This section provides a comprehensive overview of the essential processes required to ensure the longevity and optimal functioning of your writing apparatus. By following a systematic approach, users can enhance their experience and preserve the quality of their equipment.

Understanding the intricacies of your tool can significantly contribute to its performance. From basic upkeep to troubleshooting common issues, this guide aims to equip users with the knowledge needed to navigate any challenges that may arise.

Through careful attention to detail and proactive measures, you can prevent minor problems from escalating. Emphasizing routine checks and maintenance practices will ultimately lead to a more satisfying and reliable experience.

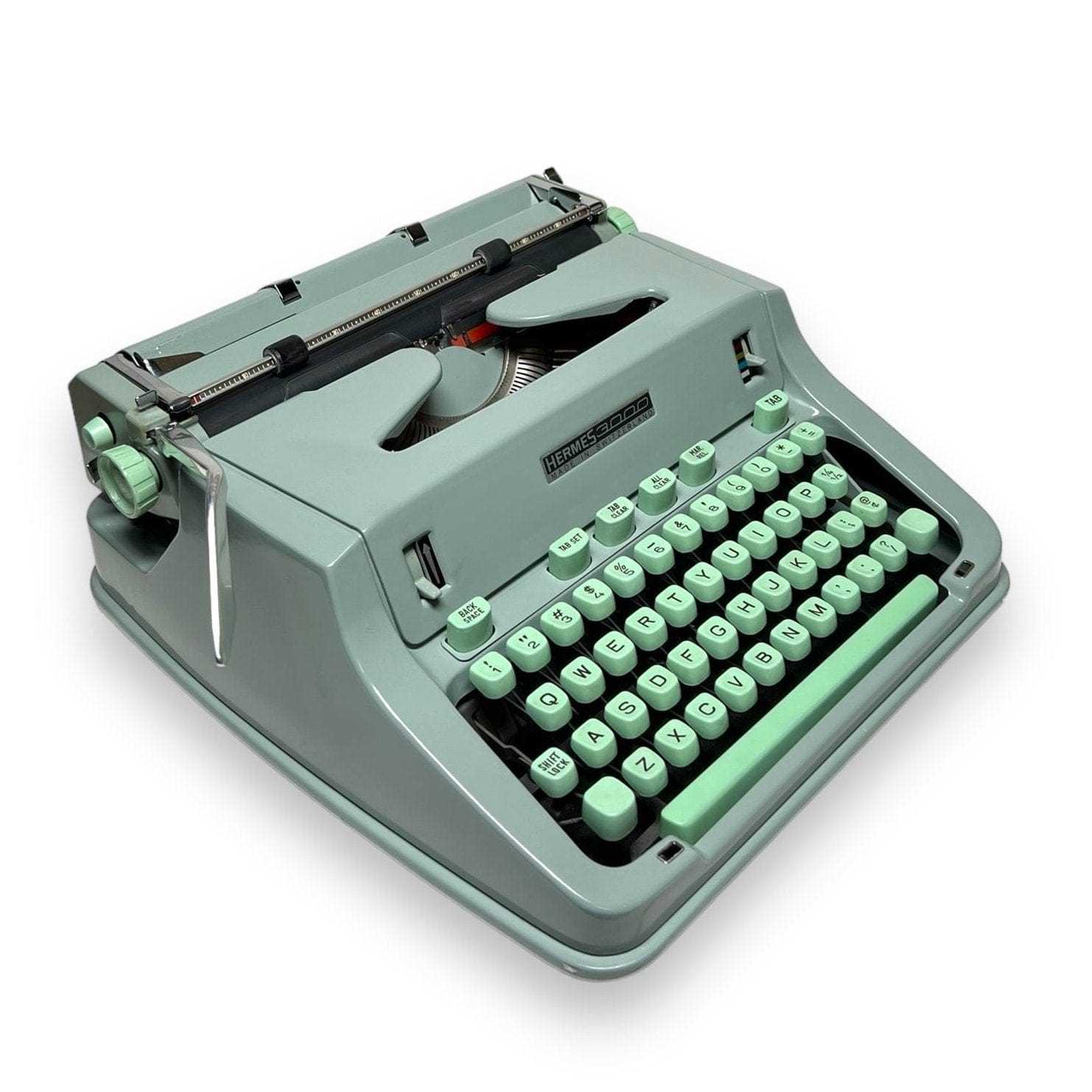

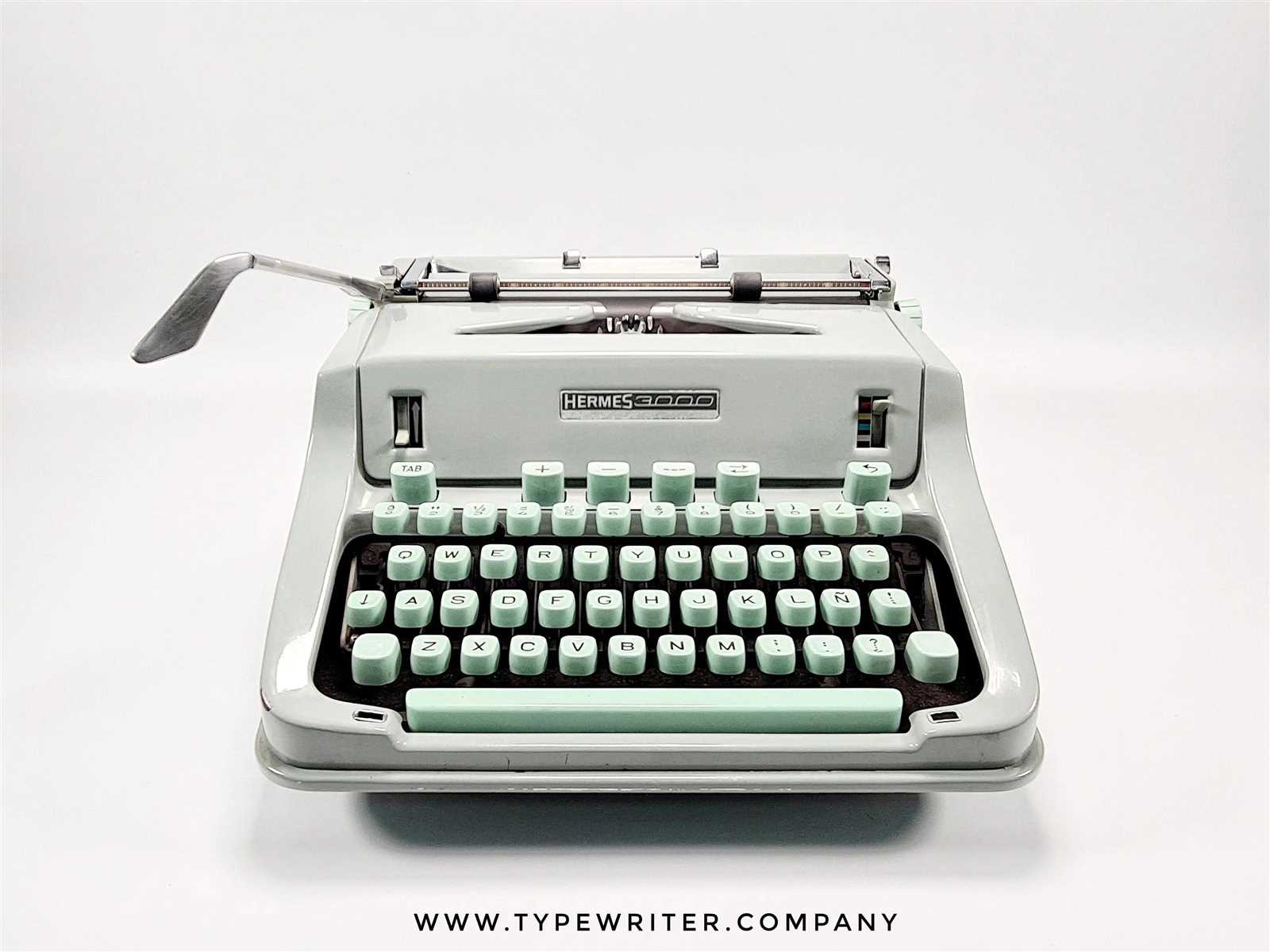

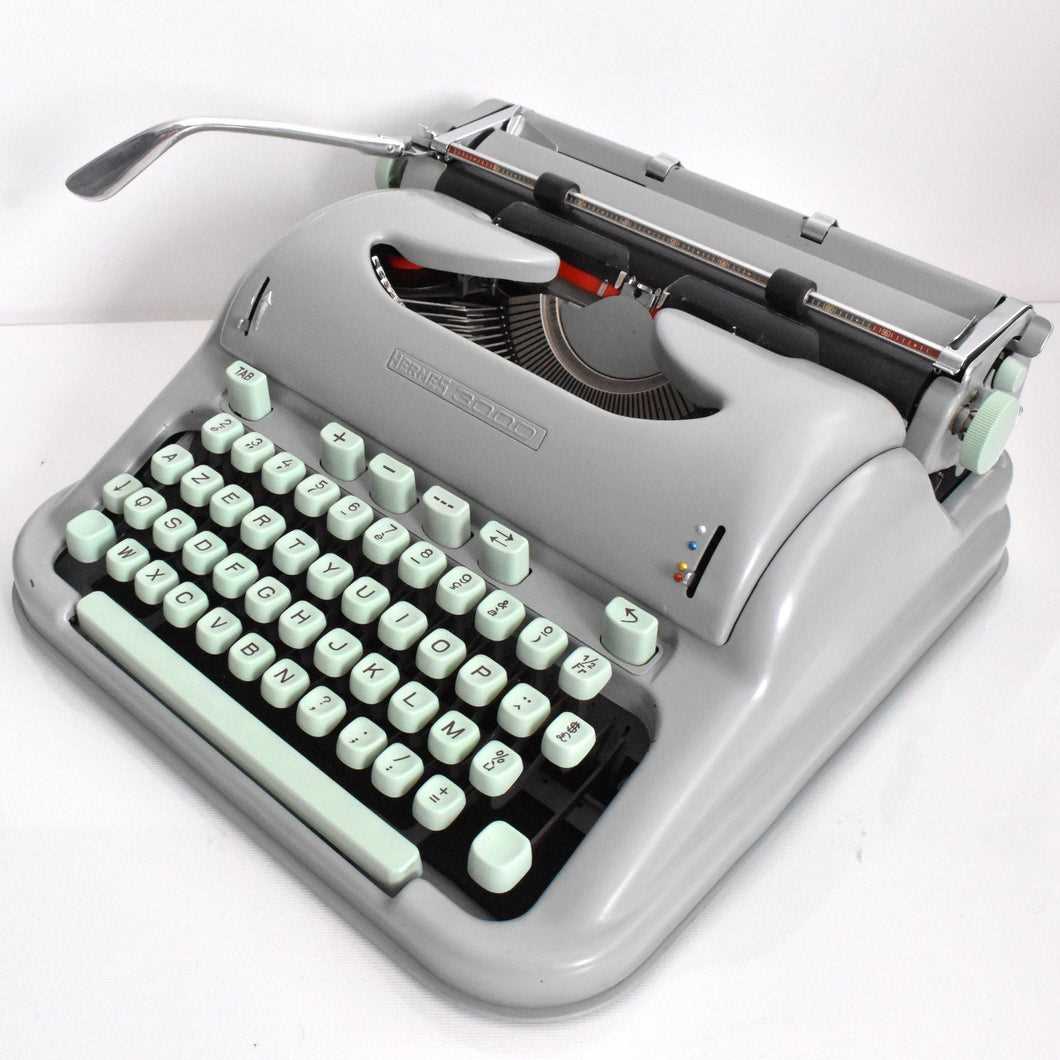

