Effective upkeep of machinery is essential for ensuring optimal performance and longevity. Understanding the intricacies of various components can prevent costly downtimes and enhance overall efficiency. This section aims to provide detailed insights into best practices for maintaining your equipment.

Proper care involves not just routine checks but also in-depth knowledge of operational protocols and troubleshooting techniques. By familiarizing yourself with essential procedures, you can address issues proactively and minimize the risk of unexpected failures. This resource is designed to empower users with the necessary skills and information.

From identifying common faults to executing advanced service strategies, mastering these aspects can significantly improve reliability and functionality. Whether you are a seasoned technician or a newcomer, this guide serves as a valuable asset in navigating the complexities of equipment care and management.

Sullair 185 Overview and Features

This section delves into a renowned portable air compressor designed for efficiency and reliability in various applications. With its robust engineering and user-centric design, this machine has gained popularity in construction, mining, and industrial settings.

Powerful Performance: The unit is equipped with a high-performance engine that delivers a consistent air output. This capability ensures that it can meet demanding requirements on job sites, making it an invaluable asset for contractors and operators alike.

Compact Design: Its compact form factor allows for easy transportation and maneuverability in tight spaces. This feature is particularly beneficial in urban environments where space is at a premium.

Durability: Constructed with high-quality materials, this equipment is built to withstand harsh working conditions. Its resilient design minimizes downtime and maintenance, ensuring long-lasting operation.

User-Friendly Controls: The interface is intuitive, allowing operators to easily adjust settings for optimal performance. This user-friendly aspect enhances productivity and minimizes the learning curve for new users.

Versatile Applications: Suitable for a wide range of tasks, from powering pneumatic tools to assisting in heavy-duty operations, this machine adapts seamlessly to the needs of various projects.

In summary, this portable air compressor stands out for its powerful performance, durability, and versatility, making it an essential tool for professionals in many fields.

Common Issues with Sullair 185

When operating portable air compressors, several challenges can arise that may affect their efficiency and longevity. Identifying these frequent problems is crucial for maintaining optimal performance and minimizing downtime.

| Issue | Description | Possible Solutions |

|---|---|---|

| Air Leaks | Loss of compressed air due to worn or damaged hoses and fittings. | Inspect all connections and replace faulty components. |

| Oil Contamination | Presence of oil in the air output, indicating issues with the separator or filtration system. | Change filters and separators regularly to prevent buildup. |

| Overheating | Excessive heat can lead to component failure and reduced efficiency. | Ensure proper ventilation and clean cooling fins. |

| Pressure Drop | Inability to maintain required pressure levels, affecting tool performance. | Check for blockages and ensure the compressor is properly sized for the application. |

| Starting Issues | Difficulty in starting the unit, which can be caused by electrical problems or low battery. | Inspect electrical connections and replace weak batteries. |

Maintenance Tips for Sullair 185

Proper upkeep is essential for ensuring optimal performance and longevity of any machinery. By following a few key practices, operators can prevent common issues and enhance efficiency. Regular attention to these areas will minimize downtime and extend the life of the equipment.

Routine Inspections

Conducting frequent inspections is crucial. Check fluid levels, filters, and belts regularly to identify potential problems before they escalate. Keeping an eye on wear and tear will help maintain smooth operation and reduce unexpected failures.

Cleaning and Lubrication

Maintaining cleanliness is vital for equipment health. Regularly clean the exterior and internal components to prevent debris buildup. Additionally, ensure that all moving parts are adequately lubricated according to manufacturer guidelines to reduce friction and wear.

Step-by-Step Repair Procedures

This section outlines a systematic approach to maintaining and restoring functionality to the equipment. Each step is designed to guide the technician through the process efficiently, ensuring that all aspects are covered comprehensively. Following these instructions will help in diagnosing issues and executing necessary fixes with precision.

| Step | Description | Tools Required |

|---|---|---|

| 1 | Assess the current condition of the unit to identify any visible problems. | Inspection tools |

| 2 | Disconnect the power supply and ensure all safety measures are in place. | Safety gear |

| 3 | Remove any panels or covers to access internal components. | Screwdriver set, wrench |

| 4 | Inspect critical parts such as filters, hoses, and connections for wear and damage. | Flashlight, inspection mirror |

| 5 | Replace any faulty components identified during the inspection. | Replacement parts, hand tools |

| 6 | Reassemble the unit carefully, ensuring all fasteners are tightened. | Screwdriver set, torque wrench |

| 7 | Reconnect the power supply and conduct a test run to verify functionality. | Testing equipment |

| 8 | Document any changes made and note any future recommendations. | Notebook, pen |

Tools Needed for Sullair Repairs

Effective maintenance of portable air equipment requires a variety of instruments and devices. Having the right tools ensures that all tasks can be performed efficiently and safely, ultimately extending the lifespan of the machinery.

