Proper upkeep of your gardening apparatus is essential for ensuring its longevity and efficiency. Understanding the intricacies of your machinery can lead to a smoother experience during your outdoor tasks. This section delves into essential practices and troubleshooting techniques to keep your equipment operating at its best.

Regular attention to mechanical elements can prevent minor issues from escalating into significant problems. By following a structured approach, you can enhance performance and reduce the likelihood of malfunctions. This resource provides insights into common challenges and practical solutions that every user should know.

In addition to maintenance tips, this guide emphasizes the importance of safety and proper handling. Familiarizing yourself with operational procedures will not only extend the life of your tools but also promote a safer working environment. Dive into the specifics and discover how to keep your outdoor gear in prime condition.

Toro Self-Propelled Lawn Mower Overview

This section provides a comprehensive look at a popular type of outdoor equipment designed for efficiently maintaining grass and gardens. These machines are engineered to offer ease of use while ensuring optimal performance, making them a favorite among homeowners and landscapers alike.

Key features often found in these machines include:

- Ergonomic design for comfortable handling

- Adjustable cutting heights for various grass types

- Robust engines for reliable power

- Durable materials for long-lasting use

- Innovative technologies for enhanced maneuverability

Many users appreciate the convenience that these tools bring, especially in larger outdoor spaces. Their ability to tackle different terrains and grass conditions makes them versatile choices for garden maintenance.

Common benefits include:

- Reduced physical effort when cutting grass

- Consistent and even trimming results

- Time-saving features, such as efficient speed settings

In summary, this equipment represents a blend of innovation and practicality, aimed at simplifying garden care while delivering high-quality results.

Common Issues with Toro Mowers

When maintaining a gardening machine, users often encounter a range of typical problems that can hinder performance. Understanding these challenges can help in troubleshooting and ensuring the equipment runs smoothly. This section highlights some frequent issues that may arise, along with suggestions for addressing them effectively.

One prevalent concern is the engine not starting. This can stem from a variety of causes, such as fuel-related issues, spark plug malfunctions, or battery problems. Regularly checking fuel levels and ensuring the spark plug is clean can prevent this hassle.

Another common issue involves uneven cutting. Factors like dull blades or improper wheel height settings often lead to this problem. Keeping blades sharp and adjusting the height settings appropriately can enhance the overall cutting performance.

Overheating is also a frequent complaint, which can be caused by debris buildup or insufficient oil levels. Regular cleaning of air filters and monitoring oil levels can mitigate this risk and prolong the machine’s lifespan.

Lastly, users may notice difficulty in maneuvering their equipment. This can be due to worn-out wheels or a malfunctioning drive system. Periodic inspection of these components ensures smooth operation and helps maintain efficiency.

Essential Tools for Repairs

Having the right instruments at your disposal is crucial for efficiently addressing mechanical issues. A well-equipped toolkit not only simplifies the process but also enhances the quality of your work. Below is a list of indispensable devices that every enthusiast should consider for effective maintenance tasks.

| Tool | Description |

|---|---|

| Socket Set | Versatile collection of sockets for loosening and tightening various fasteners. |

| Wrench | Essential for gripping and turning nuts and bolts in tight spaces. |

| Screwdriver Set | Includes both flathead and Phillips varieties for different types of screws. |

| Pliers | Useful for gripping, twisting, and cutting wires or small components. |

| Torque Wrench | Ensures that fasteners are tightened to the correct specifications to prevent damage. |

| Multimeter | Measures electrical properties to diagnose issues in electrical systems. |

| Oil Can | Facilitates lubrication of moving parts to ensure smooth operation. |

| Safety Gear | Protective eyewear and gloves to ensure safety during maintenance activities. |

Step-by-Step Maintenance Guide

Proper upkeep of your outdoor equipment is essential for optimal performance and longevity. This guide provides a structured approach to ensuring your device runs efficiently, minimizing the risk of breakdowns and enhancing its functionality.

