This section is dedicated to providing essential information for the upkeep and troubleshooting of wall finishing equipment. Proper maintenance is crucial for ensuring optimal performance and longevity of these tools. Here, you will find comprehensive insights aimed at both novice and experienced users.

Understanding the intricacies of tool functionality can help prevent common issues and enhance your overall experience. Regular attention to these instruments not only promotes efficiency but also ensures that they deliver consistent results during various projects.

In this guide, we will cover various aspects of maintaining your equipment, including troubleshooting techniques, common problems, and preventative measures. Equipped with this knowledge, users will be better prepared to tackle challenges that may arise while utilizing these essential tools.

This section provides an insightful overview of a popular brand known for its effective tools designed for surface finishing. The focus is on understanding the essential features and specifications of these devices, which are crucial for achieving smooth and flawless surfaces in various projects.

These tools are widely recognized for their reliability and efficiency in sanding tasks. Here are some key points about their characteristics:

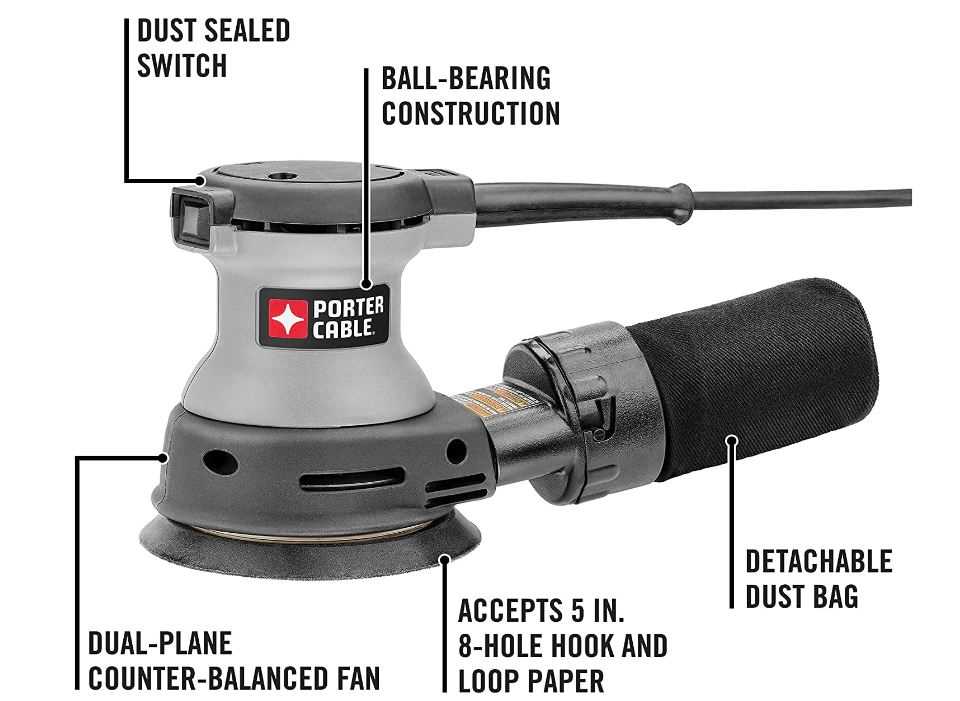

- Powerful Performance: These machines are equipped with robust motors that ensure consistent and high-quality results.

- User-Friendly Design: They often feature ergonomic handles and adjustable settings, making them easy to operate for extended periods.

- Versatile Applications: Suitable for a range of surfaces, these tools can handle different materials, including plaster, wood, and more.

- Durability: Built to withstand rigorous use, they are constructed from high-quality materials that enhance their lifespan.

Understanding the general principles and functionalities of these tools helps users make informed decisions regarding their maintenance and troubleshooting.

Common Issues with Drywall Sanders

When using power tools for surface finishing, various challenges can arise that affect performance and efficiency. Understanding these typical problems is essential for maintaining optimal functionality and ensuring high-quality results.

Performance Degradation

A frequent concern involves a noticeable drop in efficiency, often caused by worn components or accumulation of dust. This can lead to uneven surfaces and prolong the finishing process. Regular maintenance, including cleaning and component checks, is crucial to avoid these setbacks.

Motor Malfunctions

Another common issue is the failure of the motor, which can stem from overheating or electrical faults. Users should monitor for unusual sounds or smells, which may indicate underlying problems. Addressing these signs promptly can prevent complete breakdowns and costly repairs.