Essential Tools

- Wrenches: Both adjustable and fixed sizes for loosening and tightening bolts.

- Screwdrivers: A set of both flathead and Phillips for various fastening needs.

- Socket Set: To tackle different sizes of nuts and bolts with ease.

- Pliers: Useful for gripping, twisting, and cutting wires.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

Additional Equipment

- Multimeter: For electrical diagnostics and troubleshooting.

- Oil Filter Wrench: Essential for maintaining proper fluid levels.

- Safety Gear: Including gloves, goggles, and ear protection for personal safety.

- Pressure Gauge: To monitor and maintain optimal operating conditions.

- Cleaning Supplies: Brushes, rags, and solvent for maintenance tasks.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring the safety of personnel and equipment is paramount. Adhering to specific guidelines minimizes the risk of accidents and enhances overall efficiency. It is crucial to approach each task with a clear understanding of potential hazards and the necessary precautions to mitigate them.

Personal Protective Equipment

- Always wear appropriate safety gear, including gloves, goggles, and ear protection.

- Use sturdy footwear to protect against falling objects and slipping hazards.

- Consider wearing a hard hat in areas where there is a risk of overhead hazards.

Work Area Safety

- Ensure the workspace is clean and free from clutter to prevent trips and falls.

- Keep tools organized and in designated places to avoid accidents.

- Be aware of your surroundings and identify any potential hazards before starting work.

- Ensure proper ventilation when working with chemicals or in enclosed spaces.

By following these essential safety measures, individuals can significantly reduce the likelihood of injury and ensure a successful maintenance experience.