Regular Cleaning

Begin by regularly cleaning the exterior and undercarriage of your machine. Remove any debris, grass clippings, and dirt using a brush or a damp cloth. Keeping the components free from buildup not only improves appearance but also prevents rust and ensures smoother operation.

Check and Change Fluids

It’s crucial to monitor and change fluids as needed. Regularly check the oil level and condition; replace it according to the manufacturer’s guidelines. Additionally, inspect any other fluids, such as fuel and coolant, ensuring they are clean and at appropriate levels to maintain optimal function.

Tip: Always consult your user guide for specific recommendations on fluid types and replacement intervals.

By adhering to these steps, you will contribute to the efficiency and durability of your equipment, ensuring it serves you well for years to come.

How to Change the Oil

Changing the lubricating fluid in your machine is a crucial maintenance task that ensures optimal performance and longevity. Regularly updating the oil not only keeps the engine running smoothly but also prevents potential damage caused by old or contaminated oil.

Follow these steps to effectively perform the oil change:

- Gather Necessary Tools:

- New oil

- Oil filter (if applicable)

- Wrench or socket set

- Oil drain pan

- Funnel

- Gloves and rags

- Prepare the Machine:

- Ensure the engine is cool to avoid burns.

- Position the unit on a flat surface.

- Drain Old Oil:

- Remove the oil filler cap.

- Place the drain pan beneath the oil pan.

- Unscrew the drain plug and allow the old oil to flow into the pan.

- Replace Oil Filter (if necessary):

- Locate the oil filter and remove it using an appropriate tool.

- Install the new filter, ensuring it is tightened properly.

- Refill with New Oil:

- Use the funnel to pour in the recommended amount of new oil.

- Check the dipstick to ensure the correct level is achieved.

- Clean Up:

- Replace the drain plug securely.

- Dispose of the old oil and filter responsibly.

Performing this maintenance task regularly will enhance the efficiency and lifespan of your equipment, allowing you to tackle your outdoor tasks with ease.

Replacing the Air Filter

Maintaining optimal performance of your equipment involves regular checks and replacements of essential components. One crucial part that often requires attention is the air filter. A clean air filter ensures that your engine receives the proper airflow, enhancing efficiency and longevity.

Before starting the replacement process, gather the necessary tools: a screwdriver and a new air filter suitable for your specific model. Make sure to consult the specifications to select the correct replacement.

Steps for Replacement:

- Disconnect the power: Always ensure the device is turned off and unplugged to avoid any accidents.

- Locate the air filter housing: This is usually situated near the engine. Remove any covers or screws holding it in place.

- Remove the old filter: Carefully take out the existing filter, being cautious not to let any debris fall into the intake.

- Install the new filter: Place the new filter into the housing, ensuring it fits snugly and securely.

- Reassemble the housing: Replace any covers or screws that were removed, ensuring everything is tightly fastened.

- Reconnect power: Once everything is back in place, restore power and perform a brief check to confirm proper operation.

Regularly changing the air filter can prevent engine damage and maintain peak performance. It’s a simple yet effective way to extend the life of your equipment.

Troubleshooting Engine Problems

Engine issues can significantly hinder the performance of your equipment. Identifying the root cause is essential for effective resolution. This section provides a systematic approach to diagnosing and fixing common engine-related troubles.

Here are some common problems you might encounter:

- Starting Difficulties: If the engine won’t start, check the following:

- Fuel level and quality.

- Battery charge and connections.

- Ignition components for wear or damage.

lessCopy code

- Clogged air filter affecting airflow.

- Fuel lines that may be blocked.

- Overheating due to low oil levels.

- Loose or damaged components.

- Debris lodged in moving parts.

- Worn bearings or belts.

- Fuel quality and mixture.

- Spark plug condition.

- Throttle linkage for proper function.

By systematically addressing these areas, you can enhance the efficiency and longevity of your machinery. Regular maintenance and prompt attention to issues will prevent more significant problems down the line.

