When it comes to keeping your vehicle running smoothly, understanding the intricacies of its power unit is essential. This section delves into the vital aspects of upkeep and troubleshooting, providing valuable insights for both novice and experienced enthusiasts. By familiarizing yourself with the inner workings, you can ensure longevity and optimal performance.

Knowledge is Key: A thorough comprehension of your vehicle’s machinery will empower you to identify potential issues before they escalate. Whether it’s routine maintenance or complex diagnostics, having a reliable source of information at your fingertips is crucial. This guide serves as a foundational tool for those looking to enhance their skills.

Hands-On Learning: Engaging with practical tasks not only reinforces theoretical knowledge but also builds confidence in handling various challenges. This resource offers step-by-step instructions and tips to navigate common scenarios, making the learning process both effective and rewarding.

Understanding the 3zz Engine

This section aims to provide insights into a specific type of power unit known for its efficiency and performance. By examining its components and functionality, we can better appreciate its design and operational principles.

Key aspects to consider include:

- Design characteristics

- Performance metrics

- Maintenance requirements

- Common issues and troubleshooting

Familiarity with these elements can greatly enhance your understanding and facilitate better decision-making regarding upkeep and modifications.

Common Issues with the 3zz Engine

When it comes to the performance of this specific power unit, several recurring challenges can arise. Understanding these common complications can aid in identifying symptoms early and ensuring optimal functioning. This section delves into frequent problems associated with this particular configuration and offers insights into their causes and potential solutions.

Frequent Complications

Among the notable issues encountered are oil leaks, overheating, and irregular idling. These conditions can significantly impact performance and lead to further damage if not addressed promptly. Below is a summary of these typical challenges:

| Issue | Description | Potential Causes |

|---|---|---|

| Oil Leaks | Presence of oil around the engine components. | Worn gaskets, damaged seals, or loose fittings. |

| Overheating | Excessive temperature causing performance decline. | Coolant leaks, faulty thermostat, or radiator issues. |

| Irregular Idling | Inconsistent engine speed at rest. | Vacuum leaks, dirty fuel injectors, or sensor malfunctions. |

Addressing These Challenges

To mitigate these common difficulties, regular maintenance checks and timely interventions are crucial. Keeping an eye on fluid levels, replacing worn components, and ensuring the cooling system is functioning properly can enhance longevity and reliability.

Tools Needed for Repairing 3zz

When tackling any automotive task, having the right equipment is essential for ensuring a smooth process and successful outcome. This section outlines the various implements and devices that are crucial for maintaining and overhauling the specific type of power unit in question.

Basic Hand Tools: A solid set of hand tools is fundamental. Wrenches, sockets, and screwdrivers of various sizes are necessary for loosening and tightening components. A torque wrench is particularly important to ensure that fasteners are secured to the manufacturer’s specifications.

Diagnostic Equipment: To accurately assess performance issues, diagnostic tools such as OBD-II scanners can provide valuable insights. These devices help in reading error codes and understanding underlying problems that may not be visible externally.

Specialty Tools: Certain jobs may require specific tools, such as pullers for removing bearings or specialized sockets for accessing hard-to-reach bolts. Investing in these items can save time and prevent damage during disassembly and reassembly.

Safety Gear: Never underestimate the importance of personal protective equipment. Safety glasses, gloves, and steel-toed boots are essential to safeguard against potential hazards encountered during the work.

Fluid Containers: Efficiently managing fluids is crucial for any maintenance task. Having containers for used oil, coolant, and other fluids helps maintain a clean workspace and ensures proper disposal practices.

Equipped with the right tools, you will be well-prepared to take on any challenges that may arise while working on the power unit, leading to effective and efficient outcomes.

