In any household, maintaining essential plumbing fixtures is crucial for ensuring functionality and convenience. When issues arise within these systems, understanding the underlying mechanisms can facilitate effective solutions. This guide aims to equip you with the knowledge necessary to address common problems, enhance performance, and prolong the lifespan of your water management equipment.

Familiarizing yourself with the components and operations of your system can significantly simplify the process of diagnosing malfunctions. With a focus on straightforward instructions and practical tips, this resource will serve as an invaluable reference for homeowners and DIY enthusiasts alike. By adopting a proactive approach to maintenance, you can mitigate potential disruptions and enjoy a seamless experience.

Whether you’re dealing with inconsistent performance, unusual noises, or complete failures, recognizing the signs of wear and tear is essential. The following sections will delve into various aspects of upkeep and troubleshooting, empowering you to tackle challenges with confidence and efficiency.

Sloan Flushmate Overview

This section provides a comprehensive understanding of a popular pressure-assisted flushing system commonly used in toilets. These systems enhance performance and efficiency by utilizing pressurized water to deliver a powerful flush, ensuring effective waste removal.

Key features of this technology include:

- Enhanced flushing power

- Water conservation

- Durability and reliability

- Minimal noise during operation

Typically, these systems are designed to work seamlessly with various toilet models, providing a modern solution for improved sanitation. Users often appreciate the reduction in water usage compared to traditional gravity-based systems, making them an environmentally friendly choice.

Regular maintenance is essential to ensure optimal performance. Common issues may include:

- Inconsistent flushing

- Water leakage

- Noisy operation

Understanding these elements can aid in troubleshooting and prolonging the lifespan of the system, promoting a more efficient and pleasant bathroom experience.

Common Issues with Flushmate Systems

Understanding the frequent problems that can arise with pressure-assisted toilet systems is crucial for maintaining optimal functionality. Users often encounter various challenges that can affect performance, leading to inconvenience and potential damage. Below are some of the most typical concerns associated with these systems.

Frequent Problems

- Weak Flushing Power: Insufficient pressure may result in ineffective waste removal.

- Constant Running: A continuous flow of water can lead to increased utility bills and wasted resources.

- Noise Issues: Unusual sounds during operation may indicate internal malfunctions or air leaks.

- Leakage: Water pooling around the base can suggest seal failures or cracks in the system.

Symptoms to Watch For

- Toilet not fully flushing.

- Water levels fluctuating in the tank.

- Visible corrosion or rust on components.

- Frequent need for manual intervention to flush.

Recognizing these common issues early can help ensure efficient operation and prolong the lifespan of the system.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing issues related to a specific type of toilet flushing system. By following a clear sequence of actions, you can effectively resolve common problems and restore proper functionality.

Identifying the Problem

The first step in addressing any malfunction is to pinpoint the exact issue. Observe the behavior of the flushing mechanism. Listen for unusual sounds, check for leaks, and note any irregularities in the flushing performance. Understanding these symptoms will guide you in determining the necessary adjustments or replacements.

Executing the Fix

Once the problem is identified, gather the required tools and replacement parts. Begin by turning off the water supply to avoid any overflow. Carefully disassemble the relevant components, ensuring to keep track of each piece. Replace any faulty parts and reassemble everything in reverse order. Finally, turn the water supply back on and conduct a test flush to verify that the issue has been resolved.

By following these steps diligently, you can ensure that your flushing system operates smoothly and efficiently.

Tools Needed for Maintenance

Proper upkeep of your plumbing system requires specific instruments to ensure everything functions smoothly. Having the right tools on hand not only simplifies the task but also enhances efficiency and effectiveness during the maintenance process. Below is a list of essential equipment that will aid in routine inspections and troubleshooting.

Essential Equipment

| Tool | Purpose |

|---|---|

| Adjustable Wrench | For loosening or tightening fittings and connections. |

| Screwdriver Set | For removing and securing screws on various components. |

| Pliers | To grip, twist, and cut wires or plumbing elements. |

| Tape Measure | For accurate measurements of pipes and fixtures. |

| Utility Knife | For cutting materials such as tape or insulation. |

| Bucket | To catch water and debris during maintenance tasks. |

Additional Items

In addition to the primary tools, certain supplementary items can enhance your maintenance experience. Safety goggles and gloves are crucial for protecting yourself during repairs, while a flashlight can help illuminate hard-to-see areas. Having these items readily available will contribute to a safer and more effective maintenance routine.

