Maintaining your compact transport vehicle is essential for ensuring its longevity and optimal performance. Understanding the intricacies of your machine can greatly enhance your experience, allowing you to tackle issues proactively and efficiently. This guide aims to provide insights and resources for anyone looking to delve into the upkeep of their ride.

Whether you’re a seasoned enthusiast or a newcomer, navigating the complexities of vehicle mechanics can seem daunting. However, with the right information and tools, even the most intricate problems can be addressed. By familiarizing yourself with essential components and common challenges, you can save time and money while gaining a sense of accomplishment.

In the following sections, we will explore various aspects of maintenance, including troubleshooting techniques, parts identification, and practical tips. With this knowledge at your fingertips, you’ll be better equipped to ensure your vehicle runs smoothly, allowing you to enjoy all the benefits it has to offer.

Understanding Yamaha Golf Carts

When exploring the world of small electric vehicles designed for leisure activities, it’s essential to grasp their mechanics and functionalities. These vehicles are often utilized in various settings, from recreational areas to residential communities, and understanding their components can enhance user experience and maintenance efforts.

Key Components

- Chassis: The foundational structure providing stability and support.

- Power Source: Typically powered by batteries, crucial for mobility.

- Drive System: Includes motors and transmission elements that control movement.

- Steering Mechanism: Ensures maneuverability and ease of navigation.

- Braking System: Vital for safety, allowing the vehicle to slow down or stop effectively.

Maintenance Tips

- Regularly check the power source and connections for wear.

- Inspect the tires for proper inflation and tread wear.

- Keep the chassis clean and free of debris to prevent corrosion.

- Monitor fluid levels in the braking and steering systems.

- Schedule routine professional inspections to ensure optimal performance.

By understanding these elements and maintenance practices, users can ensure longevity and reliability, making their experience with these versatile vehicles enjoyable and efficient.

Common Issues with Yamaha Models

When it comes to specific vehicle types, users may encounter a variety of recurring problems that can affect performance and reliability. Identifying these common challenges is crucial for maintaining optimal functionality and ensuring a smooth operation.

Frequent Problems

- Electrical system malfunctions

- Battery drainage issues

- Steering difficulties

- Brake performance inconsistencies

- Speed control failures

Maintenance Tips

- Regularly check and replace batteries as needed.

- Inspect wiring and connections for wear and tear.

- Ensure brakes are adjusted and functioning properly.

- Maintain proper tire pressure to enhance steering response.

- Schedule periodic inspections to preemptively address potential issues.

By being aware of these common challenges and following proactive maintenance strategies, users can significantly improve the longevity and performance of their vehicles.

Essential Tools for Repairs

When maintaining and restoring your vehicle, having the right instruments is crucial for efficiency and success. Various tasks may require specific items, ensuring that you can tackle any issue that arises with ease. Below is a list of fundamental tools that every enthusiast should have on hand for optimal upkeep.

| Tool | Description |

|---|---|

| Wrench Set | Used for loosening and tightening bolts and nuts of various sizes. |

| Screwdriver Set | Essential for adjusting and removing screws, available in various head types. |

| Multimeter | Instrument for measuring voltage, current, and resistance, crucial for electrical diagnostics. |

| Jack and Stands | Used to elevate the vehicle safely for access to the underside. |

| Socket Set | Includes various sized sockets for faster and more efficient fastener engagement. |

| Pliers | Handy for gripping, twisting, and cutting wires or small components. |

| Torque Wrench | Ensures fasteners are tightened to the manufacturer’s specifications. |

| Diagnostic Scanner | Helps to read error codes and troubleshoot issues in the system. |

Equipped with these essential tools, you can effectively address a range of maintenance tasks, ensuring your vehicle remains in optimal condition for years to come.

Step-by-Step Maintenance Guide

Regular upkeep of your vehicle is essential for ensuring its longevity and optimal performance. This guide provides a comprehensive approach to maintaining your transportation unit, covering critical tasks that enhance functionality and prevent potential issues.

Routine Checks

Begin with periodic inspections of essential components. Check the battery connections for corrosion and ensure they are secure. Inspect the tires for proper inflation and tread wear, as these factors significantly influence handling and safety. Additionally, examine the lights and signals to ensure they function correctly.

