In the world of outdoor equipment, understanding the intricacies of machinery is crucial for ensuring longevity and optimal performance. This section delves into essential strategies for maintaining and fixing various power tools, focusing on enhancing user experience and functionality.

By familiarizing oneself with the core components and potential issues, operators can significantly reduce downtime and improve efficiency. Whether you are a seasoned professional or a novice, mastering these skills is invaluable for anyone engaged in outdoor maintenance tasks.

Equipping yourself with the right knowledge and techniques will empower you to tackle common challenges effectively. With the right guidance, even the most daunting repairs can become manageable, allowing you to keep your tools in peak condition.

Poulan Pro PP4218AVX Repair Guide

This section offers essential guidance for maintaining and fixing a popular outdoor equipment model. It emphasizes understanding common issues and provides practical steps to enhance performance and longevity. With proper care, users can ensure efficient operation and minimize potential breakdowns.

Identifying Problems: Begin by diagnosing any malfunctions. Pay attention to unusual sounds, decreased power, or failure to start. These signs often indicate the need for immediate attention.

Basic Maintenance: Regular upkeep is crucial. Ensure that the air filter is clean and the fuel system is free from debris. Replace spark plugs periodically to maintain optimal ignition performance.

Tools Required: Gather necessary tools before starting. A set of screwdrivers, wrenches, and pliers will aid in disassembly and reassembly. Additionally, a multimeter can help troubleshoot electrical issues.

Step-by-Step Guidance: Follow a structured approach when addressing issues. Start with external checks, then move to internal components. Document any changes made during the process to track repairs effectively.

Safety Precautions: Always prioritize safety. Disconnect the power source before performing any maintenance. Wear protective gear, including gloves and goggles, to prevent injuries.

Conclusion: By following these guidelines, users can tackle common issues efficiently, ensuring their equipment remains in top condition for years to come.

Common Issues with the Chainsaw

Chainsaws are powerful tools, but they can experience a range of problems that hinder their performance. Understanding these common issues can help users maintain their equipment and troubleshoot effectively.

- Starting Problems:

Difficulty in starting the device is a frequent concern. This can stem from various factors, including:

- Fuel quality or contamination

- Faulty spark plug

- Clogged air filter

- Stalling:

A chainsaw may stall unexpectedly during operation. Possible reasons include:

- Improper fuel mixture

- Overheating due to excessive use

- Blocked exhaust

- Chain Issues:

Problems with the cutting chain can affect performance. Common chain-related issues include:

- Dull or damaged teeth

- Chain tension that is too loose or too tight

- Chain derailment

- Vibration:

Excessive vibration can be uncomfortable and indicate underlying issues, such as:

- Loose components

- Imbalance in the cutting chain

- Worn-out parts

- Oil Leaks:

Oil leaks can lead to operational inefficiencies. Common causes include:

- Worn seals or gaskets

- Damaged oil tank

- Blocked oil passages

lessCopy code

Regular maintenance and prompt attention to these common problems can significantly extend the lifespan of a chainsaw and improve its efficiency.

Essential Tools for Repairing

When undertaking maintenance tasks on outdoor equipment, having the right instruments is crucial for effective troubleshooting and restoration. A well-equipped toolkit not only facilitates the process but also enhances efficiency and precision, allowing for a smoother experience.

Key Instruments to Consider

The following instruments are fundamental for ensuring that any maintenance task can be executed successfully:

| Tool | Purpose |

|---|---|

| Screwdriver Set | Used for loosening and tightening screws of various sizes. |

| Wrench Set | Essential for gripping and turning nuts and bolts securely. |

| Socket Set | Provides better leverage and grip for fasteners, reducing the risk of stripping. |

| Pliers | Ideal for gripping, twisting, and cutting wires or small components. |

| Multimeter | Useful for testing electrical connections and diagnosing issues. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications, preventing damage. |

Additional Considerations

Beyond the basic toolkit, consider including cleaning supplies and safety gear. Keeping instruments organized in a dedicated storage space can also enhance productivity and accessibility during maintenance sessions.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring the longevity and optimal performance of your outdoor equipment. Following a structured maintenance routine can help prevent potential issues and enhance the efficiency of the machinery. This guide outlines straightforward procedures to keep your device in top condition.

Essential Maintenance Tasks

Performing the following tasks regularly will contribute to the smooth operation of your equipment:

| Task | Frequency | Description |

|---|---|---|

| Inspect Air Filter | Every 25 hours | Check for dirt and debris. Clean or replace as necessary to ensure optimal airflow. |

| Sharpen Blades | Every 50 hours | Ensure cutting components are sharp for efficient operation. Use a file or sharpening tool. |

| Check Fuel System | Before each use | Inspect for leaks and ensure fuel is fresh to avoid starting issues. |

| Clean Spark Plug | Every 100 hours | Remove and clean to ensure proper ignition. Replace if heavily worn. |

Final Tips for Optimal Performance

In addition to the tasks listed, always refer to the manufacturer’s guidelines for any specific recommendations. Keeping your machinery clean and stored properly will also help extend its lifespan and maintain performance efficiency.