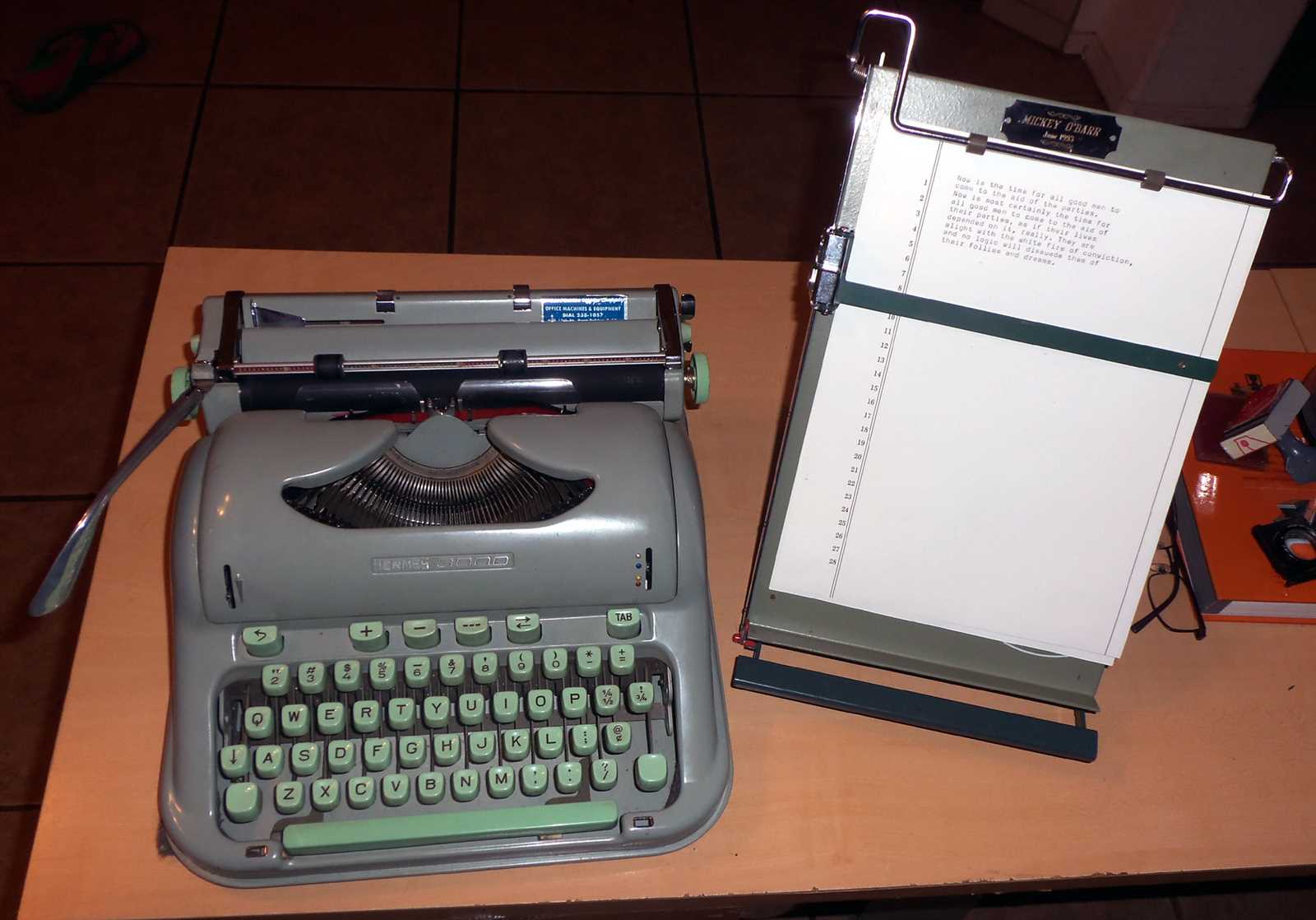

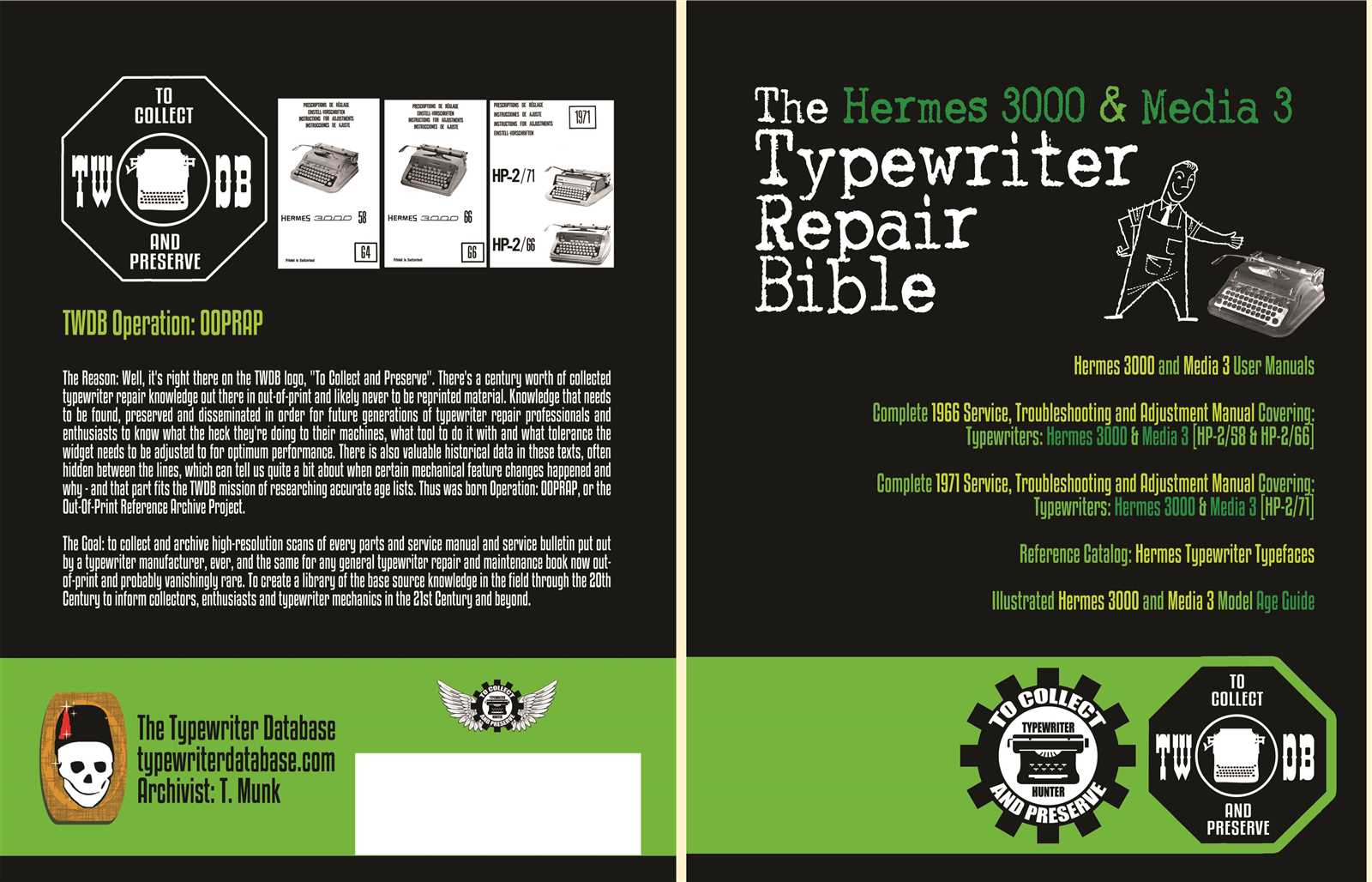

Understanding Hermes 3000 Components

In any complex device, grasping the intricacies of its individual parts is crucial for effective functionality and longevity. Each element plays a specific role, contributing to the overall performance and user experience. A thorough comprehension of these components can significantly enhance one’s ability to maintain and troubleshoot the system.

One key aspect to consider is the mechanical assembly, which encompasses the framework and moving parts. This assembly must work seamlessly to ensure smooth operation and durability. Additionally, electrical elements serve as the brain of the device, enabling communication between various components and facilitating the execution of commands.