Step-by-Step Repair Procedures

This section outlines a systematic approach to troubleshooting and fixing common issues associated with electric surface finishing tools. Following a structured method will help ensure that you address the problems effectively, resulting in restored functionality and efficiency.

Initial Assessment

Begin by examining the tool for visible signs of damage or wear. Check all components, including the motor, power cord, and any accessories. Ensure that the device is disconnected from the power source before performing any inspections. Identify any unusual sounds or behaviors during operation, as these may indicate specific issues that need attention.

Component Replacement

If a part appears damaged, consult the specifications for compatible replacements. Carefully remove the faulty component using appropriate tools, taking care to note how each piece fits together. Install the new part, ensuring that it is securely attached and aligned properly. After replacing components, reconnect the device and test its functionality to confirm that the problem has been resolved.

Tools Needed for Repairs

When tackling any maintenance task, having the right equipment is crucial for ensuring efficiency and effectiveness. This section outlines essential tools that will assist in achieving successful outcomes during your project. By preparing in advance with the appropriate items, you can streamline the process and minimize potential challenges.

| Tool | Description |

|---|---|

| Screwdriver Set | Various sizes of screwdrivers for loosening and tightening screws. |

| Wrench | Adjustable wrench for gripping and turning nuts and bolts. |

| Pliers | Multi-purpose pliers for gripping, twisting, and cutting wires. |

| Utility Knife | Sharp blade for cutting materials or removing old components. |

| Level | Tool to ensure surfaces are even and aligned correctly. |

| Measuring Tape | For accurate measurements of materials and distances. |

| Vacuum Cleaner | To clean up debris and dust after the job is completed. |

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life of your equipment. Regular maintenance not only enhances performance but also minimizes the likelihood of unexpected breakdowns. By following a few simple practices, you can keep your tool in optimal condition and ready for use whenever you need it.

Regular Cleaning

Keeping the tool clean is vital to its functionality. After each use, ensure that dust and debris are removed from all parts. Use a soft brush or cloth to gently wipe down surfaces, paying special attention to any air vents or moving components. This prevents clogging and helps maintain airflow, which is crucial for efficient operation.

Inspection and Lubrication

Frequent inspection of the tool’s components allows you to identify wear or damage early. Check for loose screws, worn belts, or any other signs of wear. Additionally, applying the appropriate lubricant to moving parts will reduce friction and prolong the lifespan of the equipment. Be sure to follow the manufacturer’s guidelines for specific lubricants and application methods.

Understanding Replacement Parts

When it comes to maintaining and enhancing the longevity of your equipment, comprehending the various components that can be substituted is crucial. Knowing the available parts enables users to make informed decisions, ensuring optimal performance and functionality over time. This section delves into the essential aspects of replacement components, highlighting their significance in keeping your tools in top condition.

Common Replacement Components

Several parts commonly require replacement due to wear and tear or damage. Familiarizing yourself with these components can aid in timely maintenance and minimize downtime. Below is a table outlining some of the most frequently replaced items:

| Part Name | Description | Purpose |

|---|---|---|

| Motor | The engine responsible for powering the device. | Drives the tool’s functionality. |

| Filter | A component that captures dust and debris. | Maintains air quality and efficiency. |

| Pad | The surface attachment used during operation. | Facilitates smooth and effective performance. |

| Power Cord | The cable that supplies electricity to the unit. | Ensures reliable operation. |

Benefits of Using Quality Replacement Parts

Utilizing high-quality replacement components is vital for the durability and efficiency of your equipment. Quality parts contribute to better performance, enhanced safety, and overall satisfaction with your tools. Investing in reliable replacements ultimately leads to a more efficient workflow and reduced likelihood of future issues.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is paramount to prevent accidents and injuries. Adhering to specific guidelines helps create a secure environment, allowing individuals to focus on their work without unnecessary risks. Below are essential considerations to keep in mind.

- Wear appropriate personal protective equipment (PPE), such as gloves, goggles, and dust masks, to shield against debris and harmful particles.

- Ensure the workspace is well-ventilated to minimize inhalation of dust and fumes.

- Keep the area tidy and free from clutter to reduce the risk of tripping and falling.

- Disconnect power sources before starting any work to prevent electrical hazards.

- Use tools properly and only for their intended purpose to avoid accidents.

- Maintain a safe distance from others while operating equipment to protect bystanders.

By following these guidelines, individuals can significantly reduce the risk of injury and create a safer working atmosphere.

Troubleshooting Electrical Problems

Addressing electrical issues is crucial for ensuring the smooth operation of your equipment. This section provides guidance on identifying common electrical faults, enabling you to take corrective actions promptly.

