When it comes to maintaining your vehicle, having access to detailed resources can make all the difference. This section provides an extensive overview of essential procedures, troubleshooting tips, and guidelines that help ensure your automobile remains in peak condition. From understanding various systems to performing routine checks, this guide is designed to empower owners with knowledge.

Whether you are addressing minor issues or preparing for major service, familiarity with your automobile’s components and functions is crucial. Emphasizing practical advice and clear explanations, this resource aims to simplify the maintenance process, making it accessible even for those without extensive technical experience. By following the recommendations outlined here, you can enhance your understanding and confidence in handling your vehicle’s needs.

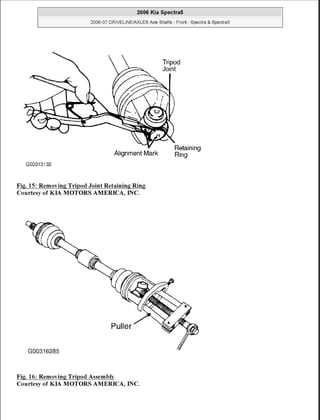

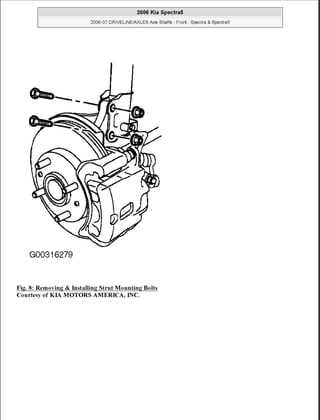

In this guide, readers will find step-by-step instructions, illustrations, and safety precautions tailored to facilitate effective maintenance practices. As you navigate through these sections, remember that a proactive approach can significantly extend the lifespan of your automobile, leading to a smoother, more reliable driving experience.

Kia Spectra Maintenance Overview

Regular upkeep is essential for ensuring the longevity and optimal performance of any vehicle. Understanding key maintenance tasks can help owners keep their automobile in excellent condition, minimizing potential issues and enhancing driving safety.

Key Maintenance Tasks

Routine checks and servicing should include various critical components. Following a structured schedule allows for timely interventions, reducing the risk of more significant repairs down the line.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 5,000 – 7,500 miles | Replacing old oil ensures smooth engine operation and protects against wear. |

| Tire Rotation | Every 6,000 – 8,000 miles | Helps promote even tire wear and extends tire life. |

| Brake Inspection | Every 10,000 miles | Checking brake pads and rotors ensures safe stopping performance. |

| Fluid Levels Check | Monthly | Inspecting coolant, brake fluid, and transmission fluid to avoid overheating and other issues. |

Conclusion

Implementing a consistent maintenance routine not only enhances reliability but also significantly contributes to the overall driving experience. Adhering to these practices can lead to improved efficiency and satisfaction on the road.

Common Issues and Troubleshooting Tips

Vehicles often encounter a range of challenges that can affect their performance and reliability. Identifying these issues early can save time and costs associated with repairs. Below are some prevalent problems and practical solutions to address them effectively.

- Engine Performance:

- Loss of power during acceleration: Check for air filter blockages and fuel supply issues.

- Rough idling: Inspect spark plugs and ignition coils for wear.

- Electrical Systems:

- Battery failure: Ensure terminals are clean and connections are secure.

- Faulty lights: Replace blown bulbs and inspect wiring for shorts.

- Transmission Problems:

- Delayed shifting: Check transmission fluid levels and consider a fluid change.

- Strange noises: Inspect for any leaks or damaged components.

- Cooling System Issues:

- Overheating: Check coolant levels and inspect for leaks in hoses.

- Low heater output: Ensure the thermostat is functioning properly.

Regular maintenance and timely troubleshooting can greatly enhance the longevity of any vehicle. Following these tips can assist in keeping your ride smooth and dependable.

Engine Specifications and Features

This section provides an overview of the powertrain characteristics and key attributes that define performance and efficiency. Understanding these details is essential for maintaining optimal functionality and ensuring a smooth driving experience.

| Specification | Details |

|---|---|

| Engine Type | 4-cylinder inline |

| Displacement | 2.0 liters |

| Horsepower | 140 hp |

| Torque | 136 lb-ft |

| Fuel System | Multi-point fuel injection |

| Transmission | 5-speed manual / 4-speed automatic |

| Fuel Economy | City: 24 mpg, Highway: 32 mpg |

Each specification plays a vital role in delivering a reliable and efficient driving experience. Regular checks and maintenance of these elements can significantly enhance vehicle longevity and performance.

Step-by-Step Repair Procedures

This section outlines a comprehensive approach to addressing common issues that may arise in vehicles. By following a systematic process, you can effectively diagnose and resolve problems, ensuring optimal performance and longevity.