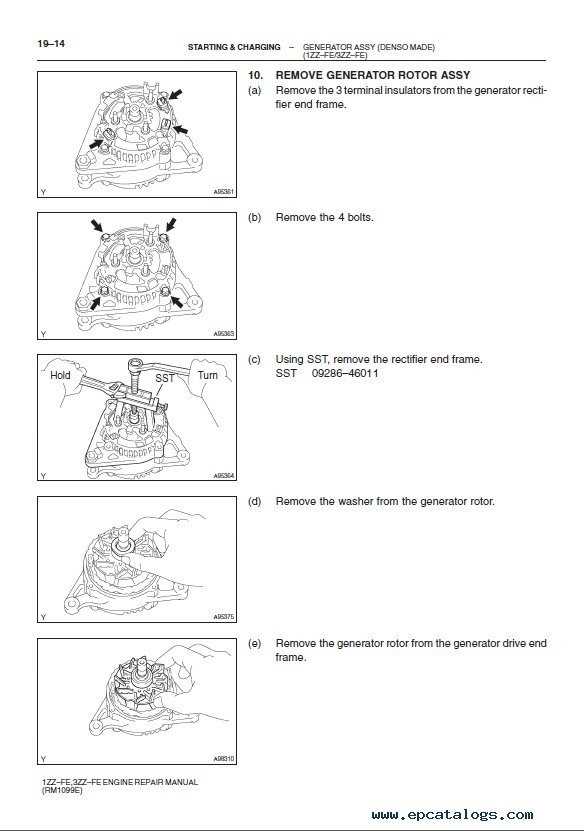

Step-by-Step Disassembly Process

This section provides a comprehensive guide to carefully dismantling the assembly for maintenance or inspection. A methodical approach ensures that each component is handled properly, reducing the risk of damage and facilitating reassembly. Following the outlined steps will help you maintain organization and clarity throughout the process.

Preparation and Tools

Before beginning, gather all necessary tools and materials. Ensure your workspace is clean and organized. Commonly required tools include wrenches, screwdrivers, pliers, and a torque wrench. Additionally, have containers ready to hold small parts and fasteners, making it easier to keep track of everything during the disassembly.

Disassembly Steps

1. Remove Covers: Start by taking off any protective covers. This typically involves unscrewing bolts or unclipping fasteners. Keep all removed parts in designated containers to avoid misplacement.

2. Detach Components: Proceed to disconnect various elements such as hoses, electrical connections, and any additional attachments. Take note of the configuration for accurate reinstallation. It’s beneficial to label connections or take photographs for reference.

3. Unscrew Bolts: Carefully unscrew all bolts securing major parts. Use a torque wrench to ensure you do not apply excessive force, which can lead to stripping threads.

4. Extract Subassemblies: Once bolts are removed, gently pull apart the subassemblies. Avoid using excessive force; if parts are stuck, check for any overlooked fasteners or clips.

By following these steps diligently, you will facilitate a smoother disassembly process, setting the foundation for effective maintenance or further inspection of the components involved.

Inspecting Engine Components Thoroughly

Conducting a detailed examination of mechanical parts is crucial for ensuring optimal performance and longevity. This process involves checking for wear, damage, and potential issues that may affect functionality. A meticulous approach can reveal underlying problems that might not be immediately apparent, allowing for timely interventions.

Key Areas to Focus On

When scrutinizing these components, prioritize areas such as seals, gaskets, and connecting elements. These parts often experience significant stress and can lead to leaks or failures if not addressed. Additionally, assess the condition of moving parts, as any signs of wear may indicate the need for replacement or adjustment.

Utilizing Appropriate Tools

Employing the right instruments for inspection enhances accuracy and efficiency. Tools such as gauges, calipers, and diagnostic devices provide invaluable insights into the condition of various components. Regularly calibrating and maintaining these tools ensures reliable readings and supports thorough evaluations.

Replacing Worn Out Parts Effectively

Ensuring the longevity and performance of your vehicle often requires attention to various components that may degrade over time. This section outlines strategies for efficiently substituting components that have lost their functionality, thereby enhancing overall reliability and performance.