Fluid Maintenance

Maintaining proper fluid levels is crucial for the smooth operation of your unit. Regularly check the oil and coolant levels, topping them up as necessary. Additionally, inspect the brake fluid and hydraulic fluids to ensure they are at the recommended levels. Change the oil according to the manufacturer’s guidelines to prolong the engine’s life and efficiency.

Following these steps will help you keep your vehicle in peak condition, ensuring a safe and enjoyable ride for years to come.

Electrical System Troubleshooting Tips

When dealing with electrical issues in a vehicle, understanding the underlying components and their interactions is crucial. This section provides valuable insights to help identify and resolve common problems that may arise in the electrical framework, ensuring smooth operation and longevity.

1. Check the Battery: A primary source of power, the battery must be in optimal condition. Ensure that it is fully charged and free from corrosion on terminals. Testing the voltage can reveal whether it needs replacement.

2. Inspect Wiring Connections: Loose or damaged wires can lead to intermittent issues. Examine all connections for signs of wear or disconnection, and ensure that they are secure. Replacing any frayed or broken wires is essential for reliable performance.

3. Evaluate Fuses: Fuses protect circuits from overload. If a particular system is malfunctioning, check the relevant fuses for any breaks. Replacing a blown fuse may restore functionality to the affected area.

4. Test Switches and Relays: Faulty switches can prevent systems from engaging properly. Use a multimeter to test the functionality of switches and relays, replacing any that do not operate as intended.

5. Utilize Diagnostic Tools: Advanced diagnostic tools can provide deeper insights into electrical issues. These tools help pinpoint problems quickly, making troubleshooting more efficient and effective.

6. Review the Grounding System: A poor ground connection can lead to erratic behavior. Ensure that all grounding points are clean and securely attached to prevent voltage drops that could affect system performance.

By systematically addressing these areas, users can effectively diagnose and rectify issues within the electrical system, leading to improved reliability and functionality.

Battery Care and Replacement Procedures

Proper maintenance and timely replacement of energy storage units are crucial for optimal performance and longevity. This section outlines essential practices to ensure these components remain efficient and reliable over time.

Regular Inspection is vital. Check for any signs of corrosion, leaks, or physical damage. Keeping terminals clean and secure helps maintain a stable connection and prevents unnecessary power loss.

Charging Practices play a significant role in battery health. Always follow the recommended charging cycles, avoiding overcharging or deep discharging. Utilizing an appropriate charger ensures safe and efficient energy replenishment.

When it comes to replacement, selecting the right specifications is key. Verify compatibility with the existing system, considering voltage and capacity requirements. Proper disposal of old units is also important for environmental responsibility.

Storage conditions can affect performance as well. If the units are not in use for extended periods, store them in a cool, dry place and maintain a partial charge to prevent sulfation.

By adhering to these guidelines, you can enhance the lifespan and functionality of your energy storage solutions, ensuring dependable operation for years to come.

