Maintaining outdoor cleaning tools is crucial for ensuring their longevity and optimal performance. This guide aims to provide valuable insights and practical advice for those who wish to keep their equipment in top condition. Understanding the intricacies of these machines can significantly enhance their efficiency and durability.

In this resource, you will find detailed instructions and tips for troubleshooting common issues, conducting routine maintenance, and performing essential adjustments. By familiarizing yourself with the workings of your device, you can prevent minor problems from escalating into costly repairs.

Equipped with the right knowledge, users can tackle challenges with confidence, ensuring that their outdoor tasks are accomplished with ease. Whether you are a seasoned user or a newcomer to the world of landscaping tools, this information will help you navigate the care and upkeep of your equipment effectively.

Poulan Pro Blower Overview

This section provides a comprehensive look at a popular outdoor tool designed for efficient leaf and debris management. Users can benefit from its various features, which enhance usability and performance in different environments.

Key characteristics of this outdoor equipment include:

- Powerful engine for effective air movement.

- Ergonomic design to reduce operator fatigue.

- Multiple speed settings for tailored performance.

- Lightweight construction for easy handling.

- Durable materials to withstand outdoor conditions.

For optimal functionality, regular maintenance is essential. Understanding how to care for this equipment will ensure longevity and consistent performance.

- Check the fuel system regularly.

- Inspect air filters and clean as needed.

- Monitor spark plug condition.

- Ensure that all components are securely fastened.

With proper attention, this versatile tool can significantly simplify yard work and enhance the efficiency of outdoor cleanup tasks.

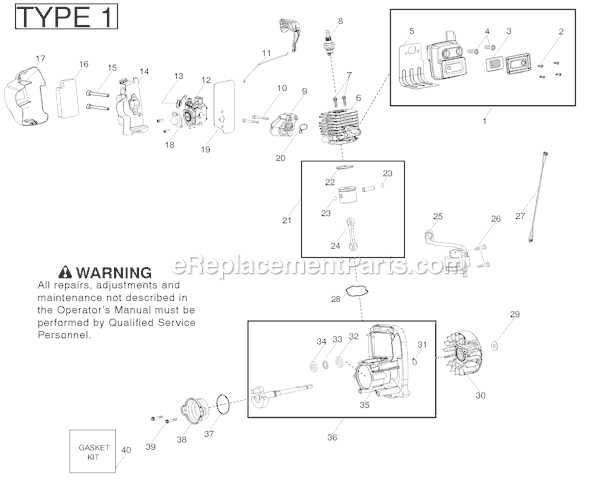

Common Issues with Poulan Pro Blowers

When using outdoor equipment for yard maintenance, various challenges can arise that hinder performance. Understanding these common problems can help in troubleshooting and ensuring smooth operation.

- Starting Difficulties:

Many users encounter issues when attempting to start their device. This may be due to:

- Old fuel or improper fuel mix

- Clogged air filter

- Faulty spark plug

- Poor Airflow:

Reduced airflow can affect efficiency. Possible causes include:

- Blocked exhaust

- Debris in the intake

- Deteriorated fan blades

- Engine Stalling:

Experiencing frequent stalls can be frustrating. Common reasons for this issue are:

- Fuel line obstructions

- Weak ignition system

- Inconsistent fuel delivery

- Excessive Noise:

Unusual sounds can indicate underlying problems. Check for:

- Loose components

- Worn bearings

- Imbalanced parts

By recognizing these prevalent issues, users can take proactive steps to maintain their equipment, ensuring optimal performance for all yard work tasks.

Tools Required for Repairs

Performing maintenance or fixing issues requires a specific set of instruments to ensure efficiency and safety. Having the right tools at your disposal can significantly simplify the process and improve the outcome.

- Wrenches: Essential for loosening or tightening various components.

- Screwdrivers: Both flathead and Phillips types are necessary for accessing different screws.

- Pliers: Useful for gripping, twisting, and cutting wires or small parts.

- Socket Set: Ideal for quickly removing and installing nuts and bolts.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Replacement Parts: Always have a selection of commonly needed components on hand.

Gathering these tools before starting any task can enhance efficiency and prevent delays. Always prioritize safety by using protective gear and following proper handling procedures.

