In the world of welding, ensuring that your equipment operates at peak efficiency is crucial for achieving high-quality results. Understanding the intricacies of your apparatus can significantly extend its lifespan and enhance performance. This section aims to provide essential insights into the upkeep and troubleshooting of your welding device, allowing you to navigate common challenges with ease.

Whether you’re a seasoned professional or a newcomer to the trade, having access to detailed information can make all the difference. From basic adjustments to more complex repairs, knowledge of the components and their functions is vital. By following systematic approaches to maintenance, you can not only resolve issues promptly but also prevent potential breakdowns.

Utilizing this guide will empower you to tackle various problems confidently. With a focus on practical tips and systematic procedures, you’ll learn how to optimize your equipment for better performance. Equip yourself with the necessary skills and information to ensure that your welding tasks are executed smoothly and effectively.

Overview of Lincoln SA-250

This section provides a comprehensive understanding of a renowned portable welding machine, known for its reliability and efficiency. Designed for heavy-duty tasks, this equipment is widely used in various industries, from construction to manufacturing.

Key Features

- Powerful engine that ensures consistent performance

- Robust construction for enhanced durability

- User-friendly interface for easy operation

- Versatile applications, accommodating different welding techniques

Applications

- Pipeline construction

- Heavy equipment repair

- Structural fabrication

- Field welding operations

Overall, this equipment stands out due to its blend of power, versatility, and ease of use, making it a top choice for professionals in various sectors.

Common Issues with Lincoln SA-250

This section addresses frequent problems encountered with a specific type of portable welding machine. Understanding these issues can help users maintain optimal performance and extend the lifespan of their equipment. Below are some common challenges operators may face, along with suggested solutions.

Electrical Problems

One of the most prevalent issues involves electrical components, which may lead to inconsistent performance. Common signs include difficulty starting, erratic operation, or power loss during use.

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Difficulty Starting | Weak battery, faulty ignition | Check battery charge, inspect ignition system |

| Power Loss | Loose connections, damaged cables | Secure connections, replace damaged cables |

Fuel System Issues

Another common area of concern relates to the fuel system. Problems here can affect performance and efficiency, leading to frustration during operations.

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Engine Stalling | Clogged fuel filter, old fuel | Replace fuel filter, use fresh fuel |

| Poor Fuel Efficiency | Incorrect carburetor settings | Adjust carburetor for optimal performance |

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of machinery requires regular upkeep and attention to detail. Implementing a consistent maintenance schedule not only extends the life of the equipment but also enhances its efficiency. Below are some essential practices to consider for maximizing longevity.

Regular Inspections

Conducting frequent evaluations can help identify potential issues before they escalate into significant problems. Pay close attention to the following components:

| Component | Inspection Frequency | Notes |

|---|---|---|

| Oil Levels | Every Week | Check for leaks and ensure proper viscosity. |

| Filters | Monthly | Replace as needed to prevent clogging. |

| Electrical Connections | Every 3 Months | Ensure all connections are secure and free of corrosion. |

| Cooling System | Every 6 Months | Inspect for blockages and proper fluid levels. |

Proper Storage Practices

When equipment is not in use, appropriate storage is crucial. Protecting it from environmental factors can prevent unnecessary wear. Consider the following guidelines:

- Store in a dry, temperature-controlled environment.

- Cover with protective materials to guard against dust and moisture.

- Keep away from direct sunlight to avoid damage to external components.

Essential Tools for Repairs

When it comes to maintaining and fixing machinery, having the right equipment at your disposal is crucial. The following section outlines the fundamental tools that will enable effective servicing, ensuring that tasks are completed efficiently and safely.

Basic Hand Tools

- Wrenches: Essential for loosening or tightening bolts and nuts, adjustable and fixed options are both beneficial.

- Screwdrivers: A variety of sizes and types, including flathead and Phillips, are necessary for various fasteners.

- Pliers: Useful for gripping, bending, and cutting wires or small components.

- Socket Set: Provides versatility and efficiency in handling different sizes of fasteners.

Power Tools

- Drill: A must-have for creating holes or driving screws into various materials.

- Angle Grinder: Ideal for cutting, grinding, or polishing metal surfaces.

- Impact Wrench: Highly effective for loosening or fastening stubborn nuts and bolts.

- Portable Generator: Provides power for tools when working in remote locations.

Equipping yourself with these tools will greatly enhance your ability to tackle a variety of tasks, ensuring your equipment remains in optimal condition.

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues encountered during operation. By following a structured procedure, you can effectively diagnose and rectify faults, ensuring optimal performance of the equipment.

