When it comes to personal watercraft, keeping each component in optimal condition ensures reliability, performance, and longevity on the water. This guide covers essential steps to preserve, diagnose, and enhance the functionality of these marine vehicles, making it invaluable for both seasoned enthusiasts and those just starting their journey in watercraft maintenance.

Here, you’ll find detailed insights into routine upkeep, problem-solving techniques, and best practices for tackling mechanical and electrical challenges. From engine adjustments to hull inspections, each section provides structured advice to help keep your vehicle performing at its peak, ultimately enhancing both its lifespan and your enjoyment.

Whether you’re addressing specific issues or simply seeking knowledge on preventive care, this guide offers comprehensive knowledge tailored to various technical needs. By following these well-researched methods, readers can confidently maintain their watercraft’s condition, ensuring smoother and more reliable performance season after season.

Kawasaki ZXI 1100 Repair Guide

This guide provides essential steps and practical advice for maintaining and resolving common issues in high-performance watercraft. By following these recommendations, users can enhance both the durability and performance of their vehicle, ensuring a reliable and enjoyable experience on the water.

Here are some key areas to focus on when keeping this type of watercraft in prime condition:

- Engine Care: Regular inspections and upkeep are vital. Check the engine’s key components frequently, including filters, seals, and connections, to avoid common malfunctions. Clean and replace parts as necessary to ensure optimal performance.

- Fuel System Maintenance: Ensuring that fuel lines and filters are in good condition helps prevent clogs and buildup. Consider using additives that can help improve fuel quality and maintain the system’s cleanliness.

- Electrical Systems: Regularly inspect wiring and connections, especially around the ignition and battery compartments. Check for corrosion or loose connections, as these can lead to start-up issues or operational inconsistencies.

