Maintaining household cleaning tools in optimal condition is essential for efficient and long-lasting performance. When these machines show signs of wear or start to lose effectiveness, a well-structured approach to restoration can bring them back to life. This guide offers insight into addressing common issues, helping users extend the functionality of their devices without unnecessary replacement.

Understanding the mechanics behind these appliances allows for a deeper comprehension of how each component contributes to the overall performance. By delving into typical issues and effective solutions, this resource provides a practical roadmap for diagnosing and resolving various malfunctions, from minor adjustments to more thorough repairs.

Our comprehensive outline highlights key areas, including identifying symptoms, applying effective troubleshooting techniques, and following preventive care recommendations. Whether dealing with minor inconveniences or more significant challenges, this guide empowers users with the knowledge needed to address concerns efficiently and confidently.

Essential Tips for Bissell Cleaner Maintenance

Maintaining your floor-cleaning equipment regularly ensures it functions optimally over time. By following a few simple steps, you can extend the life of your device and ensure consistent, high-quality results with each use.

- Regularly Empty and Rinse the Tank: Make it a habit to empty and clean the water and solution tanks after each use. This prevents buildup and keeps the appliance running smoothly.

- Inspect and Clean Filters: Periodically check filters for any debris or clogging. Cleaning or replacing filters as needed will help maintain optimal performance.

- Check for Blockages: Inspect the nozzle, hose, and other pathways for any trapped dirt or obstructions. Removing these will prevent any potential issues during operation.

- Brush Maintenance: The device’s brush roll should be cleaned regularly to remove fibers and lint that may affect its efficiency. This keeps the brush functioning well and prolongs its lifespan.

- Store Properly: Always store the device in a cool, dry place, away from direct sunlight, to avoid any unnecessary wear on parts.

By following these maintenance steps, your equipment can provide reliable, effective cleaning over an extended period, minimizing the need for repairs and ensuring that it stays in peak condition.

Identifying Common Issues and Solutions

Everyday use of floor care equipment can lead to occasional challenges, from performance inconsistencies to unexpected technical hiccups. Understanding frequent malfunctions and practical approaches to address them is essential for maintaining optimal functionality and prolonging the equipment’s lifespan.

Power and Start-Up Problems

- Device won’t turn on: Ensure the power source is stable and verify that the unit is properly plugged in. Sometimes, a quick reset or power outlet check can solve the issue.

- Intermittent power cuts: This can indicate an internal wiring issue or a loose connection. Inspect the cord and plugs for any visible damage.

Low Suction or Reduced Cleaning Performance

- Weak suction power: Blockages in hoses or filters may cause a drop in suction. Clean or replace filters regularly to avoid clogs that impact efficiency.

- Inconsistent dispensing of cleaning solution: This can occur if the solution tank is improperly seated or if the nozzle is clogged. Check and clean nozzles and ensure the tank is securely attached.

For persistent or unresolved problems, refer to advanced troubleshooting methods, or consider consulting a professional to ensure equipment remains in top working condition.

Steps to Troubleshoot a Power Failure

If the device suddenly stops functioning or does not turn on, identifying the cause of the power failure can help restore its normal operation. This section outlines essential steps to determine the root of the issue, allowing users to potentially resolve the malfunction without professional assistance.

Check the Power Source

Begin by verifying the power connection. Ensure the plug is firmly inserted into a functioning outlet. Test the outlet with another device to confirm it is delivering power. If using an extension cord, check that it is in good working condition and properly connected. A weak or loose connection can often cause power interruptions.

Inspect the Power Cord and Switch

Examine the power cord for any visible signs of wear or damage, such as cuts or exposed wires, which could interrupt the electrical flow. If the cord appears damaged, it is recommended to avoid further use until repaired. Also, ensure the power switch is set to the “on” position. In some cases, cleaning the switch area of any accumulated dust or debris can improve its function.