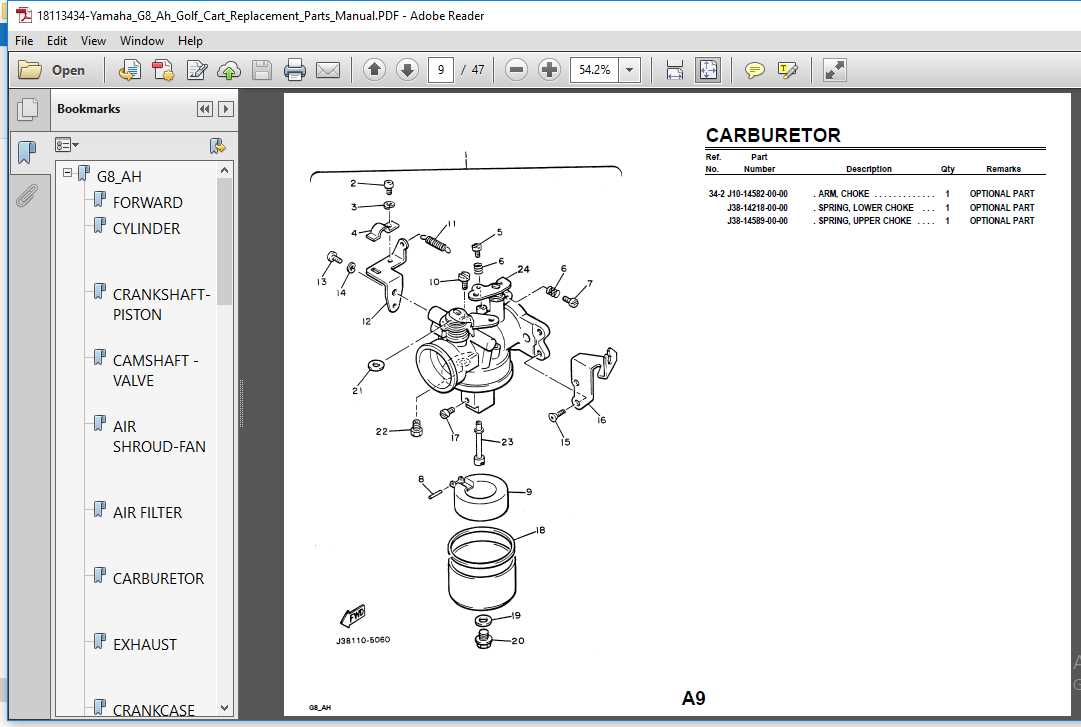

Engine Performance Enhancements

Boosting the efficiency and power of a small vehicle’s engine can lead to a more enjoyable and dynamic driving experience. This section explores various strategies and modifications that can enhance performance, ensuring a smoother and more responsive ride.

Consider the following enhancements:

- Air Intake Systems:

- Upgrade to high-flow air filters to improve airflow.

- Install a performance air intake system to enhance combustion efficiency.

- Exhaust Upgrades:

- Replace the factory exhaust with a performance option to reduce backpressure.

- Consider installing a header to improve exhaust flow and increase horsepower.

- Fuel Delivery Enhancements:

- Upgrade to high-performance fuel injectors for better fuel atomization.

- Install an adjustable fuel pressure regulator to optimize fuel delivery.

- Tuning and Optimization:

- Utilize a performance chip or ECU remap to fine-tune engine parameters.

- Monitor and adjust ignition timing for optimal performance.

By implementing these enhancements, enthusiasts can achieve significant improvements in acceleration, torque, and overall engine responsiveness, making every drive more exhilarating.

Braking System Inspection Techniques

Regular examination of the braking mechanism is crucial for ensuring optimal performance and safety. Identifying potential issues early can prevent accidents and extend the lifespan of the components involved.

When conducting an inspection, consider the following techniques:

- Visual Inspection: Check for visible signs of wear, corrosion, or damage on brake pads, rotors, and hoses.

- Listen for Unusual Noises: Pay attention to any grinding, squeaking, or other abnormal sounds when the braking system is engaged.

- Check Fluid Levels: Ensure that the brake fluid is at the recommended level and appears clean, without contamination.

- Test Pedal Feel: Press the brake pedal to assess its firmness. A spongy feel may indicate air in the system or a fluid leak.

- Examine Brake Performance: Conduct a controlled test to evaluate stopping distances and responsiveness under various conditions.

By following these techniques, one can effectively maintain the braking system and enhance overall safety and performance.

Body and Frame Repairs Explained

The structure and outer shell of a vehicle play a crucial role in its overall performance and aesthetics. Addressing any issues with these components not only enhances functionality but also maintains the vehicle’s appearance. This section delves into the essential aspects of addressing damages and ensuring durability in the framework.

Common Issues and Identification

Understanding typical problems that may arise is key to effective solutions. Common challenges include dents, rust, and misalignment. Dents can often occur due to collisions or heavy impacts, while rust typically develops from prolonged exposure to moisture. Misalignment may arise from wear and tear, leading to uneven handling and performance. Regular inspection can help identify these issues early, preventing further complications.

Repair Techniques

Once problems are identified, various techniques can be employed for resolution. For dents, tools like dent pullers or heat methods can restore the original shape. Rust requires careful sanding and application of protective coatings to prevent future decay. Addressing misalignment often involves realigning the frame using specialized equipment. Proper techniques ensure longevity and maintain structural integrity.

Upgrading Tires and Wheels

Enhancing the performance and aesthetics of your vehicle often begins with the wheels and tires. A well-chosen set can significantly improve handling, traction, and overall ride quality, making every journey more enjoyable. Upgrading not only influences functionality but can also transform the appearance, giving it a unique flair.

Choosing the Right Size is crucial when considering an upgrade. Larger diameters can enhance ground clearance and off-road capability, while narrower options may improve speed and maneuverability. Always consult specifications to ensure compatibility with your model.

