When it comes to ensuring optimal performance and longevity of heavy machinery, understanding the intricacies of their mechanical systems is essential. This resource is designed to provide a thorough overview of maintenance practices, troubleshooting techniques, and the key components involved in the operation of robust automotive power sources. By familiarizing yourself with these vital aspects, you can enhance the efficiency and reliability of your equipment.

Regular upkeep of your vehicle’s core machinery not only prevents unforeseen breakdowns but also contributes to overall safety and productivity. In this guide, you will discover valuable insights into common issues, preventive measures, and step-by-step procedures that can empower you to tackle any challenges with confidence. Whether you are a seasoned technician or a passionate enthusiast, this comprehensive compilation is tailored to elevate your understanding and skills.

Equipped with detailed instructions and practical advice, this document serves as a vital tool for anyone looking to deepen their knowledge of powertrain systems. From basic maintenance tips to advanced diagnostic strategies, you will find everything needed to keep your machinery running smoothly and effectively. Embrace the journey of mastery and ensure that your equipment remains in peak condition for years to come.

Paccar Engine Overview

This section provides a comprehensive insight into a prominent line of heavy-duty power units designed for performance and durability. These units are engineered to meet the demanding requirements of modern transportation, offering reliability and efficiency for various applications.

Manufactured with advanced technology, these power sources are known for their robust construction and innovative features. They are tailored to enhance fuel economy while minimizing emissions, reflecting a commitment to sustainability in the industry.

Key characteristics include high torque output, which ensures optimal performance even under heavy loads. The integration of sophisticated diagnostic systems allows for real-time monitoring, facilitating timely maintenance and reducing downtime.

In addition, user-friendly design elements simplify routine servicing, making these units accessible for technicians and operators alike. Overall, the combination of performance, efficiency, and ease of maintenance positions these power units as a preferred choice in the transportation sector.

Common Issues in Paccar Engines

Understanding frequent challenges in heavy-duty powertrains is essential for maintaining performance and reliability. Various factors can contribute to operational difficulties, leading to decreased efficiency and potential failures. Identifying these common concerns can help in taking proactive measures to mitigate issues and enhance longevity.

| Issue | Description | Possible Solutions |

|---|---|---|

| Overheating | Excessive temperatures can lead to component failure. | Check coolant levels, inspect the thermostat, and ensure proper airflow. |

| Oil Leaks | Fluid loss may result from worn seals or gaskets. | Regularly inspect and replace seals, and tighten loose connections. |

| Fuel Contamination | Impurities in fuel can cause misfires and reduced efficiency. | Use high-quality fuel and install appropriate filtration systems. |

| Electrical Failures | Malfunctions in the ignition or electronic systems can lead to starting issues. | Check battery connections, inspect wiring, and test components. |

| Excessive Emissions | Increased pollutants may indicate incomplete combustion or faulty sensors. | Regularly service the exhaust system and replace sensors as needed. |