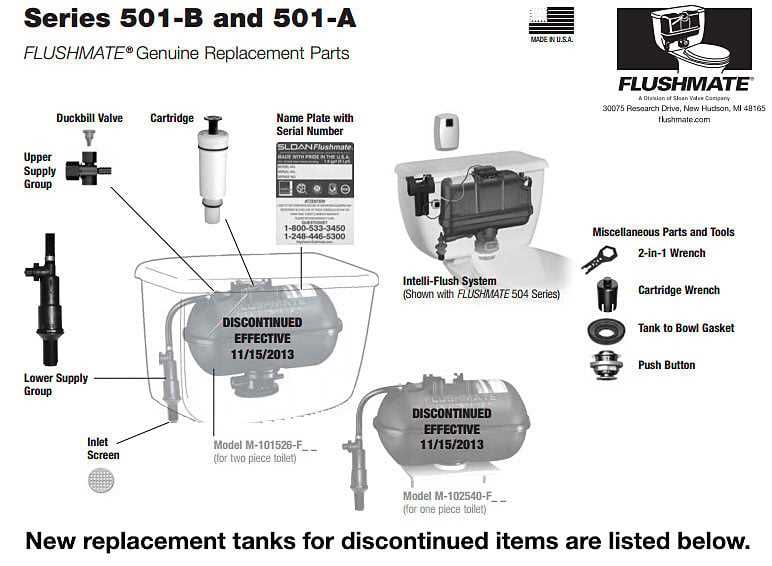

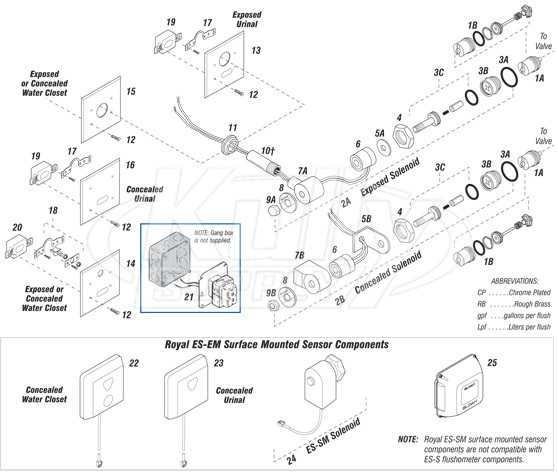

Replacing Flushmate Components

Maintaining the functionality of a toilet system often involves the replacement of essential parts to ensure optimal performance. Understanding the components and the process of substitution can help restore proper operation and improve efficiency.

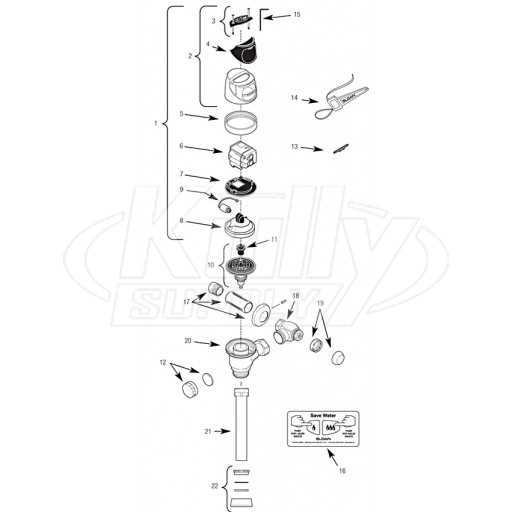

Identifying Components for Replacement

Before beginning the replacement process, it’s crucial to identify which components are faulty. Common parts that may need attention include:

- Pressure vessel

- Seal kit

- Flush valve

- Fill valve

Steps for Component Replacement

Follow these steps to successfully replace the necessary components:

- Turn off the water supply to the toilet.

- Remove the toilet tank lid carefully.

- Empty the tank by flushing the toilet.

- Disconnect the water supply line.

- Remove the faulty component as per the manufacturer’s instructions.

- Install the new part, ensuring a secure fit.

- Reconnect the water supply line and turn on the water.

- Test the toilet by flushing to check for leaks and proper function.

Regular maintenance and timely replacements will enhance the longevity of your toilet system and provide a reliable user experience.