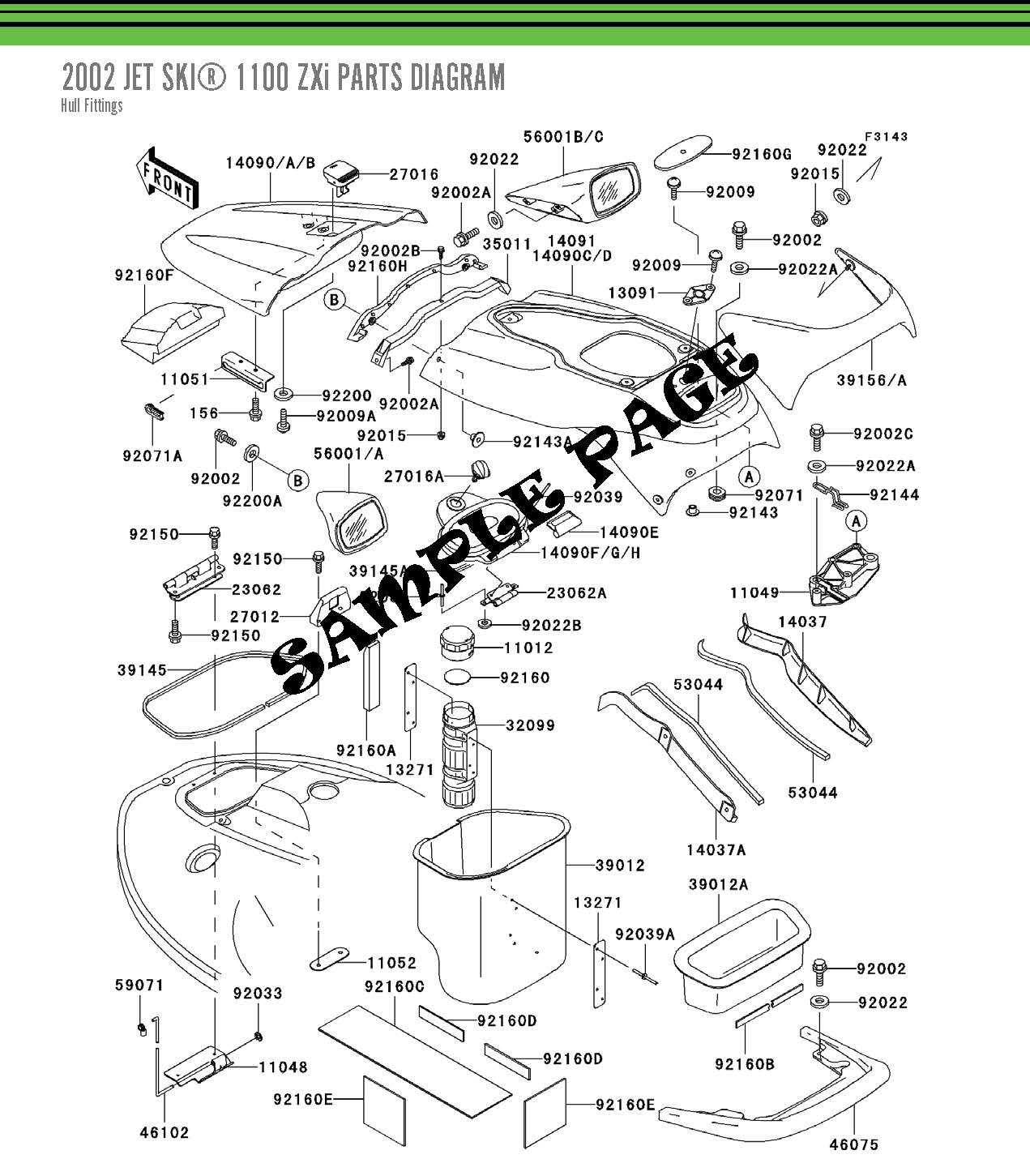

- Hull and Exterior Check: Examine the exterior structure for any signs of wear or damage, particularly after heavy use. Addressing minor repairs early can prevent further degradation and help maintain the vehicle’s aesthetics.

By adhering to these maintenance practices, owners can extend the operational life and efficiency of their watercraft, avoiding costly repairs and improving overall handling and performance.

Common Engine Issues and Fixes

Understanding potential engine issues and their solutions is crucial for keeping any watercraft in top shape. This section outlines common problems that can arise within the engine and provides practical steps for identifying and resolving these issues to ensure a smooth and reliable ride.

Engine Starting Problems

One of the most frequent issues owners encounter is difficulty starting the engine. Causes may vary, ranging from fuel supply blockages to battery complications. Begin by checking the fuel lines for any obstructions or leaks, ensuring a clear path for fuel flow. Next, inspect the battery connections for corrosion and verify that the battery holds a full charge. A well-maintained fuel and power system often resolves this issue.

Overheating Concerns

Overheating can lead to severe engine damage if left unaddressed. Regularly examine the cooling system for blockages, especially within the intake and exhaust areas. Make sure there is no buildup of debris, which can hinder water flow, an essential part of the cooling process. Additionally, check the coolant levels and top them up as needed. Regular attention to these areas can prevent overheating and prolong engine life.

Essential Tools for DIY Maintenance

Performing regular upkeep on your watercraft can greatly extend its life and enhance its performance. For those who prefer hands-on work, having a well-equipped toolkit is essential. Here, we outline the fundamental tools every DIY enthusiast should have on hand to tackle routine tasks efficiently and safely.

Basic Hand Tools

The first step to a successful maintenance routine is gathering quality hand tools. Essentials include a reliable set of screwdrivers, wrenches, pliers, and a socket set. These are the backbone of most mechanical tasks, helping you access tight spaces and adjust various fittings with precision. Look for durable materials and a comfortable grip to make your work easier and prevent hand fatigue during extended use.

Specialized Tools for Marine Engines

Beyond basic tools, there are specific instruments designed to handle marine engine tasks. A torque wrench ensures you’re applying the correct amount of force to bolts, while a compression gauge can help check engine health. Adding a multimeter to your kit is invaluable for diagnosing electrical issues, allowing you to measure voltage, current, and resistance. These specialized tools empower you to identify issues early, improving reliability and reducing costly repairs.

With the right tools, DIY maintenance becomes manageable, providing peace of mind and saving time in the long run. Equipping yourself properly will prepare you for virtually any routine task, keeping your equipment in top condition.

Fuel System Troubleshooting Tips

Maintaining optimal performance of the fuel system is crucial for smooth engine operation and efficient fuel use. A well-functioning system ensures consistent power and prevents performance issues during usage. In this section, we’ll explore key areas to check when addressing common fuel-related problems.

1. Check for Clogged Filters: Over time, filters can accumulate debris, reducing fuel flow. Regularly inspect and clean or replace filters as needed to prevent blockages that can impact performance.

2. Inspect Fuel Lines: Fuel lines should be free of kinks, cracks, or leaks. Ensure that all connections are secure, as any leaks or blockages in the lines can affect the system’s efficiency.

3. Examine the Fuel Pump: A faulty fuel pump may lead to inconsistent fuel delivery. Listen for unusual noises and check that the pump is functioning smoothly. Replacing or repairing the pump may be necessary if issues persist.

4. Look for Carburetor Issues: If the system includes a carburetor, check for signs of clogs or wear. Adjusting the fuel-air mixture and cleaning the carburetor can resolve common performance problems related to poor combustion.