Furthermore, the input and output mechanisms are essential for interaction, allowing users to engage with the device effectively. Understanding how these mechanisms function and their interrelations can lead to more informed decisions regarding upgrades or replacements, ultimately optimizing performance.

By delving into these components, users can gain invaluable insights that empower them to handle their device with confidence and skill. Whether addressing minor issues or planning enhancements, a solid grasp of the internal workings is indispensable.

Common Issues and Solutions

This section addresses frequent challenges encountered with this type of device and offers effective strategies for resolving them. Understanding these typical problems can significantly enhance user experience and prolong the lifespan of the equipment.

One of the most prevalent difficulties users face is inconsistent performance. This often stems from issues such as improper alignment or insufficient maintenance. Regularly checking the alignment and ensuring all moving parts are clean can mitigate these problems.

Another common concern involves malfunctioning keys or controls. Dust and debris can accumulate over time, leading to unresponsive buttons. Cleaning the keyboard gently with a soft brush or compressed air can restore functionality.

Lastly, users might experience connectivity issues when interfacing with other devices. Ensuring that all connections are secure and inspecting cables for wear can often resolve these disruptions. If problems persist, consulting technical support may be necessary.

Step-by-Step Repair Guide

This section provides a detailed approach to addressing common issues encountered with the device. By following a systematic procedure, you can effectively troubleshoot and restore functionality, ensuring optimal performance.

1. Identify the Problem: Begin by observing the symptoms. Take note of any unusual sounds, malfunctions, or error messages that may indicate underlying issues.

2. Gather Necessary Tools: Before commencing, collect all essential tools required for the task. This may include screwdrivers, pliers, and cleaning materials.

3. Disassemble the Unit: Carefully open the device to access internal components. Ensure to document the process to facilitate reassembly later.

4. Inspect Components: Examine each part for signs of wear or damage. Look for loose connections, dirt buildup, or broken elements that may hinder functionality.

5. Make Necessary Adjustments: Clean components as needed and tighten loose connections. Replace any damaged parts with compatible replacements to restore proper operation.