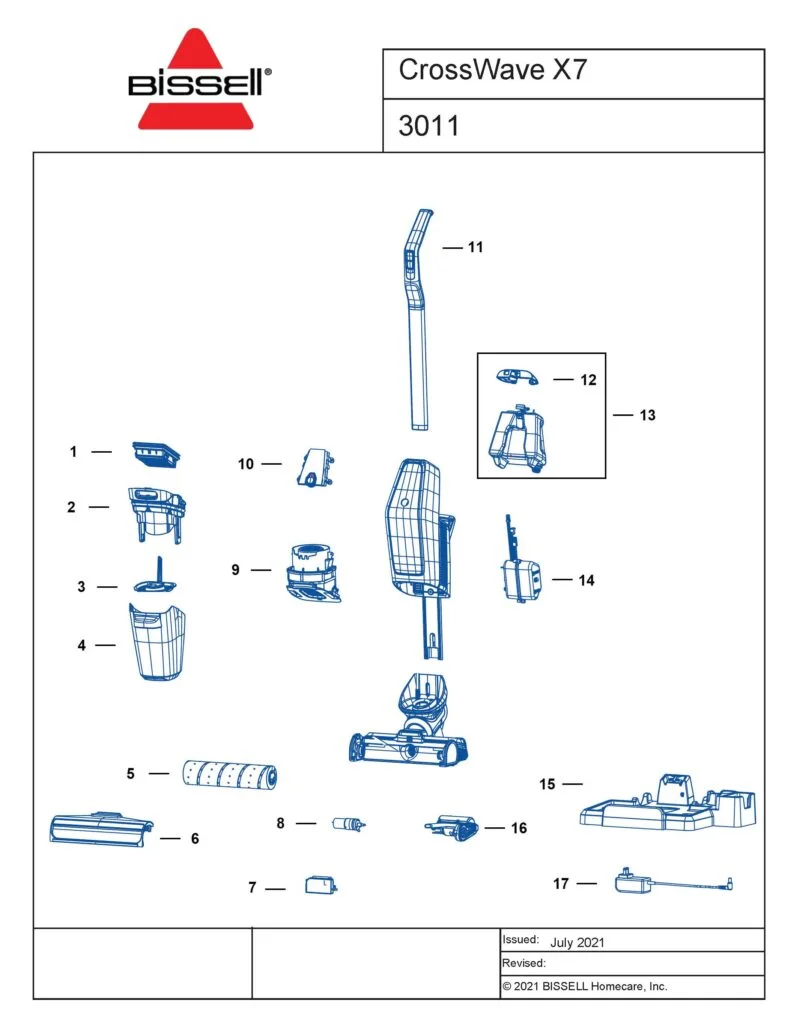

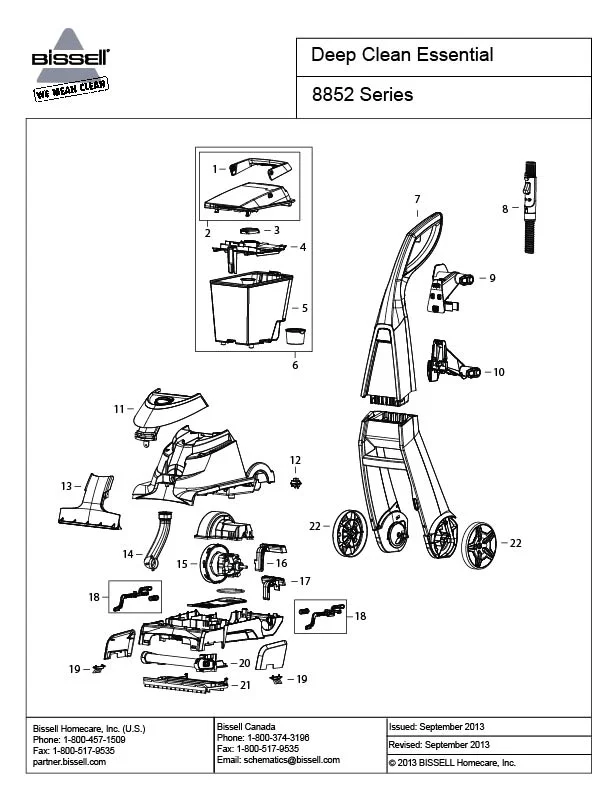

How to Replace Key Components

In this section, we’ll explore essential steps for swapping out crucial parts of your device to ensure it continues to operate effectively. By following these instructions, you can refresh worn or damaged elements, maintaining performance and extending the lifespan of the machine. Review each step carefully to understand the necessary processes for a smooth replacement.