5. Test for Air Leaks: Ensure there are no air leaks in the system, which can affect fuel delivery and engine performance. Carefully examine gaskets and seals, and replace any that show signs of wear.

By regularly inspecting these components, you can maintain the fuel system’s reliability, ensuring smooth and e

Electrical Components Diagnosis

Identifying issues within electrical parts is crucial to maintaining reliable performance. A systematic approach allows for accurate fault identification, ensuring each component operates as intended. This process involves careful testing and observation to locate potential weaknesses in the electrical system.

Basic Testing Procedures

Start by examining visible wiring and connections. Inspect for signs of wear, corrosion, or loose contacts, as these can lead to intermittent or complete failures. Use a multimeter to measure continuity and voltage at various points, helping to pinpoint areas where current flow may be obstructed or inconsistent.

Advanced Diagnostic Techniques

For more complex components, advanced techniques like resistance and current flow testing provide deeper insight into potential issues. Analyzing each part’s response under load conditions can reveal hidden faults. These methods allow for thorough diagnostics, ensuring all elements are evaluated for optimal performance.

Cooling System Maintenance Guide

Maintaining an effective cooling system is crucial for ensuring optimal performance and longevity of your watercraft. Regular attention to this system prevents overheating and promotes efficient operation, ultimately enhancing your riding experience.

Below are essential steps and tips for proper maintenance:

-

Regular Inspections:

- Check for any signs of leaks or damage in hoses and connections.

- Examine the coolant level regularly to ensure it is within the recommended range.

-

Coolant Replacement:

- Change the coolant at intervals specified by the manufacturer.

- Use a suitable coolant mixture to prevent corrosion and freezing.

-

Cleaning the Cooling System:

- Remove debris and buildup from the cooling intake and outlet.

- Flush the system with water to eliminate contaminants.

-

Checking the Water Pump:

- Inspect the impeller for wear and tear; replace if necessary.

- Ensure the water pump is functioning correctly to maintain proper flow.

By following these guidelines, you can effectively maintain the cooling system of your vessel, ensuring reliable performance and enhancing its lifespan.

Carburetor Tuning and Adjustments

Proper tuning and adjustments of the fuel delivery system are essential for optimal performance and efficiency of watercraft engines. This process ensures that the air-fuel mixture is at the right ratio, promoting smooth operation and responsiveness while minimizing emissions. Understanding the principles of adjustment can significantly enhance the overall experience on the water.

Essential Steps for Tuning

Follow these key steps to achieve precise tuning of the fuel system:

- Inspect Components: Begin with a thorough inspection of the entire fuel system, including the carburetors, hoses, and filters. Look for any signs of wear or damage that may affect performance.

- Check Float Levels: Adjust the float levels in the carburetors to ensure proper fuel supply. Incorrect float heights can lead to flooding or insufficient fuel delivery.

- Adjust Idle Speed: Set the idle speed to the manufacturer’s specifications, ensuring the engine runs smoothly at low RPMs.

- Fine-Tune Mixture Settings: Use the adjustment screws to modify the air-fuel mixture. Start with the factory settings and make incremental changes based on engine response.

Testing and Final Adjustments

After performing the initial tuning, testing is crucial to ensure everything is functioning correctly. Follow these recommendations:

- Take the vessel for a test run, paying attention to acceleration and responsiveness.

- Monitor the engine for any unusual sounds or vibrations that may indicate misadjustments.

- Make small adjustments as needed and retest to verify improvements.

Continual monitoring and fine-tuning will lead to enhanced performance and longevity of the engine.

Inspecting and Replacing the Propeller

Ensuring optimal performance of your watercraft involves regular checks and maintenance of the propulsion components. One critical element is the propeller, which plays a significant role in the efficiency and speed of your vessel. This section outlines the steps necessary to inspect and replace this essential part to maintain peak performance.

Before beginning the inspection, gather the required tools:

- Wrench set

- Screwdriver

- Propeller puller (if needed)

- Cleaning materials

- Protective gloves

Follow these steps for a thorough inspection:

- Visual Inspection: Examine the propeller for any visible signs of damage such as cracks, dents, or bent blades.

- Check for Corrosion: Look for any rust or corrosion that may affect performance. Pay special attention to the hub area.

- Test for Play: With the propeller attached, wiggle it to check for excessive play, which may indicate wear in the shaft or bearings.

If the inspection reveals significant wear or damage, replacement may be necessary. To proceed with the replacement, follow these steps:

- Remove the Old Propeller: Use a wrench to loosen the retaining nut and gently pull off the propeller. If it is stuck, a propeller puller can assist in removal.

