Understanding the intricacies of a portable sanitation system is crucial for ensuring its longevity and optimal performance. This guide aims to provide insights into common issues that may arise and effective strategies for addressing them. Proper maintenance not only enhances functionality but also contributes to a more pleasant experience during outdoor activities.

Familiarity with the components of your sanitation equipment is the first step toward successful upkeep. Each part plays a vital role, and recognizing potential points of failure can save you time and hassle. This resource will help you navigate through typical challenges, offering practical solutions to keep your system in top condition.

Whether you are preparing for a weekend getaway or using your unit regularly, knowing how to troubleshoot and maintain your setup is essential. By following the guidelines provided, you can confidently manage minor issues and prolong the life of your portable sanitation solution, ensuring comfort and convenience wherever you go.

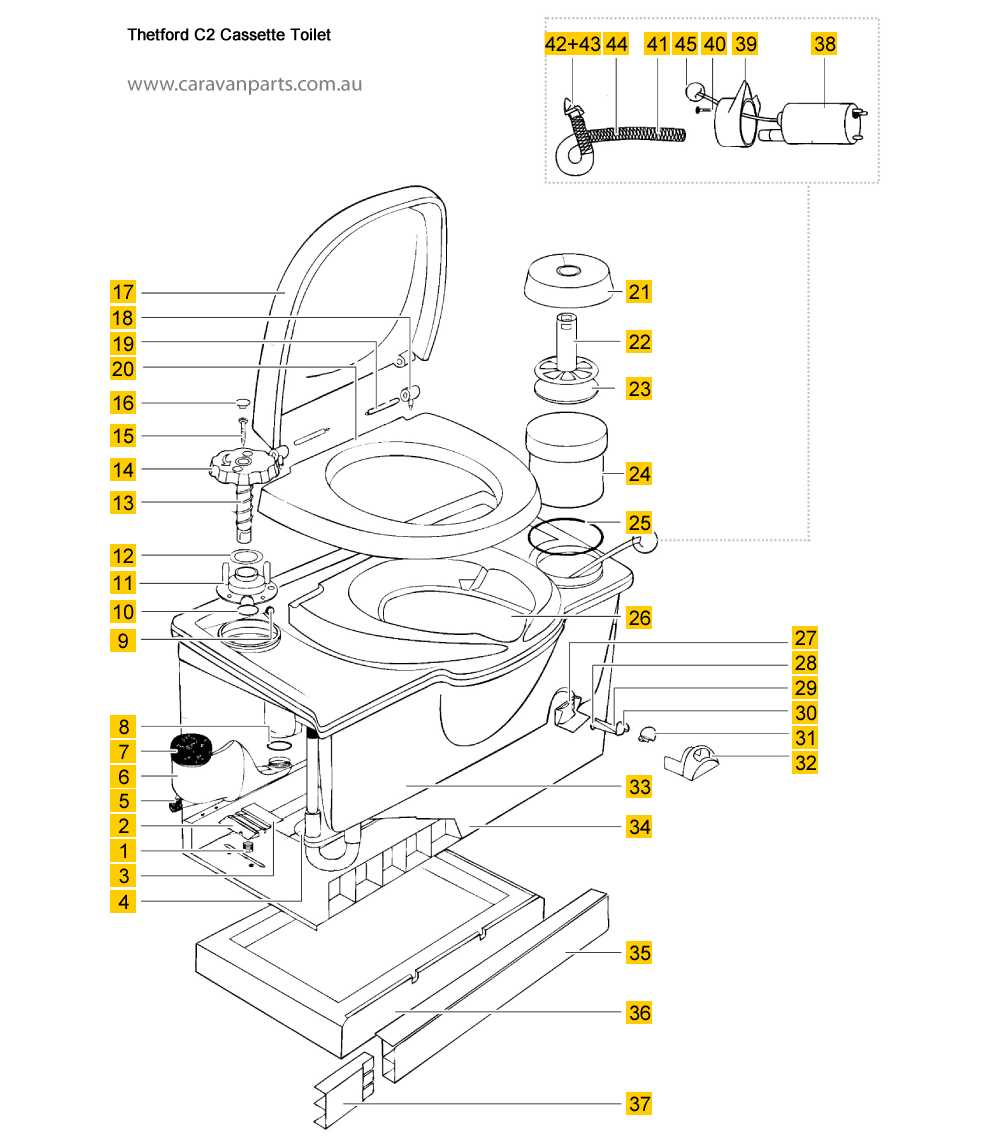

Thetford C2 Toilet Overview

This section provides a comprehensive look at a portable sanitation system designed for ease of use and convenience in various settings. It focuses on key features, functionality, and the overall user experience, making it a valuable asset for camping and outdoor adventures.

