Ensuring the longevity and optimal performance of any all-terrain vehicle requires a deep understanding of its components and systems. This resource is designed to provide essential insights and step-by-step instructions tailored for enthusiasts and owners alike. By familiarizing yourself with key aspects of care and troubleshooting, you can enhance both the functionality and reliability of your machine.

Understanding the Mechanisms is crucial for anyone looking to perform their own upkeep. This includes grasping the intricacies of the engine, drivetrain, and electrical systems. By delving into these topics, users will be better equipped to identify potential issues before they escalate, ultimately saving time and resources.

Moreover, familiarity with the tools and techniques necessary for effective maintenance can empower owners to take charge of their vehicle’s condition. From routine inspections to more complex adjustments, a comprehensive knowledge base will pave the way for a rewarding and efficient ownership experience.

Overview of Yamaha Grizzly 660

This section provides a comprehensive insight into a popular all-terrain vehicle known for its robust performance and reliability. Designed to handle a variety of terrains, this machine has become a favorite among outdoor enthusiasts and utility users alike. Its blend of power, versatility, and durability makes it suitable for both recreational activities and work-related tasks.

The vehicle is equipped with a potent engine that delivers impressive torque and acceleration, allowing it to tackle steep inclines and rough landscapes with ease. Additionally, its advanced suspension system ensures a smooth ride, even in challenging conditions. The ergonomic design contributes to operator comfort, making long journeys more enjoyable.

Moreover, the integration of modern features enhances usability, including a user-friendly control layout and ample storage options. This vehicle also boasts excellent towing capabilities, making it a practical choice for those needing to transport equipment or haul heavy loads. Overall, this model represents a perfect balance of strength, functionality, and ease of use, appealing to a wide range of users.

Key Specifications and Features

This section provides an overview of the essential characteristics and attributes of a well-regarded all-terrain vehicle. Understanding these specifications is crucial for potential users to evaluate performance, capability, and suitability for various tasks.

- Engine Type: A powerful four-stroke engine known for its reliability and efficiency.

- Displacement: An engine capacity that offers a balanced combination of power and torque, ensuring excellent performance across diverse terrains.

- Transmission: Automatic transmission that allows for smooth gear shifting and ease of use, particularly in challenging conditions.

- Drivetrain: A dependable 4WD system that enhances traction and stability, making it suitable for off-road adventures.

Additional features that contribute to its popularity include:

- Suspension System: Advanced front and rear suspension, providing superior handling and comfort on uneven surfaces.

- Towing Capacity: A robust framework designed to support substantial loads, making it ideal for hauling equipment or trailers.

- Fuel Capacity: A large tank that allows for extended rides without frequent refueling stops.

- Seating: Ergonomically designed seats that offer comfort during long periods of operation.

These specifications highlight the vehicle’s versatility, making it a favored choice among enthusiasts and professionals alike.

Common Issues with the Grizzly 660

Owners of this all-terrain vehicle often encounter a range of challenges that can impact performance and reliability. Understanding these common problems is essential for effective maintenance and ensuring a smooth riding experience.

Here are some frequent issues that users may face:

- Electrical System Failures: Problems with the battery, wiring, or starter can lead to starting difficulties.

- Overheating: Insufficient coolant levels or blocked radiators can cause the engine to run hot, risking damage.

- Transmission Problems: Slipping or rough shifting may indicate worn gears or low fluid levels.

- Suspension Issues: Worn-out shocks and bushings can lead to a bumpy ride and reduced stability.

- Fuel System Concerns: Clogged filters or fuel lines may cause starting problems or erratic performance.

Regular inspection and timely repairs can mitigate these issues and prolong the lifespan of the vehicle. It is advisable for owners to familiarize themselves with these potential problems to enhance their overall riding experience.

Maintenance Tips for Longevity

Ensuring the durability and performance of your all-terrain vehicle requires consistent care and attention. By following a few essential maintenance practices, you can significantly extend the lifespan of your machine while enhancing its overall functionality. Here are some key recommendations to keep in mind.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Oil Change | Every 50 hours of use | Use high-quality oil and replace filters to ensure smooth operation. |

| Air Filter Inspection | Every 25 hours of use | Clean or replace as necessary to maintain optimal airflow. |

| Tire Pressure Check | Monthly | Keep tires properly inflated for better traction and fuel efficiency. |

| Battery Maintenance | Every 3 months | Check connections and clean terminals to prevent corrosion. |

| Brake Inspection | Before each ride | Ensure brakes are responsive and pads are not worn out. |

Incorporating these practices into your routine will not only enhance your vehicle’s reliability but also contribute to a safer riding experience. Regular maintenance is an investment in the longevity of your machine.

Tools Needed for Repairs

When undertaking maintenance tasks on your vehicle, having the right equipment is essential for ensuring efficiency and effectiveness. This section outlines the necessary tools to facilitate various servicing procedures, helping you achieve optimal performance and longevity for your machine.

