Understanding the intricacies of vehicle performance is essential for any enthusiast or mechanic. This section delves into the critical components of automotive machinery, emphasizing the importance of maintenance and troubleshooting. By mastering the fundamental aspects of mechanical systems, one can enhance both reliability and efficiency.

Whether you are facing minor issues or embarking on a significant project, having access to detailed information can make all the difference. This guide offers valuable insights into diagnostics, procedures, and techniques that are crucial for anyone looking to gain a deeper understanding of their automotive systems. The goal is to empower readers with the knowledge to confidently tackle challenges and extend the lifespan of their machinery.

As we explore various topics, readers will discover step-by-step instructions, tips, and best practices that promote a thorough approach to vehicle maintenance. The information provided here is designed to be accessible, ensuring that both novices and seasoned professionals can benefit. Embrace the journey of learning and elevate your skills in automotive care.

Overview of the 2KD Engine

This section provides a comprehensive look at a specific power unit renowned for its reliability and efficiency in various applications. Understanding its design, components, and performance characteristics is essential for both enthusiasts and professionals involved in maintenance and upgrades.

Key Features

- Robust construction ensuring longevity and durability

- Fuel efficiency that meets modern standards

- Compact size, suitable for various vehicle types

- Advanced technology for enhanced performance

Common Applications

- Light commercial vehicles

- Pick-up trucks

- Utility vans

- Off-road vehicles

This power unit has established a solid reputation across numerous sectors, making it a preferred choice for many manufacturers and users alike.

Common Issues with the 2KD Engine

This section outlines frequent challenges encountered with a particular type of power unit known for its efficiency and reliability. While many users appreciate its performance, certain problems can arise over time, leading to reduced functionality and potential breakdowns. Understanding these issues is crucial for effective maintenance and long-term operation.

Overheating Problems

One of the most prevalent concerns involves overheating, which can result from various factors, including insufficient coolant levels, a malfunctioning thermostat, or a blocked radiator. Regular checks of the cooling system and prompt attention to warning signs can help mitigate this issue and maintain optimal temperatures during operation.

Oil Consumption and Leakage

Another common problem is excessive oil consumption or leakage, often stemming from worn seals or gaskets. This not only impacts performance but also poses a risk of environmental contamination. Routine inspections and timely replacements of affected components can prevent further complications and ensure the longevity of the unit.

Tools Needed for Engine Repair

Undertaking the task of disassembling and reassembling a power unit requires a well-organized set of implements. Having the right tools not only enhances efficiency but also ensures precision in each step of the process. This section outlines the essential instruments that should be at hand to facilitate successful maintenance and restoration work.

Essential Hand Tools

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Pliers (needle nose and standard)

- Socket set (with ratchet)

- Torque wrench

- Hammers (ball-peen and rubber)

Specialized Equipment

- Oil filter wrench

- Compression tester

- Timing light

- Vacuum gauge

- Diagnostic scanner

- Engine hoist

Equipping oneself with these tools is crucial for effectively addressing issues and achieving desired outcomes in any mechanical undertaking.