Key Features

Among its notable attributes, this unit boasts a compact design, user-friendly operation, and efficient waste management capabilities. Ideal for mobile lifestyles, it facilitates seamless disposal while ensuring hygiene and comfort.

| Feature | Description |

|---|---|

| Compact Size | Space-saving design that fits easily in smaller environments. |

| Ease of Use | Intuitive operation makes it accessible for all users. |

| Efficient Waste Management | Advanced system for effective disposal and odor control. |

User Experience

Users appreciate the combination of practicality and comfort, allowing for a hassle-free experience during outdoor excursions. The thoughtful design ensures that sanitation needs are met without sacrificing convenience.

Common Issues with C2 Toilets

Understanding the frequent challenges encountered with portable sanitation units can greatly enhance user experience and maintenance efficiency. Users may face various obstacles that, if addressed promptly, can ensure optimal functionality and longevity of the system.

| Issue | Description | Possible Solutions |

|---|---|---|

| Leaking | Fluid escape from the unit, often due to worn seals or improper assembly. | Inspect seals for damage, reassemble components tightly, and replace any faulty parts. |

| Odor | Unpleasant smells indicating potential blockages or insufficient cleaning. | Ensure regular cleaning, check for clogs, and use appropriate deodorizing agents. |

| Difficulty in Flushing | Resistance or failure in the flushing mechanism, often linked to air locks or debris. | Examine the flushing system for blockages and clear any accumulated waste. |

| Indicator Issues | Malfunctioning indicators that show incorrect levels of contents. | Check sensor functionality and clean any obstructed parts to restore accuracy. |

Tools Required for Repair

When addressing maintenance issues with your sanitation system, having the right equipment is essential. Proper tools not only facilitate efficient handling but also ensure that the process is safe and effective. Below is a list of items you will need to successfully complete the task.

| Tool | Description |

|---|---|

| Screwdriver Set | Various sizes to accommodate different screws, essential for disassembly. |

| Wrench | Adjustable or socket wrenches for loosening and tightening bolts. |

| Pliers | Useful for gripping, bending, and cutting wires or components. |

| Sealant | Used to prevent leaks and ensure a tight fit between parts. |

| Cleaning Supplies | Brushes, cloths, and disinfectants for thorough cleaning of components. |

| Protective Gear | Gloves and goggles to ensure safety while handling materials. |

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues encountered with portable sanitation units. By following these systematic instructions, you can troubleshoot and resolve problems effectively, ensuring optimal functionality.

Identifying the Issue

Before proceeding with any fixes, it’s essential to determine the specific problem. Common concerns may include:

- Blockages or clogs

- Leakage or fluid retention

- Inconsistent flushing

- Unpleasant odors

Tools Required

Gather the following tools to facilitate the troubleshooting process:

- Wrench

- Screwdriver set

- Rubber gloves

- Cleaning cloths

- Plumbing snake

With the right tools and a clear understanding of the problem, you can proceed with the steps to restore the unit’s efficiency.