Material Matters. Selecting high-quality materials for both tires and rims can lead to improved durability and performance. Lightweight alloys, for instance, can reduce strain on the suspension and enhance acceleration, while robust rubber compounds provide better grip and longevity.

Design Considerations should not be overlooked. Custom designs can make a statement, but ensure that aesthetic choices do not compromise functionality. Consider tread patterns that suit your driving conditions, whether you prioritize off-road traction or smooth pavement performance.

Lastly, professional installation is recommended for any upgrades. Proper fitting and balancing are essential to maintain safety and performance standards. With the right enhancements, your vehicle will not only perform better but also reflect your personal style.

Safety Protocols During Repairs

Ensuring a safe working environment is crucial when conducting maintenance on any vehicle. Adhering to proper protocols minimizes the risk of accidents and injuries, allowing for efficient and effective service. Awareness of potential hazards and the implementation of preventive measures are fundamental to the process.

Before commencing work, it is essential to gather the necessary tools and materials while ensuring they are in good condition. Additionally, wearing appropriate personal protective equipment is vital to safeguard against any unexpected incidents.

| Safety Measure | Description |

|---|---|

| Personal Protective Equipment | Use gloves, goggles, and sturdy footwear to protect against potential hazards. |

| Proper Ventilation | Ensure the work area is well-ventilated to avoid inhalation of fumes or dust. |

| Secure the Vehicle | Make sure the vehicle is stable and secured to prevent accidental movement. |

| Tool Safety | Inspect tools before use to ensure they are functioning properly and free from damage. |

| Electrical Safety | Disconnect batteries before working on electrical systems to prevent shocks. |

By following these protocols, individuals can significantly reduce risks associated with maintenance tasks, promoting a safer and more efficient workflow.

Finding Reliable Replacement Parts

Ensuring optimal performance of your vehicle often requires sourcing dependable components. When it comes to enhancing or fixing functionality, selecting quality parts is essential for longevity and reliability. Here, we’ll explore key considerations and resources for acquiring trustworthy replacements.

Factors to Consider

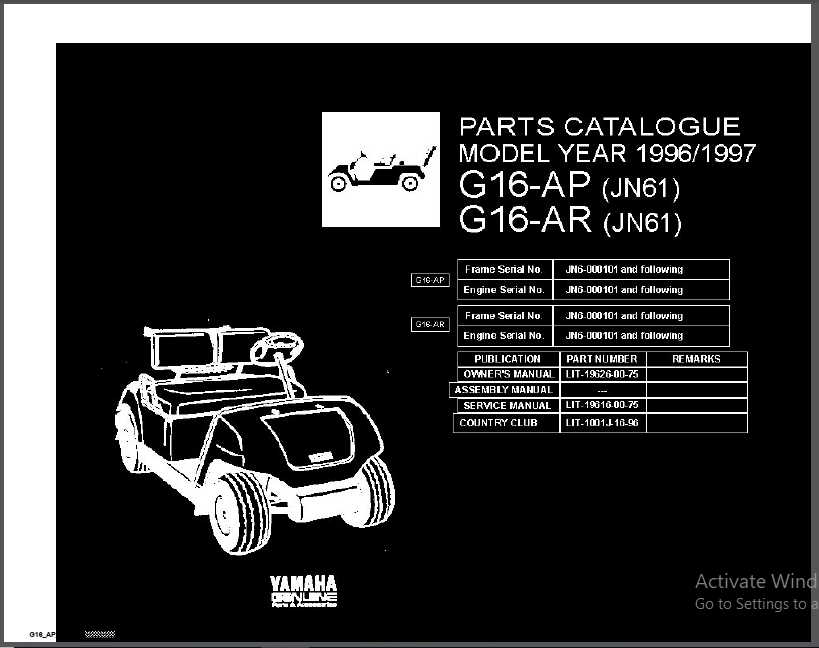

- Compatibility: Ensure that the parts you choose match the specifications of your vehicle model.

- Quality Assurance: Look for components that are built to high standards, as these will often provide better durability.

- Warranty: Opt for items that come with a warranty to safeguard your investment against defects.

Where to Find Parts

- Authorized Dealers: Visit official distributors who specialize in specific brands and offer genuine components.

- Online Marketplaces: Utilize reputable e-commerce sites where sellers provide detailed descriptions and customer reviews.

- Local Shops: Check nearby automotive supply stores that may carry a range of parts suitable for your needs.