In the world of transportation, ensuring the longevity and efficiency of equipment is paramount. This section serves as a resource for individuals seeking to enhance their knowledge and skills in maintaining and restoring essential components that are critical for safe and effective operation.

Understanding the intricacies of these systems not only improves functionality but also contributes to overall safety on the road. With the right techniques and insights, one can effectively tackle common issues, thus prolonging the lifespan of vital machinery.

Whether you are a seasoned professional or a newcomer, this guide aims to empower you with the ultimate knowledge required for effective upkeep. Delve into practical advice and step-by-step instructions that will facilitate a deeper understanding of your equipment’s needs.

Understanding Wabash Trailers

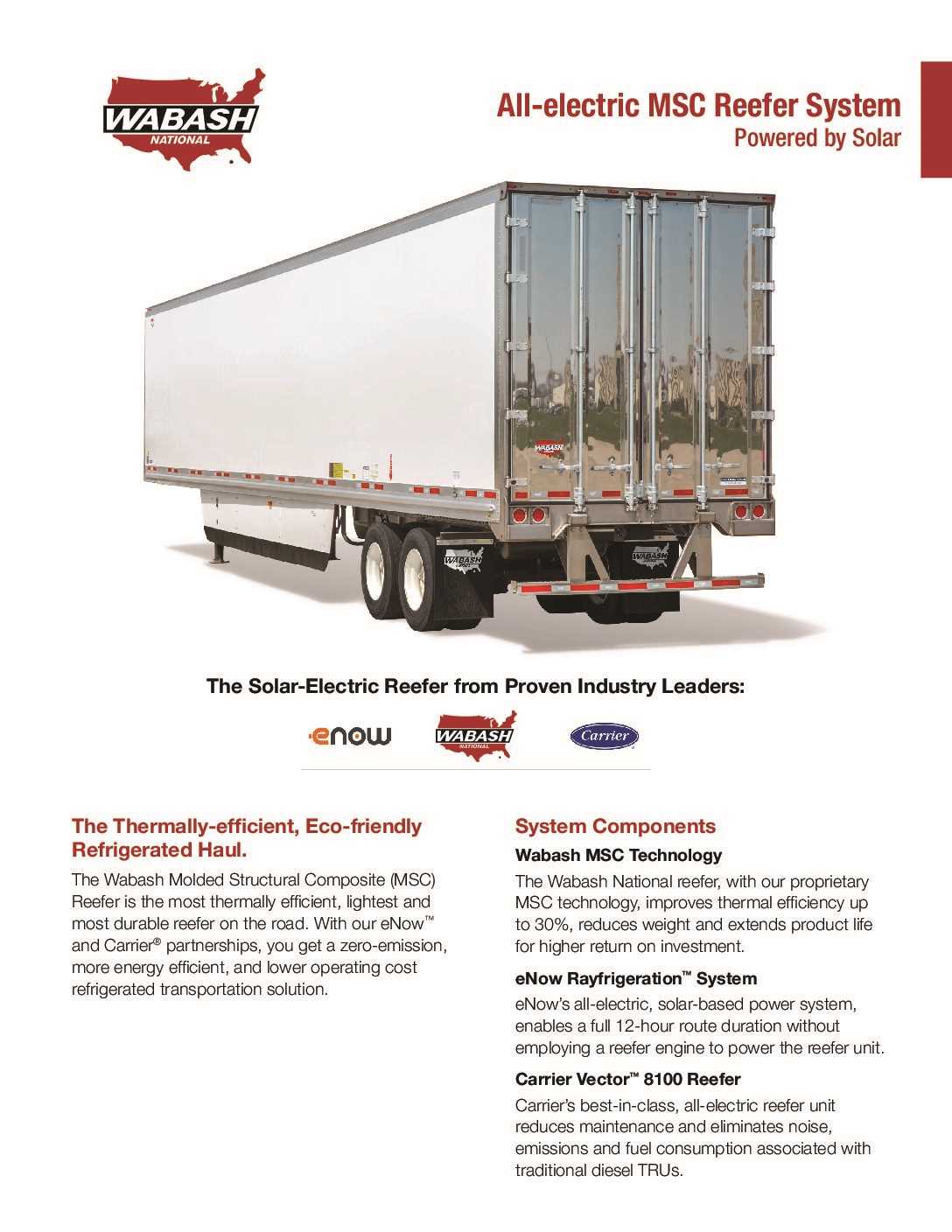

This section explores the intricacies of a well-known brand specializing in cargo transport solutions. These robust vehicles are designed to withstand the rigors of the road while providing efficiency and reliability in transporting goods. With a commitment to innovation and quality, they play a significant role in the logistics and transportation industry.

Key Features and Benefits

The products in this category are characterized by their lightweight construction and aerodynamic design, which contribute to improved fuel efficiency. Enhanced safety features ensure that cargo remains secure during transit, while durability allows for long-term use in various conditions. This makes them an ideal choice for businesses looking to optimize their fleet.

Maintenance Considerations

Key Features of Wabash Trailers