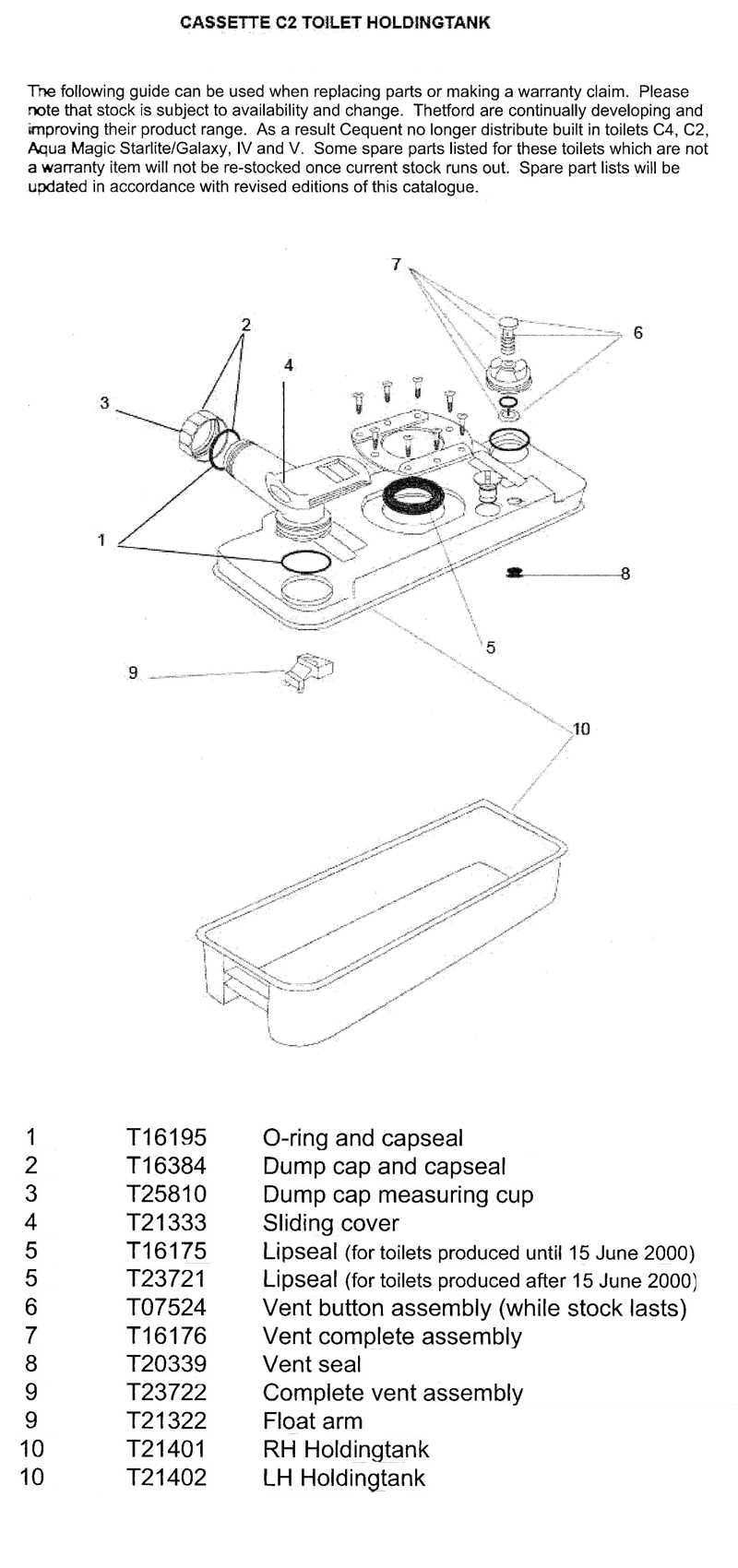

Replacing the Waste Tank

Maintaining proper sanitation in mobile sanitation units is essential for comfort and hygiene. Over time, the waste container may need to be exchanged due to wear and tear or damage. This section will guide you through the process of removing the old reservoir and installing a new one efficiently and safely.

First, ensure that the unit is fully emptied and cleaned. Safety gloves should be worn to protect against any residual materials. Begin by locating the release mechanism, which is typically found at the base of the reservoir. Carefully disengage the locking system to prevent any spills during the removal process.

Once the container is released, gently pull it out from its housing. If the tank is stuck, check for any additional locks or connections that may need to be disengaged. After successfully removing the old tank, inspect the interior for any debris or obstructions that may have accumulated over time.

Next, take the new waste reservoir and align it with the housing. Make sure all seals and connections are intact to ensure a proper fit. Slide the tank back into place until you hear a click, indicating that it is securely locked in. Double-check that all connections are snug and leak-proof before proceeding to test the unit.

Finally, conduct a brief test to ensure the new container functions correctly. Fill it slightly with water to check for leaks and confirm that all components are working as expected. Regular maintenance and timely replacement will enhance the longevity and performance of your sanitation system.

