This section aims to provide essential information for vehicle enthusiasts and technicians, focusing on optimal performance and longevity of heavy-duty machinery. Understanding the intricacies of the powertrain is crucial for anyone involved in automotive care.

Throughout this guide, you will discover valuable insights into troubleshooting common issues, as well as preventative measures to enhance the reliability of your equipment. Knowledge of the various components and their functions can significantly improve maintenance practices.

Moreover, we will explore a variety of techniques and tools that can assist in diagnosing and resolving problems effectively. Emphasizing practical advice and real-world applications, this guide seeks to empower readers with the skills needed to ensure their vehicles operate smoothly.

Common Issues with 6.0 Diesel Engines

Many vehicle owners encounter several challenges with their high-performance powertrains, particularly those designed for heavy-duty applications. These complications can stem from various factors, impacting both performance and longevity.

Fuel System Problems: One prevalent issue arises from fuel delivery. Inadequate flow can lead to poor engine performance, resulting in decreased efficiency and increased emissions.

Cooling System Failures: Overheating is another common concern. If the cooling system does not function effectively, it can result in serious damage, compromising overall engine integrity.

Electrical System Glitches: Electrical malfunctions can disrupt the ignition process, leading to starting difficulties. Regular maintenance is crucial to prevent these failures.

Injector Wear: Injectors can wear over time, causing uneven fuel distribution. This can lead to poor combustion, affecting power output and fuel economy.

Head Gasket Leaks: Leaks in the head gasket can result in coolant and oil mixing, leading to severe engine damage if not addressed promptly. Regular inspections can help catch these issues early.

Essential Tools for Repairs

Having the right equipment is crucial for any maintenance tasks. A well-equipped workshop not only enhances efficiency but also ensures that jobs are completed safely and effectively. This section highlights the fundamental instruments required for tackling various mechanical issues.

Basic Hand Tools

Hand tools form the backbone of any repair endeavor. Here are some essential items that should be included in every toolkit:

| Tool | Purpose |

|---|---|

| Wrenches | For tightening and loosening fasteners. |

| Screwdrivers | For driving screws and fastening components. |

| Pliers | For gripping, twisting, and cutting wires. |

| Socket Set | For accessing various sized nuts and bolts. |

Specialized Equipment

In addition to standard tools, certain specialized equipment may be necessary for more intricate tasks. The following items can significantly aid in troubleshooting and fixing complex systems:

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

| Compression Tester | Measures engine compression for diagnostic purposes. |

| Multimeter | For testing electrical systems and components. |

| Diagnostic Scanner | Interprets error codes and monitors system performance. |

Step-by-Step Repair Procedures

This section outlines comprehensive methods for addressing common issues that may arise in specific automotive engines. By following these detailed guidelines, mechanics can efficiently diagnose and resolve problems, ensuring optimal performance and longevity of the machinery.

Initial Assessment

Begin by conducting a thorough examination of the engine to identify visible signs of wear or damage. Check for fluid leaks, unusual noises, and any error codes from the onboard diagnostics system. Document all findings to establish a baseline for further troubleshooting.

Component Replacement

Once the issue has been identified, gather the necessary tools and replacement parts. Carefully disassemble the affected components, ensuring to follow safety protocols. Replace any faulty parts, and reassemble the engine with precision, paying close attention to torque specifications and sealant application as required.

Preventive Maintenance Tips

Regular upkeep is essential to prolong the life of any engine and enhance its performance. By implementing simple yet effective practices, vehicle owners can prevent costly repairs and ensure smooth operation. Here are some valuable suggestions to keep in mind.

Regular Fluid Checks

Routine inspection of all fluids is crucial. This includes the engine oil, coolant, transmission fluid, and brake fluid. Maintaining appropriate levels and ensuring cleanliness can prevent overheating and component wear. Always refer to your vehicle’s specifications for the correct types and intervals for changes.

Air Filter Maintenance

The air filter plays a significant role in engine efficiency. A clean filter allows for optimal airflow, improving combustion and overall performance. Regularly checking and replacing the air filter, especially in dusty environments, can greatly enhance fuel economy and reduce emissions.

