Understanding the complexities of large-scale mechanical systems is essential for ensuring their longevity and optimal performance. This resource aims to equip users with the necessary knowledge to navigate through the intricacies of upkeep and troubleshooting of advanced propulsion units commonly used in various industrial applications. By familiarizing oneself with key components and processes, operators can enhance reliability and efficiency.

Detailed instructions and insights provided here will assist in identifying common issues and implementing effective solutions. Emphasis is placed on practical techniques and safety measures, ensuring that every step taken contributes to a smoother operational experience. Whether dealing with routine inspections or more complex interventions, this guide serves as a valuable companion for anyone looking to maintain their machinery at peak performance.

By prioritizing proactive maintenance strategies, users can mitigate the risks of unexpected breakdowns and extend the lifespan of their systems. This not only reduces downtime but also fosters a more productive work environment. Engaging with this material will empower individuals to take charge of their mechanical responsibilities with confidence and precision.

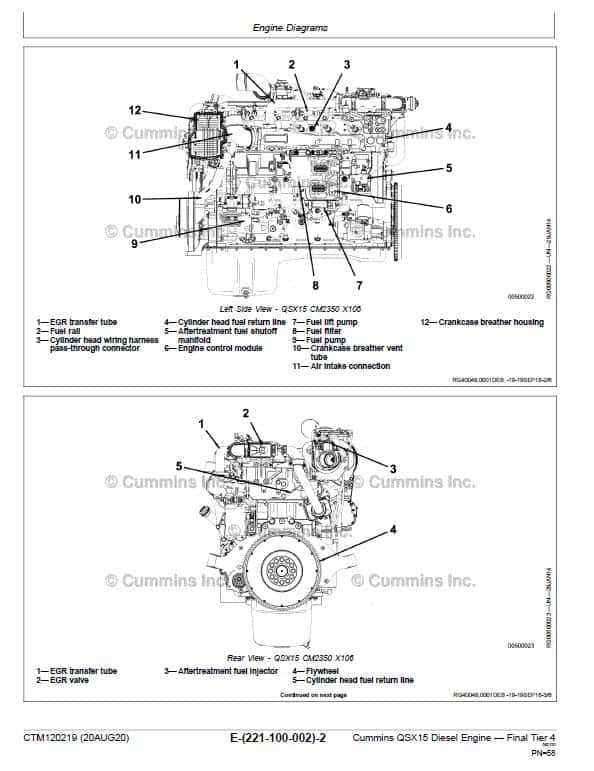

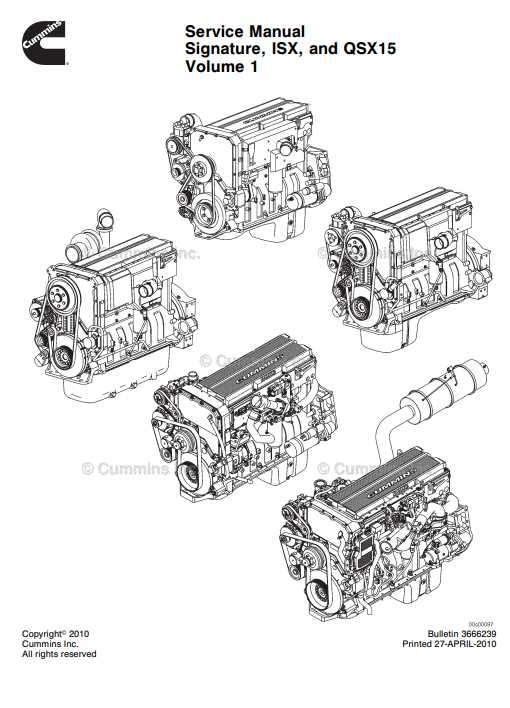

Cummins ISX Engine Overview

This section provides an insight into a robust power unit widely recognized for its performance and reliability. Known for its advanced technology and efficiency, this particular model is designed to meet the demanding requirements of various heavy-duty applications.

Key Features

Among its notable attributes, this unit boasts a high power-to-weight ratio, ensuring optimal performance under heavy loads. Innovative design elements enhance fuel efficiency and reduce emissions, making it an environmentally friendly option. Additionally, the incorporation of sophisticated electronic controls allows for precise management of power output and operational efficiency.

Applications

This power source is ideally suited for a range of heavy machinery, including trucks and construction equipment. Its versatility makes it a preferred choice in industries that require reliable performance and durability. Regular maintenance and adherence to operational guidelines ensure longevity and consistent performance in various challenging environments.