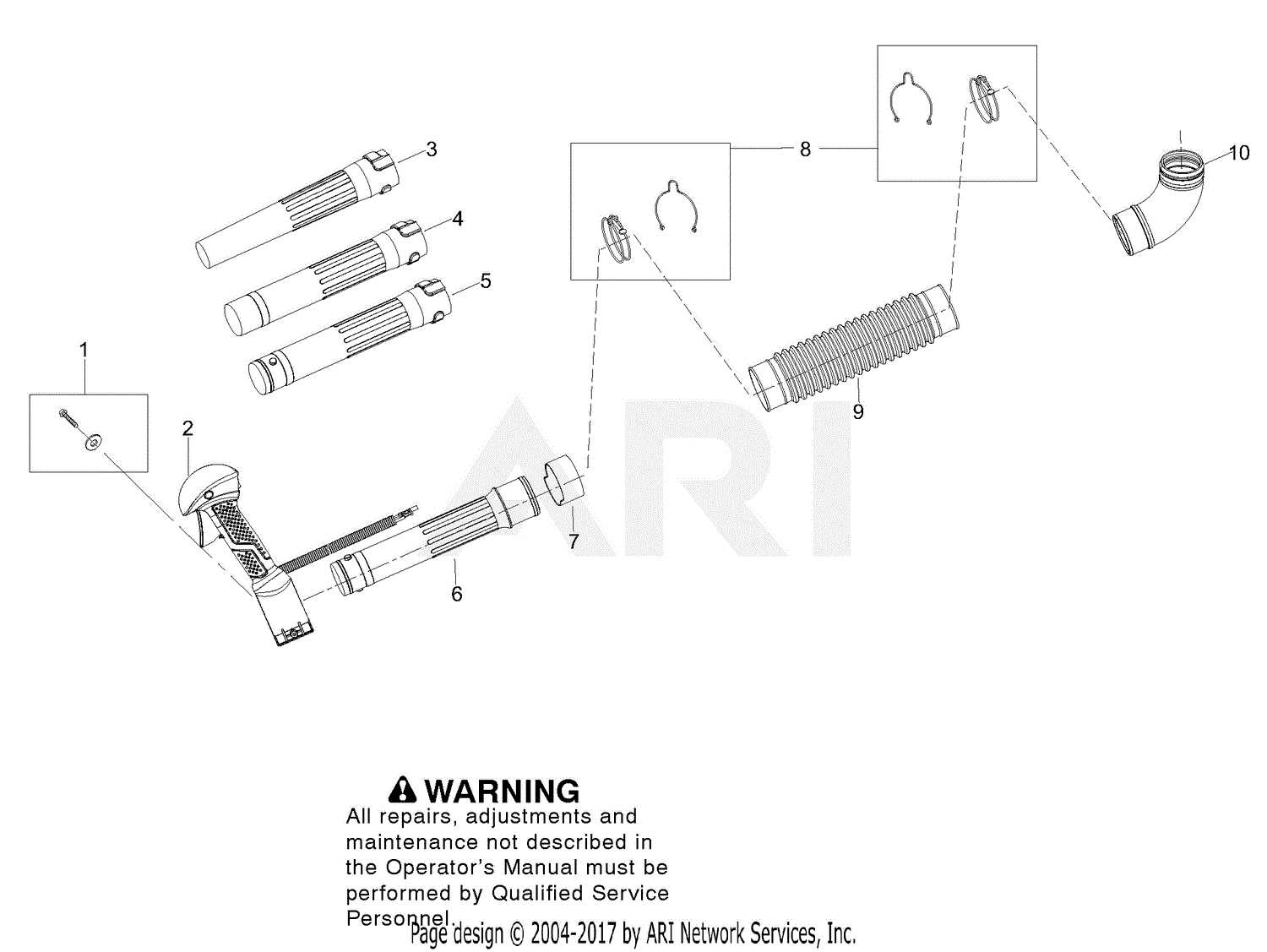

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to identifying and resolving common issues encountered with outdoor air-moving equipment. By following these detailed steps, users can effectively diagnose problems and implement solutions to restore optimal functionality.

| Issue | Potential Causes | Solutions |

|---|---|---|

| No Start | 1. Empty fuel tank 2. Faulty spark plug 3. Blocked air filter |

1. Refill with fresh fuel 2. Replace spark plug 3. Clean or replace air filter |

| Poor Performance | 1. Clogged nozzle 2. Low fuel quality 3. Damaged fan |

1. Clear nozzle of debris 2. Use high-quality fuel 3. Inspect and replace fan if necessary |

| Excessive Vibration | 1. Loose components 2. Imbalanced fan 3. Worn bearings |

1. Tighten all screws and bolts 2. Check fan balance 3. Replace bearings if worn |

| Unusual Noises | 1. Foreign objects in the motor 2. Worn belts 3. Loose housing |

1. Inspect and remove debris 2. Replace worn belts 3. Tighten housing screws |

Fuel System Maintenance Tips

Proper upkeep of the fuel system is essential for optimal performance and longevity of your equipment. Regular attention to this critical component ensures efficient operation and minimizes the risk of malfunctions caused by fuel-related issues.

Regular Fuel Checks

Consistently monitor the quality of fuel used. Stale or contaminated fuel can lead to starting difficulties and engine performance problems. It’s advisable to replace fuel every few months, especially in seasonal equipment. Always store fuel in a clean, dry container to prevent impurities.

Cleaning and Inspection

Periodically clean fuel filters and inspect all connections for leaks or cracks. A clean filter allows for better fuel flow, while any leaks can lead to dangerous situations. Ensure all parts are securely fastened and replace any worn components to maintain system integrity.

Following these maintenance tips will help keep your equipment running smoothly and efficiently, prolonging its life and enhancing performance.