Fixing Wheel and Drive Issues

Addressing problems with wheels and drive mechanisms is essential for ensuring optimal performance of your equipment. When these components malfunction, they can significantly impact mobility and functionality. Identifying the root causes and applying effective solutions can restore efficiency and extend the lifespan of your device.

Common Symptoms: Before diving into fixes, it’s crucial to recognize common indicators of wheel and drive issues. If you notice uneven movement, difficulty in acceleration, or complete lack of motion, these signs may point to underlying problems that need attention.

Troubleshooting Steps: Start by examining the wheels for any visible damage, such as cracks or excessive wear. Check the drive belts for signs of fraying or detachment. Ensure that all connections are secure and free from debris. Lubrication of moving parts is also vital; lack of grease can lead to increased friction and performance issues.

Repair Techniques: If you find damaged wheels, consider replacing them with compatible alternatives. For drive belt issues, reinstallation or replacement may be necessary depending on the extent of wear. Regular maintenance, including cleaning and lubrication, will help prevent future complications.

Conclusion: By systematically addressing wheel and drive issues, you can maintain the reliability of your equipment. Regular checks and timely repairs not only enhance performance but also contribute to a more enjoyable experience during operation.

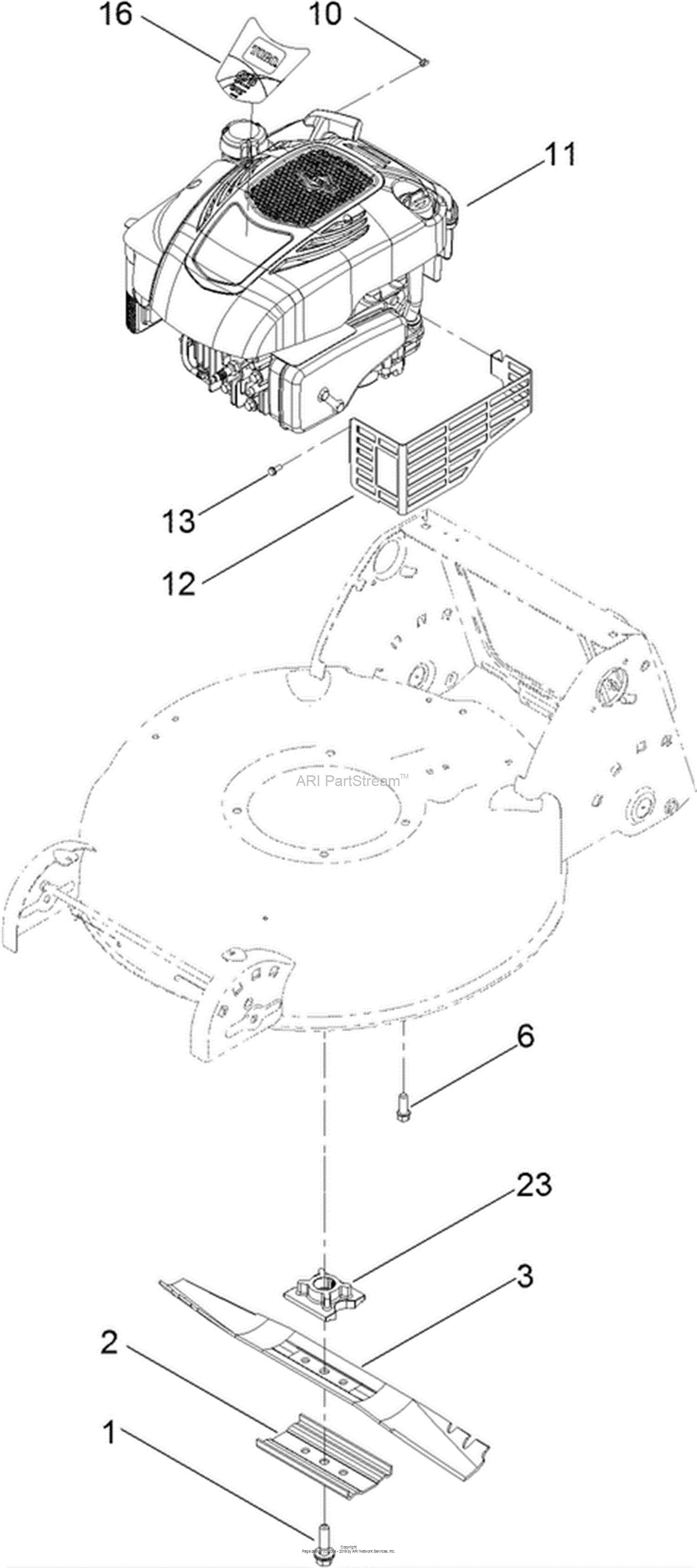

Blade Maintenance and Replacement

Maintaining and replacing cutting implements is essential for ensuring optimal performance and longevity of your gardening equipment. Regular attention to these components not only enhances efficiency but also contributes to a healthier landscape by providing clean cuts.

Inspection is the first step in proper upkeep. Periodically examine the blades for signs of wear, such as chips, dents, or excessive dullness. Keeping blades sharp is crucial; dull edges can damage grass and other plants, leading to unhealthy growth.

To maintain sharpness, sharpening should be done regularly. Use a file or sharpening stone to carefully hone the edges, following the manufacturer’s guidelines for angle and technique. This process should be performed after every few uses or as needed based on performance.

When blades become too damaged or worn beyond repair, replacement is necessary. Ensure you select the correct size and type compatible with your equipment. Follow the manufacturer’s instructions for safe removal and installation, making sure to tighten all fasteners securely to prevent accidents.