Common Issues with Cummins ISX

Many heavy-duty power units experience a range of challenges that can affect performance and reliability. Identifying these typical problems early can prevent extensive downtime and costly repairs. Understanding the common faults associated with these robust powertrains is crucial for maintaining optimal functionality.

Overheating is a frequent issue, often caused by coolant leaks, clogged radiators, or malfunctioning thermostats. This can lead to serious damage if not addressed promptly.

Oil consumption can also be a concern, where excessive use of lubrication fluids indicates potential wear in the piston rings or cylinder liners. Regular monitoring is essential to catch this early.

Fuel system failures can occur due to contaminated fuel or faulty injectors, resulting in reduced efficiency and increased emissions. Ensuring clean fuel supply and periodic inspections can mitigate these risks.

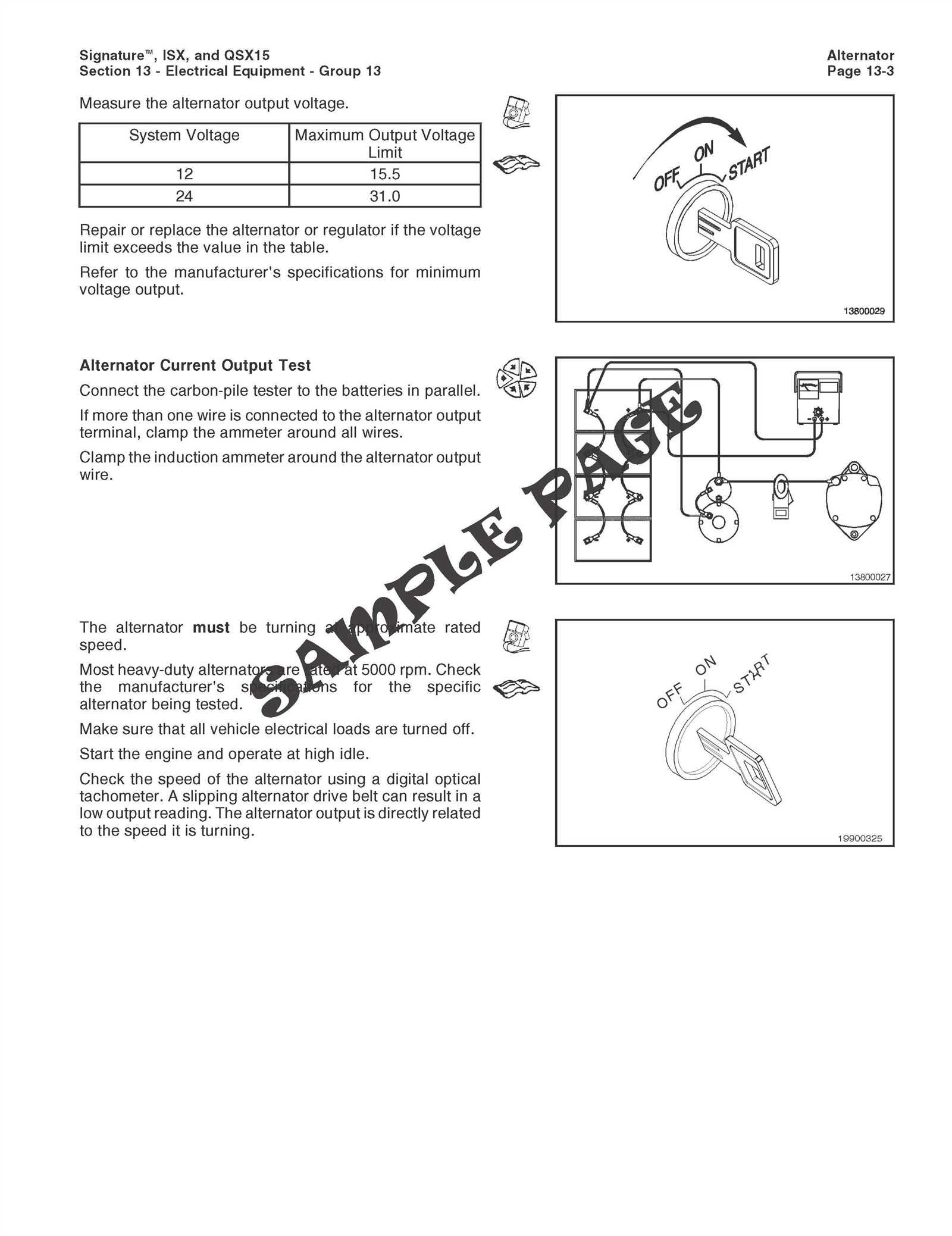

Electrical issues may arise from corroded connections or faulty sensors, impacting the overall performance of the unit. Routine checks of the electrical system can help in maintaining reliability.