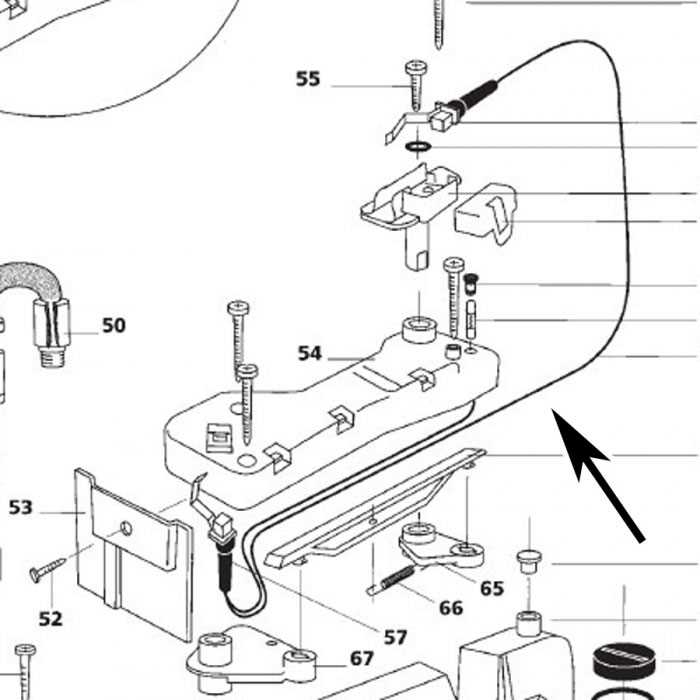

Fixing Flush Mechanism Problems

Addressing issues with the flushing system is essential for ensuring optimal performance and hygiene. Various factors can lead to malfunctions, including clogs, mechanical failures, or improper assembly. Understanding the underlying causes can facilitate effective troubleshooting and restoration of functionality.

Common Issues and Their Solutions

One prevalent problem is a weak flush, which can result from blockages in the pipes or a malfunctioning pump. To resolve this, inspect the lines for any debris and clean them thoroughly. Additionally, ensure that the pump is receiving adequate power and is free of any obstructions.

Checking and Replacing Components

If the flushing action is completely absent, it may be due to a broken or disconnected cable. Carefully examine the linkage for any signs of wear or disconnection. Replacing worn parts is often a straightforward process that can restore proper operation. Always refer to specific guidelines to ensure correct installation and functionality.

Sealing and Gasket Maintenance

Ensuring the integrity of seals and gaskets is crucial for the proper functioning of any sanitation system. These components prevent leaks and maintain pressure, contributing to the overall efficiency and longevity of the unit. Regular maintenance and timely replacements can help avoid potential issues and ensure a smooth operation.

Here are some key practices for maintaining seals and gaskets:

- Regular Inspection: Routinely check seals and gaskets for signs of wear, cracks, or damage. Early detection can prevent more significant problems later.

- Cleaning: Keep surfaces clean to promote proper sealing. Use a mild cleaner and a soft cloth to remove debris or buildup.

- Lubrication: Apply appropriate lubricants to gaskets as recommended. This can help maintain flexibility and prevent cracking.

- Replacement: Follow manufacturer guidelines for when to replace worn or damaged seals. Regular replacement is essential for optimal performance.

By adhering to these maintenance tips, users can ensure that their sanitation systems operate efficiently and without unnecessary complications.

Cleaning Tips for Longevity

Proper maintenance is essential for extending the lifespan of your portable sanitation device. Regular cleaning not only ensures optimal performance but also enhances hygiene and comfort during use. This section provides practical advice to keep your unit in top condition, ensuring it serves you well for years to come.

Essential Cleaning Practices

Adopting a routine cleaning regimen can make a significant difference. Focus on the following practices:

| Task | Frequency | Recommended Products |

|---|---|---|

| Empty and rinse | After each use | Freshwater |

| Deep clean surfaces | Weekly | Non-toxic cleaners |

| Check seals and connections | Monthly | Silicone lubricant |

Additional Tips

Utilizing specific techniques can enhance the cleaning process. Consider the following:

- Use soft cloths or sponges to avoid scratching surfaces.

- Ensure all components are dry before reassembling to prevent mold growth.

- Store in a cool, dry place when not in use.