| Component | Tools Needed | Replacement Steps |

|---|---|---|

| Motor Belt | Screwdriver, New Belt | First, detach the casing by removing the screws. Locate the belt, gently release it, and position the new belt. Secure the casing back in place. |

| Brush Roll | Screwdriver, New Brush Roll | Remove screws securing the base. Slide out the old brush roll, insert the new one, and fasten the screws to complete the replacement. |

| Water Tank Seal | Rubber Gloves, Replacement Seal | Take out the water tank, locate the damaged seal, and carefully remove it. Position the new seal securely before reattaching the tank. |

Using appropriate tools and following these steps will help ensure a successful replacement of core parts, keeping your device ready for optimal use. Regular checks and timely replacements can significantly improve efficiency and longevity.

Guide to Cleaning Internal Parts

Proper maintenance of internal components is essential for keeping any device in optimal working order. Regular cleaning helps prevent buildup that can impede performance and extend the lifespan of the equipment. This section will outline the steps for accessing and maintaining inner elements without requiring special tools or complex techniques.

Step-by-Step Cleaning Process

- Unplug and Disassemble: Begin by disconnecting the device from power. Carefully remove the outer casing and locate the primary sections that may collect dust or debris over time.

- Brush and Dust Removal: Use a soft-bristle brush or a small vacuum to gently clean all accessible areas. Focus on corners and joints where particles may accumulate, taking care not to damage sensitive parts.

- Wipe with Damp Cloth: Lightly dampen a cloth and wipe down interior surfaces, avoiding direct contact with electrical components. This step helps remove remaining residues and keeps the machine fresh.

- Dry and Reassemble: Allow all parts to air dry completely before putting the device back together. Ensure each piece is secure to avoid issues during future use.

Tips for Long-Term Maintenance

- Regular Cleaning Schedule: Establish a routine cleaning schedule based on usage to prevent excessive buildup.

- Use Recommended Tools: Utilize soft brushes and microfiber cloths to avoid scratches or damage to delicate parts.

- Inspect Components: During each cleaning, inspect parts for wear or

Maintaining Optimal Water Suction Performance

To ensure effective cleaning outcomes, it’s crucial to prioritize the efficiency of water extraction mechanisms. Regular maintenance and attention to key components can significantly enhance performance, leading to a more thorough and satisfying cleaning process.

Here are several essential practices to keep in mind:

- Regular Filter Cleaning: Periodically remove and rinse filters to prevent blockages and ensure optimal airflow.

- Inspect Hoses: Check for clogs or leaks in hoses, as these can impede water flow and suction strength.

- Maintain Seals: Ensure that all seals are intact to prevent any loss of suction. Replace any damaged seals promptly.

- Monitor Water Levels: Regularly check the water tank to ensure it is filled adequately for efficient operation.

- Use Recommended Solutions: Employ appropriate cleaning solutions that do not compromise the extraction capabilities of the device.

By implementing these maintenance tips, users can help maintain peak performance and prolong the lifespan of their cleaning equipment.

Dealing with Motor and Pump Problems

Addressing issues related to the engine and pumping system is crucial for maintaining optimal functionality in your cleaning equipment. Problems in these areas can lead to diminished performance, resulting in unsatisfactory results during use. Understanding the common symptoms can help in identifying the root causes of the malfunctions.

Common indicators of motor troubles include unusual noises, reduced suction, or the device not turning on. If the engine is making grinding or whining sounds, it may suggest internal wear or damage. Additionally, if the appliance operates but fails to generate sufficient pressure, the pump could be clogged or malfunctioning. Regular maintenance checks can prevent these issues, ensuring that the components operate smoothly.

To resolve motor issues, start by inspecting the power supply and connections for any signs of wear or damage. For pump-related problems, disassemble the relevant parts carefully and clean any debris that may be obstructing the flow. Replacing worn-out seals or gaskets can also restore proper function. Always refer to guidelines specific to your equipment for the best practices in troubleshooting and repair.