Diagnosing Engine Performance Problems

Understanding the factors that affect engine efficiency is crucial for maintaining optimal functionality. Identifying issues early can prevent more severe complications and enhance vehicle longevity. This section provides an overview of methods to assess and resolve performance-related concerns.

Common symptoms of engine performance issues include reduced power output, abnormal noises, and irregular idling. To effectively diagnose these problems, a systematic approach is essential. The following table outlines key diagnostic steps and potential causes:

| Diagnostic Step | Potential Causes |

|---|---|

| Check engine codes | Faulty sensors, electrical issues |

| Inspect air intake | Clogged filters, leaks |

| Examine fuel system | Pump failure, contaminated fuel |

| Assess exhaust output | Blocked catalytic converter, leaks |

| Test ignition system | Worn spark plugs, ignition coil issues |

By following these diagnostic steps, one can pinpoint underlying issues affecting performance and implement appropriate corrective measures to restore engine efficiency.

Replacing Fuel Injectors Effectively

When it comes to enhancing engine performance, one of the crucial components to consider is the fuel injector system. Ensuring that these elements are functioning properly can lead to improved efficiency and power output. This section focuses on the essential steps and considerations involved in the replacement process, ensuring a seamless transition and optimal functionality.

To begin with, it is vital to gather all necessary tools and components before starting the replacement. This preparation helps in minimizing downtime and allows for a more organized approach. The workspace should be clean and free of contaminants to prevent any issues during the installation.

Once the setup is complete, removing the old injectors requires careful handling to avoid damage to surrounding components. It is advisable to consult specific guidelines to ensure that all procedures are followed correctly. After the old units are taken out, inspect the injector ports for any debris or damage that may affect the new installation.

Installing the new injectors involves aligning them correctly and securing them to the designated fittings. It is crucial to follow the recommended torque specifications to avoid leaks or malfunctions. After installation, a thorough check of the entire fuel system should be conducted to ensure everything is functioning as intended.

Finally, running a diagnostic test post-installation can help verify that the new injectors are operating effectively. Monitoring engine performance after the replacement is essential to catch any potential issues early and to ensure that the vehicle is running at its best.

Cooling System Troubleshooting

Proper functioning of the cooling system is essential for maintaining optimal engine performance. Identifying and addressing issues within this system can prevent overheating and other significant problems. Here are some common troubleshooting steps to consider when diagnosing cooling system issues.

- Check Coolant Level: Ensure the coolant reservoir is filled to the appropriate level. Low coolant can indicate leaks or improper filling.

- Inspect for Leaks: Examine hoses, connections, and the radiator for any signs of coolant leaks. Look for wet spots or residue that may indicate a problem.

- Examine Thermostat Function: A malfunctioning thermostat can cause improper coolant flow. Verify that it opens and closes as expected.

- Assess Radiator Condition: Inspect the radiator for blockages or damage. A clogged radiator can impede coolant flow, leading to overheating.

- Test Water Pump Efficiency: Ensure the water pump is functioning correctly, as it is responsible for circulating coolant throughout the system.

By following these steps, you can effectively troubleshoot and resolve common issues related to the cooling system. Regular maintenance and inspections can help prevent many of these problems before they escalate.

Electrical System Diagnosis Techniques

Diagnosing electrical systems is a crucial aspect of vehicle maintenance that requires systematic approaches to identify issues accurately. Effective troubleshooting involves understanding the intricacies of electrical components and their interactions, ensuring that technicians can pinpoint malfunctions efficiently.

Common Diagnostic Tools

Utilizing a variety of diagnostic tools enhances the accuracy of electrical system evaluations. Multimeters, oscilloscopes, and scan tools are essential for measuring voltage, current, and signal patterns. Each tool serves a specific purpose, allowing for thorough analysis of circuit integrity and component functionality.

