Understanding the intricacies of engine care is essential for ensuring optimal performance and longevity of your vehicle. This segment delves into the fundamental aspects of servicing certain types of engines, providing valuable insights and techniques to enhance their functionality. Whether you are a novice enthusiast or a seasoned mechanic, the following information will empower you to tackle common issues effectively.

Engine performance relies on meticulous attention to various components, which work in harmony to deliver power and efficiency. By familiarizing yourself with these elements, you can identify potential problems before they escalate, ultimately saving time and resources. This guide emphasizes practical approaches to maintenance, equipping you with the knowledge needed for successful interventions.

Moreover, a thorough understanding of engine dynamics allows for better decision-making when it comes to troubleshooting. With the right tools and techniques, you can navigate challenges confidently. Emphasizing a hands-on approach, this guide aims to transform your perspective on engine care, fostering a proactive mindset that ensures your vehicle runs smoothly for years to come.

Twin Cylinder L Head Overview

This section provides a comprehensive understanding of a specific engine configuration that features two combustion chambers arranged in a parallel manner. This design is known for its balance between efficiency and power, making it a popular choice in various applications. Its structure allows for effective thermal management and optimal performance under different operating conditions.

Design Characteristics

The configuration is characterized by its distinctive arrangement, which facilitates smoother operation and reduced vibrations. Each chamber is designed to maximize airflow and fuel combustion, enhancing overall efficiency. Additionally, the layout often includes innovative features that contribute to better torque delivery and responsiveness.

Applications and Benefits

This type of engine setup is widely utilized in numerous vehicles and machinery, owing to its compact size and robust performance. The advantages include improved fuel economy and lower emissions, making it an environmentally friendly option. Furthermore, the maintenance requirements are often less demanding compared to other designs, providing an attractive solution for both manufacturers and users.

Common Issues in Twin Cylinder Engines

Engines with two combustion chambers often experience a range of challenges that can impact their performance and reliability. Understanding these prevalent problems is essential for effective maintenance and troubleshooting.

One frequent concern is uneven power delivery, which may arise from discrepancies in the combustion process between the two chambers. This can lead to vibrations and reduced efficiency, necessitating a thorough inspection of ignition timing and fuel distribution.

Additionally, overheating is a common issue, often caused by inadequate cooling or blockages in the cooling system. Regular checks on coolant levels and the integrity of cooling passages are vital to prevent severe damage.

Wear and tear of internal components, such as pistons and valves, can also be problematic. These parts may deteriorate over time, leading to decreased compression and increased oil consumption. Monitoring these components can help in identifying potential failures before they escalate.

Lastly, leaks in the fuel or oil systems can pose significant risks. These leaks not only compromise performance but can also lead to hazardous situations. Regular inspections and timely repairs are crucial in maintaining the engine’s overall health.

Essential Tools for L Head Repair

Having the right equipment is crucial for ensuring effective maintenance and troubleshooting of engine components. This section outlines the fundamental instruments necessary for efficiently addressing various tasks associated with the operation and upkeep of specific machinery. Proper tools not only enhance performance but also ensure safety and precision in the process.

Key Instruments

Understanding which tools to utilize can make a significant difference in achieving optimal results. Below is a list of essential instruments that should be included in any workshop for servicing related systems.

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Compression Gauge | Measures the pressure within the combustion chambers to assess engine health. |

| Socket Set | Provides various sizes for loosening and tightening bolts and nuts. |

| Feeler Gauges | Checks gaps and clearances for accurate adjustments. |

| Engine Hoist | Facilitates the removal and installation of heavy components. |

Maintenance and Safety Gear

In addition to the core tools, having the right safety equipment is essential. This ensures the well-being of the technician while also maintaining a clean work environment. The following items are recommended:

| Item | Importance |

|---|---|

| Safety Glasses | Protects eyes from debris and chemical exposure. |

| Gloves | Prevents skin contact with harmful substances and provides grip. |

| Shop Apron | Keeps clothing clean and adds an extra layer of protection. |

Step-by-Step Repair Process

This section outlines a comprehensive approach to restoring engine components effectively. Following a systematic procedure ensures that each element is addressed thoroughly, minimizing the risk of future issues. From initial assessment to final adjustments, each step is crucial for achieving optimal performance.

1. Initial Assessment

Begin by conducting a detailed inspection of the unit. Check for any visible damage, leaks, or irregularities in operation. Utilize appropriate diagnostic tools to evaluate performance metrics and identify specific problems that require attention. Document all findings for reference during the restoration process.