6. Reassemble the Device: Once adjustments are complete, carefully reassemble the unit, ensuring all pieces are securely in place.

7. Test Functionality: After reassembly, power on the device to verify that all issues have been resolved. Conduct thorough tests to confirm that everything operates smoothly.

8. Document the Process: Keep a record of the steps taken and any findings. This information can be invaluable for future reference and troubleshooting.

Tools Needed for Maintenance

Proper upkeep of your device requires a selection of essential instruments to ensure effective functionality. Using the right tools can significantly enhance the maintenance process, making it more efficient and straightforward.

- Screwdrivers: A set of flathead and Phillips screwdrivers is crucial for accessing various components.

- Wrenches: Adjustable and fixed wrenches are necessary for tightening or loosening bolts and nuts.

- Pliers: Needle-nose and standard pliers help in gripping and maneuvering small parts.

- Cleaning Supplies: Soft cloths and brushes are important for removing dust and debris from delicate surfaces.

- Lubricants: Appropriate oils or greases ensure smooth operation of moving parts.

- Multimeter: This tool is essential for checking electrical connections and diagnosing potential issues.

- Safety Gear: Gloves and goggles should be worn to protect against any accidents during maintenance.

Equipping yourself with these tools will enable you to perform necessary tasks effectively, prolonging the lifespan of your equipment.

Replacing Worn Parts Effectively

Maintaining optimal performance of your device involves timely substitution of components that show signs of deterioration. Ensuring that replacements are carried out correctly enhances longevity and functionality, contributing to a seamless user experience.

To effectively manage the replacement process, consider the following steps:

- Identify the Affected Components: Regularly inspect parts for wear and tear. Look for signs such as unusual noises, decreased efficiency, or visible damage.

- Select Quality Replacements: Opt for high-quality substitutes that meet or exceed the original specifications. This ensures compatibility and durability.

- Gather Necessary Tools: Before starting, ensure you have all required tools on hand. This may include screwdrivers, pliers, or specialized equipment.

- Follow Correct Procedures: Adhere to the recommended guidelines for disassembly and assembly. This minimizes the risk of errors and damages during the process.

- Test Functionality: After installation, perform tests to confirm that the new parts are functioning as intended. This step is crucial to ensure everything is in order.

By following these guidelines, you can maintain the efficiency and reliability of your equipment, ensuring it serves you well for years to come.

Troubleshooting Electrical Problems

When facing issues related to electrical components, it’s essential to follow a systematic approach to identify and resolve the faults effectively. Common problems often arise from connections, power supply, or component failures. By carefully examining each part of the system, users can restore functionality and ensure optimal performance.

Identifying Common Issues

Begin by checking the power source to confirm that it is delivering the appropriate voltage. Inspect all connections for signs of wear, corrosion, or loosening. Any damaged wiring can lead to intermittent functionality or complete failure. Utilize a multimeter to test for continuity and voltage at various points in the circuit.

Resolving Electrical Faults

If a specific component is suspected to be faulty, consider replacing it with a new part or a known working unit. Ensure that the replacement matches the required specifications to prevent further complications. After making any repairs, conduct a thorough test to confirm that the system is operating correctly.

Cleaning and Care Instructions

Maintaining your device in optimal condition is essential for its longevity and performance. Regular cleaning and proper care can prevent wear and ensure smooth operation over time. This section outlines effective techniques and recommendations to keep your equipment functioning at its best.

Daily Maintenance

To preserve the appearance and functionality, wipe the surface with a soft, lint-free cloth after each use. Avoid using abrasive materials that can scratch the finish. Additionally, ensure that any openings are free from dust and debris to prevent internal issues.

Deep Cleaning Procedures

For a more thorough clean, unplug the device and use a slightly damp cloth to clean the exterior. For stubborn stains, a mild soap solution can be applied, followed by drying with a clean cloth. Ensure no moisture enters any openings. Regularly check the components for any signs of wear, and address them promptly to maintain optimal performance.

Improving Performance and Longevity

Enhancing the efficiency and lifespan of your device involves a combination of regular maintenance practices and mindful usage. By following certain guidelines, you can ensure that the machine operates at its best while minimizing the likelihood of wear and tear.

Regular Cleaning: Keeping the exterior and interior free of dust and debris is crucial. Accumulated particles can hinder performance and cause unnecessary strain on components. Use appropriate cleaning tools to maintain a pristine condition.

Routine Inspections: Periodically checking all parts for signs of wear or damage allows for timely interventions. Addressing minor issues before they escalate can save time and resources, ensuring smooth operation.