When tackling the task of component replacement, consider the following steps:

- Assessment: Begin by thoroughly examining the affected parts. Look for signs of wear, damage, or malfunction. Document your findings for reference.

- Research: Identify suitable replacements. Consult manufacturer specifications and reliable resources to find compatible components.

- Quality Selection: Choose high-quality alternatives. Opt for reputable brands or OEM parts to ensure durability and compatibility.

- Preparation: Gather necessary tools and equipment. Prepare the workspace to ensure a safe and efficient replacement process.

During the actual replacement process, keep the following tips in mind:

- Follow a systematic approach to avoid confusion and ensure all components are correctly addressed.

- Maintain organization by keeping track of all removed parts and fasteners.

- Take your time to ensure each replacement is fitted correctly, paying attention to alignment and secure fastening.

Finally, after the installation, conduct a thorough check to confirm that everything is functioning as intended. A test drive can help verify the effectiveness of the new components.

Reassembling the 3zz Engine Safely

When putting components back together, meticulous attention to detail and adherence to safety protocols are paramount. A successful assembly not only ensures optimal performance but also enhances the longevity of the parts involved. Below are essential guidelines to consider during the reassembly process.

- Ensure a Clean Workspace: Begin with a tidy environment to prevent any contamination of components.

- Organize Parts: Keep all pieces sorted and labeled to facilitate an efficient reassembly.

- Use Proper Tools: Select the right instruments to avoid damaging delicate parts.

- Follow Specifications: Refer to detailed specifications to confirm the correct alignment and torque settings.

During reassembly, it’s crucial to implement a step-by-step approach. Here’s a simple outline to follow:

- Inspect All Components: Before starting, check for any wear or damage.

- Lubricate Moving Parts: Apply appropriate lubricant to ensure smooth operation.

- Assemble in Sequence: Follow the recommended order for mounting various sections.

- Double-Check Connections: Verify that all fasteners are secure and connections are tight.

- Test for Functionality: Once assembled, conduct a thorough test to confirm everything operates as intended.

By adhering to these principles, you can ensure that the reassembly process is not only safe but also effective, leading to a reliable and high-performing system.

Essential Maintenance Tips for Longevity

Ensuring the durability of your vehicle involves consistent care and attention to detail. Regular upkeep not only enhances performance but also extends the lifespan of key components. Adopting a systematic approach to maintenance can lead to significant benefits over time, providing reliability and peace of mind.

Regular Inspections

Conducting routine checks can help identify potential issues before they escalate. Regular assessments of vital systems, such as the cooling and lubrication mechanisms, are crucial. Monitoring fluid levels and conditions also plays a significant role in maintaining optimal operation.

Quality Fluids and Parts

Using high-quality fluids and replacement components is essential for long-term health. Synthetic oils, high-grade coolants, and reliable filters can significantly impact performance. Investing in premium parts ensures compatibility and longevity, reducing the likelihood of future complications.

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 5,000 miles |

| Fluid Levels Check | Monthly |

| Filter Replacement | Every 15,000 miles |

| Tire Rotation | Every 6,000 miles |

Troubleshooting Common Engine Problems

When facing issues with your vehicle’s performance, identifying the root cause can seem daunting. Various symptoms can indicate underlying faults, and understanding these signs is crucial for effective diagnostics. This section provides insights into typical challenges encountered and practical steps for resolution.

Identifying Symptoms

Common indicators of malfunction may include unusual noises, decreased power, or erratic behavior. Pay attention to sounds like knocking or grinding, which can signify serious problems. If the vehicle struggles to accelerate or displays stalling, these are also critical warnings that should not be ignored.

Basic Diagnostic Steps

Start by conducting a visual inspection of essential components. Check for signs of leaks, worn belts, or loose connections. Utilizing diagnostic tools can help pinpoint specific issues by reading error codes. Regular maintenance practices, such as fluid changes and filter replacements, are vital in preventing potential troubles.

