In the realm of outdoor machinery, ensuring optimal performance and longevity is essential. Understanding the intricacies of these complex systems empowers users to maintain their equipment effectively. This section delves into the vital aspects of upkeep, focusing on key components that are crucial for smooth operation.

Technical knowledge is paramount when addressing issues that may arise during the life cycle of your machinery. Familiarizing oneself with the various elements involved can significantly enhance the troubleshooting process. The following content aims to provide detailed insights and practical solutions for common challenges, enabling you to navigate repairs with confidence.

Moreover, regular maintenance not only prevents potential breakdowns but also contributes to overall efficiency. By exploring systematic approaches and best practices, users can maximize the functionality of their equipment while minimizing downtime. This guide serves as a valuable resource for anyone seeking to deepen their understanding and improve their skills in equipment management.

Understanding Snapper Rear Engine Design

The innovative layout of this mower type plays a crucial role in enhancing its performance and user experience. By positioning the power unit at the back, it allows for improved weight distribution, maneuverability, and cutting efficiency. This design not only aids in better traction but also contributes to a more compact structure, making it easier to navigate through various terrains.

Key Features of the Design

- Optimal Weight Distribution

- Enhanced Maneuverability

- Improved Traction

- Compact Structure

Benefits of the Configuration

- Increased Stability: The weight at the back provides a balanced feel during operation.

- Better Visibility: Operators can easily see the cutting path without obstruction.

- Efficient Cutting: The unique arrangement allows for effective grass management.

- Enhanced Control: The design permits precise handling in tight spaces.

Common Issues with Rear Engines

Understanding the typical challenges associated with the propulsion system located at the back of equipment is essential for maintaining optimal performance. Various factors can contribute to malfunctions, often resulting in reduced efficiency or complete operational failure. This section explores prevalent problems that users may encounter and offers insights into potential solutions.

Mechanical Failures

One of the most frequent concerns involves mechanical breakdowns. Over time, components may wear down due to friction, leading to decreased functionality. Issues such as misalignment or excessive vibration can further exacerbate the situation, causing additional strain on connected parts. Regular inspections and timely replacements are vital to prevent cascading failures.

Fuel and Ignition Problems

Fuel delivery and ignition systems are also prone to complications. Clogs in the fuel line or faulty spark plugs can impede performance, resulting in poor starting or inconsistent operation. Ensuring that these systems are clean and functioning properly is crucial for reliable performance. Routine maintenance can significantly reduce the likelihood of encountering these issues.

Essential Tools for Repairing Snapper

When it comes to maintaining and fixing outdoor power equipment, having the right instruments at your disposal is crucial. This section highlights the key items that will enhance your efficiency and effectiveness in addressing various tasks related to the machinery.

Basic Hand Tools

Every technician should start with a robust set of hand tools. This includes wrenches, screwdrivers, and pliers. These essential implements are necessary for loosening or tightening components, ensuring a secure fit and proper function. It’s advisable to invest in both standard and metric sizes to accommodate different specifications.

Specialized Equipment

In addition to basic tools, certain specialized equipment can significantly aid in the maintenance process. Torque wrenches are vital for applying the correct amount of force to fasteners, preventing damage or malfunction. Furthermore, a reliable multimeter can assist in diagnosing electrical issues, while a carburetor cleaning kit can help keep fuel systems operating smoothly.

Step-by-Step Repair Instructions

This section provides a comprehensive guide to troubleshooting and fixing common issues associated with your equipment. By following these detailed steps, you can effectively address problems and ensure optimal performance.

1. Preparation: Before starting, gather all necessary tools and materials. Ensure you have a clean workspace and wear appropriate safety gear to protect yourself during the process.

2. Diagnosis: Identify the symptoms and root causes of the malfunction. Listen for unusual sounds, check for leaks, and observe any performance discrepancies. Document your findings for reference.

3. Disassembly: Carefully disassemble the components that require attention. Take note of the order in which you remove parts, and keep all screws and small items organized to facilitate reassembly.

4. Inspection: Examine each part for signs of wear or damage. Pay close attention to critical components such as seals, belts, and fasteners. Replace any parts that do not meet specifications.

5. Cleaning: Thoroughly clean all components using appropriate cleaning agents. Remove dirt, debris, and old lubricants to ensure smooth operation and prevent future issues.

6. Reassembly: Begin reassembling the equipment in the reverse order of disassembly. Ensure all parts fit snugly and are secured according to manufacturer guidelines.

7. Testing: After reassembly, conduct a test run to ensure everything operates correctly. Monitor for any irregularities and make adjustments as necessary.

