The world of vintage motorcycles is a realm where enthusiasts often seek to enhance their riding experience through a deeper understanding of their machines. This guide serves as a valuable resource for those dedicated to maintaining their beloved two-wheeled companions. With the right knowledge, every rider can ensure that their motorcycle remains in peak condition, ready to conquer the open road.

Delving into the intricacies of motorcycle upkeep involves more than just occasional tune-ups; it encompasses a holistic approach to preservation. From engine adjustments to electrical system troubleshooting, each component plays a crucial role in the overall performance and safety of the vehicle. By arming themselves with practical insights and detailed procedures, owners can confidently tackle various challenges that may arise over time.

In this section, we will explore essential techniques, tips, and best practices that can empower motorcycle aficionados to undertake maintenance tasks themselves. Whether you’re a seasoned rider or a novice, this resource aims to demystify the process, making it accessible and manageable for everyone passionate about their ride. With dedication and the right information, maintaining a classic motorcycle can transform into a fulfilling endeavor.

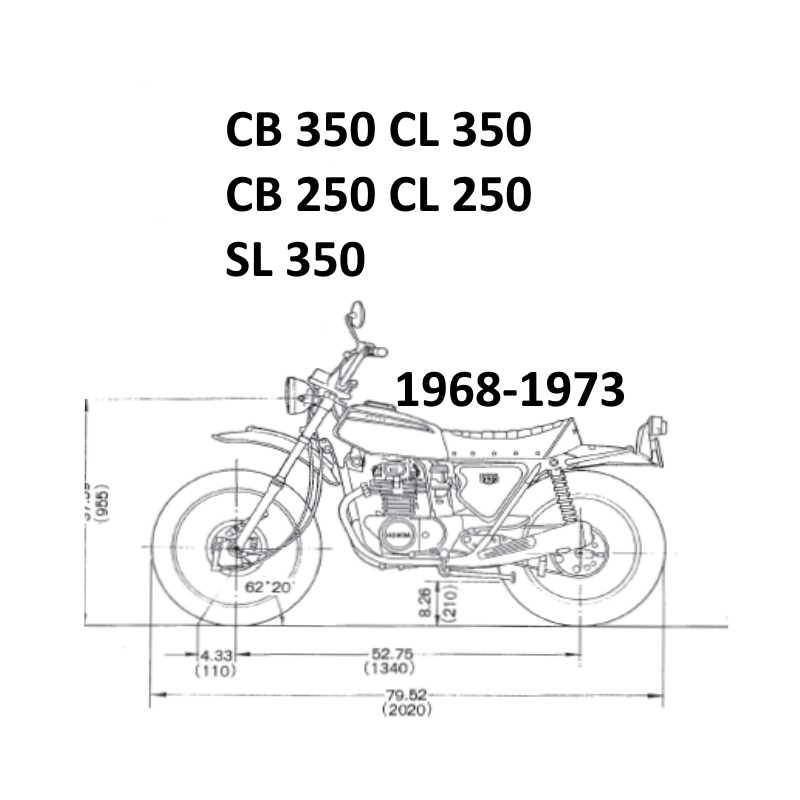

Understanding the 1972 Honda CB350

This section delves into the essential characteristics and features of a classic motorcycle that has left a significant mark in the world of two-wheeled vehicles. Appreciated for its balance of performance and reliability, this model is often celebrated by enthusiasts for its engineering and design. Exploring its components offers insights into what makes it a lasting favorite among riders.

Design and Engineering

The aesthetics of this motorcycle are both timeless and functional. With a streamlined frame and an inviting riding posture, it combines comfort with agility. The engineering emphasizes durability, ensuring that riders can enjoy both daily commuting and weekend adventures without compromise.

Performance and Handling

Equipped with a powerful engine, this machine delivers a smooth ride that appeals to both novice and experienced riders. Its lightweight design contributes to exceptional maneuverability, making it easy to navigate urban environments or winding roads. Riders often note the responsive throttle and stable handling, which enhance the overall experience.

In conclusion, understanding the intricacies of this iconic model reveals why it remains a cherished choice for many motorcycle enthusiasts. The blend of style, performance, and reliability truly exemplifies the spirit of classic motorcycles.