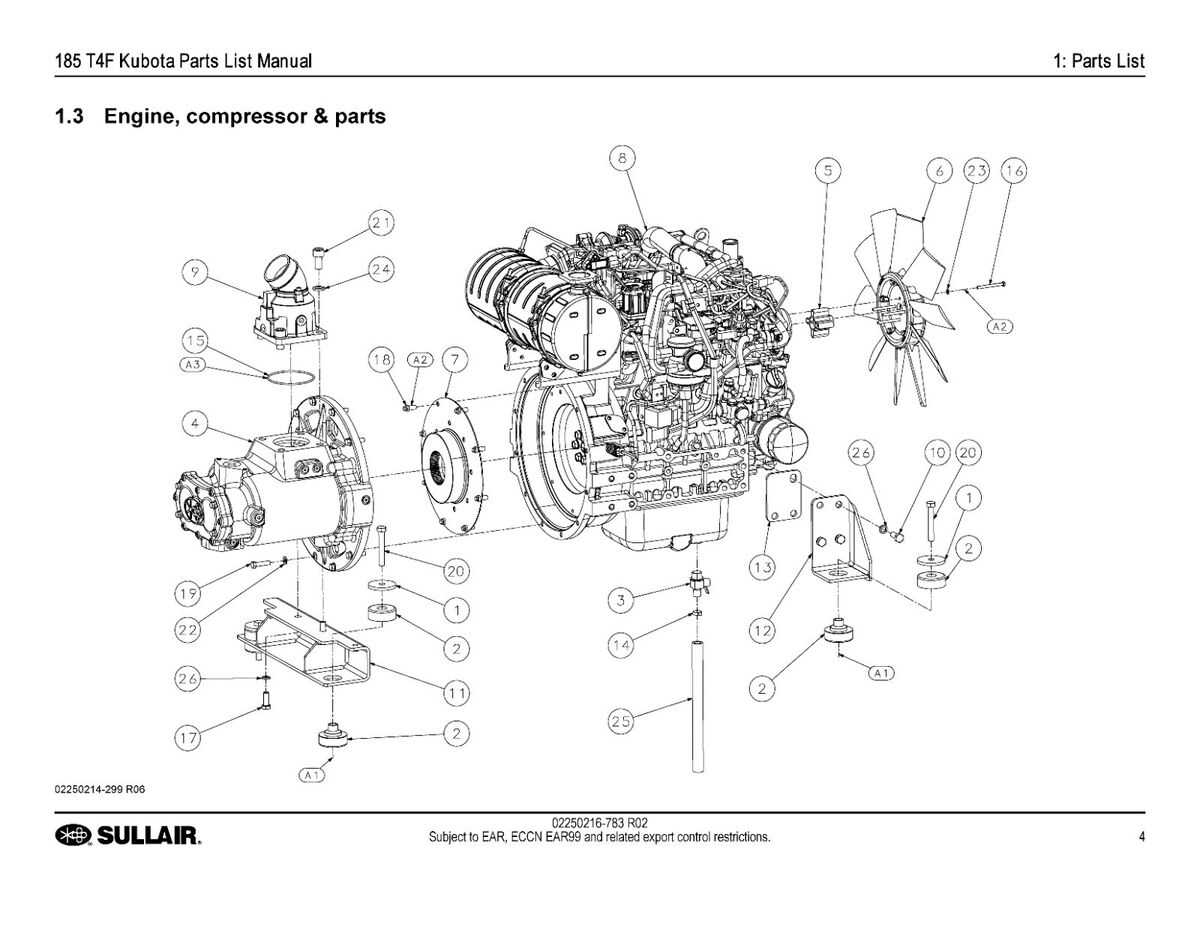

Understanding Sullair 185 Components

When delving into the intricacies of portable air compressor systems, it is essential to recognize the key elements that contribute to their efficient operation. Each component plays a vital role, ensuring that the machinery functions smoothly and reliably. A thorough comprehension of these parts not only aids in maintenance but also enhances overall performance.

Below is a table highlighting the primary components found in such compressor units, along with their respective functions:

| Component | Function |

|---|---|

| Airend | Generates compressed air by converting mechanical energy into air pressure. |

| Engine | Provides the necessary power to drive the airend and other systems. |

| Cooling System | Maintains optimal operating temperatures for the engine and airend to prevent overheating. |

| Fuel System | Delivers fuel to the engine, ensuring efficient combustion and operation. |

| Control Panel | Allows operators to monitor and adjust settings for optimal performance. |

| Air Receiver Tank | Stores compressed air and helps regulate pressure output. |

| Filters | Remove contaminants from the air and fluids to protect internal components. |

Understanding these components and their functions is crucial for anyone looking to optimize the efficiency and longevity of portable air compressor systems.

Diagnosing Engine Problems Effectively

Identifying issues within an engine requires a systematic approach that combines observation, testing, and analysis. A well-organized method helps in pinpointing the root cause of malfunctions, ensuring efficient troubleshooting and effective resolution of problems.

To begin the diagnosis, consider the following steps:

- Initial Observation: Take note of any unusual sounds, vibrations, or performance changes during operation.

- Check Fluid Levels: Ensure that oil, coolant, and fuel levels are adequate. Low levels can lead to significant engine issues.

- Review Error Codes: Use diagnostic tools to retrieve any error codes stored in the engine’s computer system.

After gathering preliminary data, proceed with more detailed assessments:

- Conduct a Visual Inspection: Look for leaks, damaged components, or signs of wear.

- Test Electrical Systems: Verify that all electrical connections are secure and functioning properly, as electrical faults can cause a variety of performance issues.

- Perform Compression Tests: Assess the engine’s compression to identify potential issues with cylinders, valves, or gaskets.

Finally, document your findings throughout the process. Keeping accurate records not only aids in current troubleshooting but also helps in future maintenance efforts. By following these guidelines, you can effectively diagnose and address engine-related problems, leading to improved performance and longevity.

Replacing Filters and Fluids

Regular maintenance of equipment is crucial for optimal performance and longevity. One of the key aspects of this upkeep involves the timely replacement of filters and fluids. This ensures that the machinery operates efficiently and minimizes the risk of costly breakdowns.

Types of Filters

Filters play a vital role in maintaining the cleanliness of various systems. There are several types that should be monitored and replaced as needed:

- Air filters

- Oil filters

- Fuel filters

Fluid Replacement Schedule

Fluids also require regular attention. The following fluids should be checked and replaced according to the manufacturer’s recommendations:

- Engine oil

- Coolant

- Hydraulic fluid

By adhering to a strict schedule for replacing filters and fluids, you can ensure that your equipment remains in peak condition and is ready for any task at hand.

When to Seek Professional Help

Understanding when to enlist the assistance of experts is crucial for maintaining the efficiency and longevity of your equipment. While some issues may seem manageable with basic troubleshooting, others require specialized knowledge and tools to ensure proper resolution and avoid further complications.

Signs That Indicate Professional Intervention

- Persistent Problems: If issues continue despite your attempts at resolution, it may be time to consult a professional.

- Unusual Noises: Strange sounds coming from the machinery can signify underlying problems that need expert assessment.

- Loss of Performance: A noticeable decline in efficiency or output often indicates a deeper issue that requires specialized skills to diagnose.

- Warning Indicators: Any alerts or notifications from the equipment should not be ignored, as they can point to serious malfunctions.

Benefits of Professional Assistance

- Expert Diagnosis: Professionals possess the training to identify and understand complex issues that may not be evident to untrained individuals.

- Quality Repairs: Skilled technicians use the right tools and techniques to ensure that repairs are done correctly the first time.

- Time Savings: Seeking help can often resolve problems more quickly than attempting to troubleshoot independently.

- Preventive Measures: Experts can provide guidance on maintenance practices that can help prevent future issues.