8. Maintenance: Regular maintenance is key to prolonging the life of your equipment. Schedule routine checks and cleanings to prevent issues from arising in the future.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your outdoor machinery requires regular attention and care. By adhering to a structured maintenance routine, you can prevent common issues and enhance performance, ultimately leading to a more efficient and reliable experience.

Regular Inspection

Conducting frequent checks can help identify potential problems before they escalate. Here are key areas to focus on:

- Check for leaks and signs of wear.

- Inspect belts and hoses for cracks or fraying.

- Ensure all bolts and screws are tightened to specification.

Routine Cleaning

Keeping your equipment clean is essential for optimal performance. Follow these steps:

- Remove debris from cooling areas to prevent overheating.

- Wash external surfaces with mild soap and water.

- Inspect air filters and replace if necessary.

By implementing these practices, you can significantly enhance the durability and efficiency of your machinery, ensuring it serves you well for years to come.

Troubleshooting Engine Performance Problems

Addressing issues related to the functionality of your power source can be challenging but essential for optimal performance. Identifying the underlying causes of diminished efficiency is crucial for restoring proper operation. A systematic approach to diagnosing problems will aid in pinpointing the source of difficulties.

Start by checking fuel quality. Contaminated or stale fuel can lead to poor combustion and sluggish performance. Ensure that the fuel used meets the necessary specifications and is fresh. Additionally, examine the fuel delivery system for any clogs or leaks that may disrupt the flow.

Next, inspect the ignition components. Worn spark plugs or faulty ignition systems can result in misfiring and a noticeable drop in power. Replacing damaged parts and ensuring proper timing can significantly enhance functionality.

Air intake is another critical factor. A blocked or dirty air filter restricts airflow, negatively impacting efficiency. Regular maintenance of the air intake system is essential to maintain optimal performance.

Finally, check for any mechanical issues. Listen for unusual noises that may indicate wear or damage. Regularly inspecting belts, hoses, and other moving parts can help prevent further complications and ensure longevity.

Replacing Components: What You Need

When undertaking the task of substituting parts in machinery, it’s essential to be well-prepared. Proper knowledge and the right tools can make a significant difference in achieving a successful outcome.

Essential Tools: Gather a set of reliable tools, including wrenches, screwdrivers, and pliers. These instruments are crucial for disassembly and reassembly processes.

Replacement Parts: Ensure you have high-quality components that match the specifications of your equipment. Using subpar materials can lead to further issues down the line.

Safety Gear: Donning protective eyewear and gloves is paramount. Safety should always be a priority when handling mechanical elements.

Documentation: Reference guides or online resources can provide valuable insights and step-by-step instructions, aiding in a smooth transition during the component swap.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is paramount. Proper precautions not only protect the individual performing the work but also safeguard equipment and the surrounding environment. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries.

Personal Protective Equipment

Wearing appropriate protective gear is essential. This includes gloves, safety goggles, and ear protection when necessary. Proper footwear is also crucial to prevent slips and injuries. By equipping oneself with the right tools and attire, individuals can minimize exposure to hazards.

Work Environment Safety

Maintaining a clean and organized workspace is vital. Ensure that tools are stored correctly and that the area is free from clutter. Good ventilation is important, especially when working with chemicals or fuels. Always have a fire extinguisher nearby and know how to use it in case of emergencies. Following these guidelines fosters a safer atmosphere for everyone involved.