When it comes to high-performance transport solutions, certain models stand out due to their exceptional design and innovative characteristics. These vehicles are engineered to enhance efficiency and durability, making them a preferred choice among professionals in the logistics sector.

Durability and Build Quality

The construction of these vehicles is focused on longevity and resilience. With robust materials and advanced engineering techniques, they are built to withstand the rigors of daily use. Corrosion-resistant coatings and reinforced structures contribute to a lifespan that surpasses industry standards.

Enhanced Aerodynamics and Fuel Efficiency

Designed with aerodynamics in mind, these models reduce drag, allowing for smoother travel. This innovative design not only improves fuel efficiency but also minimizes environmental impact. Streamlined shapes and optimized features work together to provide significant savings in fuel costs over time.

Common Issues with Wabash Trailers

Understanding frequent challenges faced by these transport solutions is crucial for maintaining optimal performance and safety. Various components may experience wear and tear, leading to complications that can affect functionality. Below are some typical problems encountered.

- Structural Damage:

Commonly caused by impacts or stress over time, which may lead to cracks or bends in the frame.

- Seal Failures:

Issues with seals can result in leaks, particularly affecting enclosed sections that need to maintain specific conditions.

- Brake System Malfunctions:

Worn or malfunctioning brake components can lead to decreased stopping power, posing safety risks.

- Tire Problems:

Improper inflation, alignment issues, or uneven wear can compromise stability and lead to blowouts.