Optimal Usage Practices: Operating the device within its designed parameters is essential for longevity. Avoid overloading or pushing it beyond its limits, as this can lead to premature deterioration.

Quality Lubrication: Applying suitable lubricants to moving parts reduces friction and enhances efficiency. Ensure that you use products recommended by the manufacturer to achieve the best results.

By implementing these strategies, you can significantly improve functionality and extend the working life of your equipment, ensuring reliable performance over the years.

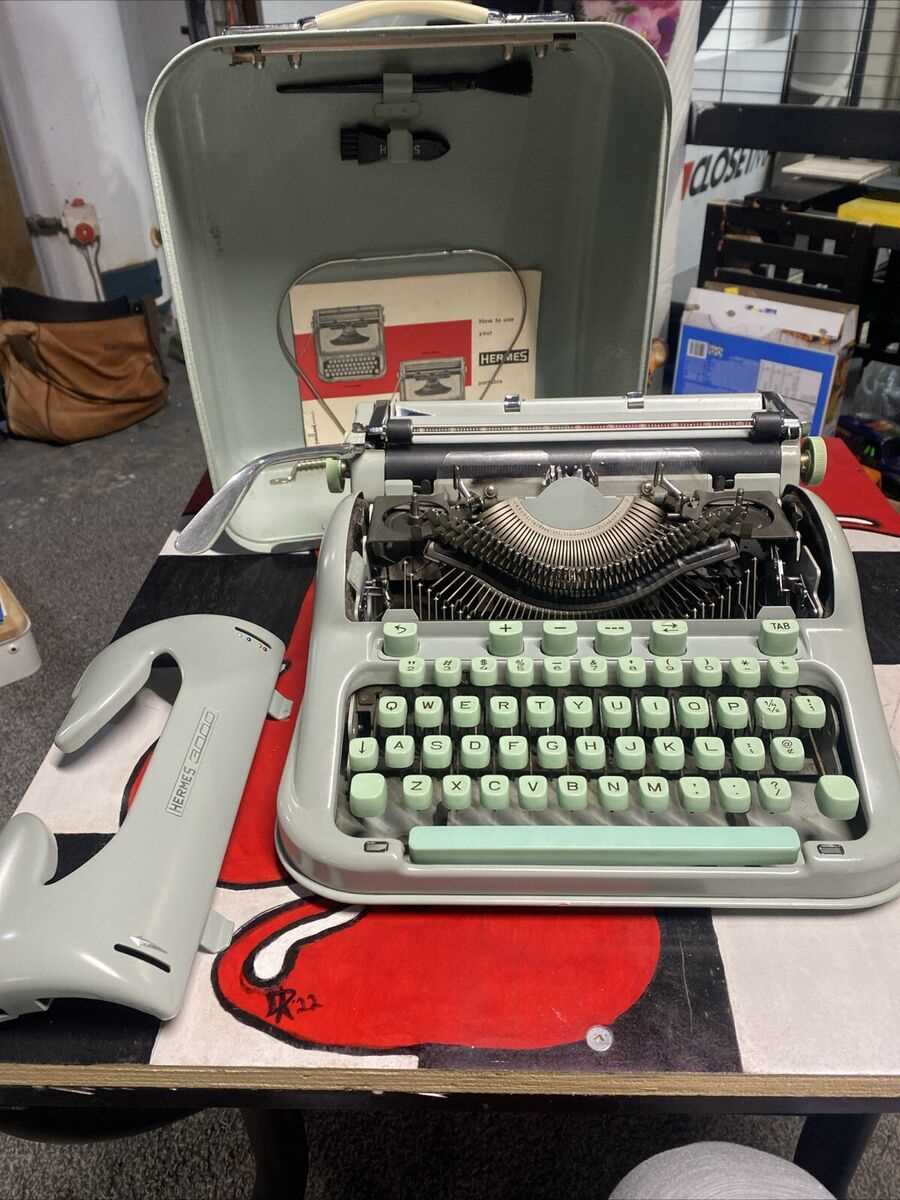

Reassembling Your Typewriter

After thorough disassembly, bringing your writing device back to its original state requires careful attention and methodical steps. This phase is crucial to ensure that all components fit seamlessly and function correctly, allowing for a smooth typing experience.

Gathering Your Tools

Before starting, collect all necessary instruments. Essential items include screwdrivers of various sizes, tweezers for handling small parts, and a soft cloth to keep surfaces clean. Having everything ready will streamline the process and minimize frustration.