Cleaning the Air Filter Effectively

Maintaining optimal performance of your equipment requires regular attention to its components, particularly the air filtration system. A clean air filter ensures that the engine receives the necessary airflow, improving efficiency and extending the lifespan of the machinery. This section will guide you through the steps for effectively cleaning the air filter.

Tools Needed

| Tool | Purpose |

|---|---|

| Soft Brush | To remove dust and debris |

| Warm Water | For soaking and rinsing |

| Soap | To clean the filter material |

| Clean Cloth | For drying |

Steps to Clean the Air Filter

Begin by removing the air filter from the machinery according to the manufacturer’s instructions. Use a soft brush to gently dislodge any loose dirt or particles. Next, immerse the filter in warm, soapy water and let it soak for several minutes. After soaking, use the brush again to clean any remaining debris. Rinse the filter thoroughly under clean water to remove all soap residues. Allow the filter to dry completely before reinstalling it to ensure proper airflow and functionality.

Replacing Spark Plugs Made Easy

Changing the ignition components in your outdoor equipment is essential for optimal performance. This straightforward process can significantly enhance engine efficiency and reliability. Below are the steps to simplify this task, ensuring you can maintain your device with ease.

- Gather Your Tools:

- New spark plugs

- Socket wrench

- Torque wrench

- Spark plug gap tool

- Safety gloves

- Prepare the Engine:

- Ensure the engine is cool to avoid burns.

- Disconnect the spark plug wire to prevent accidental starts.

- Remove Old Spark Plugs:

- Use the socket wrench to unscrew the old plugs carefully.

- Inspect the old plugs for wear and tear.

- Install New Spark Plugs:

- Check the gap on the new plugs with the gap tool; adjust if necessary.

- Screw in the new plugs by hand to avoid cross-threading.

- Use the torque wrench to tighten them to the manufacturer’s specifications.

- Reconnect Everything:

- Attach the spark plug wire securely to the new plugs.

- Double-check all connections and tools before starting the engine.

Following these steps will help you maintain your equipment’s performance and prolong its lifespan. Regular checks and replacements of ignition components are key to ensuring your machine runs smoothly.

Fixing Electrical Problems in Blowers

Addressing electrical issues in outdoor tools is essential for maintaining their performance and longevity. Understanding common symptoms and solutions can help users troubleshoot effectively, ensuring the equipment operates smoothly and efficiently. This section outlines typical electrical malfunctions and practical approaches to resolving them.

Common Symptoms of Electrical Failures

Users may encounter various signs indicating electrical difficulties. These can include failure to start, intermittent operation, or unusual noises during use. Often, these issues stem from faulty connections, damaged components, or worn-out parts. Recognizing these symptoms early can prevent further complications and facilitate timely repairs.

Troubleshooting Steps

To diagnose electrical issues, begin by checking the power source and ensuring that connections are secure. If the equipment is unresponsive, inspect the switch and circuit for any signs of damage. Replacement of fuses or resetting breakers might be necessary. For deeper issues, consulting a technician or referring to specific guides can provide detailed insights into resolving more complex electrical challenges.

By following these guidelines, users can effectively manage and rectify electrical concerns, extending the lifespan of their tools and ensuring optimal performance.

Understanding the Warranty Policy

The warranty policy serves as a safeguard for consumers, ensuring that products meet certain standards of quality and performance. It outlines the manufacturer’s commitment to repair or replace defective items within a specified time frame, providing peace of mind for users. Understanding the intricacies of this policy is crucial for making informed decisions regarding purchases and potential claims.

Key Elements of the Warranty

A typical warranty includes several important components. Firstly, it specifies the duration of coverage, which can vary significantly. Additionally, the policy often delineates what types of damage or defects are covered, as well as any exclusions that may apply. Knowing these details can help users determine their rights and responsibilities under the warranty.

How to File a Claim

If a product issue arises, consumers must understand the process for filing a claim. This usually involves gathering necessary documentation, such as proof of purchase and a description of the problem. It’s advisable to follow the guidelines provided in the warranty to ensure a smooth resolution. Being proactive and organized can significantly enhance the chances of a successful claim experience.

When to Seek Professional Help

Understanding the right moments to enlist expert assistance can significantly impact the longevity and performance of your equipment. While many maintenance tasks can be handled independently, certain issues may require specialized knowledge and tools. Recognizing the signs that indicate the need for professional intervention is crucial for effective problem resolution.

Signs of Complex Issues

If you notice persistent performance problems, unusual noises, or visible damage that you cannot identify or fix, it’s advisable to consult a technician. These symptoms may suggest underlying issues that require advanced diagnostics and repair techniques beyond standard maintenance practices.

Safety Concerns

Whenever you encounter problems that pose safety risks, such as electrical malfunctions or fuel leaks, it is essential to prioritize your safety by seeking help. Attempting to address these dangers without adequate training can lead to accidents or further damage, making professional guidance a wise choice.