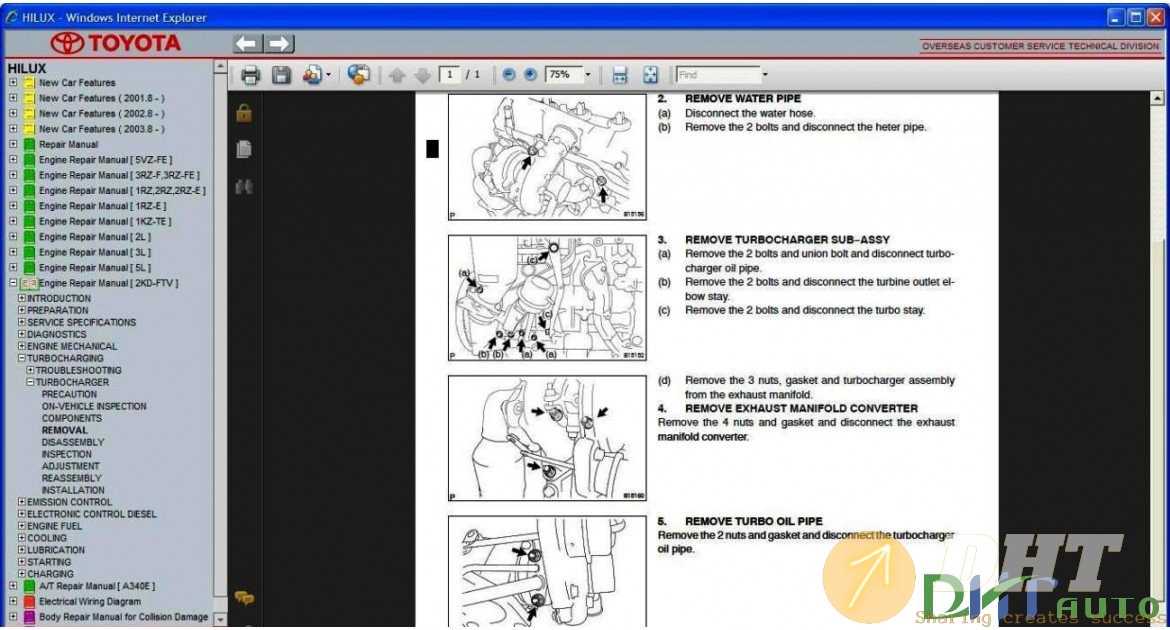

Step-by-Step Repair Procedures

This section provides a comprehensive guide to systematically addressing common issues related to a specific automotive unit. By following these detailed steps, enthusiasts and technicians alike can effectively diagnose and resolve problems, ensuring optimal performance and longevity. Each phase is designed to build upon the last, making the process accessible and efficient.

Preparation and Safety

Before initiating any work, it is crucial to gather the necessary tools and materials. Ensuring a clean and organized workspace can significantly enhance efficiency. Moreover, safety should be a top priority; proper protective gear should always be worn to prevent accidents.

| Step | Description |

|---|---|

| 1 | Disconnect the battery to prevent electrical hazards. |

| 2 | Remove any covers or shields to access the component. |

| 3 | Inspect all parts for signs of wear or damage. |

| 4 | Replace any faulty components with high-quality substitutes. |

| 5 | Reassemble the unit, ensuring all connections are secure. |

| 6 | Reconnect the battery and perform a functionality test. |

Final Checks and Maintenance

Once the work is completed, conducting a thorough review is essential. This includes verifying that all tools are removed from the workspace and that no components are left unsecured. Regular maintenance checks can prolong the life of the unit and prevent future issues.

