignment.

Cleaning and Lubrication

Keeping track joints clean and lubricated promotes smooth operation. Follow these steps:

- Remove any dirt or debris using a soft brush or cloth.

- Apply a suitable lubricant to the joints to minimize friction.

- Wipe off excess lubricant to prevent buildup.

Restoring Paint and Finishes

Maintaining the aesthetics of your equipment often involves rejuvenating the surface layers. Over time, various factors can lead to wear and damage, affecting the appearance and longevity of the material. This section focuses on techniques and methods to effectively refresh and restore these outer coatings, ensuring a polished look and protection against future deterioration.

Preparing the Surface

Before applying any new coatings, it is essential to prepare the surface thoroughly. This involves cleaning the area to remove dirt, grease, and old finishes that may hinder adhesion. Use a mild cleaner and a soft cloth for gentle scrubbing, followed by a rinse with clean water. Once dry, inspect the surface for imperfections such as scratches or dents that may need filling.

Applying New Coatings

When selecting a finish, consider the original type and color to achieve a uniform appearance. Choose high-quality paints or finishes suitable for the material. Apply the product evenly using a brush or spray, depending on the area’s size and detail. Multiple thin coats are preferable to a single thick layer, as this helps avoid drips and ensures a smooth application. Allow each coat to dry completely before applying the next, following the manufacturer’s recommendations for optimal results.

Final Touches: After the final coat has dried, inspect for any imperfections and address them as necessary. A clear protective layer can be added to enhance durability and maintain the new look for a longer period.

Ensuring Smooth Train Operation

Maintaining optimal functionality is crucial for any form of transportation. Effective management and timely upkeep play a significant role in guaranteeing seamless journeys. By focusing on specific practices, operators can enhance performance and ensure safety for all passengers.

Key Maintenance Practices

Regular inspections and preventive actions can significantly reduce the risk of malfunctions. Here are essential practices to consider:

Practice Description Routine Inspections Conducting systematic checks of all components to identify wear and tear. Lubrication Applying appropriate lubricants to reduce friction and enhance efficiency. Component Replacement Substituting worn-out parts promptly to avoid operational issues. System Testing Regularly testing systems to ensure they function as intended. Monitoring Performance

Continuous observation of operational metrics allows for quick identification of potential issues. Utilizing modern technology can facilitate this process, leading to improved reliability and safety. By implementing these strategies, operators can foster a secure environment for travel.

Preventive Care and Long-Term Storage

Ensuring the longevity and optimal performance of machinery requires a thoughtful approach to maintenance and storage. By adopting proactive measures, users can minimize potential issues and enhance the lifespan of their equipment.

To maintain peak efficiency, consider the following recommendations:

- Regular Inspections: Conduct routine checks to identify any signs of wear or damage.

- Cleaning: Keep the equipment free from dirt and debris, as these can lead to malfunctions.

- Lubrication: Apply appropriate lubricants to moving parts to prevent friction and deterioration.

- Calibration: Regularly calibrate systems to ensure accuracy and reliable operation.

When preparing for long-term storage, follow these guidelines:

- Ensure the equipment is thoroughly cleaned and dried to prevent corrosion.

- Remove any batteries or fuel to avoid leaks and degradation.

- Cover the machinery to protect it from dust and environmental factors.

- Store in a climate-controlled environment to maintain optimal conditions.

By implementing these preventive strategies and storage practices, users can safeguard their investments and ensure that their equipment remains functional for years to come.