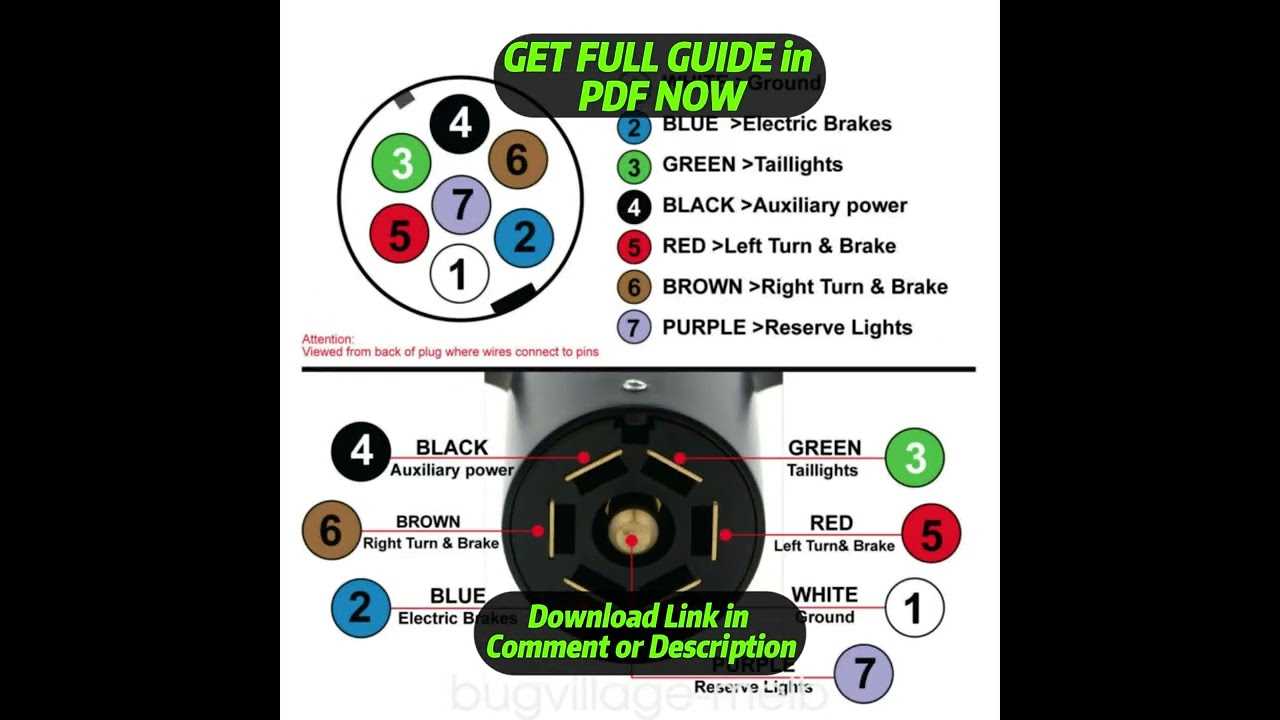

- Electrical Failures:

Faulty wiring or connections can cause lighting issues, affecting visibility during transport.

Regular inspections and prompt addressing of these issues can significantly enhance longevity and reliability, ensuring safe operations throughout their use.

Essential Tools for Trailer Repair

When it comes to maintaining and fixing heavy-duty vehicles, having the right equipment is crucial for effective and safe outcomes. The following list highlights key instruments that can significantly enhance your ability to address various issues that may arise.

- Socket Set: A comprehensive socket set allows for efficient loosening and tightening of bolts and nuts.

- Wrenches: Adjustable and fixed wrenches are essential for handling a range of fasteners.

- Jack: A reliable hydraulic or mechanical jack is vital for lifting heavy components for inspection or replacement.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage.

- Safety Gear: Personal protective equipment, including gloves and goggles, is necessary to protect against potential hazards.

In addition to the basic tools, having specialized instruments can further streamline your tasks:

- Pliers: Useful for gripping, twisting, and cutting wires or other materials.

- Drill and Bits: Essential for creating holes or removing screws in various components.

- Measuring Tape: Accurate measurements are critical for ensuring parts fit correctly.

- Level: A leveling tool helps confirm that surfaces are even, crucial for proper alignment.

- Work Light: Adequate lighting is necessary to see clearly in dimly lit areas during tasks.

Equipping yourself with these essential instruments will not only enhance your proficiency but also ensure that the maintenance process is carried out safely and effectively.

Step-by-Step Repair Procedures

This section outlines a systematic approach to addressing various issues that may arise with your equipment. Following these detailed steps will ensure that each task is performed efficiently and effectively, minimizing downtime and maximizing functionality.

Preparation

- Gather necessary tools and materials.

- Ensure the workspace is clean and well-lit.

- Review any relevant safety guidelines before starting.

Procedure Overview

- Identify the specific issue that needs attention.

- Consult documentation for initial troubleshooting tips.

- Begin with external examinations to locate visible damage.

- Disassemble components carefully, noting their arrangement.

- Replace or repair parts as needed, ensuring compatibility.

- Reassemble all components, following the reverse order of disassembly.

- Conduct a thorough test to confirm functionality.