Preparation Phase

Before initiating any troubleshooting process, it is crucial to gather the necessary tools and materials. This phase includes assessing the environment, ensuring safety protocols are in place, and compiling a list of required components.

| Tool/Material | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts |

| Screwdriver | For accessing internal components |

| Multimeter | For checking electrical connections |

| Lubricant | To reduce friction on moving parts |

Diagnostic Process

Once preparation is complete, proceed with the diagnostic steps. Start by observing the unit’s behavior and identifying any unusual sounds or malfunctions. Document your findings, then move on to inspecting each component methodically.

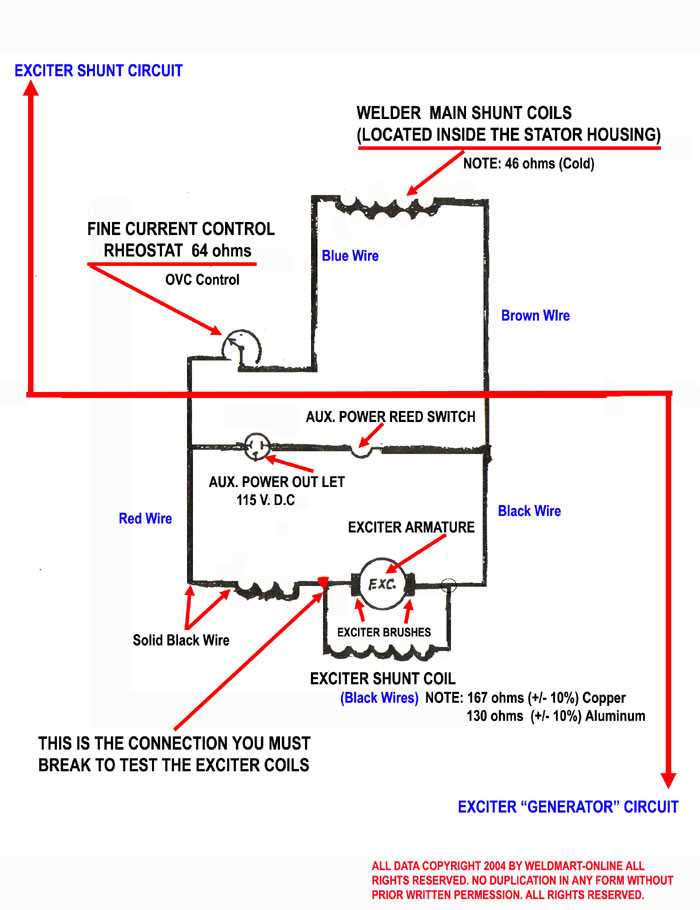

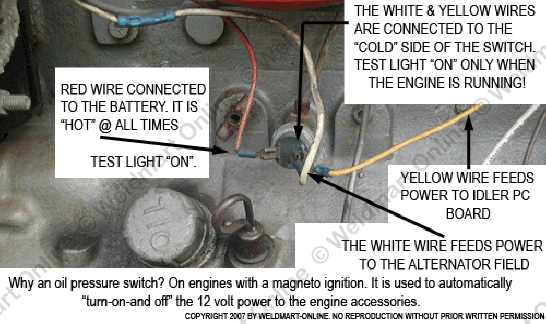

Troubleshooting Electrical Problems

When dealing with electrical issues in machinery, a systematic approach is essential for identifying and resolving malfunctions. These problems can manifest in various forms, such as inconsistent power delivery, erratic behavior, or complete failures. By understanding common symptoms and applying logical diagnostic techniques, you can effectively pinpoint the source of the trouble.

Start by inspecting all connections to ensure they are secure and free from corrosion. Loose or damaged wires can lead to interruptions in the electrical flow, causing unreliable operation. If necessary, use a multimeter to check the continuity of the circuits, ensuring that electricity is traveling through the intended paths.

Next, examine the fuses and circuit breakers for any signs of failure. A blown fuse or tripped breaker can interrupt power supply and should be replaced or reset accordingly. Additionally, be on the lookout for any unusual odors or visual signs of damage, such as burnt components, which may indicate overheating or short circuits.

Lastly, consider the role of the electrical components themselves. Test relays, switches, and solenoids to confirm they are functioning properly. If any part appears faulty, replacing it may resolve the issues at hand. Maintaining a methodical approach will help ensure that all potential electrical problems are addressed effectively.

Fuel System Maintenance Techniques

Maintaining the fuel system is crucial for ensuring optimal performance and longevity of your equipment. Regular attention to this area can prevent costly repairs and enhance efficiency. Understanding the components and their functions is key to effective upkeep.

Inspection of the fuel lines and connections is essential. Look for any signs of leaks or wear, as these can lead to significant issues if left unaddressed. Checking for clogs in filters should also be a routine practice, as dirty filters can restrict flow and reduce overall performance.

Another important aspect is cleaning. Periodic cleaning of fuel injectors and the tank can prevent the buildup of contaminants that might compromise functionality. Using appropriate solvents and cleaning agents ensures that the system remains clear and efficient.