Preparation and Tools

Before beginning any procedure, gather the necessary tools and materials. This preparation will facilitate a smoother workflow and help avoid interruptions during the process.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts |

| Screwdriver Set | For removing and installing screws |

| Jack and Stands | To lift the vehicle safely |

| Diagnostic Scanner | For reading error codes |

Step-by-Step Process

Follow these steps to efficiently tackle repairs:

- Identify the issue through observation and testing.

- Consult the appropriate documentation to understand the specifications and procedures.

- Gather the necessary tools and materials as outlined above.

- Begin disassembly as needed, taking care to label parts for easy reassembly.

- Perform the necessary repairs or replacements.

- Reassemble components in reverse order of disassembly.

- Conduct tests to ensure the issue has been resolved and the vehicle operates smoothly.

Electrical System Diagnostics

The evaluation of the electrical system is crucial for maintaining optimal performance in vehicles. Proper assessment ensures that all components function correctly and efficiently, reducing the likelihood of unexpected failures.

To initiate the diagnostics, it is essential to gather relevant tools and understand the schematic diagrams. Begin by examining the battery voltage and connections, as these are foundational for the entire system. Faulty connections can lead to various electrical issues, impacting the operation of numerous systems.

Next, focus on testing the fuses and relays. Inspecting these components can reveal potential circuit interruptions or overloads. Utilize a multimeter to check continuity and voltage at various points within the electrical network, allowing for a detailed assessment of the system’s health.

Additionally, consider the role of electronic control units (ECUs) in managing electrical operations. Scanning for diagnostic trouble codes (DTCs) can provide insights into specific malfunctions. This proactive approach aids in identifying issues before they escalate, ensuring a reliable driving experience.

Transmission Fluid Change Process

Regular maintenance of the vehicle’s transmission system is essential for optimal performance and longevity. Changing the fluid is a crucial step that helps prevent potential issues and ensures smooth gear transitions. This procedure typically involves draining the old fluid, replacing it with new fluid, and checking for any leaks or abnormalities.

Preparation Steps

Before beginning the fluid change, ensure you have the necessary tools and materials. This includes the appropriate type of fluid, a fluid pump, a drain pan, and wrenches. It’s advisable to park the vehicle on a level surface and engage the parking brake for safety. Allow the engine to cool if it has been running, as the fluid can be hot.

Fluid Change Procedure

Start by locating the transmission fluid pan and removing the drain plug to let the old fluid flow into the drain pan. Once fully drained, replace the drain plug securely. Next, use a funnel to pour the new fluid into the designated fill opening. It’s important to follow the manufacturer’s specifications regarding the type and amount of fluid. After filling, run the engine for a few minutes while shifting through the gears to circulate the new fluid, then check the fluid level and top off if necessary.

Brake System Maintenance Guidelines

Ensuring optimal performance of the braking mechanism is crucial for vehicle safety and efficiency. Regular inspection and maintenance can prevent potential issues, extending the lifespan of components and enhancing overall functionality.

It is important to follow a systematic approach when maintaining the braking system. The following guidelines can assist in achieving proper upkeep:

| Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Monthly | Check for leaks, wear, and any visible damage to components. |

| Brake Fluid Check | Every 6 months | Ensure the fluid is at the recommended level and free from contamination. |

| Pad Replacement | As Needed | Monitor wear and replace brake pads when they reach the minimum thickness. |

| System Bleeding | Every 2 years | Remove air from the system to maintain effective braking performance. |

| Rotor Inspection | Every 2 years | Examine rotors for warping and wear, replacing them as necessary. |

Following these recommendations will help ensure the braking system remains reliable and effective, contributing to a safer driving experience.

Suspension Components and Repairs

The suspension system plays a crucial role in ensuring vehicle stability, handling, and ride comfort. Understanding its components and the necessary maintenance practices is essential for optimal performance.

Key elements of the suspension system include:

- Shock Absorbers: These dampen the impact of road irregularities and help maintain tire contact with the surface.

- Struts: Often integrated with shock absorbers, struts support vehicle weight and provide structural integrity.

- Coil Springs: These components bear the vehicle’s weight and absorb shocks from the road.

- Control Arms: These link the chassis to the suspension, allowing for controlled movement of the wheels.

- Ball Joints: These provide pivot points for the steering system and suspension components.

Regular inspections and timely replacements are vital to prevent performance issues. Here are some common repairs:

- Inspect and replace worn shock absorbers and struts to enhance ride quality.

- Check and replace damaged coil springs to maintain proper vehicle height.

- Lubricate control arms and ball joints to ensure smooth movement and prevent wear.

- Align the suspension system after any component replacement to avoid uneven tire wear.

By understanding these components and their maintenance needs, owners can ensure a safer and more comfortable driving experience.