Essential Hand Tools

Hand tools are indispensable for performing routine tasks. Below is a list of commonly used tools:

| Tool | Purpose |

|---|---|

| Wrench Set | For tightening and loosening bolts and nuts. |

| Screwdriver Set | For fastening and removing screws. |

| Pliers | For gripping and manipulating objects. |

| Torque Wrench | To apply a specific torque to fasteners. |

| Hammer | For driving or removing objects. |

Specialized Equipment

In addition to hand tools, certain specialized instruments can greatly aid in more complex tasks. Here are a few recommended items:

| Equipment | Function |

|---|---|

| Diagnostic Scanner | For identifying issues through error codes. |

| Oil Filter Wrench | For easy removal of oil filters. |

| Multimeter | To measure electrical values. |

| Chain Breaker | For repairing or replacing chains. |

| Safety Gear | To protect yourself while working. |

Step-by-Step Repair Procedures

This section outlines a detailed approach to maintaining and fixing common issues encountered with all-terrain vehicles. Following a systematic method can enhance both the efficiency and effectiveness of the maintenance process, ensuring optimal performance and longevity.

Before starting any task, ensure you have the necessary tools and materials at hand. This preparation will help streamline your workflow and minimize interruptions.

- Gather tools: wrench set, screwdriver, pliers, etc.

- Obtain replacement parts as needed.

- Prepare a clean workspace to avoid contamination.

Here are the essential steps to follow:

- Initial Assessment:

- Inspect the vehicle for visible damage.

- Check fluid levels and top up if necessary.

- Listen for unusual noises during operation.

- Disassembly:

- Carefully remove panels or covers using the appropriate tools.

- Keep track of all screws and components during disassembly.

- Inspection:

- Examine each component for wear or damage.

- Look for cracks, leaks, or corrosion.

- Replacement:

- Install new parts where necessary, following the manufacturer’s specifications.

- Ensure proper alignment and fit during reassembly.

- Reassembly:

- Carefully put all components back in their original positions.

- Tighten screws and bolts to the recommended torque specifications.

- Final Testing:

- Start the vehicle and observe for any irregularities.

- Test functionality of all systems and controls.

By following these structured procedures, you can effectively address various issues and ensure your vehicle remains in peak condition for all your adventures.

Electrical System Troubleshooting

Diagnosing issues within the electrical framework of an all-terrain vehicle can be essential for ensuring optimal performance and safety. Understanding the various components and their functions is crucial for effective troubleshooting. This section outlines common problems, symptoms, and steps to identify and resolve electrical faults.

Common symptoms of electrical system issues include:

- Inconsistent starting or failure to start

- Dim or flickering lights

- Unresponsive controls or instruments

- Unexpected shutdowns during operation

To troubleshoot these problems, follow these steps:

- Check the battery condition:

- Ensure it is fully charged.

- Inspect for corrosion on terminals.

- Test voltage with a multimeter.

- Examine wiring and connections:

- Look for frayed or damaged wires.

- Verify tightness of connectors.

- Check for any signs of shorts.

- Inspect fuses and relays:

- Replace any blown fuses.

- Test relays for proper operation.

- Evaluate components such as the ignition system and starter motor:

- Test the ignition coil and spark plugs.

- Check the starter for functionality.

By systematically following these steps, most electrical issues can be diagnosed and addressed efficiently, ensuring the vehicle operates smoothly and reliably.

Engine Overhaul Guidelines

Conducting an engine overhaul is a critical process that ensures optimal performance and longevity of your machine. This procedure involves a thorough examination and refurbishment of the internal components, addressing wear and tear while restoring functionality. Proper planning and execution can greatly enhance the reliability and efficiency of the power unit.

Preparation Steps

Before starting the overhaul, it is essential to gather all necessary tools and components. Create a clean workspace to prevent contamination. Review the service history and gather any documentation that provides insight into previous issues. Additionally, having a detailed checklist can help streamline the process, ensuring that no critical steps are overlooked.

Disassembly and Inspection

Carefully disassemble the engine, taking note of the arrangement of parts for easier reassembly. Inspect each component for signs of damage, wear, or corrosion. Parts that may require replacement include pistons, rings, gaskets, and bearings. Pay close attention to the cylinder walls and crankshaft, as these are crucial for the engine’s performance. Cleaning the parts with appropriate solvents will help reveal hidden issues and prepare them for reinstallation.

Suspension and Steering Adjustments

Proper tuning of the suspension and steering systems is essential for optimal vehicle performance and rider comfort. Making precise adjustments can significantly enhance handling characteristics, stability, and overall ride quality. Understanding the key elements involved in these adjustments allows for a tailored driving experience, whether on rugged terrain or smooth trails.

Suspension Settings

To achieve the best suspension performance, begin by assessing the preload settings. Preload affects ride height and responsiveness to bumps. Increasing preload can stiffen the suspension, making it more suitable for aggressive riding or heavier loads, while decreasing it may improve comfort on uneven surfaces.

Steering Alignment

Another critical factor is steering alignment, which ensures that the wheels point in the correct direction. Misalignment can lead to uneven tire wear and unpredictable handling. Regularly checking and adjusting the toe and camber angles can maintain optimal steering response and prolong the life of your tires.