Step-by-Step Troubleshooting Process

A structured troubleshooting process typically involves several steps: starting with a visual inspection of wiring and connectors, followed by testing components individually to verify their operational status. Employing a methodical approach minimizes guesswork and fosters a deeper understanding of the electrical system’s performance.

Upgrading Components for Better Performance

Enhancing the efficiency of your vehicle often involves optimizing various elements that contribute to overall functionality. By focusing on specific upgrades, drivers can experience improved power output, fuel efficiency, and responsiveness. This section will explore several components that can be modified to achieve these goals, ultimately leading to a more satisfying driving experience.

Key Components for Enhancement

When considering performance improvements, several vital components warrant attention. Each of these elements plays a significant role in the vehicle’s operation and can greatly influence its capabilities.

| Component | Upgrade Options | Benefits |

|---|---|---|

| Intake System | High-flow air filters, performance intake manifolds | Increased airflow and improved engine response |

| Exhaust System | Cat-back exhaust systems, high-performance catalytic converters | Reduced back pressure and enhanced exhaust flow |

| Tuning Software | ECU remapping, performance chips | Optimized fuel maps for better acceleration and economy |

Considerations for Upgrades

Before proceeding with modifications, it is essential to consider compatibility with existing systems. Each upgrade may interact differently with the vehicle’s stock components, and some may require additional adjustments to ensure optimal performance. Consulting with experienced professionals can help navigate these choices effectively.

Understanding Engine Oil Specifications

Choosing the right lubricant for an internal combustion engine is crucial for optimal performance and longevity. The specifications for engine oils vary widely and understanding these differences can significantly impact the efficiency and health of the engine.

Several key factors determine the appropriateness of a particular lubricant:

- Viscosity Grade: This refers to the oil’s thickness and its flow characteristics at different temperatures. The right viscosity ensures proper lubrication under varying operating conditions.

- Additives: Many oils contain additives that enhance performance, including detergents, anti-wear agents, and oxidation inhibitors. These components play a vital role in maintaining engine cleanliness and preventing wear.

- Certification Standards: Various organizations set performance standards for engine oils. Familiarizing yourself with these certifications helps in selecting products that meet or exceed the requirements for specific engines.

By understanding these specifications, vehicle owners can make informed decisions about which lubricants will best suit their engines, ultimately leading to improved performance and durability.

Warranty Considerations for Repairs

When addressing service needs for a specific engine type, it is essential to understand the implications of warranty coverage. Each manufacturer may have distinct policies that outline what is included and what is excluded during the service process. Familiarity with these guidelines helps ensure that any necessary interventions do not inadvertently void existing protections.

Key Factors to Consider

Several critical elements influence warranty status during maintenance activities. These include the nature of the work performed, the parts utilized, and adherence to manufacturer protocols. Understanding these factors can safeguard your investment and provide peace of mind.

Important Warranty Guidelines

| Factor | Description |

|---|---|

| Authorized Service Centers | Using approved facilities often ensures compliance with warranty requirements. |

| Quality of Parts | Utilizing original or approved components is crucial to maintain warranty validity. |

| Documentation | Keeping detailed records of all services performed is essential for warranty claims. |