Understanding the Cooling System

The cooling mechanism of a vehicle plays a crucial role in maintaining optimal operating temperatures, preventing overheating, and ensuring engine efficiency. This system comprises various components working in harmony to regulate temperatures, allowing the engine to function effectively under different conditions.

Key Components of the Cooling Mechanism

Essential elements include the radiator, water pump, thermostat, and coolant. The radiator dissipates heat, while the water pump circulates the coolant through the engine and back. The thermostat regulates the flow of coolant, maintaining the desired temperature. A failure in any of these components can lead to significant performance issues.

Maintenance Tips

Regular inspection and maintenance of the cooling system are vital. Checking coolant levels, looking for leaks, and ensuring that the radiator is clear of debris can prevent overheating and prolong the lifespan of the engine. Always refer to the manufacturer’s guidelines for specific maintenance recommendations.

Routine Oil Change Instructions

Regular maintenance of the engine’s lubrication system is crucial for optimal performance and longevity. This section outlines the essential steps for executing a routine oil replacement, ensuring that the engine operates smoothly and efficiently.

Required Tools and Materials: Before starting, gather the necessary tools and materials, including an oil filter, the appropriate grade of motor oil, a wrench set, an oil catch pan, and a funnel.

Step-by-Step Procedure:

- Start the engine and allow it to run for a few minutes to warm up the oil, which facilitates drainage.

- Turn off the engine and ensure the vehicle is on a level surface. Secure the vehicle with wheel chocks and jack stands if needed.

- Locate the oil drain plug underneath the engine. Using a wrench, carefully remove the plug and allow the old oil to drain into the catch pan.

- Once the oil has completely drained, replace the drain plug and tighten it securely.

- Next, remove the old oil filter using the wrench. Apply a small amount of new oil to the rubber gasket of the new filter before installing it.

- Install the new filter by hand, ensuring it is snug but not overtightened.

- Pour the new oil into the engine through the oil filler cap using the funnel. Check the owner’s manual for the correct oil capacity and grade.

- After adding oil, start the engine and let it run for a minute. Check for any leaks around the filter and drain plug.

- Finally, turn off the engine and check the oil level using the dipstick. Add more oil if necessary to reach the recommended level.

Conclusion: Following these straightforward steps ensures that the engine remains properly lubricated, contributing to its efficiency and performance. Regular oil changes are an essential aspect of vehicle upkeep.

Exhaust System Inspection Techniques

Effective examination of the exhaust system is crucial for maintaining vehicle performance and ensuring compliance with emission standards. This section outlines various methods to evaluate the integrity and efficiency of exhaust components, helping to identify potential issues before they escalate.

Visual Inspection: Begin with a thorough visual assessment of the entire exhaust system. Look for signs of damage, such as rust, cracks, or loose connections. Pay special attention to joints and hangers, as these areas are prone to wear.

Sound Test: A distinctive sound during operation can indicate problems within the exhaust system. Listen for unusual noises such as hissing or popping, which may suggest leaks or failing parts. A change in sound may warrant further investigation.

Smoke Test: Employing a smoke test can effectively pinpoint leaks. Introduce smoke into the system and observe for any escaping vapors. This method is particularly useful in identifying hard-to-spot issues.

Pressure Test: Conducting a pressure test will help verify the system’s integrity. Utilize specialized equipment to measure back pressure, ensuring that it remains within the manufacturer’s specified range.

Emissions Testing: Regular emissions testing can provide insights into the system’s performance and compliance. Analyze the results for any discrepancies, which may indicate underlying issues that require attention.

Safety Precautions During Repairs

Ensuring a secure environment while performing maintenance tasks is crucial for both the individual and the vehicle. Adopting necessary safety measures minimizes risks and enhances the overall effectiveness of the process.

Proper Personal Protection: Always wear appropriate protective gear, such as gloves, safety goggles, and steel-toed boots. This equipment safeguards against potential hazards, including sharp objects and harmful substances.

Workspace Organization: Maintain a clean and organized workspace. This reduces the chance of accidents caused by clutter and allows for efficient movement while working.

Use of Tools: Employ the correct tools for each task. Using inappropriate instruments can lead to injuries or damage to components. Regularly inspect tools for wear and tear to ensure they are in safe working condition.

Electrical Safety: When handling electrical systems, always disconnect the battery to prevent shocks or short circuits. Use insulated tools to further protect against electrical hazards.

Ventilation: Ensure adequate airflow in the workspace, especially when working with chemicals or fuels. This prevents the buildup of harmful fumes that can pose serious health risks.

Emergency Preparedness: Familiarize yourself with emergency procedures and keep a first aid kit readily available. Being prepared for unexpected situations can make a significant difference in handling emergencies effectively.