Home mobility solutions often face wear over time, affecting their smooth operation and reliability. Regular upkeep and prompt handling of issues are crucial to maintain these devices at their peak functionality, ensuring both safety and comfort. This guide provides practical insights into tackling various technical challenges encountered with household lifting mechanisms, focusing on common problems, effective solutions, and tips to enhance durability.

In addition to essential troubleshooting methods, readers will find advice on assessing the condition of equipment components, from mechanical structures to control systems. Clear instructions are provided to assist users in identifying and rectifying minor faults, often without needing professional assistance. This knowledge not only minimizes downtime but also extends the service life of these valuable devices.

Key considerations for safe and efficient maintenance are emphasized throughout the guide. Learn how to prevent common malfunctions, spot early signs of wear, and understand basic techniques for component replacement. By following these practical guidelines, users can ensure their mobility equipment remains dependable and ready to serve when needed.

Essential Guide to Stannah 260 Maintenance

Proper upkeep of your mobility device ensures longevity, safety, and a smoother operation experience. Routine inspections and timely adjustments can prevent common issues, making it easier to enjoy reliable functionality every day.

Below are essential steps and practices to keep in mind:

- Regularly check the track for any dust buildup or obstructions, as these can affect movement quality. Clean the path gently to avoid any impact on device alignment.

- Inspect the seating and armrests for secure attachment. Loose components may cause discomfort or potential risk during use.

- Lubricate moving parts as recommended by the manufacturer to reduce wear over time. Avoid over-lubrication to prevent residue buildup.

- Test control functions periodically to ensure smooth response. A delayed or inconsistent reaction may indicate a need for technical adjustments.

- Examine safety features, such as braking systems and emergency stops, to confirm they engage correctly. These checks are crucial for maintaining safe operation.

Following these maintenance practices will help keep your device in excellent working order, ensuring both efficiency and peace of mind.

Common Issues and Their Solutions

Various mechanical aids designed for home accessibility can encounter challenges over time due to regular use, wear, or environmental factors. This section covers typical problems and effective ways to address them, helping to maintain reliable function and comfort.

Power Supply and Battery Concerns

- Frequent power loss: If experiencing intermittent power, ensure the device is fully seated in its charging position when not in use. Regularly check the main power connection and inspect for any loose wiring.

- Battery not holding charge: For batteries that seem to drain quickly, consider replacing older batteries. It’s recommended to check for corrosion or any signs of wear on battery terminals.

Movement and Alignment Challenges

- Stalled movement: If the equipment stops unexpectedly, check for obstructions along the track. Clean the track regularly to prevent buildup and ensure smooth operation.

- Unusual noise or jerking: Lubricate the moving parts periodically and inspect for any misaligned sections along the track or rail. Proper lubrication can prevent wear and reduce noise.

Troubleshooting Electrical System Failures

Identifying issues in the electrical components of a motorized chair system requires a systematic approach. Minor faults in connections, switches, or wiring can interrupt operation, often leading to malfunctions. Understanding the primary indicators and diagnostic steps can simplify problem-solving, reducing the time and effort spent on finding solutions.

Common Issues and Symptoms

Typical malfunctions in the electrical structure may include unresponsive controls, intermittent power, or strange noises when starting. These signs frequently point to issues with wiring integrity, loose connections, or worn-out circuit components. Before diving into complex diagnostics, visually inspect the setup for any disconnected or frayed wires and ensure that all connectors are firmly attached.

Basic Diagnostic Steps

To begin, confirm that the power source is consistent and meets the necessary voltage requirements. Use a multimeter to measure voltage across key terminals, checking for any unexpected fluctuations. Additionally, examine switches and controls to verify functionality, as damaged switches often impede smooth operation. By systematically reviewing each part of the electrical assembly, many common issues can be identified and resolved efficiently.

Battery Replacement Tips and Instructions

Ensuring consistent operation often depends on the proper maintenance of essential components, and one key aspect is timely battery replacement. Over time, power sources may lose efficiency, leading to decreased performance and reliability issues. This section offers clear guidance on handling this process safely and effectively.

Step 1: Gather Necessary Tools

Begin by assembling the required tools, typically a screwdriver and replacement batteries compatible with the device. Having the right equipment on hand ensures a smooth process without interruptions.

Step 2: Access the Battery Compartment

Carefully locate and access the battery compartment, often found at the base or within a concealed panel. Exercise caution to avoid damage to adjacent components when opening the compartment.

Step 3: Disconnect and Remove Old Batteries

Once accessed, gently disconnect any connectors or terminals attached to the existing batteries. Remove them carefully, avoiding contact with any circuitry or wires.

Step 4: Insert and Connect New Batteries

Place the new batteries in the designated slots, ensuring correct polarity alignment. Securely reconnect any terminals or connectors to restore power flow to the device.

Step 5: Test for Proper

How to Adjust Safety Sensors

Ensuring the safety sensors are correctly calibrated is essential for optimal operation and user protection. These sensors detect any obstructions or irregularities along the pathway, halting movement if necessary to prevent accidents. Proper adjustment enhances sensitivity and responsiveness, which is key for smooth and secure functionality.