Troubleshooting Starting Problems

Experiencing difficulties with starting machinery can be frustrating. This section aims to guide users through common issues that may prevent proper ignition and provide potential solutions to ensure smooth operation.

Before diving into specific fixes, it is crucial to check several fundamental components that may affect starting performance. Below is a table summarizing key areas to inspect and potential causes of starting issues:

| Component | Possible Issues | Recommended Actions |

|---|---|---|

| Fuel System | Old or contaminated fuel | Replace with fresh fuel; ensure the fuel line is clear. |

| Spark Plug | Worn or fouled plug | Inspect for damage; clean or replace as necessary. |

| Air Filter | Blocked filter | Clean or replace the air filter to ensure proper airflow. |

| Battery | Weak or dead battery | Test the battery; charge or replace if needed. |

| Starter Assembly | Faulty starter mechanism | Inspect connections and wiring; replace starter if malfunctioning. |

By systematically examining these areas, users can often identify and resolve starting issues effectively, leading to a smoother operational experience.

Replacing the Chain and Bar

Maintaining the cutting components of your tool is crucial for optimal performance. When the chain and bar become worn or damaged, they can significantly affect efficiency and safety. This section outlines the steps for replacing these essential parts to ensure smooth operation.

Before starting the replacement process, gather the necessary tools and ensure you have a compatible chain and bar on hand. This preparation will facilitate a smooth workflow and prevent interruptions.

| Step | Action |

|---|---|

| 1 | Disconnect the power source to avoid accidental activation. |

| 2 | Loosen the tensioning screw to relieve pressure on the chain. |

| 3 | Remove the cover that secures the bar and chain in place. |

| 4 | Carefully slide off the old chain and bar from the guide. |

| 5 | Position the new bar onto the guide and thread the new chain around it. |

| 6 | Reattach the cover and tighten the tensioning screw to secure the new components. |

| 7 | Reconnect the power source and test the tool for proper operation. |

Following these steps will help ensure that the cutting equipment remains effective and reliable. Regular maintenance of these parts can extend the life of your tool and improve your overall experience.

Understanding Engine Components

The internal mechanisms of an engine are vital for its efficient operation and longevity. Each component plays a significant role in the overall functionality, contributing to the seamless conversion of fuel into power. Familiarity with these elements can enhance maintenance practices and troubleshooting capabilities.

Key Components Overview

Engines consist of several crucial parts, including the cylinder, piston, crankshaft, and valves. The cylinder serves as the chamber where combustion occurs, while the piston moves within it, converting fuel energy into mechanical motion. The crankshaft translates this linear movement into rotational power, ultimately driving the machine. Valves regulate the flow of air and fuel into the combustion chamber, ensuring optimal performance.

Importance of Regular Maintenance

Understanding these components is essential for effective upkeep. Regular inspections can identify wear and tear, preventing larger issues from arising. Monitoring parts like the spark plug and fuel filter ensures that the engine operates smoothly, reducing the risk of unexpected breakdowns and extending its lifespan.

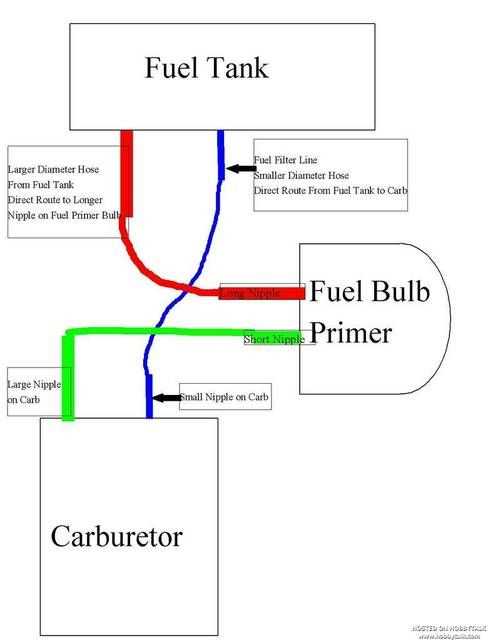

Fuel System Care Tips

Maintaining the fuel system is crucial for optimal performance and longevity of outdoor power equipment. Regular attention to this area ensures that the machinery operates smoothly and efficiently, minimizing the risk of costly repairs and downtime.

1. Use Fresh Fuel: Always use fresh, high-quality fuel to prevent issues related to stale gasoline. Store fuel in a clean, airtight container and use it within a month to maintain its efficacy.

2. Check Fuel Lines: Regularly inspect the fuel lines for any signs of wear, cracks, or leaks. Damaged lines can lead to fuel loss and hinder performance, so replace them as needed.

3. Clean the Fuel Filter: A clogged fuel filter can restrict flow and affect engine performance. Clean or replace the filter according to the manufacturer’s guidelines to ensure a steady fuel supply.

4. Monitor Fuel Levels: Keep an eye on the fuel levels to avoid running the equipment on empty, which can introduce debris into the system. Refilling before it runs low helps maintain clean fuel flow.