Following the Sequence

Begin the reassembly by reversing the order of disassembly. Start with larger components and work your way down to smaller pieces. Ensure that each part is oriented correctly before securing it in place. Patience is key, as forcing components can lead to damage.

Tips for Successful Repairs

Ensuring effective restoration of devices requires a blend of knowledge, patience, and attention to detail. Understanding the fundamentals and having the right tools at your disposal can greatly enhance the likelihood of a positive outcome.

Essential Tools

Having the appropriate instruments is crucial for efficient handling. Below is a list of must-have items:

| Tool | Purpose |

|---|---|

| Screwdriver Set | To remove and secure screws |

| Multimeter | For testing electrical connections |

| Pliers | To grip and bend materials |

| Cleaning Solution | To ensure components are free of debris |

Step-by-Step Approach

A methodical process can make challenging tasks manageable. Follow these steps for effective handling:

- Identify the issue clearly before disassembly.

- Document the process with notes or pictures to ensure reassembly.

- Work in a well-lit and organized space to minimize errors.

Where to Find Replacement Parts

Locating components for your device can be a straightforward task if you know where to look. Numerous options are available to ensure you find the right pieces to restore functionality.

Start by checking online marketplaces, which often feature a wide array of options from various sellers. Websites dedicated to vintage equipment and repair supplies can be particularly useful. Additionally, local electronics shops may carry compatible items or can order them for you.

Consider joining online forums or communities focused on maintenance and restoration, as fellow enthusiasts frequently share resources and recommendations for sourcing necessary elements. Networking with others can lead to discovering rare or hard-to-find parts.

Lastly, do not overlook the possibility of salvage shops or recycling centers, where you might uncover usable items at a fraction of the cost. Exploring multiple avenues increases your chances of successfully obtaining the required components.

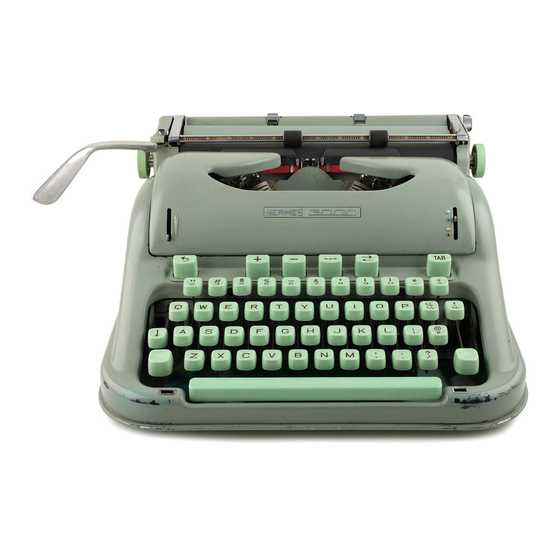

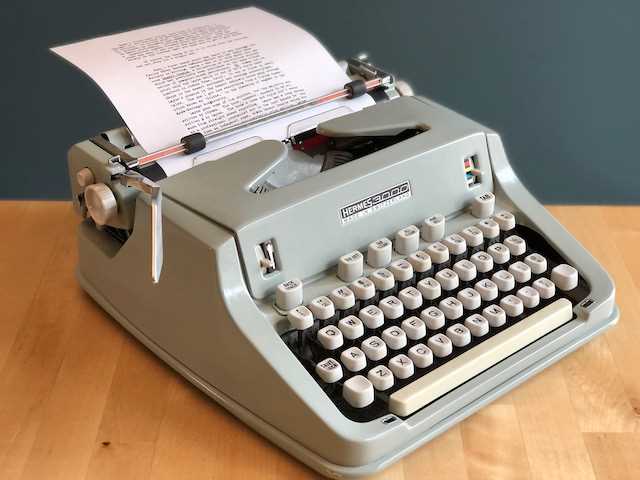

Maintaining Your Hermes 3000

To ensure the longevity and optimal performance of your typewriter, regular upkeep is essential. This process not only enhances functionality but also preserves its aesthetic appeal. Below are key practices to consider for effective maintenance.

Regular Cleaning

- Dust the exterior frequently to prevent buildup.

- Use a soft cloth to clean the keys and surfaces.

- Periodically check for any debris inside the mechanism and gently remove it.

Lubrication and Adjustments

- Apply a small amount of oil to moving parts to ensure smooth operation.

- Check alignment and make necessary adjustments to keep everything in sync.

- Inspect the ribbon and replace it when it shows signs of wear for clear impressions.