2. Disassembly and Cleaning

Carefully dismantle the assembly, ensuring that all components are cataloged for reassembly. Use a suitable solvent to clean each part, removing any buildup of grime or debris. Pay particular attention to precision components that may require specialized cleaning techniques. After cleaning, inspect each piece for wear and replace any that do not meet standards.

Once all components are prepped, proceed to the reassembly phase, ensuring that each part is aligned and secured properly. Adhere to the manufacturer’s specifications for torque settings and assembly sequences to guarantee reliability and efficiency in operation.

Diagnosing Engine Performance Problems

Understanding the nuances of engine functionality is crucial for identifying issues that may hinder optimal performance. Various factors can contribute to inefficiencies, from fuel delivery to air intake and ignition timing. A systematic approach to diagnosis can help pinpoint the root cause of problems, ensuring effective resolution and restoration of power and efficiency.

Common Symptoms of Performance Issues

Engines exhibiting lack of power, stalling, or unusual noises are often signaling underlying troubles. Frequent misfires, poor acceleration, and decreased fuel economy are also red flags that require attention. Observing these symptoms can guide the troubleshooting process, allowing for targeted inspections and tests.

Step-by-Step Diagnostic Process

To accurately assess performance issues, begin by gathering information about the symptoms. Conduct visual inspections for obvious signs of wear or damage. Utilize diagnostic tools to retrieve error codes and analyze performance metrics. Testing components such as spark plugs, fuel injectors, and sensors can further clarify the condition of the system. A methodical approach will lead to effective solutions and restore reliable operation.

Replacing Gaskets and Seals

Proper maintenance of sealing components is crucial for ensuring optimal performance and preventing leaks. Over time, these parts can wear out, leading to potential issues within the system. This section outlines the essential steps and considerations for effectively replacing these vital elements.

Tools and Materials Needed

- New gaskets and seals

- Gasket scraper or razor blade

- Torque wrench

- Cleaning solvent

- Rags or paper towels

Step-by-Step Replacement Process

- Begin by disconnecting any necessary components to access the sealing areas.

- Carefully remove old gaskets and seals, ensuring that no debris is left behind.

- Clean the surfaces thoroughly using the solvent to remove any residue.

- Position the new gasket or seal, ensuring proper alignment with the mounting surfaces.

- Reassemble the components, applying the correct torque settings to avoid damage.

Following these guidelines will help maintain the integrity of the system and extend its lifespan. Regular inspection and timely replacement of worn parts are key to preventing more significant issues down the line.