Upgrading Components for Better Performance

Enhancing the capabilities of your vehicle can lead to a more thrilling driving experience. By focusing on specific parts and making informed upgrades, you can significantly improve responsiveness, efficiency, and overall power delivery. This section explores various enhancements that can elevate performance levels and provide a more engaging ride.

Intake and Exhaust Systems

One of the most effective ways to boost performance is by optimizing airflow. Upgrading the intake system allows for better air entry, while a high-performance exhaust system facilitates smoother exhaust flow. These modifications not only improve power output but also enhance the auditory experience, giving your vehicle a more aggressive sound.

Fuel Delivery Enhancements

Another crucial area for improvement lies in the fuel delivery system. Installing larger fuel injectors or a high-flow fuel pump can ensure that your setup receives adequate fuel supply during high-demand situations. Coupled with a remapped engine control unit (ECU), these changes can lead to noticeable gains in acceleration and throttle response.

Investing in these upgrades can lead to a more thrilling and responsive driving experience, making every journey more enjoyable. Always ensure that any modifications are compatible and consider seeking professional assistance to maximize the potential of your enhancements.

Cost Estimates for Repairs

Understanding the financial aspects of maintaining your vehicle is essential for any owner. Various factors contribute to the overall expenses, including labor, parts, and additional services. Accurate budgeting helps ensure that you can handle any necessary adjustments without financial strain.

When assessing potential costs, it’s crucial to consider both minor and major fixes. Minor issues may require simple part replacements, while significant malfunctions might demand extensive labor and multiple components. Gathering multiple quotes from different service providers can provide a clearer picture of what to expect.

Additionally, parts availability can influence pricing. OEM components tend to be pricier than aftermarket alternatives, which can impact overall expenditures. Always weigh the pros and cons of different options to make an informed choice that aligns with your budget and long-term goals.

Lastly, keep in mind that preventative maintenance can save money in the long run. Regular check-ups can help identify potential problems early, ultimately reducing the need for extensive and costly interventions.

Finding Quality Replacement Parts

Locating high-quality components is essential for ensuring optimal performance and longevity of your vehicle. Choosing the right parts can significantly affect not only the functionality but also the safety of your ride. In this section, we will explore effective strategies for sourcing reliable replacements.

Researching Suppliers

Finding trustworthy vendors is crucial. Consider the following tips:

- Look for established businesses with positive customer reviews.

- Check if the supplier specializes in the specific parts you need.

- Evaluate their return policy and customer support services.

Identifying Quality Components

Not all components are created equal. Here are some factors to consider:

- Examine the material and craftsmanship.

- Verify if the parts meet industry standards or certifications.

- Consider purchasing from original equipment manufacturers (OEM) for guaranteed quality.

By following these guidelines, you can confidently find the parts that will keep your vehicle running smoothly.

Resources for Further Learning

Expanding your knowledge in automotive maintenance and troubleshooting can significantly enhance your skills and confidence. Various resources are available to help enthusiasts and professionals alike deepen their understanding of vehicle mechanics and related systems. Engaging with these materials can provide valuable insights and practical techniques.

Books and eBooks on automotive technology offer comprehensive overviews and detailed explanations of various components and their functions. Online courses and webinars conducted by experts in the field provide interactive learning experiences, allowing participants to ask questions and engage with the material actively.

Forums and community groups can serve as excellent platforms for sharing experiences and seeking advice. Engaging with fellow enthusiasts allows for the exchange of tips and troubleshooting strategies. Additionally, instructional videos on platforms like YouTube demonstrate hands-on techniques, making complex processes more accessible.

Finally, manufacturers’ websites and technical bulletins often provide up-to-date information about specifications and best practices, ensuring that your knowledge remains current. Utilizing these resources can empower you to tackle maintenance tasks with greater expertise and confidence.