Common Issues and Solutions

Every vintage motorcycle has its unique set of challenges, and understanding these can help enthusiasts maintain optimal performance. Below are some frequently encountered problems along with practical solutions that can enhance longevity and reliability.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine Won’t Start | Dead battery, fuel blockage, ignition failure | Check battery charge, inspect fuel lines, test ignition components |

| Overheating | Low coolant, blocked radiator, faulty thermostat | Ensure coolant levels are adequate, clean radiator fins, replace thermostat if necessary |

| Poor Braking Performance | Worn brake pads, air in brake lines, low brake fluid | Replace pads, bleed brake lines, top up fluid |

| Leaking Oil | Worn seals, loose bolts, damaged gaskets | Replace seals, tighten bolts, check and replace gaskets as needed |

| Electrical Issues | Corroded connections, faulty wiring, blown fuses | Inspect connections for corrosion, replace damaged wires, check and replace fuses |

Essential Tools for Repairs

When undertaking maintenance or restoration tasks on your motorcycle, having the right equipment at your disposal is crucial for achieving success and ensuring safety. A well-equipped workspace not only streamlines the process but also enhances the overall experience of working on your machine.

Here are some indispensable tools you should consider having:

- Socket Set: A comprehensive socket set is essential for loosening and tightening various fasteners with ease.

- Wrenches: Both adjustable and fixed wrenches are important for handling nuts and bolts in different sizes.

- Screwdrivers: A variety of Phillips and flathead screwdrivers will cover most fastening needs.

- Pliers: Needle-nose and standard pliers are helpful for gripping and manipulating components.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage.

Additionally, consider these supplementary items:

- Service Manual: A detailed guide can provide invaluable information about specifications and procedures.

- Multimeter: Useful for electrical diagnostics, helping to troubleshoot issues efficiently.

- Work Light: Good lighting is essential for visibility, especially in tight or dark spaces.

- Cleaning Supplies: Keep your tools and workspace tidy with rags, brushes, and cleaning solutions.

- Safety Gear: Always wear gloves, goggles, and appropriate clothing to protect yourself during any task.

Equipped with these tools, you’ll be better prepared to tackle various tasks, ensuring that your motorcycle remains in optimal condition for the road ahead.

Step-by-Step Maintenance Guide

Regular upkeep of your motorcycle is essential for ensuring optimal performance and longevity. This comprehensive guide will walk you through the necessary tasks to keep your machine running smoothly, enhancing both safety and enjoyment during rides.

Checking and Changing Fluids

One of the fundamental aspects of motorcycle care involves monitoring and replacing vital fluids. Start by inspecting the oil level; if it’s low or dirty, it’s time for a change. Ensure you use the recommended type of lubricant for optimal engine health. Additionally, check the coolant and brake fluid levels, topping off or replacing them as needed. Proper fluid maintenance prevents overheating and maintains braking efficiency.

Tire Inspection and Maintenance

Maintaining your tires is crucial for safety and handling. Regularly inspect tire pressure, ensuring it aligns with the manufacturer’s specifications. Look for signs of wear or damage, such as cracks or uneven tread. Rotate tires if necessary and replace them when tread depth becomes insufficient. Keeping tires in good condition maximizes grip and stability, especially in adverse conditions.

Engine Troubleshooting Techniques

Troubleshooting engine issues requires a systematic approach to identify and resolve problems effectively. Understanding the common symptoms and utilizing a methodical process can significantly improve the chances of restoring optimal performance.

1. Listen for Unusual Noises: Pay attention to any irregular sounds coming from the engine. Knocking, rattling, or excessive vibrations can indicate underlying mechanical issues. Document these noises to aid in diagnosis.

2. Monitor Engine Performance: Keep track of any changes in power delivery, acceleration, or fuel efficiency. A sudden decline in these areas may point to issues such as fuel delivery problems or ignition system malfunctions.

3. Check Fluid Levels: Regularly inspect oil, coolant, and fuel levels. Low or contaminated fluids can lead to overheating or lubrication failures, resulting in severe engine damage.

4. Conduct Visual Inspections: Examine the engine bay for any visible leaks, worn belts, or damaged hoses. A thorough visual check can often reveal problems before they escalate.

5. Use Diagnostic Tools: Employ diagnostic equipment, such as multimeters or compression testers, to gather data on the engine’s condition. These tools can provide insights into electrical systems and compression levels, aiding in pinpointing issues.

6. Assess Ignition System: Ensure that spark plugs and ignition components are functioning correctly. A weak spark or faulty plugs can lead to misfires and reduced performance.

7. Evaluate Fuel System: Investigate the fuel delivery system for clogs or leaks. A clean fuel filter and properly functioning fuel pump are essential for optimal operation.