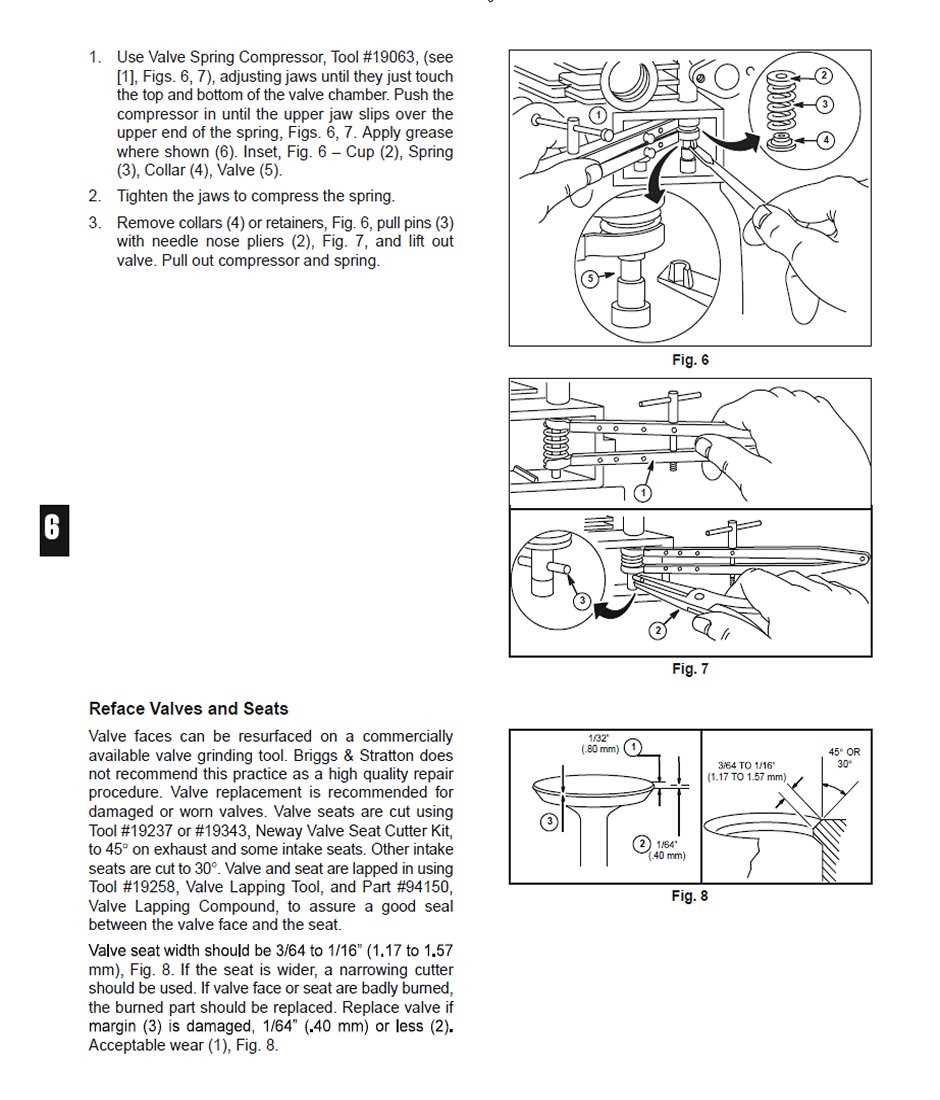

Valves and Timing Adjustments

This section focuses on the crucial aspects of managing intake and exhaust mechanisms along with their synchronization. Proper adjustment of these components ensures optimal engine performance, fuel efficiency, and emission control. Understanding the specific requirements for each mechanism is essential for effective maintenance.

Importance of Proper Adjustment

Ensuring that these mechanisms are correctly set can lead to several benefits:

- Improved engine efficiency

- Enhanced power output

- Reduced wear and tear on components

- Lower emissions and environmental impact

Adjustment Procedure

Follow these steps to achieve proper alignment:

- Gather necessary tools: feeler gauge, wrenches, and timing tools.

- Remove any components obstructing access to the mechanisms.

- Locate the specifications for the ideal clearance and timing settings.

- Adjust the clearance by carefully turning the adjustment screws or nuts.

- Use the timing tools to ensure synchronization aligns with manufacturer specifications.

- Reassemble all components and perform a final check for proper operation.

Regular maintenance of these systems is key to longevity and reliability. Always consult relevant documentation for precise specifications and techniques unique to your engine type.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your engine components. Regular attention can prevent costly repairs and ensure optimal performance over time. Here are key practices to maintain your machinery effectively.

Regular Inspections

- Check for leaks or unusual noises.

- Inspect gaskets and seals for wear.

- Monitor fluid levels and conditions regularly.

Routine Cleaning

- Keep parts free of debris and dirt.

- Use appropriate cleaning agents to avoid damage.

- Ensure ventilation areas remain unobstructed.

By following these tips, you can significantly enhance the reliability and efficiency of your equipment, ultimately leading to a longer operational life.

Upgrading Components for Efficiency

Enhancing the performance of your machinery involves a strategic approach to optimizing key elements. By carefully selecting and upgrading various parts, you can significantly improve overall functionality and fuel efficiency. This process not only maximizes power output but also extends the lifespan of the engine.

Key Components to Consider

- Fuel System: Upgrading injectors and fuel pumps can lead to better combustion and increased power.

- Exhaust System: A high-performance exhaust can reduce back pressure and improve airflow.

- Ignition System: Investing in advanced spark plugs and ignition coils enhances combustion efficiency.

- Cooling System: A more efficient radiator or upgraded cooling fan can help maintain optimal operating temperatures.

Benefits of Upgrading

- Improved Performance: Upgraded components can lead to noticeable gains in horsepower and torque.

- Better Fuel Economy: Enhanced efficiency often translates to lower fuel consumption.

- Increased Reliability: Newer parts are typically more durable, reducing the likelihood of breakdowns.

- Lower Emissions: Optimized systems contribute to cleaner exhaust output, benefiting the environment.

Safety Precautions During Repair

Ensuring a safe working environment is essential when undertaking mechanical tasks. Proper precautions not only protect the individual performing the work but also prevent potential damage to equipment. Following a systematic approach to safety can significantly reduce the risk of accidents and injuries.

General Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and masks.

- Ensure the workspace is well-lit and organized to avoid tripping hazards.

- Keep all tools and materials in their designated places to prevent clutter.

- Use the right tools for each task to minimize the chance of injury.

Handling Hazardous Materials

- Read and understand the safety data sheets (SDS) for any chemicals or lubricants used.

- Store hazardous substances in properly labeled containers, away from direct sunlight and heat sources.

- Dispose of waste materials in accordance with local regulations to prevent environmental contamination.

- In case of spills, follow the appropriate clean-up procedures immediately.