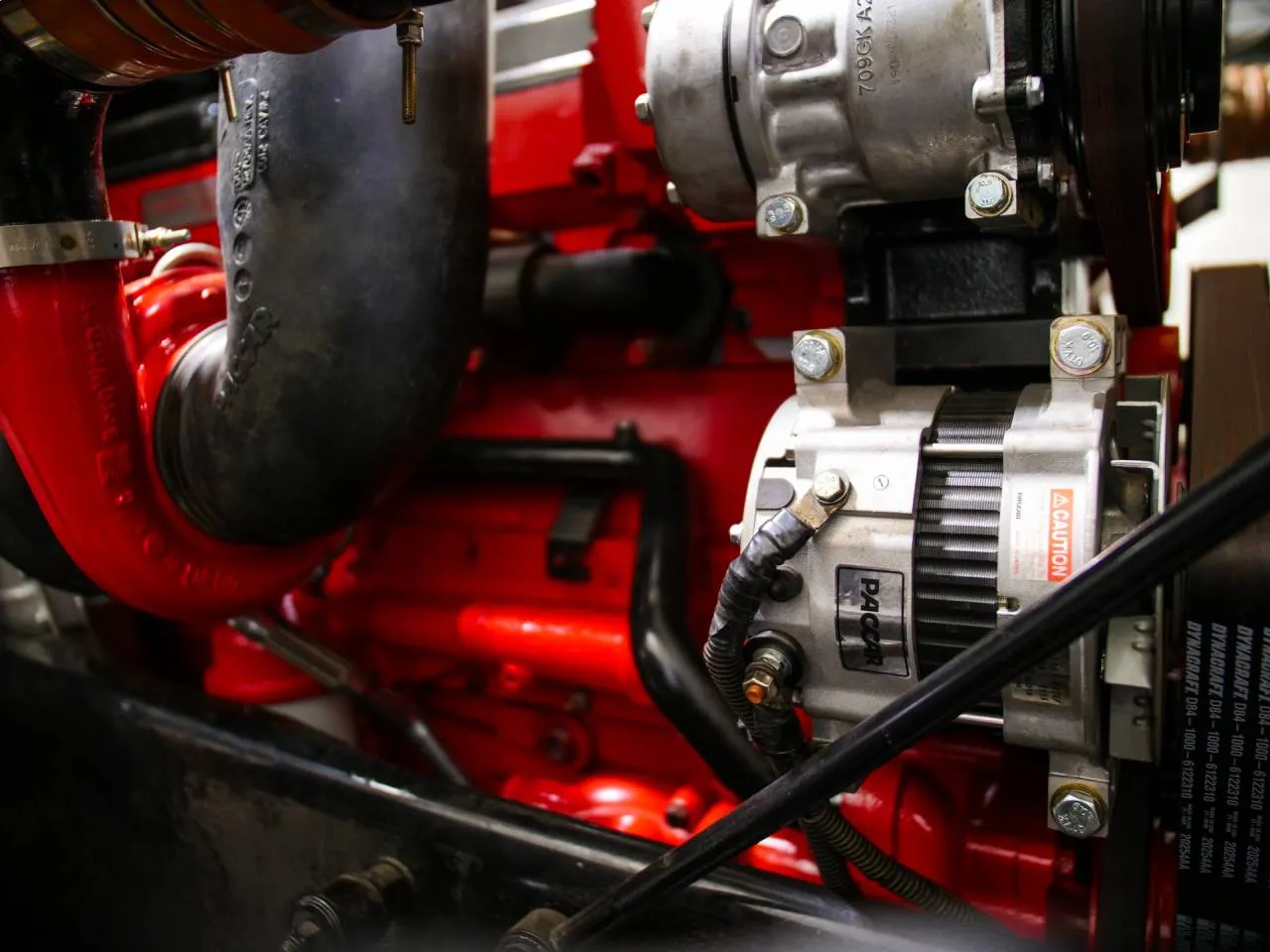

Tools Required for Engine Repair

Undertaking the task of servicing an internal combustion unit demands a diverse set of instruments to ensure efficiency and precision. These implements are essential for diagnosing issues, conducting maintenance, and performing overhauls. Familiarity with the right tools not only streamlines the workflow but also enhances the quality of the outcome.

The primary items include wrenches, screwdrivers, and pliers, which are vital for loosening and tightening various components. Diagnostic equipment, such as pressure gauges and scan tools, plays a crucial role in identifying faults. Additionally, specialized tools like torque wrenches ensure that parts are secured to manufacturer specifications, preventing future complications.

Furthermore, a comprehensive set of safety gear, including gloves and goggles, is indispensable to protect the technician during the process. Organizational tools like toolboxes and trays help maintain a tidy workspace, reducing the risk of misplaced items and improving overall efficiency.

In summary, equipping oneself with the proper tools is fundamental for successful servicing of mechanical units. Each instrument serves a distinct purpose, contributing to a seamless and effective maintenance experience.

Step-by-Step Repair Procedures

This section outlines a systematic approach to addressing issues related to machinery, ensuring each phase is thoroughly executed for optimal performance. By following a structured method, users can effectively diagnose problems, implement solutions, and enhance overall functionality.

Preparation and Inspection

Begin by gathering all necessary tools and safety equipment. Carefully examine the unit for any visible signs of damage or wear. Document your findings, as this will aid in identifying the root cause of the issues. Ensure that the workspace is clean and organized to facilitate a smooth workflow.

Disassembly and Maintenance

Proceed with disassembling the components, taking care to label each part for easy reassembly. Clean all surfaces and inspect each piece for signs of malfunction. Replace any damaged items and lubricate moving parts as needed. Follow this by reassembling the unit in the reverse order, ensuring that all connections are secure and functioning correctly.

Safety Precautions During Repairs

Ensuring safety is paramount when conducting maintenance on mechanical systems. A thorough understanding of potential hazards and the implementation of appropriate measures can significantly reduce risks. Awareness and preparedness are essential for creating a secure work environment.

