Understanding the intricacies of small marine engines is essential for any boating enthusiast. Proper upkeep ensures optimal performance, longevity, and reliability on the water. This section delves into effective strategies for maintaining two-cycle engines, focusing on practical solutions and expert tips.

Comprehensive knowledge of your engine’s components and functioning is crucial. Familiarizing yourself with the essential parts allows for efficient troubleshooting and enhances your ability to address common issues. Regular assessments and maintenance practices can significantly reduce the likelihood of unexpected breakdowns.

Step-by-step instructions will guide you through essential maintenance tasks, from routine inspections to resolving minor malfunctions. By following these guidelines, you will gain confidence in managing your engine’s care, ensuring a smooth and enjoyable experience during your aquatic adventures.

This section aims to present a comprehensive overview of a popular outboard engine model known for its reliability and performance. Understanding the key features, components, and maintenance aspects of this engine can greatly enhance its longevity and efficiency. Here, we will explore various facets that are crucial for users and technicians alike.

Engine Specifications

Detailed technical specifications provide insight into the capabilities and limitations of the engine.

- Power Output

- Weight

- Fuel Type

- Cooling System

Common Issues

Identifying frequent problems can assist in proactive maintenance and troubleshooting.

- Starting Difficulties

- Overheating

- Fuel Leaks

- Exhaust Smoke

Essential Tools

Having the right tools on hand can facilitate effective maintenance and repair tasks.

- Wrench Set

- Socket Set

- Screwdriver Set

- Multimeter

Routine Maintenance Tasks

Performing regular upkeep is crucial for optimal performance and safety.

- Oil Changes

- Filter Replacements

- Propeller Inspection

- Electrical System Checks

Assembly and Disassembly

Understanding the assembly and disassembly processes is vital for repair and inspection.

- Step-by-step Guide

- Safety Precautions

- Component Identification

Fuel System Maintenance

Proper care of the fuel system ensures smooth operation and prevents breakdowns.

- Fuel Filter Replacement

- Fuel Line Inspection

- Carburetor Cleaning

Ignition System Overview

A well-functioning ignition system is essential for reliable engine starting.

- Spark Plug Maintenance

- Coil Inspection

- Wiring Checks

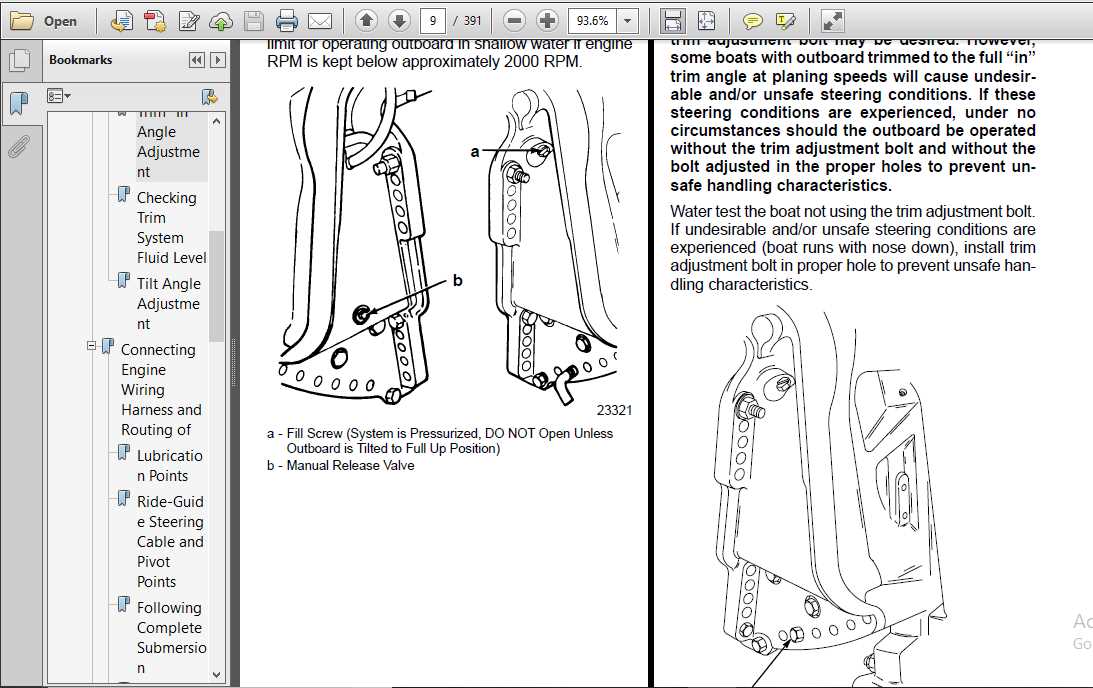

Cooling System Functionality

Ensuring the cooling system operates efficiently prevents overheating and engine damage.