By adhering to this structured approach, you can enhance the longevity and performance of your equipment while ensuring that all tasks are completed safely and correctly.

Maintenance Tips for Longevity

Ensuring the prolonged lifespan of your transport equipment requires regular attention and care. Implementing effective practices not only enhances performance but also minimizes the likelihood of costly issues down the line. Below are essential strategies to keep your unit in optimal condition.

- Regular Inspections: Conduct thorough checks on a scheduled basis to identify wear and tear before it escalates.

- Cleaning: Keep surfaces free from dirt, debris, and corrosive substances to prevent damage and maintain aesthetics.

- Lubrication: Regularly apply appropriate lubricants to moving parts to ensure smooth operation and reduce friction.

- Tire Maintenance: Monitor tire pressure and tread depth frequently; rotate tires as needed to promote even wear.

In addition to these practices, following manufacturer guidelines can greatly enhance the durability of your equipment. Incorporating these simple yet effective tips into your routine will yield significant benefits over time.

- Electrical System Check: Regularly inspect the wiring and connectors for signs of corrosion or wear.

- Brake Maintenance: Ensure that brake components are in good condition and replace them as necessary to guarantee safety.

- Storage Care: When not in use, store the unit in a sheltered environment to protect it from harsh weather conditions.

By adhering to these guidelines, you can ensure that your equipment remains reliable and efficient for years to come.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance work is paramount. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries. By prioritizing safety measures, individuals can create a workspace that is conducive to efficient and effective servicing activities.

Personal Protective Equipment

Wearing appropriate personal protective gear is essential. This includes safety goggles to shield the eyes from debris, gloves to protect the hands from sharp objects, and steel-toed boots to prevent foot injuries. High-visibility clothing can also enhance awareness of surroundings, particularly in busy environments.

Proper Use of Tools

Utilizing tools correctly is critical for safety. Always inspect equipment for any damage before use and ensure it is suitable for the task at hand. Maintain a tidy workspace to prevent trips and falls, and follow all operational guidelines for each tool. This careful approach will help to minimize hazards and promote a safer working atmosphere.

Diagnosing Electrical Problems

Identifying issues within an electrical system can be a challenging task, requiring a systematic approach to isolate and resolve malfunctions. Whether dealing with faulty connections, malfunctioning components, or unexpected power losses, understanding the underlying principles and employing effective diagnostic techniques is essential for restoring functionality.

Common Symptoms

Recognizing the signs of electrical malfunctions is the first step in the diagnostic process. Here are some typical indicators to be aware of:

| Symptom | Possible Cause |

|---|---|

| Flickering Lights | Loose connections or overloaded circuits |

| No Power | Blown fuses or tripped breakers |

| Unusual Sounds | Faulty components or wiring issues |

| Burning Smell | Overheating wires or short circuits |

Diagnostic Techniques

Employing effective methods is crucial for accurately pinpointing electrical issues. Consider the following strategies:

- Visual Inspection: Examine all wiring and components for visible damage or wear.

- Multimeter Testing: Use a multimeter to check voltage levels and continuity in circuits.

- Load Testing: Assess whether components can handle their rated loads without overheating or failure.

Replacing Damaged Parts Effectively

When components of your vehicle show signs of wear or damage, timely and proper replacement is essential for maintaining performance and safety. This section focuses on the best practices to ensure a seamless process when substituting faulty elements, helping you to avoid complications and extend the lifespan of your equipment.

Before diving into the replacement process, consider the following steps to prepare:

- Assess the damage: Carefully inspect the affected areas to determine the extent of wear or breakage.

- Gather necessary tools: Ensure you have all required instruments and replacement parts on hand.

- Consult specifications: Refer to product details for guidance on compatible components and installation procedures.

Once you’re prepared, follow these effective strategies for part replacement:

- Follow instructions: Adhere strictly to the guidelines provided for your specific components.

- Utilize quality replacements: Always opt for high-quality parts to guarantee durability and reliability.