5. Use Fuel Stabilizer: When storing the equipment for extended periods, consider adding a fuel stabilizer. This helps prevent the fuel from breaking down and forming deposits that can clog the system.

By following these care tips, users can enhance the reliability and performance of their equipment, ensuring that it operates efficiently for years to come.

Electrical System Diagnostics

Diagnosing issues within the electrical framework of equipment is crucial for optimal performance and longevity. This process involves identifying malfunctions in the wiring, components, and connections that are vital for the proper operation of the machinery.

Initial Assessment: Start by conducting a visual inspection of the electrical system. Look for any signs of wear, damage, or corrosion on connectors and wires. Ensure all connections are secure and free from debris.

Testing Components: Utilize a multimeter to measure voltage, current, and resistance in various parts of the system. This will help in pinpointing faulty components. Focus on switches, fuses, and ignition systems, as these are common sources of electrical problems.

Interpreting Results: Once tests are completed, analyze the data carefully. Any readings outside the expected range may indicate a malfunction. For instance, if a fuse repeatedly blows, it could suggest a short circuit or overload in the system.

Taking Action: After diagnosing the issue, plan the necessary steps for repair or replacement of faulty parts. Regular maintenance checks can help prevent future problems and ensure the system operates smoothly.

Identifying Safety Features

Understanding the essential safety mechanisms in outdoor power equipment is crucial for ensuring user protection and minimizing risks during operation. These features are designed to enhance safety by preventing accidents and promoting responsible use. Recognizing these elements can significantly contribute to safer handling and maintenance practices.

Key Mechanisms to Look For

Among the most important safety features are automatic shut-off systems, which deactivate the equipment when certain conditions are met, preventing potential hazards. Additionally, proper guard placements and ergonomic designs help protect users from accidental contact with moving parts. Recognizing these components is vital for maintaining a safe working environment.

Importance of User Awareness

Users should be aware of safety indicators and warnings present on the equipment. Labels and instructions provide essential information regarding operational limits and safety precautions. Regular checks and adherence to safety guidelines ensure that all mechanisms function effectively, promoting overall safety during use.

Storage Recommendations for Longevity

Proper storage is essential for ensuring the durability and optimal performance of your equipment over time. By following specific guidelines, you can significantly extend its lifespan and maintain its functionality. Here are some key practices to consider when storing your device.

- Clean Before Storage: Always clean the unit thoroughly to remove any debris or residues. This prevents corrosion and damage during the storage period.

- Choose a Suitable Environment: Store the equipment in a cool, dry place. Avoid exposure to extreme temperatures and humidity, as these can lead to deterioration.

- Use Protective Covers: Utilize covers or bags specifically designed for protection against dust and moisture. This will help shield the equipment from potential harm.

- Maintain Fuel Levels: If applicable, drain any fuel to prevent it from deteriorating and causing engine issues. If you choose to leave fuel, add a stabilizer to prolong its life.

- Check for Damage: Regularly inspect the equipment for signs of wear or damage. Address any issues immediately to prevent further complications.

Implementing these recommendations will help ensure that your equipment remains in excellent condition, ready for use whenever needed. Regular maintenance and mindful storage practices are key to achieving longevity.

How to Find Replacement Parts

Locating suitable components for your equipment can significantly enhance its performance and longevity. Understanding where to search and how to identify the right items is crucial for effective maintenance.

Online Retailers: Numerous websites specialize in outdoor machinery parts. Use specific model numbers or component names to refine your search, ensuring you select compatible items.

Manufacturer’s Website: The official site often provides a parts catalog, allowing you to view available components. This resource can also direct you to authorized dealers who carry genuine replacements.

Local Dealers: Visiting nearby shops that sell outdoor equipment can be beneficial. Knowledgeable staff can assist in finding the right parts, and you may even inspect components before purchasing.

Forums and Community Groups: Engaging with enthusiasts in online communities can yield valuable insights. Members often share sources for hard-to-find parts and may offer recommendations based on their experiences.

Parts Catalogs: Physical catalogs from manufacturers or third-party suppliers can be a handy tool. They typically list parts along with diagrams, making it easier to identify what you need.

Tips for Preventive Maintenance

Regular upkeep of your equipment is essential to ensure its longevity and optimal performance. By following a few straightforward guidelines, you can minimize the risk of breakdowns and extend the lifespan of your machinery. This section provides practical suggestions for maintaining your tools in peak condition.

Routine Inspections

Conducting periodic checks is crucial for identifying potential issues before they escalate. Focus on the following areas during your inspections:

| Component | Check Frequency | Maintenance Action |

|---|---|---|

| Air Filter | Every 10 hours | Clean or replace as needed |

| Spark Plug | Every 25 hours | Inspect and replace if worn |

| Fuel System | Before each use | Check for leaks and clean filters |

Lubrication and Cleaning

Maintaining cleanliness and proper lubrication of moving parts helps prevent wear and tear. Regularly apply suitable lubricants and clean debris to enhance functionality and safety.