- Water Pump Checks

- Cooling System Flush

- Thermostat Function

Electrical Components

Understanding the electrical components is crucial for troubleshooting and repairs.

- Batteries

- Wiring Diagrams

- Connection Points

Safety Considerations

Implementing safety measures can prevent accidents during maintenance and operation.

- Personal Protective Equipment

- Safe Fuel Handling

- Work Environment Safety

Performance Enhancements

Simple modifications can significantly improve the performance of the engine.

- Upgraded Fuel Injectors

- Improved Exhaust Systems

- Propeller Selection

Seasonal Storage Tips

Proper storage techniques help maintain the engine during off-seasons.

- Fuel Stabilization

- Drying Out the Engine

- C

Common Issues with 2 Stroke Engines

Two-cycle engines are known for their simplicity and lightweight design, but they often encounter a range of challenges that can impact their performance and reliability. Understanding these common problems can help users maintain optimal operation and avoid potential breakdowns.

- Fuel Mixture Problems:

Incorrect fuel-to-oil ratios can lead to inadequate lubrication, resulting in excessive wear or engine seizure. It’s crucial to follow manufacturer guidelines for mixing fuel and oil.

- Carbon Buildup:

Over time, carbon deposits can accumulate in the combustion chamber, exhaust ports, and spark plugs. This buildup can restrict airflow and decrease efficiency.

- Starting Difficulties:

Many users experience issues starting their engines, often caused by a clogged fuel line or a faulty ignition system. Regular inspection and maintenance can help address these issues.

- Overheating:

Engines can overheat due to insufficient cooling or improper operation. Monitoring the temperature and ensuring proper airflow is essential for preventing heat-related damage.

- Worn Components:

Components such as pistons and rings can wear down over time, leading to decreased compression and overall power loss. Regular checks can identify these wear issues before they become critical.

By staying vigilant about these common concerns, users can enhance the longevity and efficiency of their two-cycle engines.

Essential Tools for Repair

When undertaking maintenance tasks for marine engines, having the right equipment is crucial for efficiency and effectiveness. Proper tools not only facilitate smoother operations but also enhance safety during the process. Below is a selection of indispensable instruments that every technician should consider for effective servicing.

Tool Description Socket Set A comprehensive socket set is vital for loosening and tightening various bolts and nuts, ensuring proper assembly and disassembly. Wrench Set Having a variety of wrenches, including adjustable options, helps in accessing tight spaces and applying the necessary torque. Screwdriver Set Different types and sizes of screwdrivers are essential for handling screws found in various components of the engine. Multimeter A multimeter is crucial for diagnosing electrical issues, measuring voltage, and ensuring all systems are functioning correctly. Torque Wrench This tool is necessary for applying a precise amount of force to bolts and nuts, preventing damage to components from overtightening. Step-by-Step Maintenance Guide

Regular upkeep is essential for optimal performance and longevity of your outboard motor. This section provides a comprehensive approach to ensure that your engine runs smoothly and efficiently. By following these structured steps, you can enhance its reliability and prevent potential issues down the line.

Essential Tools and Supplies

- Wrench set

- Screwdrivers

- Cleaning supplies (rags, brushes)

- Fresh oil

- Fuel stabilizer

- Replacement parts (filters, spark plugs)

Maintenance Steps

- Check and change the oil regularly to keep the engine lubricated.

- Inspect the fuel system for leaks or damages.

- Clean or replace the fuel filter as necessary.

- Examine spark plugs and replace them if they show signs of wear.

- Flush the cooling system to prevent overheating.

- Inspect all hoses and connections for signs of wear or cracking.

- Store the engine properly during off-seasons to avoid corrosion.

Troubleshooting Electrical Problems

Identifying and resolving electrical issues in outboard motors is crucial for optimal performance. This section provides guidance on diagnosing common electrical faults, enabling you to effectively troubleshoot and rectify them, ensuring smooth operation of your engine.