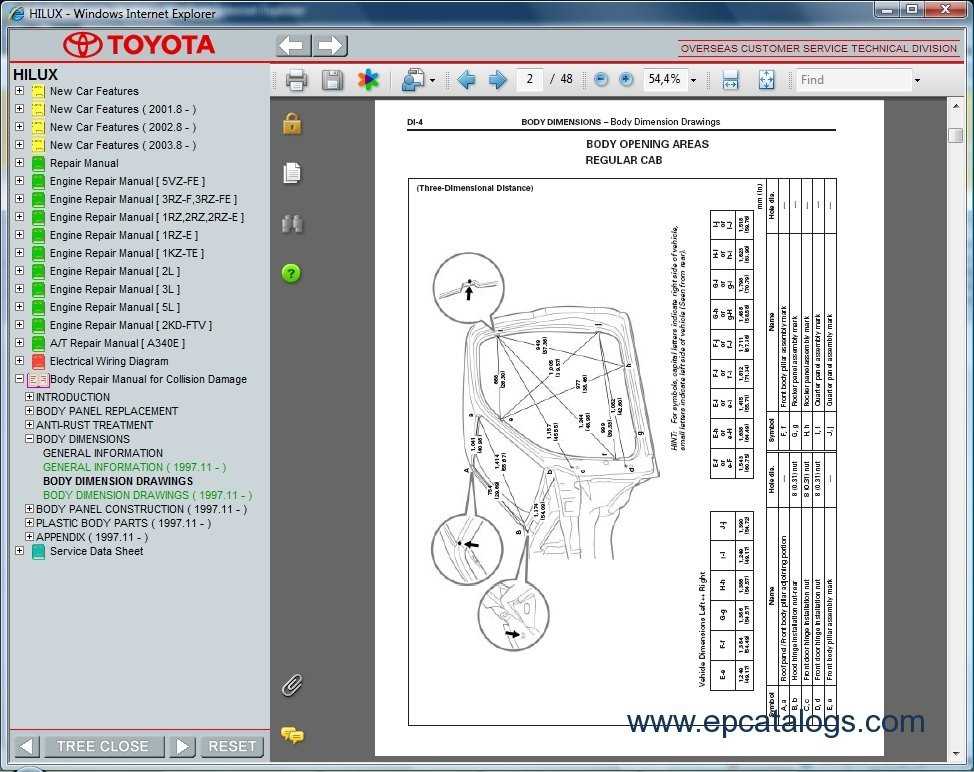

Understanding Engine Components and Functions

The intricate machinery of a vehicle consists of various parts, each playing a crucial role in its overall performance. Comprehending how these components interact and function together is essential for anyone looking to enhance their knowledge or maintain their vehicle efficiently. This section will delve into the primary elements and their respective duties within the system.

At the heart of this system lies the core assembly, responsible for converting fuel into motion. This process is facilitated by the controlled combustion of fuel and air, which generates power. Surrounding this core are numerous parts that regulate and support this vital function, ensuring optimal operation and efficiency.

Each component, from the ignition system to the cooling apparatus, contributes uniquely. The ignition system initiates the combustion process, while the cooling apparatus prevents overheating, maintaining safe operational temperatures. Meanwhile, the fuel delivery system ensures a precise mixture, allowing for smooth performance.

Additionally, the exhaust system plays a critical role in managing byproducts, channeling them away from the assembly, which not only promotes efficiency but also minimizes environmental impact. Understanding these interactions can lead to better diagnostics and informed decisions regarding maintenance and enhancements.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life of any mechanical system. Regular attention and care can significantly enhance performance and reliability, preventing costly breakdowns and reducing the frequency of necessary interventions.

1. Routine Inspections: Conduct regular checks to identify potential issues before they escalate. This includes monitoring fluid levels, inspecting belts and hoses, and looking for signs of wear or leaks.

2. Quality Fluids: Utilize high-quality lubricants and fluids as recommended. This not only promotes optimal operation but also protects critical components from excessive wear and corrosion.

3. Timely Replacements: Adhere to replacement schedules for filters, spark plugs, and other crucial parts. Using original or high-standard replacement components ensures compatibility and performance.

4. Driving Habits: Practice smooth and measured driving techniques. Avoiding rapid acceleration and hard braking can reduce stress on the system, leading to less wear and tear.

5. Regular Cleaning: Keep the exterior and ventilation areas clean. Accumulated dirt and debris can obstruct airflow and lead to overheating, which negatively impacts performance.

6. Professional Servicing: Engage professionals for comprehensive inspections and services. Their expertise can identify issues that may not be apparent during routine checks.

By incorporating these practices, you can significantly enhance the lifespan and reliability of your machinery, ensuring it continues to perform efficiently for years to come.