Understanding Flushmate Operation

The mechanism behind high-efficiency toilet systems is essential for optimal performance and water conservation. Understanding how these systems function can greatly enhance the user experience and address common issues that may arise over time.

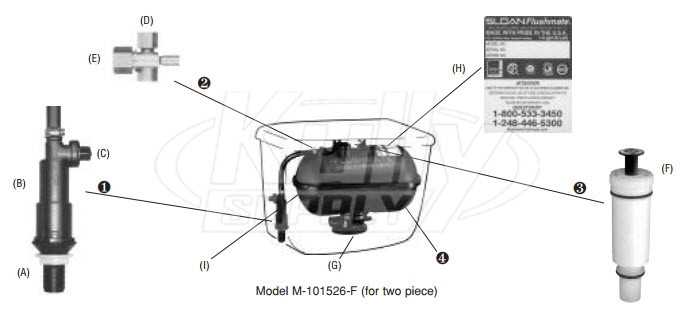

Core Components

At the heart of these advanced systems lies a pressure vessel that plays a crucial role in the flushing process. When activated, this component creates a powerful surge that effectively removes waste while minimizing water usage. Below is a summary of the key elements involved:

| Component | Function |

|---|---|

| Pressure Vessel | Generates the force needed for efficient waste removal. |

| Fill Valve | Controls the water flow into the tank after each flush. |

| Flush Handle | Activates the flushing mechanism, initiating the cycle. |

| Seal Mechanism | Ensures proper sealing to maintain pressure until the next flush. |

Operational Process

The operational cycle begins with the user engaging the flush handle, which releases the pressure stored in the vessel. This sudden release propels water into the bowl, generating a powerful flush. As the tank refills, the fill valve regulates water flow, ensuring efficiency and preventing overflow. Understanding this cycle can help users troubleshoot issues and maintain optimal functionality.

Preventive Measures for Longevity

Maintaining the functionality of bathroom systems is essential for ensuring their durability and performance. Implementing regular maintenance routines and being mindful of usage can significantly extend the lifespan of these units. This section outlines key strategies to prevent issues and promote lasting efficiency.

Regular Maintenance Schedule

Establishing a consistent maintenance schedule can help identify potential problems early. Regular inspections and cleanings can prevent buildup and ensure all components are functioning correctly.

| Action | Frequency |

|---|---|

| Inspect seals and connections | Monthly |

| Clean internal components | Every 3 months |

| Check water levels | Monthly |

| Replace worn parts | As needed |

Usage Tips

Using the system correctly can greatly reduce wear and tear. Avoid flushing inappropriate materials and be cautious of water temperature to prevent damage.

Flushmate Troubleshooting Tips

When dealing with issues related to your flushing system, understanding common problems and their solutions can significantly enhance your experience. This guide provides helpful suggestions for identifying and addressing various challenges that may arise, ensuring efficient operation and longevity of your equipment.

| Issue | Possible Causes | Solutions |

|---|---|---|

| No flush or weak flush | Low water supply, clogging, faulty components | Check the water valve, inspect for blockages, and replace damaged parts |

| Unusual noises during operation | Air in the system, loose fittings | Bleed the system of air and tighten connections |

| Water leaks | Worn seals, improper installation | Replace seals and ensure all parts are correctly fitted |

| Frequent cycling | Faulty sensor, incorrect water levels | Adjust water levels and test the sensor for functionality |

| System not activating | Power issues, control malfunction | Check power supply and reset or replace the control unit |

By addressing these common issues with the suggested solutions, you can maintain optimal performance and extend the lifespan of your system. Regular maintenance and prompt attention to problems will help ensure a seamless experience.

When to Call a Professional

Determining when to seek expert assistance can significantly impact the efficiency and longevity of your plumbing system. While many issues can be addressed through DIY methods, certain situations require specialized knowledge and tools.

- Persistent Issues: If problems persist despite your attempts to resolve them, it’s time to consult a technician.

- Complex Repairs: For tasks involving intricate components or systems, professional intervention is advisable.

- Unusual Sounds: Any unexpected noises during operation may indicate deeper issues that need expert evaluation.

- Water Damage: Signs of leakage or water damage can lead to more extensive problems if not handled promptly.

- Health Risks: Issues that pose a risk to your health, such as sewage backups, should always be managed by professionals.

Recognizing these scenarios can help you avoid further complications and ensure your plumbing operates effectively.