In summary, consistent maintenance and timely replacement of cutting implements will not only improve the effectiveness of your equipment but also prolong its lifespan, making your gardening tasks more enjoyable.

Cleaning the Deck Effectively

Maintaining the cleanliness of the deck is crucial for optimal performance and longevity of your equipment. A well-kept surface not only enhances efficiency but also prevents potential damage caused by accumulated debris. This section provides essential steps and tips for achieving a thorough clean.

Here are some effective methods to ensure your deck remains in top condition:

- Gather Necessary Supplies:

- Stiff-bristle brush

- Garden hose or pressure washer

- Cleaning solution (mild detergent recommended)

- Protective gloves

- Prepare the Area:

- Ensure the engine is off and cool.

- Disconnect any power sources if applicable.

- Clear the surrounding area of obstacles.

- Remove Debris:

- Use a brush to dislodge grass clippings and dirt.

- Pay special attention to hard-to-reach areas.

- Wash the Deck:

- Apply the cleaning solution with a brush or cloth.

- Rinse thoroughly with water to remove residue.

- Consider using a pressure washer for stubborn grime.

- Dry and Inspect:

- Allow the surface to dry completely.

- Check for any signs of wear or damage.

Regular cleaning not only improves performance but also extends the life of your machinery. Incorporate these practices into your maintenance routine for best results.

Storing Your Mower Safely

Properly securing your equipment after use is essential for maintaining its longevity and ensuring safety. A well-planned storage strategy can prevent damage, deter pests, and keep your space organized. Here are some key considerations to keep in mind.

Choosing the Right Location

Selecting an appropriate spot for storage is crucial. Consider the following options:

- Indoors: A garage or shed provides protection from weather elements.

- Outdoors: If indoor storage isn’t feasible, choose a sheltered area that is dry and well-ventilated.

Preparing for Storage

Before placing your equipment in storage, take the time to prepare it properly:

- Clean the equipment thoroughly to remove dirt and debris.

- Inspect for any damage and make necessary repairs.

- Empty the fuel tank to prevent degradation over time.

- Check and tighten all bolts and fasteners to ensure stability.

By following these guidelines, you can enhance the durability of your equipment and ensure it remains in optimal condition for the next use.