By being aware of these prevalent challenges, operators can take proactive measures to ensure longevity and performance, thereby maximizing the investment in their heavy-duty power units.

Tools Needed for ISX Repairs

Undertaking maintenance on a heavy-duty power unit requires a well-equipped toolkit. Each task may demand specific instruments to ensure efficiency and precision. Proper preparation not only enhances the quality of the work but also contributes to safety and longevity of the machine.

| Tool Type | Description |

|---|---|

| Socket Set | A comprehensive socket set with various sizes is essential for accessing different fasteners. |

| Torque Wrench | Necessary for applying precise torque to components, ensuring they are secured according to specifications. |

| Diagnostic Equipment | Advanced diagnostic tools help in identifying issues quickly and accurately. |

| Oil Filter Wrench | Facilitates the removal and installation of oil filters, making maintenance tasks easier. |

| Pliers and Cutters | Essential for gripping, bending, and cutting wires or other materials. |

| Fluids and Lubricants | Quality fluids and lubricants are crucial for optimal performance and longevity of the system. |

Having the right set of instruments at hand not only simplifies tasks but also enhances overall effectiveness. Proper care and usage of these tools contribute significantly to maintaining the functionality of the unit.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to performing maintenance tasks on heavy machinery components. Following systematic instructions ensures efficiency and precision, minimizing the risk of errors during the process. Understanding each stage of the procedure is crucial for achieving optimal functionality and longevity of the unit.

Preparation Phase

Before commencing any work, it is vital to gather all necessary tools and equipment. Ensure that the workspace is clean and organized, as this contributes to safety and effectiveness. Review the specifications and requirements for the task at hand to avoid complications.

Execution of Procedures

Begin with the initial steps outlined for the task, focusing on removing any parts as needed. Document each action taken, as this will help in reassembly. Follow the detailed guidelines methodically, paying attention to torque specifications and connection sequences.

| Step | Description | Tools Required |

|---|---|---|

| 1 | Disconnect the power supply | Wrenches, Safety gear |

| 2 | Remove the protective covers | Screwdrivers, Pliers |

| 3 | Inspect components for wear | Inspection tools |

| 4 | Replace damaged parts | Replacement components, Torque wrench |

| 5 | Reassemble and test | Basic tools, Testing equipment |

Maintenance Tips for Longevity

Ensuring the durability and reliability of your machinery requires consistent care and attention. Proper upkeep not only enhances performance but also extends the lifespan of the system. Following a set of best practices can prevent common issues and save on costly repairs in the long run.

Regularly checking fluid levels is essential. Keeping oil, coolant, and other vital liquids at the recommended levels helps maintain optimal function. Additionally, scheduling routine inspections allows for early detection of wear and tear, enabling timely interventions.

Pay attention to filter changes, as clean filters are crucial for preventing contaminants from damaging internal components. Adhering to a maintenance schedule for these changes can significantly improve efficiency.

Monitoring operating temperatures is another key aspect. Overheating can lead to severe damage, so ensuring that the cooling system is functioning properly is vital. This includes inspecting hoses and radiators for leaks or blockages.

Finally, investing in high-quality parts and lubricants can enhance overall performance. Quality materials tend to withstand wear better, providing greater reliability and longevity. By following these guidelines, you can significantly increase the lifespan of your equipment.

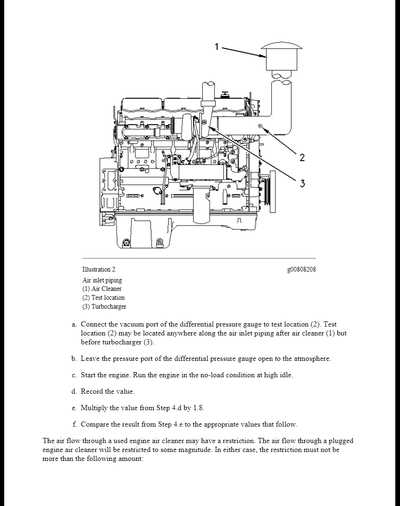

Diagnostic Techniques for Engine Problems

Identifying issues in heavy machinery requires a systematic approach. Employing effective diagnostic techniques can significantly enhance the troubleshooting process, leading to quicker resolutions and reduced downtime.

Here are several key methods to consider when assessing malfunctions:

- Visual Inspection: Begin with a thorough examination of the components. Look for signs of wear, leaks, or physical damage.