Instructions for Deep Brush Maintenance

Ensuring optimal performance of your cleaning device involves regular upkeep of its brushing components. Proper maintenance not only enhances efficiency but also prolongs the lifespan of the equipment. This section outlines essential practices for keeping the deep brush in excellent condition.

Routine Cleaning Procedures

To maintain peak functionality, it is vital to carry out regular cleaning of the brush assembly. This process prevents the buildup of debris and ensures consistent operation. Follow these steps for effective maintenance:

Step Description 1 Unplug the device and remove the brush unit according to the manufacturer’s instructions. 2 Use scissors to carefully cut away any tangled hair or fibers around the bristles. 3 Wipe down the brush and its housing with a damp cloth to remove dust and dirt. 4 Inspect the bristles for wear and replace if necessary to maintain effective cleaning performance. Storage Recommendations

Proper storage is equally important for maintaining the condition of the brushing components. After each use, follow these recommendations to ensure longevity:

- Store the device in a dry area to prevent moisture-related damage.

- Avoid placing heavy items on top of the unit to prevent warping or damage to the brush.

Understanding Warning Lights and Signals

Warning lights and indicators are essential features in many devices, providing crucial information about their operational status. Recognizing these signals can help users identify potential issues before they escalate, ensuring efficient usage and maintenance. This section will explore the meanings behind various alerts, guiding users on how to interpret them effectively.

Common Warning Indicators

- Power Indicator: Typically illuminates when the device is operational.

- Maintenance Alert: Signals that routine upkeep is required.

- Error Light: Indicates a malfunction or error in the system.

Interpreting the Signals

Each light or signal serves a specific purpose. Understanding these meanings can aid in troubleshooting and maintaining the device’s performance. Here are some tips for interpreting the signals:

- Refer to the user guide for detailed explanations of each light.

- Pay attention to the color of the light–different colors often signify different levels of urgency.

- If multiple lights are activated, it may indicate a more complex issue requiring immediate attention.

Adjusting Settings for Effective Cleaning

To achieve optimal results during the cleaning process, it is crucial to fine-tune various parameters of your device. Proper adjustments not only enhance performance but also ensure that the surfaces are treated with the right amount of care and attention. Understanding how to manipulate these settings can significantly impact the overall effectiveness of the task.

Understanding Pressure and Flow

Pressure plays a vital role in determining the efficacy of the cleaning solution application. Too much pressure can damage delicate surfaces, while too little may result in insufficient cleaning. Adjusting the flow rate allows for better control over how much solution is dispensed, optimizing the cleaning experience.

Choosing the Right Cleaning Solution

Using an appropriate cleaning solution is essential for different materials. Certain formulas are designed for specific tasks, and selecting the right one can enhance results. Always refer to the product guidelines to ensure compatibility with your device, which will contribute to achieving a pristine finish.

Preventive Tips to Extend Cleaner Life

Maintaining the functionality of your cleaning device requires regular attention and care. By implementing simple practices, you can significantly enhance its longevity and performance, ensuring that it operates effectively for years to come.

Regular Maintenance: Consistent upkeep is essential for optimal operation. Clean the components regularly to prevent dirt and debris accumulation, which can hinder performance.

Proper Storage: When not in use, store the apparatus in a dry and cool environment. This helps prevent damage from humidity and extreme temperatures, which can affect its internal mechanisms.

Use Recommended Solutions: Utilizing the right cleaning solutions is crucial. Avoid harsh chemicals that may cause deterioration of parts or create residues that impair functionality.

Check for Wear: Periodically inspect the device for any signs of wear and tear. Addressing issues early can prevent more significant problems down the line, ensuring the unit remains in excellent condition.

Follow Usage Instructions: Adhering to the manufacturer’s guidelines during operation is vital. This ensures that you use the device correctly, maximizing its effectiveness and minimizing the risk of damage.

By following these preventive measures, you can help ensure that your cleaning apparatus remains reliable and effective, extending its useful life and maintaining performance standards.