In the world of modern equipment, the need for maintenance and rejuvenation has never been more critical. Whether it’s ensuring functionality or prolonging the lifespan of essential components, understanding the processes involved in bringing items back to their prime is invaluable. This segment aims to equip you with the necessary knowledge to tackle various challenges that may arise.

Many individuals encounter obstacles with their apparatus, leading to frustration and downtime. Through a systematic approach, you will discover effective strategies and methods to address these issues. By following detailed instructions and utilizing appropriate tools, you can restore performance and enhance usability.

Furthermore, this guide emphasizes the importance of preventative measures. With the right insights, users can avoid common pitfalls and ensure their devices operate smoothly over time. Empower yourself with the skills needed to maintain and revive essential tools, transforming potential setbacks into opportunities for improvement.

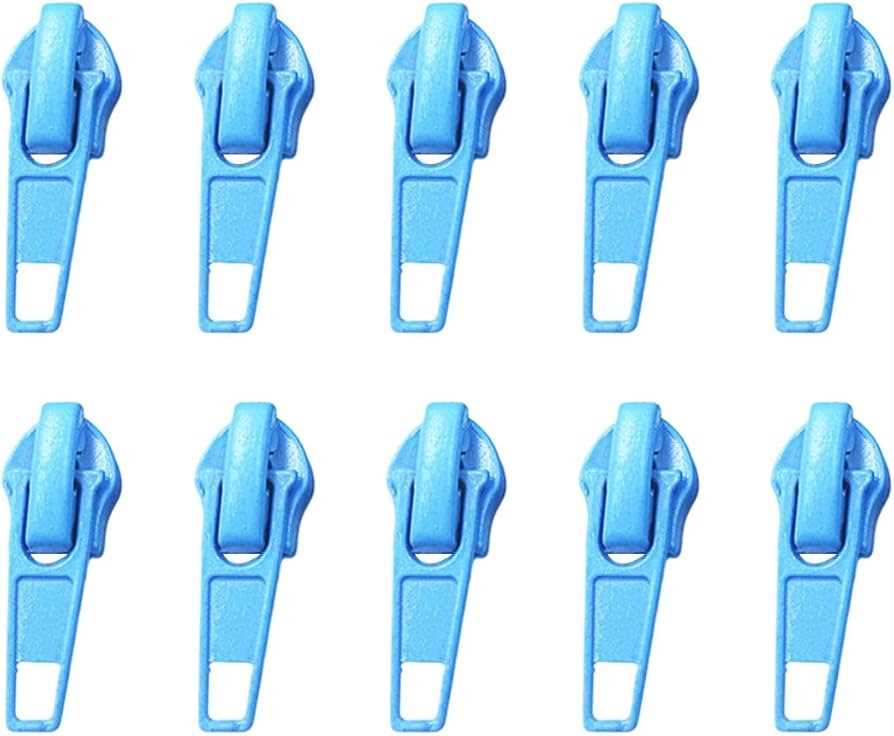

Understanding Sky Slider Mechanism

The intricate system responsible for the smooth operation of an elevated opening mechanism plays a crucial role in modern engineering. This mechanism combines precision and design to enable seamless movement, ensuring functionality and durability under various conditions.

At its core, this assembly consists of multiple components working in harmony. Each part, from the guiding tracks to the actuating elements, is meticulously engineered to provide optimal performance. Understanding the interaction between these elements is essential for grasping how this system achieves its remarkable efficiency.

Additionally, the design incorporates safety features that enhance reliability during operation. These safeguards prevent unintended movement and ensure user protection, demonstrating the thoughtful consideration given to both functionality and safety in its development.

To fully appreciate the mechanism, one must examine the engineering principles that underpin its operation. Key aspects include force distribution, material selection, and maintenance protocols that contribute to its longevity. A thorough comprehension of these factors enables users to better engage with the system and address any potential issues effectively.

Common Issues with Sky Sliders

When it comes to retractable window systems, users often encounter several recurring challenges that can impact functionality and performance. Understanding these prevalent problems can aid in timely resolution and enhance the overall experience.

| Issue | Description | Possible Solutions |

|---|---|---|

| Sticking Mechanism | Components may become obstructed, preventing smooth operation. | Inspect for debris and lubricate tracks regularly. |

| Alignment Problems | Units can become misaligned, causing difficulty in opening and closing. | Check and adjust the framework to ensure proper positioning. |

| Wear and Tear | Over time, parts may degrade, leading to reduced efficiency. | Replace worn components as needed and conduct routine maintenance. |

| Water Leakage | Improper sealing can result in water entering the interior space. | Inspect seals and replace damaged weatherstripping to prevent leaks. |

| Temperature Sensitivity | Extreme temperatures can affect the operation of materials. | Avoid exposing the system to direct sunlight for prolonged periods. |

Essential Tools for Repair

Having the right instruments at your disposal is crucial for effectively addressing any issues that may arise. A well-equipped toolkit not only simplifies the process but also enhances efficiency and accuracy in your tasks. Below are some indispensable items that every technician should consider having on hand.