- Clean the Shaft: Remove any debris or corrosion from the shaft where the new propeller will be installed.

- Install the New Propeller: Align the new propeller onto the shaft and secure it with the retaining nut. Ensure it is tightened to the manufacturer’s specifications.

- Final Check: After installation, rotate the propeller by hand to ensure it spins freely without obstruction.

Regularly inspecting and replacing the propeller will contribute to the longevity and performance of your watercraft, ensuring enjoyable and safe outings on the water.

Hull and Bodywork Restoration Tips

Restoring the exterior of your watercraft involves meticulous attention to detail and an understanding of the materials involved. Whether you’re dealing with scratches, fading, or structural damage, proper techniques can significantly enhance both the appearance and longevity of the hull and surrounding components.

Assessing Damage

Before embarking on any restoration project, it’s essential to conduct a thorough evaluation of the damage. Look for signs of wear, such as cracks, dents, or discoloration. Identifying the extent of the issues will help in determining the best approach for repair. It’s advisable to document the findings, as this can guide your restoration process and track improvements over time.

Repair Techniques

Once you have assessed the damage, you can choose appropriate repair methods. For minor scratches, using a polishing compound can effectively restore shine. For more significant issues, consider using epoxy or fiberglass materials to fill gaps and reinforce structural integrity. After repairs, sanding and refinishing the surface will provide a smooth, professional appearance. Finally, applying a protective coating will safeguard the surface from future damage.

Steering and Handlebar Adjustments

Ensuring optimal control and comfort while operating a watercraft is crucial for an enjoyable experience. Proper alignment and adjustment of the steering and handlebar system contribute significantly to maneuverability and rider safety. This section provides insights into how to achieve these adjustments effectively.

Importance of Proper Alignment

Alignment issues can lead to difficulty in steering and an overall lack of stability. Regular checks and adjustments can prevent potential handling problems. Key points to consider include:

- Assessing the straightness of the handlebars.

- Verifying the steering mechanism’s response to input.

- Ensuring that the grips are securely fastened and positioned for comfort.

Adjustment Process

Follow these steps to adjust the steering and handlebars:

- Loosen the handlebar clamps using the appropriate tool.

- Position the handlebars to your desired angle, keeping in mind the natural wrist position for comfort.

- Retighten the clamps, ensuring even pressure on both sides.

- Check for any play in the steering system by turning the handlebars from side to side.

By maintaining proper adjustments, you enhance both the performance and safety of your watercraft, allowing for a more enjoyable ride.

Routine Lubrication for Moving Parts

Proper maintenance of mechanical systems is essential for ensuring optimal performance and longevity. Regular lubrication of moving components plays a vital role in reducing friction, minimizing wear, and preventing corrosion. This section highlights the importance of routine lubrication and provides guidance on best practices to keep these systems operating smoothly.

Adhering to a consistent lubrication schedule can significantly enhance the lifespan of various components. Here are some key points to consider:

- Identify all moving parts that require lubrication.

- Use the recommended lubricant types based on manufacturer specifications.

- Inspect components for signs of wear or damage before applying lubricant.

Following are the steps to perform effective lubrication:

- Clean the surfaces of moving parts to remove dirt and old lubricant.

- Apply the appropriate lubricant evenly to each part, ensuring full coverage.

- Remove any excess lubricant to prevent buildup, which can attract dirt.

- Regularly check lubrication levels and replenish as needed.

Incorporating these practices into a routine maintenance schedule will help maintain efficiency and reduce the likelihood of mechanical failures.

Preparing for Off-Season Storage

When the time comes to put your watercraft away for the colder months, proper preparation is essential to ensure its longevity and optimal performance for the next season. Taking the right steps during this period can help prevent damage and deterioration, keeping your vehicle in excellent condition until you’re ready to use it again.

First, start by thoroughly cleaning the exterior and interior of the craft. Removing any debris, salt, or grime will help prevent corrosion and other issues that could arise during storage. Use a mild soap solution and fresh water to scrub down surfaces, and ensure everything is dry before covering it up.

Next, check the fluid levels. This includes oil, coolant, and fuel. Topping off or changing these fluids not only ensures they remain in good condition but also minimizes the risk of contaminants causing damage during the off-season. Consider adding a fuel stabilizer to prevent the fuel from degrading over time.

Additionally, disconnecting the battery and storing it in a cool, dry place can prevent discharge and prolong its life. If possible, use a trickle charger to keep it in good shape while it’s not in use. Finally, cover the vehicle with a breathable cover to protect it from dust and moisture while allowing air circulation.

By following these steps, you can ensure that your watercraft remains in prime condition during the off-season, ready for adventure when the weather turns favorable again.