Symptoms Indicating Engine Problems

Recognizing early signs of malfunction in your vehicle’s power unit can save you from costly repairs and ensure safe operation. Various indicators may suggest underlying issues that require immediate attention. Understanding these symptoms is crucial for maintaining optimal performance.

| Symptom | Description |

|---|---|

| Unusual Noises | Sounds such as knocking, tapping, or grinding may indicate internal wear or damage. |

| Excessive Smoke | Smoke from the exhaust can signal burning oil or coolant leaks, depending on the color. |

| Warning Lights | Illumination of dashboard warning indicators often points to specific issues needing investigation. |

| Loss of Power | A noticeable decrease in performance can stem from various factors, including fuel delivery problems. |

| Fluid Leaks | Puddles or stains beneath the vehicle may suggest leaks from critical components, such as the oil or coolant system. |

| Overheating | Consistently high temperatures can indicate coolant deficiencies or malfunctioning parts. |

Essential Safety Precautions During Repairs

When undertaking mechanical work, prioritizing safety is crucial to prevent accidents and ensure a secure environment. Implementing the right measures not only protects individuals involved but also safeguards equipment and surrounding areas. Awareness of potential hazards and adherence to safety guidelines can significantly reduce risks during any maintenance task.

Before commencing any work, it is vital to assess the workspace and equipment for potential dangers. Proper preparation includes wearing suitable protective gear and having emergency equipment readily accessible. Below are essential precautions to consider:

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Always wear gloves, goggles, and masks to shield against debris and harmful substances. |

| Workspace Organization | Maintain a clean and clutter-free area to minimize tripping hazards and ensure easy access to tools. |

| Ventilation | Ensure adequate airflow, especially when working with chemicals or materials that emit fumes. |

| Emergency Procedures | Familiarize yourself with emergency exits and the location of first aid kits and fire extinguishers. |

| Equipment Inspection | Regularly check tools and machinery for defects to prevent malfunctions during use. |

By adhering to these essential safety measures, individuals can create a safer environment, enhancing both personal well-being and the efficiency of their tasks. Awareness and proactive steps are key to successful outcomes in any maintenance endeavor.

Cost Considerations for Repairs

When addressing mechanical issues, understanding the financial implications is essential for effective planning. Various factors influence the overall expenses, from parts and labor to unforeseen complications that may arise during the process. Evaluating these aspects can help ensure that budgeting aligns with the necessary work.

Parts Quality: The choice between original equipment manufacturer (OEM) and aftermarket components can significantly impact costs. While OEM parts may offer reliability, they often come at a premium. Conversely, aftermarket options might be more affordable, but quality can vary widely. It’s crucial to assess the long-term benefits of each option.

Labor Costs: Labor fees can differ based on the location and the expertise of the technicians. High-demand areas may see inflated rates, while specialized shops may charge more due to their expertise. It’s advisable to compare estimates from multiple sources to find a reasonable balance between cost and skill.

Unexpected Repairs: During the inspection phase, additional issues may be discovered, leading to increased expenses. Preparing for potential surprises by allocating a contingency budget can prevent financial strain and ensure all necessary work is completed.

Preventive Maintenance: Investing in regular upkeep can ultimately reduce costs. By addressing minor issues before they escalate, vehicle owners can save significantly in the long run. Understanding the correlation between maintenance and long-term expenses is key to making informed decisions.

When to Seek Professional Help

Knowing when to call in an expert can save time, money, and frustration. Some issues may seem manageable at first glance, but can quickly escalate if not addressed correctly. It’s important to recognize your limits and understand when professional assistance is necessary to ensure proper handling of complex problems.

Signs You Need Expert Assistance

There are several indicators that suggest it’s time to consult a specialist. Recognizing these signs early can prevent further complications.

| Indicator | Description |

|---|---|

| Persistent Issues | If a problem continues despite attempts to fix it, professional evaluation may be required. |

| Unusual Noises | Strange sounds during operation often signal underlying concerns that need expert analysis. |

| Warning Lights | Dashboard alerts should never be ignored, as they indicate specific malfunctions that need attention. |

| Fluid Leaks | Any visible leaks can be a sign of serious issues and should prompt a call to a professional. |

Benefits of Professional Expertise

Engaging a qualified technician not only ensures safety but also provides peace of mind. Professionals possess the necessary tools and knowledge to diagnose and rectify problems effectively, reducing the risk of further damage and enhancing overall performance.