Locating the Sensor Units

The first step in adjusting these components is identifying their positions, typically found near pivotal areas that may encounter obstacles. Carefully inspect each sensor, as their placement may vary slightly based on the model. Familiarizing yourself with these positions allows for precise and effective adjustments.

Adjusting Sensitivity Levels

Once located, fine-tune each sensor’s sensitivity. This may involve adjusting screws or switches near the unit to increase or decrease its response threshold. A balance between sensitivity and reliability ensures the system only activates when genuinely necessary. Test each setting incrementally, ensuring that even minor obstructions are detected without causing unwarranted stops.

Understanding Motor Malfunctions

In the realm of mechanical assistance devices, motor issues can pose significant challenges. These complications may lead to reduced performance or complete inoperability. Identifying the symptoms and underlying causes is essential for effective resolution and restoring functionality.

Common Symptoms of Motor Issues

Recognizing the signs of motor failure is the first step toward troubleshooting. Users may notice unusual sounds, erratic movements, or a total lack of response. These indicators often suggest underlying electrical or mechanical problems that require attention.

Troubleshooting Steps

Once symptoms are identified, a systematic approach to diagnosing the problem is vital. Following a logical sequence can help pinpoint the root cause. Below is a table outlining common motor issues along with possible solutions:

| Issue | Possible Causes | Recommended Actions |

|---|---|---|

| No movement | Power supply failure, motor burnout | Check power connections; inspect motor for damage |

| Unusual noises | Worn bearings, debris in motor | Inspect and clean motor components; lubricate moving parts |

| Erratic operation | Loose wiring, control circuit faults | Examine wiring connections; test control circuits |

Regular Cleaning and Lubrication Tips

Maintaining the optimal performance of your mobility solution involves regular upkeep practices, including thorough cleaning and proper lubrication. These essential tasks help ensure the longevity and efficiency of the system, providing users with a reliable and safe experience.

Adhering to a consistent maintenance schedule is key. Here are some practical recommendations:

| Task | Frequency | Instructions |

|---|---|---|

| Surface Cleaning | Weekly | Use a soft cloth and mild detergent to clean surfaces, avoiding harsh chemicals that may damage components. |

| Track Cleaning | Monthly | Remove debris from the tracks using a vacuum or brush to ensure smooth operation. |

| Lubrication of Moving Parts | Every 3 Months | Apply a light lubricant to all moving components, following manufacturer guidelines for specific products. |

| Inspection of Electrical Components | Biannually | Check for any loose connections or signs of wear. Consult a professional if issues are detected. |

Regular attention to these areas not only enhances performance but also contributes to user safety and satisfaction. By integrating these practices into your routine, you can ensure a dependable experience for all users.

Guide to Diagnosing Control Errors

Identifying and troubleshooting control malfunctions is essential for maintaining optimal functionality in any lifting device. This process involves a systematic approach to isolate issues that may prevent the equipment from operating correctly. By understanding common symptoms and their underlying causes, users can effectively resolve problems and ensure safe usage.

Common Symptoms of Control Issues

Frequent indicators of control difficulties may include unresponsive buttons, erratic movements, or unusual sounds during operation. These signs can point to a range of potential faults, from electrical interference to mechanical blockages. Users should remain vigilant for any abnormalities that disrupt normal operation.

Troubleshooting Steps

To effectively address control errors, start by checking the power supply and connections to ensure proper voltage levels. Next, examine the control panel for any visible damage or wear. If the issue persists, consult the user guide for diagnostic codes that may help pinpoint the malfunction. In more complex cases, it may be necessary to involve a qualified technician to conduct a thorough assessment.