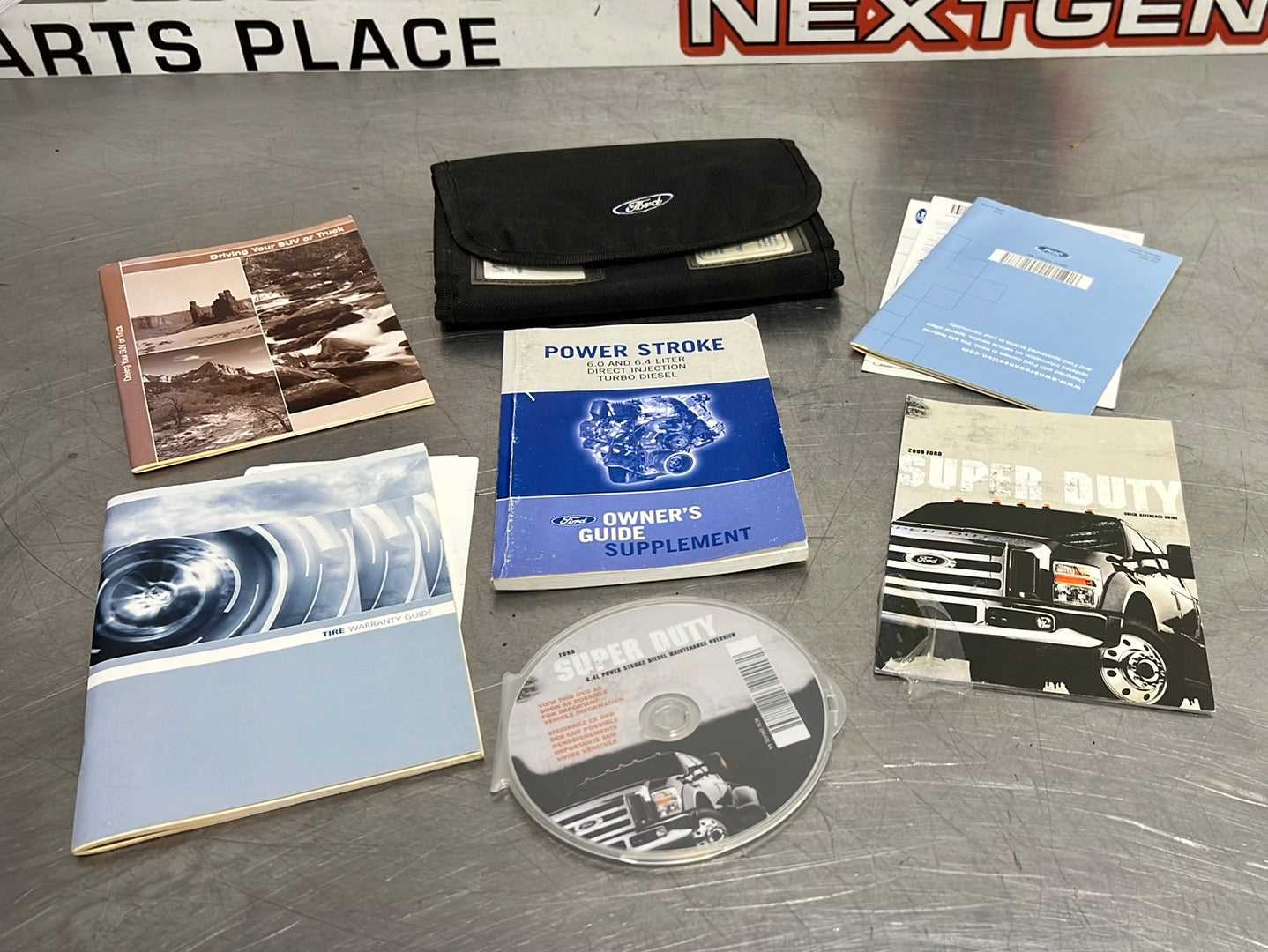

Resources for Ford Diesel Owners

Owning a heavy-duty vehicle requires access to comprehensive support and information to ensure optimal performance. Various resources are available to assist enthusiasts in maintaining their machines, troubleshooting issues, and enhancing their overall experience.

Online Communities and Forums

Participating in online communities offers invaluable insights and shared experiences among fellow vehicle owners. Engaging in discussions can provide practical solutions to common problems, recommendations for upgrades, and tips for routine maintenance. These platforms foster a sense of camaraderie and support, making them essential for enthusiasts.