Brake System Maintenance and Repair

Proper upkeep of the braking mechanism is essential for ensuring optimal performance and safety. Regular inspections and timely interventions can prevent serious issues and prolong the lifespan of the system. This section provides essential insights into maintenance and troubleshooting practices.

Routine Inspection

Conducting regular checks can identify potential problems before they escalate. Focus on the following components:

- Brake pads and shoes

- Brake fluid level and quality

- Brake lines for leaks or wear

- Rotors and drums for damage

Common Issues and Solutions

Understanding frequent malfunctions can help in effective resolution:

- Brake Fade: Caused by overheating; allow cooling and check for fluid contamination.

- Noisy Brakes: Often due to worn pads; replace as necessary.

- Soft Brake Pedal: Check for air in the system; consider bleeding the brakes.

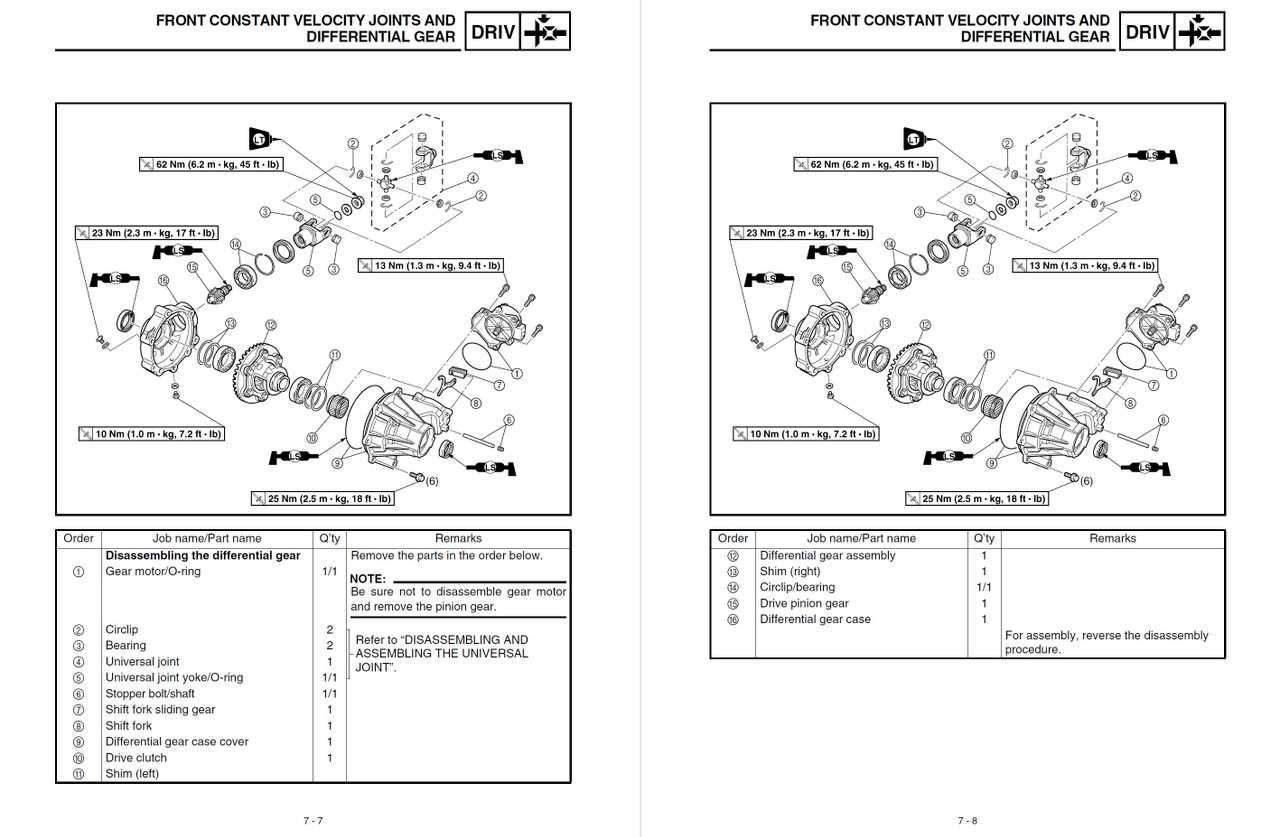

Transmission and Drivetrain Insights

This section delves into the intricacies of the transmission and drivetrain systems, crucial components that facilitate efficient power transfer in off-road vehicles. Understanding their operation and maintenance is essential for ensuring optimal performance and longevity.

The transmission plays a pivotal role in regulating the engine’s power output, allowing for smooth acceleration and deceleration. It is designed to adapt to various terrains and driving conditions, making it indispensable for versatility.

| Component | Function | Maintenance Tips |

|---|---|---|

| Transmission | Shifts engine power to the wheels | Check fluid levels regularly and inspect for leaks |

| Drive Shaft | Transmits torque from the transmission to the wheels | Ensure proper alignment and inspect for wear |

| Differential | Allows wheels to rotate at different speeds | Change fluid as recommended and check for unusual noises |

Regular inspection and maintenance of these elements are vital for enhancing performance and preventing breakdowns during demanding rides. Awareness of their functions and upkeep can significantly impact the overall experience of handling the vehicle.