- Screwdrivers: A variety of sizes and types, including flathead and Phillips, are essential for loosening and tightening screws.

- Pliers: Both needle-nose and standard pliers are useful for gripping, twisting, and cutting materials.

- Wrenches: A set of adjustable and socket wrenches will help in dealing with nuts and bolts of different sizes.

- Multimeter: This device is critical for measuring voltage, current, and resistance, aiding in diagnosing electrical issues.

Additionally, consider including the following tools for enhanced capability:

- Hex Keys: Often used for assembling components, these are indispensable for dealing with hex screws.

- Wire Cutters: Essential for trimming wires and cables, ensuring clean and precise cuts.

- Heat Gun: Useful for softening materials or shrinking tubing.

- Tape Measure: Accurate measurements are key, making this tool a must-have for any task.

By ensuring that your toolkit includes these vital instruments, you will be well-prepared to tackle any challenges that may present themselves during your work.

Step-by-Step Repair Guide

This section provides a detailed approach to troubleshooting and fixing common issues associated with the device. By following the outlined steps, users can systematically identify problems and implement effective solutions, ensuring optimal performance.

Before starting, gather all necessary tools and materials. This preparation is essential for a smooth process and will save time during the task. Below is a checklist of items you might need:

| Tool/Material | Purpose |

|---|---|

| Screwdriver Set | To remove screws and access internal components |

| Multimeter | To test electrical connections and functionality |

| Replacement Parts | For any components that need to be substituted |

| Cleaning Cloth | To clean surfaces and improve functionality |

Follow these key steps to effectively address issues:

- Identify the problem: Observe the device carefully and note any irregularities.

- Gather tools: Ensure you have all necessary tools and materials ready.

- Access the internal components: Use the screwdriver to remove the casing carefully.

- Inspect connections: Check for loose wires or damaged components using the multimeter.

- Replace faulty parts: If any components are broken, substitute them with new ones.

- Reassemble the device: Carefully put everything back together, ensuring all screws are tightened.

- Test functionality: Power on the device and check if the issues are resolved.

By adhering to this structured approach, users can enhance their troubleshooting skills and effectively maintain the device’s functionality over time.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of any mechanical device. By following a few straightforward guidelines, users can ensure optimal performance and minimize the likelihood of issues over time. Regular attention to maintenance can lead to enhanced efficiency and a more enjoyable experience overall.

Regular Inspections

Conducting routine assessments is crucial. Look for signs of wear and tear, ensuring that all components are functioning correctly. Identifying minor problems early can prevent them from escalating into major failures.

Lubrication and Cleaning

Keep all moving parts well-lubricated to reduce friction and wear. Regular cleaning helps to eliminate debris that could impede operation. A clean system not only performs better but also lasts longer.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Monthly | Check for any visible damage or wear. |

| Lubrication | Quarterly | Use appropriate lubricants for specific components. |

| Deep Cleaning | Annually | Remove all dirt and debris, ensuring smooth operation. |

Safety Precautions During Repair

When engaging in maintenance tasks, ensuring personal safety and protecting the equipment is paramount. Adhering to proper guidelines can prevent accidents and prolong the lifespan of the apparatus. This section outlines essential measures to consider while undertaking such activities.

General Safety Guidelines

- Always work in a well-ventilated area to avoid inhaling harmful fumes.

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and masks.

- Ensure the power source is disconnected before starting any work.

- Keep your workspace organized to minimize the risk of accidents.

- Be mindful of any sharp edges or moving parts that could cause injury.

Tools and Equipment Handling

- Use tools that are in good condition and suitable for the task at hand.

- Always follow the manufacturer’s instructions for tool usage.

- Store tools safely after use to prevent tripping hazards.

- Inspect all equipment before use to ensure it is functioning properly.

By following these precautions, you can help ensure a safe and effective working environment during maintenance activities.

Replacing Broken Components

Maintaining the functionality of your equipment often involves addressing damaged or malfunctioning parts. This section outlines the essential steps and considerations for effectively substituting compromised elements to ensure optimal performance.

Before beginning the replacement process, it’s crucial to follow a systematic approach:

- Identify the Issue: Thoroughly examine the equipment to pinpoint which components are damaged.

- Gather Necessary Tools: Prepare all required tools and replacement parts ahead of time to streamline the process.