When encountering performance issues, start by checking the power supply. Ensuring that the device is properly connected and that there is power flowing to it is fundamental. If the device does not respond, further investigation is required.

| Issue | Possible Causes | Solutions |

|---|---|---|

| No power | Disconnected power cord, blown fuse, or faulty outlet | Check connections, replace the fuse, or test the outlet with another device |

| Intermittent operation | Loose wiring or internal component malfunction | Inspect wiring for damage and ensure all connections are secure |

| Unusual noises | Worn-out motor or debris in the device | Clean the unit and replace any worn components |

| Overheating | Blocked vents or prolonged use | Allow the device to cool down and ensure ventilation is clear |

By systematically identifying and addressing these issues, you can enhance the longevity and performance of your equipment, reducing the need for extensive interventions.

Adjusting Sanding Speed Settings

Fine-tuning the velocity settings of your equipment is crucial for achieving optimal results during surface preparation tasks. Different materials and project requirements necessitate varying levels of abrasiveness, making it essential to adjust the speed accordingly.

Understanding Speed Control: Most machines are equipped with a speed control feature that allows users to modify the rotation rate of the sanding disc. This capability enables you to adapt the tool for both delicate finishes and more aggressive sanding operations.

Steps for Adjustment: Begin by examining the control dial or switch, typically located within easy reach on the body of the device. Adjust the setting to a lower speed for finer surfaces to prevent damage and ensure a smooth finish. Conversely, increase the speed for tougher materials where a more vigorous approach is warranted.

Testing and Evaluation: After making adjustments, conduct a test run on a sample piece similar to your project material. This trial will help you determine if the selected speed is appropriate and if further modifications are necessary to achieve the desired finish.

Regularly recalibrating the speed settings based on specific tasks can significantly enhance performance and prolong the life of your equipment.

Cleaning and Dust Management

Maintaining a clean workspace is crucial for achieving optimal results in any project involving surface preparation. Effective cleaning and dust control not only enhance the quality of work but also contribute to a safer environment. This section outlines key practices and tools necessary for efficient cleanup and minimizing dust during operations.

To ensure a tidy workspace, consider the following strategies:

- Use a Vacuum System: Employ a high-efficiency particulate air (HEPA) vacuum to capture fine particles directly at the source.

- Protect Surrounding Areas: Cover furniture and floors with drop cloths to prevent dust from settling on surfaces.

- Regularly Empty Collection Bags: Frequently dispose of collected dust to maintain suction power and efficiency.

Additionally, proper cleaning techniques after each use can prolong the life of your equipment:

- Detach and clean all detachable parts according to the manufacturer’s guidelines.

- Wipe down the exterior surfaces to remove any dust accumulation.

- Store the equipment in a dry place to avoid moisture buildup, which can lead to damage.

By implementing these practices, you will ensure a cleaner, safer workspace while enhancing the longevity of your tools.

When to Seek Professional Help

Knowing when to call in an expert can save time and prevent further damage. There are instances when DIY approaches may not be sufficient to address the issues effectively. Recognizing these situations early can help ensure that the problem is resolved with the appropriate level of expertise.

If you encounter persistent issues that do not resolve despite your best efforts, it might be time to consider professional assistance. Complex electrical or mechanical failures often require specialized knowledge and tools that an average user may not possess. Attempting to fix such problems without the necessary skills can lead to accidents or exacerbate the situation.

Additionally, if you find yourself feeling overwhelmed or unsure about the process, reaching out to a qualified technician can provide peace of mind. Professional services not only bring experience but also ensure safety and efficiency in handling complicated tasks. In situations involving high-risk components or intricate systems, enlisting a professional is a wise decision to protect both yourself and your equipment.

Resources for Further Assistance

In any project involving complex machinery, having access to additional resources can significantly enhance your understanding and troubleshooting capabilities. Whether you’re facing a specific challenge or seeking general advice, numerous avenues exist to gain insights and support.

Online Forums and Communities

Engaging with online platforms dedicated to home improvement and tool maintenance can provide valuable information. Users share their experiences, solutions, and tips that can help you resolve issues effectively. Participating in discussions allows you to learn from others’ successes and challenges, creating a collaborative environment for problem-solving.

Manufacturer Support and Documentation

Many manufacturers offer comprehensive customer service, including troubleshooting guides and technical assistance. Consulting official documentation can often provide specific solutions tailored to your equipment. Additionally, contacting customer service representatives can connect you with knowledgeable experts who can assist with more complex problems.