Lastly, testing the fuel system’s pressure can help identify potential problems early. Maintaining the correct pressure is vital for optimal operation, and monitoring this can lead to a more reliable performance overall.

Replacing Components Safely

Ensuring the safe replacement of parts is crucial for maintaining the performance and longevity of any equipment. Proper procedures not only protect the integrity of the machinery but also safeguard the user from potential hazards. This section outlines essential practices that should be followed during component swaps to mitigate risks and ensure efficiency.

Preparation is key to a successful replacement process. Before beginning, it is important to gather all necessary tools and components, ensuring everything is compatible and in good condition. Familiarize yourself with the equipment’s specifications and the specific requirements for the parts you intend to replace. This preliminary step reduces the likelihood of mistakes and enhances safety.

Next, power down the device completely. Disconnect it from any power sources to prevent accidental activation while you work. Utilize lockout/tagout procedures if applicable, as they provide an additional layer of safety by ensuring that the equipment remains inoperable during maintenance.

When handling parts, wear appropriate personal protective equipment. Gloves, safety glasses, and other protective gear can prevent injuries and ensure a safe working environment. Additionally, keep the workspace organized and free from clutter to minimize the risk of accidents.

During the actual replacement, follow manufacturer guidelines closely. Adhering to specified torque settings and connection methods is essential for the correct assembly of components. If any issues arise during the process, do not hesitate to consult resources or seek assistance from knowledgeable professionals.

Finally, after completing the replacement, conduct a thorough inspection before reactivating the equipment. Check for any loose connections or visible damage. This final step can prevent further complications and ensure that the machinery operates smoothly and safely.

Upgrading Your Lincoln SA-250

Enhancing your equipment can significantly improve performance and efficiency. This section explores various strategies to elevate your machine’s capabilities, ensuring it meets your evolving needs and expectations.

Key Areas for Improvement

Consider focusing on the electrical system, fuel efficiency, and overall mobility. Upgrading components like the generator or adding a more efficient exhaust system can lead to substantial enhancements. Regular maintenance of these areas also contributes to longevity and reliability.

Benefits of Modernization

Implementing advanced features not only boosts performance but also increases safety and ease of use. For instance, integrating modern technology can provide better diagnostics and monitoring, allowing for more precise operation and timely maintenance. Investing in these upgrades ultimately leads to a more productive experience.

Understanding Engine Performance Metrics

Engine performance metrics are essential indicators that help assess how effectively an engine operates. These metrics provide insights into various aspects of performance, efficiency, and reliability. By analyzing these parameters, operators can make informed decisions regarding maintenance, adjustments, and overall engine management.

Key Performance Indicators

- Horsepower: A measure of the engine’s power output, indicating how much work it can perform over time.

- Torque: Represents the rotational force produced by the engine, crucial for understanding acceleration and load capacity.

- Fuel Efficiency: Often measured in miles per gallon (MPG), this metric indicates how effectively the engine converts fuel into usable energy.

- RPM (Revolutions Per Minute): Reflects the engine speed, influencing performance and power delivery.

Analyzing Performance Metrics

To fully grasp engine performance, it is important to evaluate these metrics collectively rather than in isolation. Here are some factors to consider:

- Operational Conditions: Factors like temperature and altitude can significantly impact performance metrics.

- Engine Load: Understanding how different loads affect horsepower and torque is critical for optimal performance.

- Maintenance Practices: Regular servicing can enhance metrics by ensuring the engine operates at its best.

By keeping a close watch on these indicators, users can enhance engine longevity and efficiency, leading to improved performance and reduced operational costs.

Parts List for Lincoln SA-250

This section provides a comprehensive inventory of essential components for the specific model, ensuring proper functioning and maintenance. Each item is critical to the overall performance and reliability of the equipment, allowing users to identify and source replacements as needed.

Essential Components

Key elements include the engine, electrical systems, and various mechanical parts. Understanding the specifications of these components helps in selecting the right replacements and maintaining optimal performance.

Maintenance and Replacement Parts

Regular upkeep is vital for longevity. Commonly replaced items such as filters, belts, and hoses should be monitored and substituted as required to prevent operational issues.

Resources for Further Learning

Exploring additional materials can greatly enhance your understanding and skills in the field. Whether you’re looking to deepen your technical expertise or broaden your knowledge, a variety of resources are available to support your journey. From online courses to instructional videos, these tools can provide valuable insights and practical guidance.

Online Courses and Tutorials

Many platforms offer comprehensive courses tailored to various skill levels. These programs often include video lectures, interactive exercises, and assessments to ensure effective learning. Look for platforms that specialize in technical training, as they typically provide up-to-date content relevant to current practices.

Community Forums and Discussion Groups

Engaging with peers in discussion forums can be an excellent way to share experiences and seek advice. Many communities focus on specific areas of interest, allowing you to connect with others who have similar goals. Participating in these groups can also lead to discovering additional resources, such as articles and expert opinions.