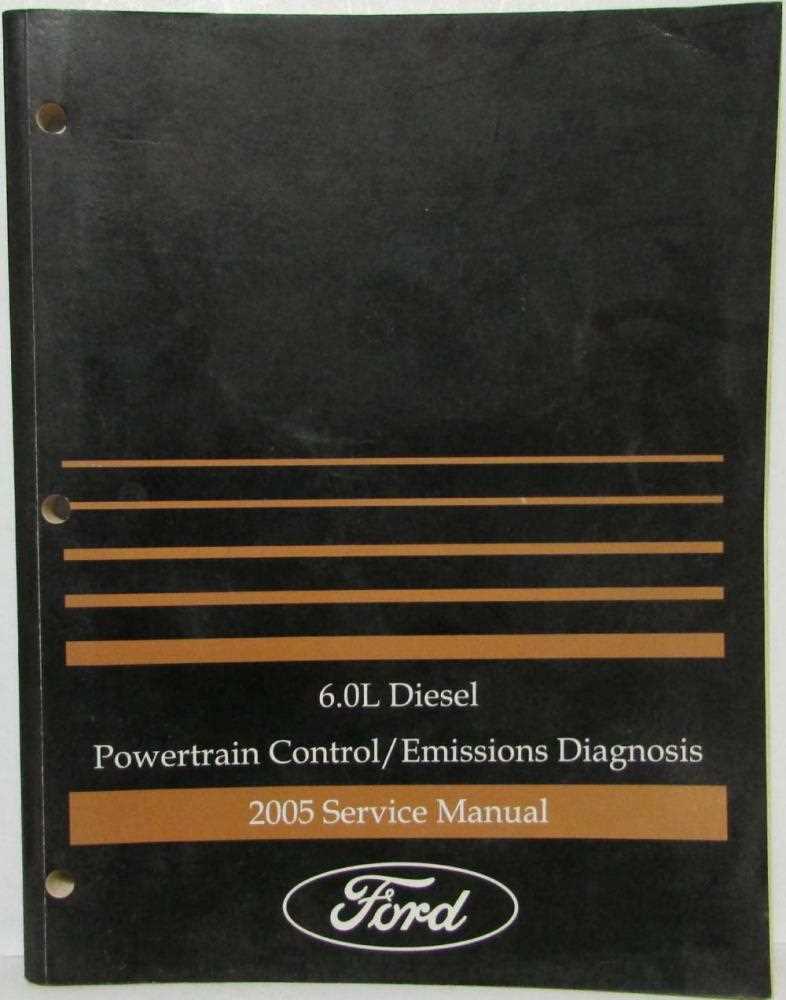

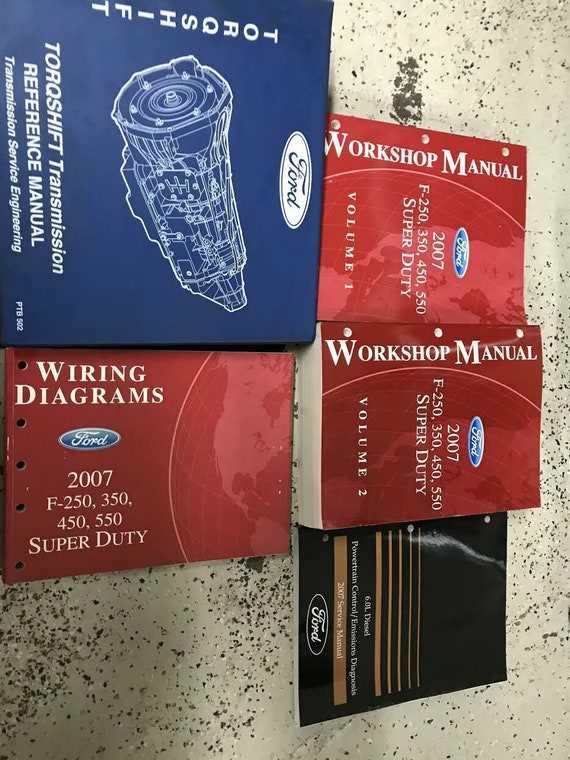

Technical Publications and Guides

Utilizing technical publications can greatly aid in understanding the intricacies of your vehicle. These guides typically cover a range of topics from basic operations to more complex procedures. They serve as a reference point for anyone looking to deepen their knowledge and improve their skills in vehicle care and performance enhancement.