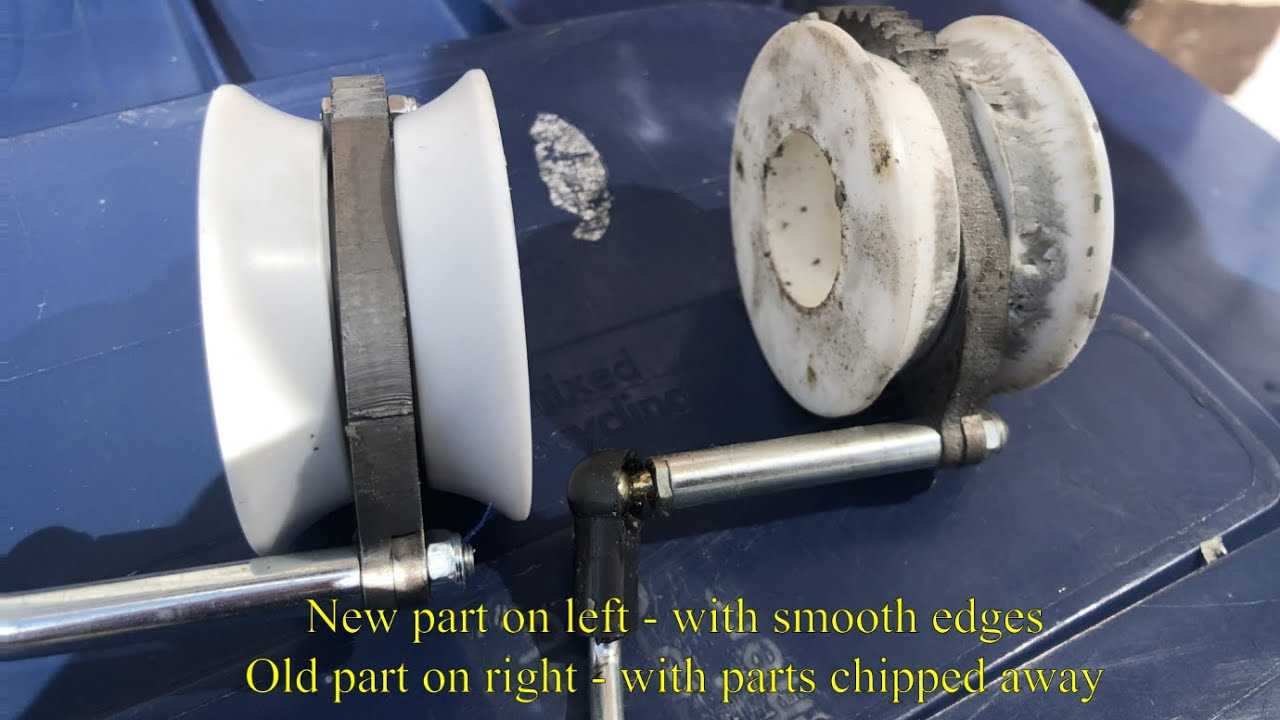

Replacing Damaged Seat Parts

When components of a seating mechanism become worn or damaged, timely intervention is crucial for maintaining optimal functionality and safety. Addressing these issues not only enhances the overall user experience but also prolongs the lifespan of the entire system. This section outlines the necessary steps and considerations for effectively replacing damaged elements of the seating apparatus.

Identifying Damaged Components

Before proceeding with any replacements, it is essential to accurately assess which parts are compromised. Common indicators of damage may include:

- Visible wear or tears on upholstery

- Loose or unstable support structures

- Malfunctions in seat adjustment mechanisms

Replacement Process

Once the damaged parts have been identified, follow these steps for replacement:

- Gather necessary tools and replacement parts, ensuring compatibility with your specific model.

- Turn off the power supply and disconnect any electrical components.

- Carefully remove the damaged parts, noting their positions for reference.

- Install the new components, ensuring a secure fit and proper alignment.

- Reattach any electrical connections, and restore power to the device.

- Test the seating mechanism to confirm proper operation and safety.

Regular maintenance and prompt replacement of damaged parts will help ensure the continued effectiveness and reliability of the seating mechanism.

Inspection Checklist for Annual Service

Regular evaluation and maintenance of mobility systems are crucial for ensuring optimal performance and safety. An annual inspection not only enhances reliability but also extends the lifespan of the device. The following checklist serves as a guideline for essential areas to assess during the yearly servicing.

1. Visual Inspection: Examine the entire unit for any signs of wear, damage, or corrosion. Ensure that all components are securely attached and that there are no loose parts.

2. Electrical System Check: Test the power supply and connections. Confirm that the charging system functions properly and that all safety features are operational.

3. Mechanical Components: Assess the condition of the drive belt and gears. Lubricate moving parts as needed and verify that the mechanisms operate smoothly without any unusual noises.

4. Safety Features: Inspect all safety devices, including emergency stop buttons and sensors. Test their functionality to guarantee they respond correctly in case of an emergency.

5. Track and Rail Condition: Evaluate the tracks for debris, obstructions, or damage. Ensure that they are clean and properly aligned for safe movement.

6. User Controls: Check the operation of user controls, including remote and onboard buttons. Ensure they are responsive and easy to use.

7. Documentation Review: Confirm that all maintenance records are up to date. Document any findings during the inspection and schedule necessary repairs.

Following this checklist will help maintain a safe and efficient environment for users, ensuring the system operates reliably for years to come.

Safety Precautions During Repairs

When conducting maintenance on lifting devices, adhering to safety measures is essential to ensure the well-being of both the technician and the users. Proper precautions not only minimize the risk of accidents but also enhance the efficiency of the servicing process.

Essential Safety Measures

- Always disconnect the power supply before starting any work to prevent electric shocks.

- Use appropriate personal protective equipment (PPE), including gloves, goggles, and hard hats.

- Ensure the work area is clean and free from obstructions to avoid tripping hazards.

- Have a first-aid kit readily available in case of emergencies.

- Follow the manufacturer’s guidelines for safe handling of components and tools.

Emergency Procedures

- In case of an injury, assess the situation and administer first aid if trained to do so.

- Immediately notify a supervisor or emergency services if necessary.

- Document the incident and report it according to company policies.