By following these troubleshooting techniques, one can effectively diagnose engine issues and implement appropriate solutions, ensuring a smoother and more reliable riding experience.

Electrical System Overview

The electrical system in a motorcycle plays a crucial role in its overall functionality, enabling various components to operate effectively. This system encompasses everything from the battery to the wiring, ensuring that power is delivered where needed and that the bike runs smoothly. Understanding its components and operation is essential for maintaining performance and safety.

Key Components

Several vital elements make up the electrical system, each contributing to the overall operation of the vehicle. Here’s a summary of the primary parts:

| Component | Function |

|---|---|

| Battery | Stores electrical energy to start the engine and power accessories. |

| Alternator | Generates electricity to recharge the battery while the engine runs. |

| Ignition System | Provides the spark needed to ignite the fuel-air mixture in the engine. |

| Wiring Harness | Distributes electrical power to various components throughout the motorcycle. |

| Lights and Indicators | Ensure visibility and communication with other road users. |

System Maintenance Tips

Regular checks and maintenance of the electrical system are essential for preventing issues. Ensure that connections are secure, inspect for frayed wires, and keep the battery charged. Additionally, replacing old bulbs and ensuring proper grounding can enhance the reliability of the electrical system.

Brake System Repair Procedures

Ensuring optimal performance of the braking mechanism is essential for safe operation. Proper maintenance and troubleshooting can prevent complications, enhancing both safety and reliability. This section outlines essential techniques and guidelines for addressing common issues within the braking system.

Inspection is the first step in maintaining the braking system. Begin by examining the brake pads for wear and tear. If the pads appear thin or damaged, they should be replaced. Additionally, check the rotors for any signs of scoring or warping, as these conditions can adversely affect braking efficiency.

Next, focus on the brake fluid. Ensure that it is at the correct level and free from contaminants. If the fluid appears dirty or discolored, it may be necessary to flush the system and replace it with fresh fluid. Regularly replacing brake fluid can help maintain hydraulic pressure and performance.

Another critical aspect involves adjusting the brake cables. If you notice excessive slack or tension, adjustments should be made to ensure proper engagement and release of the brakes. This can significantly enhance responsiveness and control while riding.

Finally, test the braking system after completing maintenance. A thorough test will help verify that all components are functioning correctly. Listen for unusual noises and pay attention to any changes in feel while engaging the brakes. Consistent performance is key to safe operation.

Suspension Adjustments and Care

Maintaining optimal performance of a motorcycle’s suspension system is crucial for ensuring a smooth ride and enhancing safety. Proper adjustments and routine care can significantly improve handling and comfort. Understanding the components involved and how to tweak them can lead to a more enjoyable riding experience.

Regular inspection of the suspension components is essential. Check for signs of wear, leaks, or damage that could impact performance. Maintaining the correct settings according to your riding style and terrain is equally important, as it directly affects stability and maneuverability.

| Adjustment Type | Description | Recommended Frequency |

|---|---|---|

| Preload | Adjusts the initial tension on the spring, affecting ride height and comfort. | Every 500 miles or after significant load changes |

| Compression | Controls how quickly the suspension compresses when encountering bumps. | Every 1000 miles or when handling feels off |

| Rebound | Regulates the speed at which the suspension returns to its original position after compression. | Every 1000 miles or with changes in terrain |

Keep the suspension clean and free of debris to ensure longevity. Regularly lubricating moving parts helps to maintain functionality and prevent rust. Following these guidelines will enhance not only the lifespan of the suspension but also the overall riding experience.

Replacing Tires and Wheels

Proper maintenance of your motorcycle’s tires and wheels is crucial for ensuring safety and performance. This section will guide you through the essential steps for replacing these components, helping you maintain optimal handling and stability on the road.

Before starting the replacement process, it’s important to gather the necessary tools, including a tire lever, a socket set, and a torque wrench. Make sure to work in a clean, well-lit area to avoid any mishaps.

Step 1: Removing the Wheel

Begin by loosening the axle nut while the motorcycle is still on the ground. Once it’s loose, elevate the bike using a stand. Carefully detach the brake caliper if applicable, then remove the axle and pull the wheel off the fork or swingarm.

Step 2: Tire Removal

Using a tire lever, pry the tire away from the rim. It may be helpful to let some air out of the tire to ease the process. Work your way around the rim until the tire is completely removed.

Step 3: Installing the New Tire

Begin by placing one side of the new tire onto the rim. Ensure the rotation direction indicated on the tire aligns correctly. Once one side is in place, use the tire lever to fit the other side onto the rim, making sure it seats properly without pinching the inner tube.