Troubleshooting C2 Electrical Components

When dealing with electrical systems in portable sanitation devices, it’s essential to identify and address common issues that may arise. Proper diagnostics can enhance functionality and ensure a seamless user experience. This section focuses on various electrical components, their potential problems, and practical solutions.

Power Supply Issues

One of the most frequent challenges encountered is a lack of power. This can stem from a faulty connection, a blown fuse, or a depleted battery. Begin by checking all connections to ensure they are secure. If the device operates on batteries, confirm they are charged and properly installed. For units relying on a power source, inspect the fuse and replace it if necessary.

Switch Malfunctions

Switches are crucial for controlling operation. If a switch fails, it may not activate the system as intended. Test the switch with a multimeter to determine if it is functioning correctly. If not, consider replacing it to restore functionality.

Indicator Lights and Sensors

Indicator lights provide vital feedback on system status. If lights do not illuminate or behave erratically, this may indicate a malfunction. Inspect the bulbs and connections, replacing any faulty components. Additionally, sensors that monitor levels can become misaligned or obstructed, leading to inaccurate readings. Cleaning and recalibrating these sensors can resolve many issues.

Wiring Problems

Wiring issues can result in intermittent faults or complete system failure. Visually inspect wires for any signs of wear, corrosion, or damage. Ensure that all connections are tight and that there are no exposed wires. Repair or replace damaged sections as needed.

By systematically addressing these areas, users can effectively troubleshoot and rectify electrical complications, ensuring reliable operation of their portable sanitation equipment.

Upgrading Your Toilet System

Enhancing your waste disposal system can significantly improve your overall experience while using your mobile living space. Upgrades can range from simple component replacements to more advanced features that enhance comfort and efficiency. By investing in modern alternatives, you not only increase functionality but also ensure a more pleasant environment during your travels.

Consider Modern Technologies

Exploring the latest technologies can lead to a more efficient and user-friendly setup. Innovations such as improved flushing mechanisms and water-saving designs can help conserve resources while maintaining optimal performance. Additionally, systems equipped with built-in sensors can provide real-time feedback on waste levels, alerting you when maintenance is needed.

Enhancing Comfort and Convenience

Improving comfort can be achieved through various additions, such as upgraded seating or enhanced ventilation systems. Options like heated seats or odor-control features can create a more inviting space. Consider integrating storage solutions that allow for easy access to necessary supplies, ensuring that your setup remains functional and user-friendly.

Safety Precautions During Repair

Ensuring a safe environment while conducting maintenance tasks is crucial. Proper precautions help prevent accidents and injuries, safeguarding both the individual and the surrounding area. Adhering to guidelines and utilizing appropriate tools contributes significantly to a smooth and efficient process.

First and foremost, it is essential to wear suitable personal protective equipment. Gloves, goggles, and masks can protect against potential hazards, including chemicals or sharp objects. Additionally, ensuring that the workspace is well-ventilated can mitigate risks associated with fumes or dust.

Before beginning any work, always disconnect the power supply and, if applicable, shut off water sources. This step prevents unwanted leaks and electrical shocks, creating a safer atmosphere. It is also advisable to familiarize oneself with the components involved to avoid unnecessary mishandling.

Maintaining a tidy workspace is equally important. Clutter can lead to slips and falls, which can cause serious injuries. Organizing tools and materials not only enhances safety but also improves efficiency during the task.

Lastly, if unsure about any procedure, consulting with a professional or referring to reliable resources can provide additional guidance. Taking the time to ensure safety not only protects the individual but also enhances the longevity and functionality of the system being addressed.

When to Seek Professional Help

Understanding when to call in experts is crucial for maintaining functionality and preventing further issues. While some problems may be manageable on your own, others require specialized knowledge and tools.

Consider professional assistance in the following situations:

- Persistent Issues: If problems persist despite your efforts, it may indicate a deeper underlying issue.

- Complex Repairs: Tasks involving intricate components or systems are often best left to those with expertise.

- Time Constraints: If you’re short on time, hiring a professional can save you from prolonged inconvenience.

- Safety Concerns: If any aspect poses a risk to your health or safety, it’s wise to consult a qualified technician.

- Warranty Considerations: If your unit is still under warranty, repairs by unauthorized individuals may void it.

Seeking help from professionals ensures that issues are addressed correctly, minimizing the risk of future complications. Prioritizing safety and efficiency can save you both time and money in the long run.