- Ensure Safety: Disconnect the power source and take safety precautions to protect yourself during the replacement.

Once you are prepared, follow these steps to replace the broken parts:

- Remove the Damaged Component: Carefully detach the defective part, making sure not to damage surrounding areas.

- Install the New Component: Position the new part correctly and secure it according to the manufacturer’s specifications.

- Test the Equipment: After installation, reconnect the power and test the system to confirm proper functionality.

Regular maintenance and timely replacements can significantly extend the lifespan of your apparatus. Keep a checklist of common issues and their solutions for future reference.

Troubleshooting Common Malfunctions

When working with mechanical devices, it’s not uncommon to encounter various issues that may affect performance. Identifying and addressing these problems promptly can enhance functionality and prolong the lifespan of the equipment. This section outlines typical malfunctions and offers guidance on how to resolve them effectively.

1. Unresponsive Mechanism

If the device does not respond to commands, several factors could be at play. Start by checking the power source; ensure that connections are secure and that the battery, if applicable, is charged. If the issue persists, inspect for any visible damage or wear that may impede operation. Regular maintenance can help prevent this from occurring.

2. Unusual Noises

Strange sounds during operation often signal underlying issues. Listen carefully for grinding, squeaking, or rattling noises, as these may indicate insufficient lubrication or misalignment of components. To rectify this, apply an appropriate lubricant to moving parts and realign any misaligned sections. Regular checks can mitigate the risk of further complications.

When to Seek Professional Help

Knowing when to call in an expert is crucial for ensuring safety and efficiency. Some issues require specialized knowledge and tools that only a professional possesses. Here are several indicators that it might be time to seek assistance.

- Persistent Issues: If problems continue to arise despite your best efforts, it’s a sign that a deeper issue may be present.

- Unusual Noises: Strange sounds during operation can indicate mechanical failures that need expert evaluation.

- Visible Damage: Cracks, bends, or other visible defects should prompt immediate professional assessment to avoid further complications.

- Difficulty in Operation: If functioning becomes erratic or inconsistent, professional diagnosis is necessary to restore proper performance.

- Lack of Experience: When unfamiliar with the necessary tools or techniques, it’s best to leave the task to those with the right expertise.

Consulting a specialist can save time, prevent accidents, and ultimately ensure that everything operates smoothly and safely.

Cost Analysis of Repairs

Understanding the financial implications of maintenance is crucial for informed decision-making. A comprehensive evaluation involves assessing both direct and indirect expenses associated with the restoration process. This section aims to break down the various components that contribute to the overall cost, enabling stakeholders to grasp the economic aspects effectively.

Initial Assessment Costs: The first step in any evaluation is the preliminary examination, which often requires the expertise of a professional. These fees can vary significantly based on the complexity of the issue and the technician’s experience.

Parts and Materials: Another key factor in the financial landscape is the cost of necessary components. Prices can fluctuate due to factors such as brand, quality, and availability, making it essential to compare options before proceeding.

Labor Expenses: Skilled workmanship is vital for successful interventions. Labor charges may depend on regional rates and the duration of the job. It’s advisable to obtain quotes from multiple service providers to ensure a competitive price.

Additional Fees: Often, unforeseen expenses arise during the process. These may include disposal fees for old materials, emergency service charges, or travel costs. Planning for these contingencies can prevent budget overruns.

By thoroughly analyzing these elements, individuals can make well-informed decisions that align with their financial capabilities and long-term goals.

Upgrading Your Sky Slider

Enhancing the performance and functionality of your outdoor equipment can greatly improve your overall experience. This section outlines various methods to elevate your current setup, ensuring it operates at its best. From simple modifications to advanced enhancements, these strategies will help you enjoy the full potential of your system.

Consider the following options for effective upgrades:

- Material Enhancements: Upgrading components with more durable materials can significantly extend lifespan and performance.

- New Features: Incorporate additional functionalities, such as improved locking mechanisms or advanced control systems, to increase usability.

- Weight Reduction: Switching to lighter materials can enhance maneuverability and ease of use.

- Environmental Adaptations: Adjusting parts to better withstand weather conditions can prevent wear and ensure consistent performance.

Before proceeding with any modifications, assess your current setup to identify areas for improvement. Prioritize upgrades that align with your specific needs and usage patterns.

For successful implementation, follow these steps:

- Research: Investigate available options that fit your model and performance goals.

- Compatibility Check: Ensure that new components are compatible with existing parts.

- Installation: Follow instructions carefully, or seek professional assistance if necessary.

- Testing: After upgrades, thoroughly test the system to ensure all enhancements work as intended.

By strategically upgrading your equipment, you can create a more enjoyable and efficient experience, maximizing its capabilities for your specific activities.