Step 4: Reassembling the Wheel

Once the tire is securely in place, carefully reattach the wheel to the motorcycle. Ensure the axle is tightened to the manufacturer’s specifications using a torque wrench. Reinstall the brake caliper if it was removed.

Step 5: Final Checks

Finally, check the tire pressure and ensure that it meets the recommended levels. Conduct a visual inspection for any signs of misalignment or damage before taking your motorcycle out for a ride.

By following these steps, you can effectively replace your tires and wheels, ensuring a smooth and safe riding experience.

Cleaning and Maintaining the Carburetor

The proper upkeep of the fuel delivery system is crucial for ensuring optimal performance and longevity of the engine. Regular cleaning and maintenance of the carburetor can prevent issues such as poor fuel efficiency and erratic engine behavior. This section outlines the essential steps to effectively care for this vital component.

Gather Necessary Tools and Supplies

Before beginning the cleaning process, assemble the required tools, including a screwdriver set, carburetor cleaner, brushes, and clean rags. Having everything ready will streamline the procedure and minimize disruptions.

Remove the Carburetor

Carefully detach the carburetor from the engine. This may involve disconnecting fuel lines, throttle cables, and any associated linkages. Make sure to label any components to simplify reassembly.

Disassemble the Unit

Once removed, disassemble the carburetor by unscrewing the various parts. Pay attention to the order of disassembly to ensure correct reassembly. Store small parts in a labeled container to avoid losing them.

Clean Thoroughly

Use a carburetor cleaner to remove any buildup of dirt and varnish. Utilize brushes to scrub hard-to-reach areas, ensuring all passages and jets are clear. Rinse with clean solvent to remove any remaining residue.

Inspect Components

While cleaning, inspect all components for wear or damage. Look for signs of corrosion, cracks, or wear on gaskets and O-rings. Replace any faulty parts to ensure proper functioning.

Reassemble and Reinstall

Once everything is clean and inspected, carefully reassemble the carburetor in the reverse order of disassembly. Make sure all screws and connections are secure before reinstalling it onto the engine.

Final Checks

After reinstalling, perform a thorough check for leaks and ensure that all connections are tight. Start the engine and allow it to warm up, monitoring its performance for any irregularities.

Regular maintenance of the carburetor not only enhances the performance of the engine but also contributes to its longevity. By following these steps, you can keep this essential component in excellent working condition.

Upgrading Components for Performance

Enhancing the efficiency and responsiveness of a classic motorcycle can transform the riding experience. By focusing on key components, enthusiasts can achieve improved power delivery, better handling, and an overall increase in performance. Below are several crucial areas to consider when upgrading various parts of the bike.

- Exhaust System:

Switching to a performance exhaust can reduce weight and improve airflow, leading to better engine performance. Look for options that enhance both sound and efficiency.

- Carburetors:

Upgrading to high-performance carburetors can provide more precise fuel delivery, enhancing throttle response and overall power. Consider tuning them for optimal performance.

- Suspension:

Improving the suspension system can dramatically affect handling. Upgraded shocks and forks can provide better stability and comfort during rides.

- Braking System:

Investing in advanced brake components ensures better stopping power and control. Look for upgraded calipers, rotors, and brake lines for enhanced safety.

- Ignition System:

A modern ignition system can provide more reliable starts and improved engine efficiency. Consider upgrading to a high-performance ignition coil and module.

Each of these upgrades contributes to a more enjoyable and dynamic riding experience. Carefully selecting and installing components can yield significant improvements, making your ride not only faster but also more thrilling.

Safety Tips for DIY Repairs

Engaging in hands-on maintenance of your vehicle can be rewarding and cost-effective. However, it is essential to prioritize safety to prevent accidents and injuries during the process. By following some fundamental precautions, you can ensure a secure and successful experience.

Preparation Before You Begin

- Read the documentation thoroughly to understand the procedures.

- Gather all necessary tools and equipment beforehand.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Ensure adequate lighting to see clearly and avoid mistakes.

Safety Gear and Practices

- Always wear appropriate personal protective equipment, such as gloves and safety glasses.

- Keep a fire extinguisher nearby when working with flammable materials.

- Secure the vehicle properly to prevent any movement while working on it.

- Be cautious of hot surfaces and sharp edges to avoid injuries.

By implementing these guidelines, you can create a safer environment for your maintenance tasks, allowing you to focus on the work at hand without unnecessary risks.