- Listening for Unusual Noises: Abnormal sounds can indicate specific issues, such as knocking or grinding, which may point to underlying problems.

- Fluid Analysis: Analyzing oil or coolant can reveal contaminants or abnormal wear particles, providing insights into internal conditions.

- Using Diagnostic Tools: Employ electronic diagnostic equipment to retrieve trouble codes and monitor performance parameters.

In addition to these techniques, consider the following steps:

- Check Historical Data: Review past maintenance records to identify recurring issues that may require further investigation.

- Conduct Performance Tests: Running specific tests can help isolate the problem by comparing performance against standard benchmarks.

- Consult Technical Documentation: Reference service guidelines and troubleshooting charts for specific insights related to the machinery in question.

By integrating these diagnostic techniques, technicians can more effectively identify and address issues, ensuring optimal functionality and longevity of the equipment.

Replacement Parts for ISX Engines

When it comes to maintaining optimal performance in heavy-duty machinery, the quality of components plays a crucial role. The availability of reliable substitutes can significantly enhance the longevity and efficiency of your power units.

Essential Components: Critical elements such as pistons, gaskets, and fuel injectors are pivotal for seamless operation. Selecting high-quality replacements ensures compatibility and durability.

Aftermarket Options: Many users consider aftermarket alternatives that can provide cost-effective solutions without compromising performance. It’s vital to evaluate the reputation of suppliers before making a decision.

OEM Parts: Original parts are designed specifically for optimal fit and function. While they may come at a premium, the investment can lead to enhanced reliability in the long run.

Regular Maintenance: Staying proactive with part replacements not only minimizes downtime but also maximizes efficiency. A well-maintained unit is less prone to unexpected failures, ultimately saving costs.

Safety Precautions During Repairs

Ensuring a secure environment is paramount when performing maintenance tasks. Implementing appropriate safety measures not only protects the technician but also safeguards equipment and enhances overall efficiency. Prioritizing safety creates a conducive atmosphere for effective troubleshooting and service.

Personal Protective Equipment

Wearing the right protective gear is essential. This equipment minimizes the risk of injury during maintenance activities. Key items include:

- Safety goggles to protect eyes from debris and chemicals.

- Gloves to prevent skin contact with harmful substances.

- Steel-toed boots for foot protection against heavy components.

- Ear protection when working in noisy environments.

Workspace Organization

A well-organized workspace significantly reduces hazards. Consider the following tips:

- Keep tools and materials neatly arranged to avoid tripping hazards.

- Ensure proper ventilation when dealing with fumes or chemicals.

- Store heavy items at lower levels to prevent falling risks.

- Clear any clutter to maintain a safe working area.

Performance Enhancements for ISX

Improving the capabilities of heavy-duty power units involves several strategic modifications and upgrades. By focusing on specific components and tuning aspects, operators can achieve significant gains in efficiency and overall output. Here are some key enhancements to consider.

- Turbocharger Upgrades:

- Install high-performance turbos to boost airflow.

- Consider variable geometry models for better response.

- Fuel System Optimization:

- Upgrade injectors for improved atomization.

- Implement a high-flow fuel pump for enhanced delivery.

- Exhaust Modifications:

- Use larger diameter exhaust piping to reduce back pressure.

- Install a performance muffler or straight pipe for better flow.

- ECU Tuning:

- Reprogram the control unit for optimized fuel mapping.

- Adjust parameters to enhance power without sacrificing reliability.

- Cooling System Enhancements:

- Upgrade radiators for improved heat dissipation.

- Consider intercooler upgrades to lower intake temperatures.

Implementing these modifications can lead to noticeable improvements in performance, allowing for increased productivity and efficiency in demanding applications. Always ensure compatibility and reliability when making enhancements to ensure the longevity of your power unit.

Resources for Further Learning

Expanding your knowledge and skills in the field of mechanical systems is essential for both professionals and enthusiasts. A variety of resources can provide valuable insights, practical techniques, and theoretical background to enhance your understanding and capabilities. Here are some recommended materials and platforms to consider.

Books and Publications

- Technical handbooks that cover principles of mechanical systems.

- Industry journals featuring the latest research and advancements.

- Instructional guides offering step-by-step processes and troubleshooting tips.

Online Platforms

- Websites with forums and discussion boards for knowledge sharing.

- Video tutorials demonstrating hands-on techniques and maintenance practices.

- Webinars hosted by experts covering current trends and innovations.

Utilizing these resources will not only deepen your comprehension but also keep you updated on best practices and new developments in the field.