Personal Protective Equipment

Utilizing personal protective equipment (PPE) is crucial. Always wear safety goggles to shield your eyes from debris and chemicals. Gloves are important to protect your hands from sharp objects and harmful substances. Additionally, sturdy footwear can prevent injuries from falling tools or components.

Workspace Organization

A well-organized workspace is vital for maintaining safety. Keep tools and materials neatly arranged to avoid tripping hazards. Ensure that all equipment is in good condition and properly stored. Implementing a clean and clutter-free area will enhance focus and minimize the chance of accidents.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires regular attention and care. By following a few essential practices, you can significantly extend the lifespan of your equipment, reducing the likelihood of unexpected failures and costly repairs.

- Regular Inspections: Schedule frequent check-ups to identify wear and tear early. Look for signs of leaks, unusual noises, or irregular performance.

- Cleanliness: Keep components clean and free of debris. Accumulated dirt can lead to overheating and inefficient operation.

- Fluid Checks: Monitor and replace lubricants and coolants as recommended. Maintaining optimal fluid levels is crucial for proper functionality.

- Scheduled Maintenance: Adhere to a strict maintenance schedule based on the manufacturer’s guidelines. Regular servicing can prevent minor issues from escalating.

- Quality Parts: Use high-quality components for replacements. Inferior parts can compromise performance and longevity.

By implementing these practices, you can ensure that your machinery operates smoothly and efficiently over time, providing reliable service for years to come.

Understanding Engine Specifications

Comprehending the details of power units is essential for optimal performance and longevity. These specifications encompass a range of attributes that define the capabilities and requirements of a power unit. By delving into these particulars, one can ensure proper maintenance and enhance efficiency.

Key Attributes to Consider

- Displacement: Refers to the total volume of all cylinders in the power unit, influencing power output and fuel efficiency.

- Compression Ratio: The ratio of the maximum to minimum volume in the combustion chamber, impacting power and efficiency.

- Horsepower and Torque: These figures represent the unit’s capability to perform work and its ability to generate rotational force, respectively.

- Fuel Type: Indicates the kind of fuel required, which can affect performance and operational costs.

- Cooling System: Describes the mechanism used to manage operating temperatures, crucial for preventing overheating.

Importance of Following Specifications

Adhering to the outlined parameters is vital for several reasons:

- Ensures compatibility with components, leading to smoother operation.

- Maximizes efficiency, reducing unnecessary wear and tear.

- Aids in troubleshooting issues by providing clear guidelines.

- Facilitates adherence to regulatory standards and environmental considerations.

In summary, a thorough understanding of the characteristics of power units plays a crucial role in effective operation and maintenance. Knowledge of these specifications empowers users to make informed decisions that enhance performance and longevity.

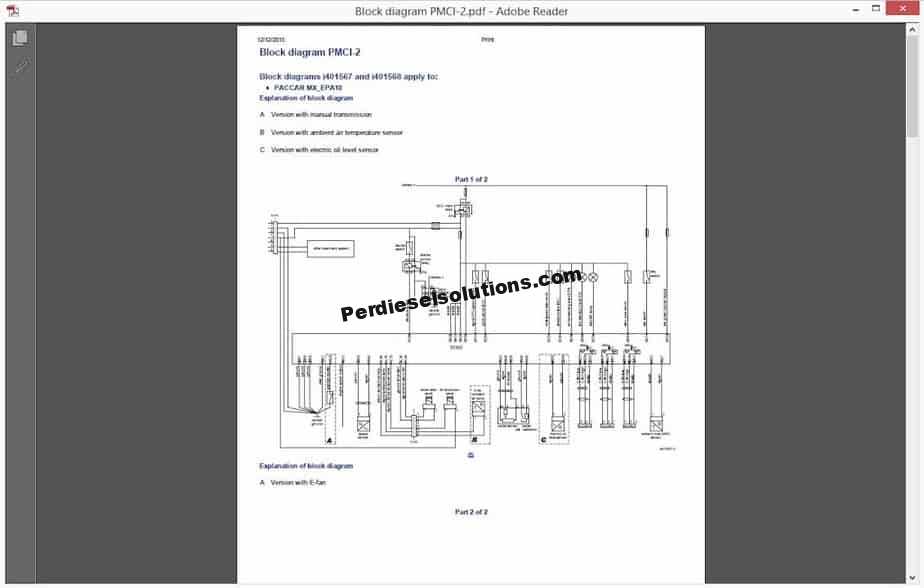

Diagnostics and Troubleshooting Techniques

Effective identification and resolution of mechanical issues are crucial for maintaining optimal performance in vehicles. This section outlines essential methodologies for assessing functionality and addressing malfunctions. Employing systematic approaches can significantly enhance the efficiency of the diagnostic process.