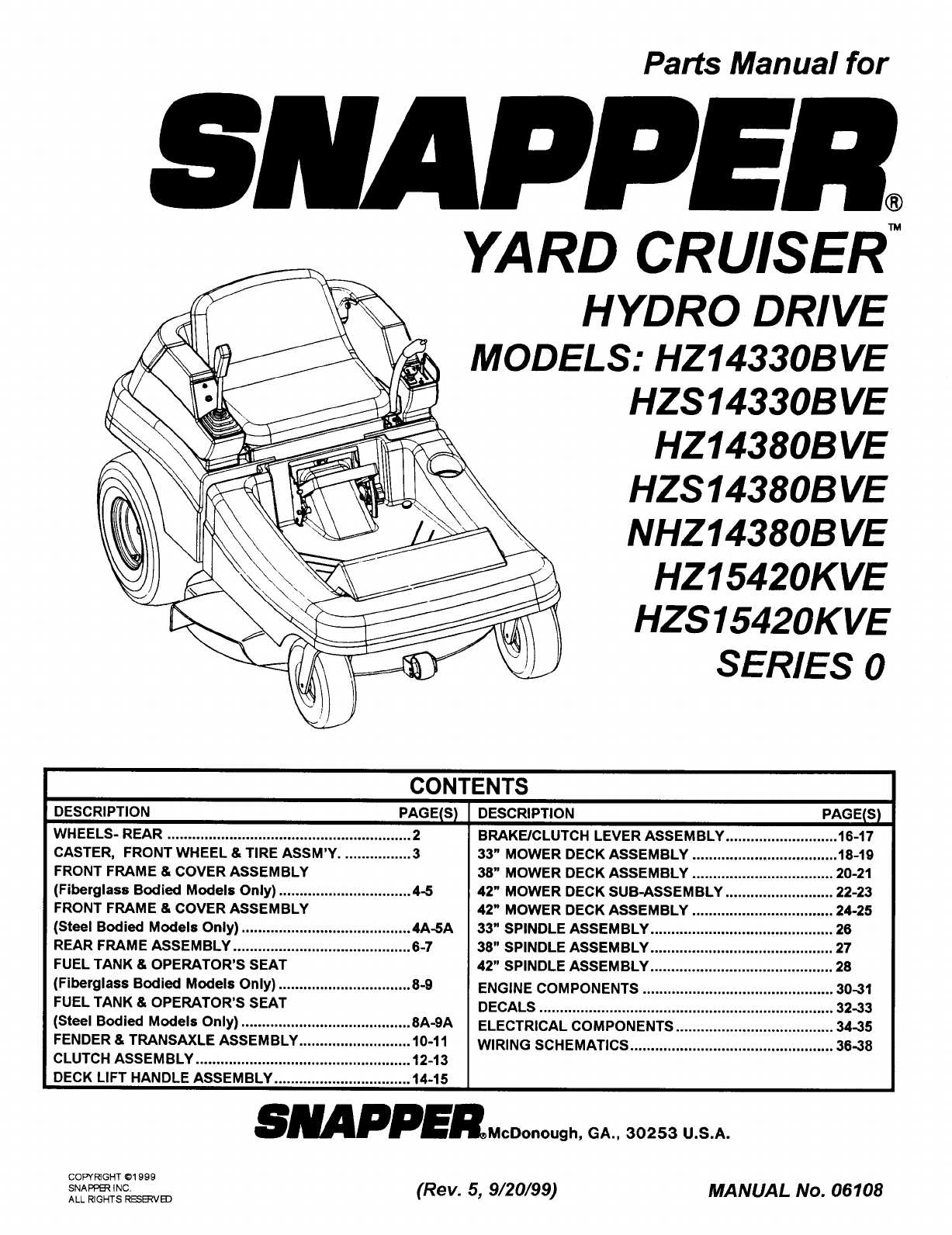

Identifying Parts for Snapper Models

When it comes to maintaining outdoor power equipment, understanding the components is essential for effective upkeep and troubleshooting. Each model consists of various parts that serve specific functions, and recognizing these elements can greatly enhance the overall performance and longevity of the unit.

1. Familiarize Yourself with Diagrams: The first step in identifying components is to consult detailed diagrams that illustrate the assembly of the machine. These visual aids provide clarity on where each part is located and how they interact with one another.

2. Refer to Model Numbers: Each unit is assigned a unique identification code that reflects its specifications. Knowing the model number allows you to access tailored information and resources, ensuring you find the correct replacements.

3. Component Categories: It is helpful to categorize parts into groups such as propulsion, power, and control systems. Understanding these categories can simplify the identification process and guide you in sourcing the right items.

4. Consult the Community: Engaging with forums or communities dedicated to outdoor equipment can provide valuable insights. Experienced users often share tips and resources that can aid in the identification of components.

5. Online Resources: Numerous websites offer detailed specifications and part numbers. Utilizing these resources can save time and ensure accuracy when seeking replacements.

By systematically approaching the identification of components, you can ensure that your outdoor equipment remains in optimal working condition, ready for any task at hand.

When to Seek Professional Help

Knowing when to enlist the expertise of a professional can save time, effort, and potentially prevent further complications. Certain situations may arise where advanced skills and specialized tools are necessary to address the issue effectively.

It is essential to recognize the signs that indicate a need for outside assistance. Below are common scenarios where seeking help is advisable:

| Situation | Reason for Professional Assistance |

|---|---|

| Unusual Noises | Sounds that are out of the ordinary can signal significant underlying problems that require expert evaluation. |

| Persistent Issues | If the same problem recurs despite attempts at resolution, a professional may identify root causes that are not apparent to an untrained eye. |

| Lack of Knowledge | When unsure about the necessary procedures or required tools, consulting a specialist ensures the job is done correctly. |

| Safety Concerns | In situations where safety is at risk, it is crucial to rely on someone with the right qualifications to handle the task. |

In conclusion, recognizing the limits of your expertise and knowing when to call for help is vital in maintaining optimal functionality and ensuring safety.