Start by inspecting the electrical system for visible signs of damage or wear. Check the wiring, connectors, and components for any corrosion or loose connections. Regular maintenance and prompt attention to any irregularities can help prevent further complications.

Problem Potential Cause Solution Engine won’t start Dead battery or faulty connections Test battery voltage and clean or replace connections Intermittent power Loose wiring or corroded terminals Tighten connections and clean terminals Warning lights activated Electrical short or component failure Inspect for shorts and replace faulty components Fuel pump not operating Faulty relay or wiring issue Check relay function and inspect wiring for damage By methodically checking these components and understanding the possible issues, you can effectively troubleshoot electrical problems, ensuring your motor runs reliably and efficiently.

Fuel System Inspection Techniques

Ensuring the optimal performance of a marine engine relies heavily on the integrity of its fuel system. Regular evaluation of this system can prevent potential issues that may arise from fuel contamination, leaks, or component failure. Adopting effective inspection techniques will enhance both reliability and efficiency.

Begin by examining the fuel lines for any signs of wear, cracks, or leaks. A thorough visual inspection can reveal issues that may not be immediately obvious. It’s essential to check for proper connections and ensure that all fittings are secure to prevent fuel loss.

Next, assess the fuel filter. Regular replacement or cleaning of the filter is vital to maintaining a clean fuel supply. Inspect it for any blockages or signs of deterioration, as this can significantly affect engine performance.

Additionally, evaluate the fuel pump’s functionality. Listen for any unusual noises during operation, which may indicate wear or malfunction. Testing the fuel pressure with a gauge can also provide insights into the pump’s efficiency and overall health.

Lastly, consider the quality of the fuel itself. Contaminants can lead to engine problems, so it’s prudent to use fresh, high-quality fuel and store it properly to avoid degradation. Implementing these inspection techniques will contribute to the longevity and smooth operation of the engine.

How to Clean the Carburetor

Maintaining optimal performance of your outboard engine requires regular attention to its components, particularly the fuel delivery system. One essential part of this system is the carburetor, which plays a crucial role in mixing air and fuel. Over time, deposits and contaminants can accumulate, affecting efficiency and performance. Regular cleaning is vital to ensure smooth operation and longevity of your engine.

Necessary Tools and Materials

Before starting the cleaning process, gather the following tools and materials:

- Carburetor cleaner – A specialized solvent designed for removing varnish and deposits.

- Screwdrivers – Various sizes to disassemble the carburetor.

- Cleaning brushes – Soft brushes to gently scrub components without damage.

- Compressed air – Useful for blowing out debris and drying parts.

Cleaning Procedure

Follow these steps to effectively clean the carburetor:

- Disassemble the carburetor: Carefully remove it from the engine, taking note of the orientation and position of all components.

- Inspect parts: Check for wear or damage, and replace any faulty components before proceeding.

- Apply cleaner: Use the carburetor cleaner on all internal and external surfaces. Allow it to sit for a few minutes to dissolve any buildup.

- Scrub gently: Utilize the cleaning brushes to remove stubborn deposits. Be cautious not to scratch or damage delicate surfaces.

- Rinse and dry: Thoroughly rinse all parts with clean solvent and blow them dry with compressed air.

- Reassemble: Carefully put the carburetor back together, ensuring all components are correctly positioned.

By following this cleaning routine, you can enhance the performance and reliability of your engine, ensuring a smooth and enjoyable boating experience.

Rebuilding the Powerhead Explained

Reconstructing the engine’s upper section is a critical process that ensures optimal performance and longevity. This task involves several steps aimed at restoring functionality and efficiency to the engine. Understanding the intricacies of this procedure is essential for both enthusiasts and technicians alike.

Initially, it is vital to gather the necessary tools and components, which include gaskets, seals, and specialized instruments. Careful disassembly is crucial; each component should be inspected for wear and damage. Attention to detail during this phase will prevent future issues and enhance the overall performance of the engine.

Once disassembled, thorough cleaning of all parts is essential. This step removes debris and buildup that can hinder functionality. After cleaning, assess each component for any signs of damage or excessive wear. Replacement of faulty parts is necessary to maintain the integrity of the assembly.

Reassembly requires precise alignment and torque specifications to ensure a secure fit. Utilize a torque wrench to adhere to the manufacturer’s specifications. Following proper procedures during reassembly will significantly impact the performance and durability of the engine.