Begin by gathering relevant information about the symptoms observed. This includes listening for unusual noises, noting performance changes, and checking for warning indicators. Next, utilize both visual inspections and advanced diagnostic tools to pinpoint the source of the problem.

| Technique | Description |

|---|---|

| Visual Inspection | Examine components for signs of wear, damage, or leaks. |

| Code Scanning | Use diagnostic equipment to retrieve fault codes from the system. |

| Pressure Testing | Assess fluid pressures to ensure they are within specified ranges. |

| Temperature Monitoring | Check operating temperatures of various systems to identify anomalies. |

By systematically applying these techniques, one can accurately determine the root cause of issues and implement effective solutions, ensuring reliability and longevity in performance.

Replacing Engine Components Effectively

Maintaining the optimal performance of a vehicle requires attention to various parts that may wear out over time. Properly addressing the replacement of these crucial elements can enhance efficiency and prolong the lifespan of the machinery. Understanding the intricacies involved in this process is vital for achieving successful outcomes.

Preparation is key before initiating the replacement process. Ensuring that all necessary tools and replacement parts are readily available can significantly streamline the task. It is also essential to consult relevant guidelines to familiarize yourself with the specific procedures and safety measures required.

When removing components, careful handling is crucial to avoid damaging surrounding areas. Utilizing the appropriate techniques for disassembly helps prevent complications that could arise during the installation of new parts. Always consider the orientation and positioning of each component, as this will aid in correctly reinstalling the replacements.

After securing new elements, thorough inspection is necessary to ensure everything is in proper working order. Testing the functionality before reassembling the entire system allows for the identification of any potential issues early on. Moreover, adhering to torque specifications and connection methods can significantly enhance the reliability of the new installations.

In conclusion, the process of replacing vital components requires diligence, organization, and knowledge. By following structured procedures and maintaining a focus on detail, you can effectively manage these essential tasks, leading to improved performance and durability.

Recommended Lubricants and Fluids

Choosing the appropriate lubricants and fluids is crucial for maintaining optimal performance and longevity of your machinery. These substances play a vital role in reducing friction, preventing wear, and ensuring smooth operation under various conditions.

Engine Oil: High-quality engine oil is essential for optimal functionality. Look for oils that meet the specific viscosity and performance standards outlined by the manufacturer. Synthetic options often provide superior protection and efficiency.

Transmission Fluid: Proper transmission fluid is necessary for smooth shifting and overall transmission health. Ensure to select a fluid that adheres to the recommended specifications to avoid potential issues.

Coolant: The right coolant is crucial for regulating temperature and preventing overheating. Use a fluid that offers both freeze and corrosion protection, tailored to the requirements of your system.

Grease: Lubricating grease is vital for components that experience heavy loads or are exposed to contaminants. Select a high-quality grease that matches the environmental conditions and load specifications.

Always consult the relevant guidelines to ensure the right products are utilized, as using inappropriate substances can lead to performance issues and increased maintenance costs.

Resources for Further Information

For those seeking to deepen their understanding of mechanical systems, numerous resources are available to assist in expanding knowledge and troubleshooting skills. These materials range from comprehensive literature to online platforms that cater to both novice and seasoned professionals.

Books and technical publications provide in-depth insights and guidelines, often authored by industry experts. Consider exploring reputable titles available in libraries or online bookstores that cover various aspects of maintenance and diagnostics.

Online forums and communities are excellent platforms for exchanging ideas and experiences. Engaging with fellow enthusiasts can lead to valuable tips and shared solutions, enhancing practical know-how.

Moreover, official websites and manufacturers often offer downloadable resources, including specifications and troubleshooting guides, which are indispensable for effective problem-solving. Utilizing these materials can significantly improve proficiency and confidence in handling complex machinery.

Lastly, workshops and training courses are vital for hands-on learning. Many organizations offer programs designed to equip individuals with the necessary skills to excel in this field. Investing time in these opportunities can lead to greater expertise and career advancement.