- Document the process: Take notes or photographs during disassembly to assist in reassembly.

- Test after replacement: Once new parts are installed, conduct thorough testing to ensure everything functions correctly.

By adhering to these recommendations, you can effectively replace damaged components, enhancing the overall efficiency and safety of your vehicle.

Wabash Trailer Upgrades and Modifications

Enhancing the functionality and performance of your hauling unit can significantly improve your overall experience and efficiency. Upgrades and modifications can address various aspects, from structural integrity to technological enhancements, ensuring that the unit meets modern standards and user needs.

Common Enhancements

- Suspension Systems: Upgrading to advanced suspension components can enhance ride quality and stability, especially under heavy loads.

- Lighting Solutions: Implementing LED lights not only improves visibility but also increases energy efficiency and longevity.

- Brake Improvements: Installing upgraded braking systems can enhance safety and performance, providing more responsive handling.

Technological Additions

- GPS Tracking: Integrating GPS technology allows for real-time location tracking, improving logistics and fleet management.

- Telematics Systems: These systems can monitor various performance metrics, enabling better maintenance and operational efficiency.

- Smart Load Monitoring: Installing sensors that monitor load distribution can prevent structural stress and enhance safety.

By carefully considering these enhancements, you can significantly extend the lifespan and performance of your equipment, making it more reliable for various transportation needs.

Understanding Trailer Suspension Systems

Suspension systems play a crucial role in maintaining stability and comfort during transportation. They are designed to absorb shocks, support loads, and enhance the overall performance of the vehicle. A thorough understanding of these systems is essential for optimal functionality and safety.

There are several key components that contribute to the effectiveness of suspension systems:

- Springs: These elements provide the primary support and cushioning, allowing for movement while absorbing road imperfections.

- Shocks and Struts: These components dampen the oscillations caused by the springs, ensuring a smoother ride and better control.

- Axles: They connect the wheels and transfer loads, playing a vital role in the overall structural integrity.

- Linkages: These parts connect various components and help maintain alignment, allowing for better handling.

Understanding the different types of suspension systems is also important:

- Leaf Spring Systems: Commonly used for their durability and simplicity, they offer a good balance between load-carrying capacity and comfort.

- Torsion Bar Systems: Utilizing a twisting motion to provide resistance, these systems are compact and effective in smaller applications.

- Air Suspension Systems: These systems use air bags to provide adjustable ride height and enhanced comfort, making them suitable for various loads and terrains.

Regular maintenance and inspection of these components are vital for ensuring safe and efficient operations. Identifying wear and tear early can prevent more significant issues down the road, enhancing performance and longevity.

Resources for Wabash Trailer Owners

For those who own a specialized transport unit, having access to quality information and resources is essential for optimal performance and longevity. This section aims to provide valuable insights and tools that can enhance the experience of managing and maintaining these vital assets.

Here are some key resources to consider:

- Online Forums: Engage with communities of like-minded owners to share experiences and solutions.

- Manufacturer Support: Utilize the official website for FAQs, product information, and customer service contacts.

- Maintenance Guides: Access comprehensive guides that cover essential upkeep practices and troubleshooting tips.

- Local Workshops: Attend workshops or seminars focused on maintenance techniques and safety protocols.

- Parts Suppliers: Identify reliable suppliers for genuine components to ensure quality replacements.

By leveraging these resources, owners can enhance their knowledge and ensure their equipment remains in top condition for years to come.

Finding Professional Repair Services

Locating skilled services for maintenance and restoration tasks can greatly enhance the longevity and performance of your equipment. Ensuring you choose a reputable provider is essential for achieving high-quality outcomes.

Factors to Consider

- Experience and Expertise

- Customer Reviews and Testimonials

- Certifications and Credentials

- Service Warranty and Guarantees

Where to Search

- Online Directories and Listings

- Local Community Boards

- Trade Associations

- Word of Mouth Recommendations