Finally, once the powerhead is rebuilt, it is crucial to conduct a series of tests to verify its performance. These tests can help identify any remaining issues and ensure that the engine runs smoothly. Proper rebuilding of the engine’s upper section not only restores its original capabilities but also contributes to a longer lifespan.

Propeller and Shaft Maintenance Tips

Regular upkeep of the propeller and shaft is essential for optimal performance and longevity of your marine vessel. These components play a crucial role in propulsion, and ensuring they are in top condition can prevent unnecessary wear and tear.

Inspection: Frequently examine the propeller and shaft for signs of damage, such as dents, cracks, or corrosion. Look for any debris that may be lodged between the blades, as this can hinder efficiency.

Cleaning: Maintain cleanliness by removing any accumulated salt, algae, or barnacles. A simple rinse with fresh water after each outing can significantly extend the life of these parts.

Lubrication: Regularly apply appropriate lubricants to the shaft to reduce friction and protect against rust. Ensure that all moving parts are well-greased to maintain smooth operation.

Alignment: Proper alignment of the shaft is vital for efficient performance. Misalignment can cause excessive vibration and lead to premature failure. Periodically check and adjust as necessary.

By adhering to these maintenance tips, you can enhance the performance and durability of your vessel’s propulsion system.

Diagnosing Cooling System Failures

Proper functioning of the cooling system is essential for the longevity and efficiency of your outboard engine. Identifying issues within this system can prevent severe damage and costly repairs. This section will guide you through common signs of cooling problems and effective diagnostic steps to resolve them.

Common Symptoms of Cooling Issues

One of the first indicators of cooling system malfunctions is an unexpected increase in engine temperature. Other symptoms include inconsistent water flow from the telltale, unusual noises, or visible leaks around the engine. These signs should prompt immediate investigation to avoid overheating and subsequent damage.

Diagnostic Steps

Begin by inspecting the water intake and ensuring it is clear of debris. A blocked intake can significantly hinder water flow, leading to overheating. Next, check the thermostat for proper operation, as a malfunctioning thermostat can disrupt the flow of coolant. Lastly, examine the water pump for any signs of wear or failure, as this component is critical for maintaining adequate circulation.

Replacing Spark Plugs Effectively

Changing the ignition components is a crucial maintenance task that can enhance engine performance and efficiency. This process ensures optimal combustion and smooth operation, which are essential for any watercraft.

Tools and Materials Needed

- New spark plugs

- Socket wrench

- Gap gauge

- Torque wrench

- Anti-seize compound

Steps for Replacement

- Ensure the engine is cool before beginning the replacement.

- Remove the ignition wires carefully to avoid damage.

- Use the socket wrench to unscrew the old components.

- Check the gap of the new plugs with a gauge and adjust if necessary.

- Apply a small amount of anti-seize compound to the threads of the new plugs.

- Screw in the new plugs by hand, then tighten with the socket wrench to the manufacturer’s specified torque.

- Reconnect the ignition wires securely.

Regular replacement of these components is vital for maintaining optimal engine function and longevity. Following these steps ensures a hassle-free process, contributing to the overall health of your watercraft.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when conducting maintenance tasks on marine engines. Proper precautions not only protect the individual but also extend the longevity of the equipment. Following recommended guidelines can help mitigate risks and create an efficient workflow.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Work in a well-ventilated area to prevent inhalation of harmful fumes.

- Ensure that tools and work surfaces are clean and organized to reduce hazards.

- Disconnect the battery to prevent accidental starts during maintenance.

Emergency Preparedness

- Keep a first aid kit accessible at all times in case of injuries.

- Familiarize yourself with the location of fire extinguishers and emergency exits.

- Have a plan in place for reporting accidents and handling emergencies.

Finding Replacement Parts Resources

Locating the right components for your engine can significantly enhance its performance and longevity. Whether you’re looking for original equipment or aftermarket alternatives, various avenues can help you source the necessary parts efficiently.

Online Marketplaces

Numerous online platforms offer a wide range of components for various engine models. Websites like eBay and Amazon feature both new and used parts, providing options for different budgets. Always check seller ratings and reviews to ensure a reliable transaction.

Local Dealers and Shops

Visiting local dealerships or specialized marine supply stores can be beneficial. These establishments often have access to genuine parts and knowledgeable staff who can assist you in identifying the right components for your needs. Additionally, local shops may offer personalized service and advice tailored to your specific situation.

- Fuel Mixture Problems: