Maintaining your outdoor machinery is crucial for ensuring longevity and optimal performance. Whether you are a seasoned gardener or a weekend warrior, understanding how to care for your equipment can save you time and money. This section delves into essential practices that will help you keep your machinery running smoothly.

From troubleshooting common issues to performing routine upkeep, having a solid grasp of maintenance techniques can enhance the efficiency of your equipment. This guide offers a detailed look at various aspects of upkeep, equipping you with the knowledge needed to address problems effectively.

Additionally, familiarizing yourself with the components and functions of your machinery will empower you to make informed decisions. Regular attention and timely interventions can prevent minor issues from escalating into costly repairs, ensuring that your equipment remains a reliable partner in your outdoor tasks.

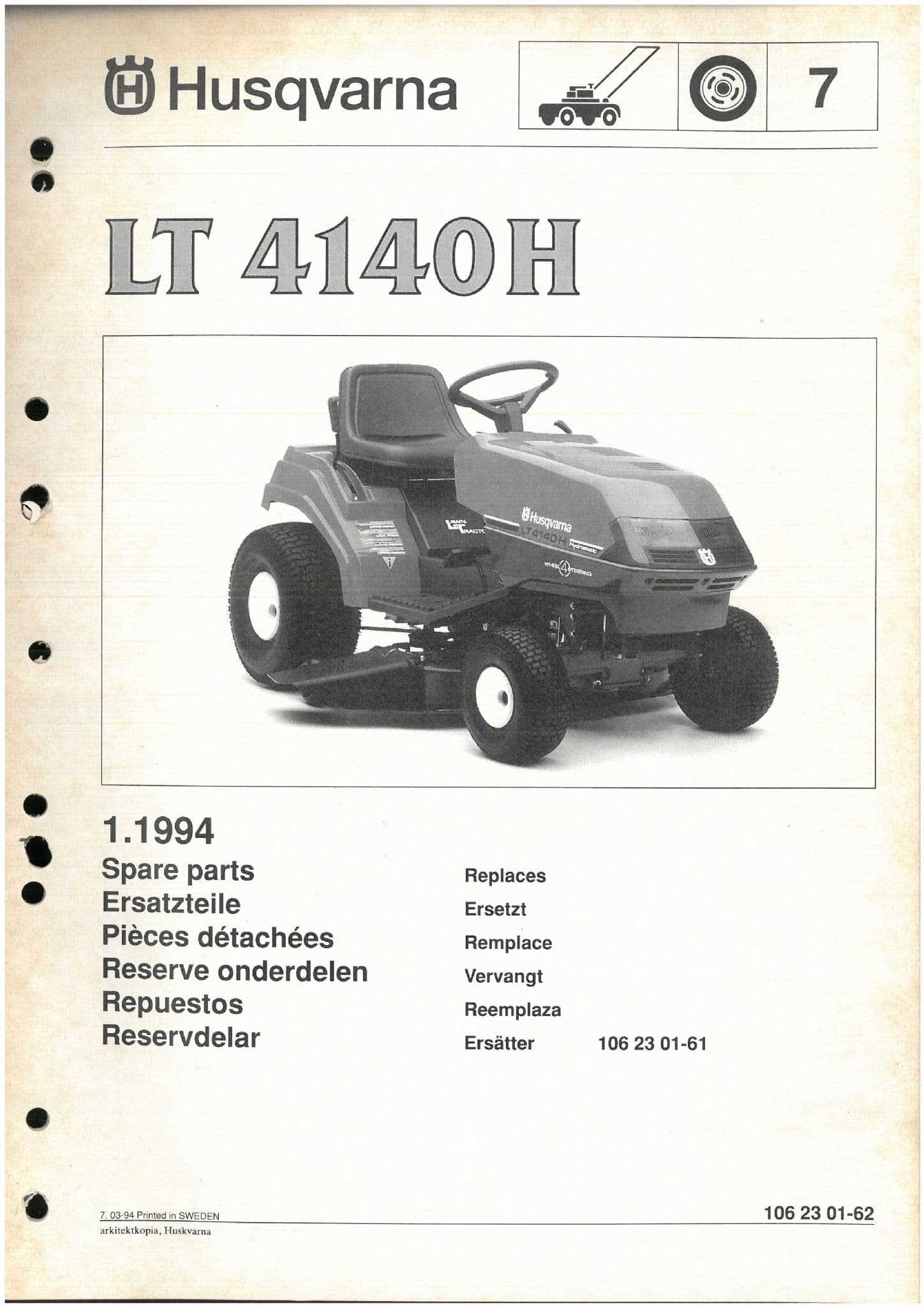

Understanding Husqvarna Lawn Tractors

This section explores the essential features and functionality of garden maintenance machines, emphasizing their role in ensuring a well-kept outdoor space. By examining various aspects, users can gain insight into optimizing performance and longevity.

Key Features

- Powerful engines designed for efficiency and reliability

- Advanced cutting systems for a clean and even finish

- User-friendly controls for seamless operation

- Durable construction to withstand various weather conditions

Maintenance Tips

- Regularly check and change the oil to ensure engine health.

- Sharpen blades frequently for optimal cutting performance.

- Inspect belts and cables for signs of wear and replace as needed.

- Keep the machine clean to prevent rust and maintain efficiency.

Common Issues with Lawn Tractors

Maintaining your outdoor equipment can often reveal a variety of common challenges. Identifying these problems early can save you time and effort in the long run. Below are some frequent issues that users may encounter, along with potential causes and solutions.

- Engine Won’t Start

- Check the fuel level and quality.

- Inspect the battery for a proper charge.

- Look for issues with the ignition system.

- Uneven Cutting

- Examine the blades for sharpness and damage.

- Ensure the cutting height is adjusted properly.

- Check for uneven tire pressure.

- Transmission Problems

- Inspect the belts for wear and tear.

- Check the fluid levels if applicable.

- Look for obstructions in the drive system.

- Overheating

- Ensure the cooling system is clean and functioning.

- Check the oil level and quality.

- Look for blockages in air intake areas.

- Steering Difficulties

- Inspect the steering components for wear.

- Check for proper alignment of the wheels.

- Look for any obstructions in the steering mechanism.

By understanding these typical issues and their potential solutions, you can ensure better performance and longevity for your equipment. Regular maintenance and timely troubleshooting can greatly enhance your experience.

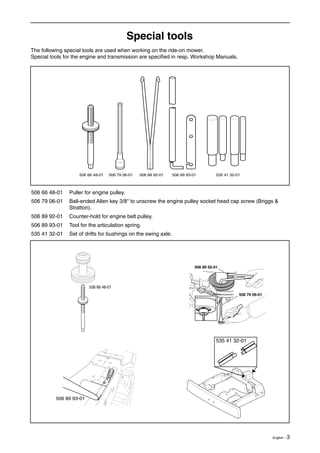

Essential Tools for Repairs

When it comes to maintaining your equipment, having the right instruments at your disposal is crucial. A well-equipped workspace not only makes the task easier but also ensures that repairs are conducted safely and effectively. Below are some indispensable items that every enthusiast should consider when tackling maintenance tasks.

Basic Hand Tools

- Wrenches: Adjustable and fixed-size wrenches are essential for loosening and tightening bolts.

- Screwdrivers: A set of both flathead and Phillips screwdrivers will cover most fastening needs.

- Pliers: Needle-nose and standard pliers are useful for gripping, twisting, and cutting wires or small components.

- Socket Set: A socket set allows for quick access to various sizes of nuts and bolts, making assembly and disassembly easier.

Power Tools

- Drill: An electric or cordless drill is invaluable for creating holes or driving screws quickly.

- Angle Grinder: Useful for cutting, grinding, and polishing metal parts that may require shaping or repair.

- Impact Wrench: This tool provides the extra torque needed for stubborn fasteners.

Equipping your workspace with these essential tools will facilitate smooth and efficient maintenance, ensuring that your equipment remains in optimal condition for years to come.

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring optimal performance and longevity of your outdoor machinery. This guide provides a structured approach to maintain your equipment, focusing on key aspects to enhance functionality and prevent potential issues.

1. Check Oil Levels: Regularly inspect the oil level to ensure proper lubrication. Change the oil according to the manufacturer’s recommendations to keep the engine running smoothly.

2. Clean Air Filter: A clean air filter is vital for efficient operation. Remove and clean the filter as needed to prevent debris from entering the engine.

3. Inspect Blades: Sharp blades are crucial for effective cutting. Check the blades for wear and sharpen or replace them if necessary.

4. Battery Maintenance: Keep the battery terminals clean and ensure a secure connection. Charge the battery as needed to avoid starting issues.

5. Tire Pressure: Check the tire pressure regularly for optimal traction and performance. Inflate to the recommended levels for even wear.

6. Belts and Cables: Inspect belts and cables for signs of wear or fraying. Replace any damaged components to ensure reliable operation.

7. Storage Tips: If storing for an extended period, clean the equipment thoroughly, add fuel stabilizer, and cover it to protect against dust and moisture.

By following these steps diligently, you can delve deeper into the care of your machinery, ensuring it remains in peak condition and ready for use when needed.

Troubleshooting Engine Problems

Addressing issues related to engine performance can be a straightforward process when approached methodically. By identifying symptoms and analyzing potential causes, you can often restore functionality without extensive intervention. This section aims to guide you through common engine difficulties and their resolutions.

Common Symptoms and Their Causes

Several indicators can suggest underlying engine issues. For instance, if the machine fails to start, it could be due to a drained battery, clogged fuel filter, or faulty ignition system. Unusual noises, such as knocking or grinding, may point to mechanical wear or insufficient lubrication. Additionally, excessive smoke from the exhaust can signify problems ranging from burning oil to fuel mixture imbalances.

Steps to Diagnose and Fix

Begin by conducting a thorough visual inspection. Check the battery connections, fuel levels, and air filters. If everything appears normal, proceed with testing the ignition system and examining the spark plugs for wear. Cleaning or replacing components as needed can often resolve the issue. For more complex problems, consulting detailed technical guidelines may be necessary to ensure accurate diagnosis and effective solutions.

How to Change the Blades

Maintaining sharp cutting tools is essential for achieving a pristine finish on your green spaces. Regularly replacing these components ensures optimal performance and extends the life of your equipment.

Step 1: Before beginning, ensure the engine is off and cool. Safety gear, such as gloves and goggles, is recommended to protect against sharp edges.

Step 2: Elevate the machine securely, either with a jack or ramp, to gain easy access to the cutting mechanism. Consult your model’s guidelines for specific lifting instructions.

Step 3: Locate the blade attachment points. Use a wrench to remove the bolts holding the blades in place. Keep these bolts safe for reinstallation.

Step 4: Carefully detach the old blades, taking note of their orientation for proper installation of the new ones. Clean the mounting area to ensure a snug fit.

Step 5: Position the new blades correctly and secure them with the bolts. Ensure they are tightened firmly to prevent movement during operation.

Step 6: Lower the equipment back to the ground and perform a quick check. Start the engine to confirm everything is functioning smoothly before use.

Regularly changing the cutting elements not only enhances efficiency but also contributes to a healthier environment for your greenery.

Fuel System Care and Repair

Maintaining the efficiency and longevity of your equipment’s fuel system is essential for optimal performance. A well-functioning fuel mechanism ensures reliable operation and can prevent costly issues down the line. This section covers important aspects of maintenance and troubleshooting to keep your fuel system in excellent condition.

Here are some key areas to focus on:

- Regular Inspection: Frequently check for leaks, cracks, or any signs of wear in hoses and connections.

- Fuel Quality: Always use high-quality fuel. Contaminated or old fuel can lead to clogs and engine problems.

- Filter Replacement: Replace the fuel filter as recommended to ensure clean fuel flow and prevent debris from entering the system.

- Carburetor Cleaning: Keep the carburetor clean to ensure proper air-fuel mixture. Use a suitable cleaner and follow the manufacturer’s guidelines.

When it comes to troubleshooting, consider the following common issues:

- Starting Difficulties: If the engine struggles to start, check for fuel blockages or air leaks.

- Poor Performance: Lack of power may indicate a clogged filter or carburetor that needs attention.

- Excessive Fuel Consumption: This could signal a malfunction in the fuel delivery system or improper adjustments.

By adhering to these guidelines, you can enhance the reliability and efficiency of your equipment, ensuring it operates smoothly for years to come.

Electrical System Diagnostics

The electrical system is vital for the efficient functioning of any machinery. Proper diagnostics can identify issues that may hinder performance or lead to failure. Understanding how to assess electrical components will help in maintaining optimal operation and prolonging the life of the equipment.

Common Issues and Symptoms

Recognizing typical electrical problems is the first step in diagnostics. Below are some common issues and their associated symptoms:

| Issue | Symptoms |

|---|---|

| Battery Failure | Difficulty starting, dim lights, unusual noises |

| Faulty Wiring | Intermittent power loss, blown fuses, erratic behavior |

| Defective Switches | Non-responsive controls, inconsistent operation |

| Malfunctioning Charging System | Battery not charging, warning lights illuminated |

Diagnostic Steps

Follow these steps to effectively diagnose electrical issues:

- Inspect battery connections for corrosion or looseness.

- Test the battery voltage with a multimeter.

- Examine wiring for signs of damage or wear.

- Check fuses and replace any that are blown.

- Evaluate the operation of switches and relays.

Cleaning the Air Filter

Maintaining optimal performance of your outdoor equipment involves regular upkeep, and one critical aspect is the cleanliness of the air intake component. A clean filter ensures that the engine receives an adequate supply of air, which is essential for efficient combustion and overall functionality.

Here are the steps to effectively clean the air filtration system:

- Gather Supplies:

- Soft brush or compressed air

- Warm, soapy water

- Clean, dry cloth

- Protective gloves (optional)

- Remove the Filter:

Locate the air filter housing and carefully detach it. Take care not to damage any surrounding components.

- Clean the Filter:

If the filter is foam or paper, use a soft brush or compressed air to remove dirt and debris. For washable filters, soak it in warm, soapy water, then rinse thoroughly.

- Dry the Filter:

Ensure the filter is completely dry before reinstallation. Use a clean cloth to gently pat it dry or allow it to air dry.

- Reinstall the Filter:

Once dry, carefully place the filter back into the housing, ensuring a snug fit to prevent any unfiltered air from entering the engine.

Regular inspection and cleaning of the air intake component will enhance the longevity and performance of your equipment. Aim to check it at least once every season or more frequently in dusty conditions.

Transmission Troubleshooting Tips

Dealing with transmission issues can be frustrating, but understanding common problems and their solutions can simplify the process. This section outlines essential strategies for diagnosing and addressing transmission-related concerns, ensuring your equipment runs smoothly.

Common Symptoms and Causes

Identifying the signs of transmission malfunctions is the first step towards effective resolution. Below is a table that summarizes typical symptoms along with potential causes:

| Symptom | Possible Cause |

|---|---|

| Unresponsive controls | Fluid levels low or contaminated |

| Slipping gears | Worn components or incorrect adjustments |

| No movement | Damaged linkage or broken belt |

| Noisy operation | Insufficient lubrication or worn bearings |

Steps for Troubleshooting

Once you identify the symptoms, follow these steps to troubleshoot the transmission effectively:

1. Check Fluid Levels: Ensure the transmission fluid is at the correct level and replace it if it appears dirty or degraded.

2. Inspect Belts and Linkages: Look for any signs of wear or damage. Replace any faulty components to restore proper function.

3. Adjust Controls: Make necessary adjustments to ensure that controls respond accurately. This might involve calibrating or tightening connections.

4. Lubricate Moving Parts: Apply appropriate lubricants to prevent wear and ensure smooth operation.

By following these tips and systematically addressing each issue, you can enhance the performance and longevity of your equipment.

Seasonal Preparation for Your Tractor

Ensuring your outdoor equipment is ready for the changing seasons is crucial for optimal performance and longevity. Each season brings its own set of challenges, requiring specific maintenance tasks to keep your machinery in peak condition. Proper preparation not only enhances efficiency but also minimizes potential issues during critical usage periods.

Here are key tasks to consider for seasonal readiness:

- Spring Preparation:

- Check and change the oil to ensure smooth operation.

- Inspect the air filter for cleanliness and replace if necessary.

- Sharpen blades for effective cutting performance.

- Examine tires for wear and proper inflation.

- Summer Maintenance:

- Regularly clean the deck to prevent grass buildup.

- Monitor fuel levels and use fresh gasoline.

- Check for overheating and ensure cooling systems are clear.

- Autumn Preparation:

- Drain fuel or add a stabilizer to prevent gumming.

- Clean and store equipment properly to avoid damage.

- Inspect battery and clean terminals to ensure reliable starts.

- Winter Care:

- Store in a dry, sheltered area to protect against the elements.

- Cover to prevent dust accumulation and moisture damage.

- Conduct a thorough inspection for any necessary repairs before spring.

Following these seasonal preparations will help maintain your equipment’s functionality and readiness for each new phase of the year.

When to Seek Professional Help

Understanding the limits of your own skills is crucial when it comes to maintenance and troubleshooting of outdoor equipment. While some issues can be resolved with basic knowledge and tools, others may require the expertise of a qualified technician. Recognizing when to seek assistance can save time and prevent further damage.

Signs That Indicate Professional Assistance Is Needed

- Persistent Issues: If a problem continues after your attempts to fix it, it’s a sign that professional evaluation is necessary.

- Unusual Noises: Unexplained sounds during operation may indicate serious mechanical issues that require expert diagnosis.

- Fluid Leaks: Any signs of leaking fluids could signal critical issues that need immediate attention.

- Performance Decline: A noticeable decrease in efficiency or power should prompt you to consult a professional.

Benefits of Seeking Professional Help

- Access to specialized knowledge and tools that can expedite the repair process.

- Minimized risk of further damage, potentially saving you money in the long run.

- Increased safety, as professionals can handle hazardous components safely.

- Warranty preservation, ensuring that any existing warranties remain valid.