Every sewing enthusiast knows the joy of creating beautiful pieces with their trusted machine. However, even the most reliable devices can face occasional challenges. Understanding how to address these issues effectively can significantly enhance your sewing experience, allowing for uninterrupted creativity and productivity.

In this section, we will explore common problems that can arise with your stitching companion and provide insightful solutions to help you navigate these hurdles. With a bit of guidance, you can quickly identify the source of the issue and apply the necessary fixes, ensuring your machine remains in top-notch condition.

Whether you’re a novice or a seasoned professional, having a solid foundation of troubleshooting techniques can empower you to take control of your crafting journey. Dive into the nuances of maintenance and problem-solving to keep your device running smoothly and efficiently.

Understanding the Brother CS6000i

This section provides an overview of a popular sewing machine model, designed for both novice and experienced users. It highlights key features that enhance the sewing experience, making it an ideal choice for various projects, from simple repairs to more complex creations.

The device boasts a user-friendly interface, equipped with an array of built-in stitches that cater to diverse sewing needs. Additionally, it offers adjustable settings that allow users to customize their stitching preferences, ensuring optimal results with every project.

Portability is another notable aspect, as this machine is lightweight and easy to transport, perfect for those who enjoy sewing on the go. Its robust construction ensures durability, while thoughtful design elements enhance accessibility and ease of use.

In summary, this versatile sewing machine stands out for its combination of functionality and convenience, making it a valuable tool for anyone looking to explore their creativity in fabric crafting.

Common Issues with CS6000i Machines

Many users encounter a variety of challenges with their sewing machines. Understanding these common problems can help in troubleshooting and ensuring a smoother sewing experience. Below are some frequent issues faced by owners, along with their potential causes and solutions.

- Thread Jamming:

This can occur when the thread is not threaded correctly or if there is debris in the bobbin area.

- Skipped Stitches:

Skipped stitches may be a result of using the wrong needle type or improper tension settings.

- Machine Not Turning On:

If the machine fails to power up, check the power cord and foot pedal connections.

- Unusual Noises:

Strange sounds could indicate that the machine needs lubrication or that parts are misaligned.

- Tension Problems:

Incorrect tension can lead to thread bunching or loops on the fabric surface.

By addressing these common issues, users can often restore functionality and enhance their sewing experience.

Tools Needed for Basic Repairs

Having the right equipment is essential for performing straightforward maintenance and fixes on your sewing machine. Proper tools not only enhance efficiency but also ensure that tasks are completed safely and effectively. Below is a list of essential items that can help you tackle common issues with ease.

- Screwdrivers: A set of both flat-head and Phillips screwdrivers is crucial for loosening and tightening various screws.

- Needle Nose Pliers: These are helpful for gripping small components and reaching into tight spaces.

- Seam Ripper: A handy tool for removing stitches or mistakes without damaging the fabric.

- Cleaning Brushes: Small brushes help remove dust and lint from the machine’s interior.

- Lubrication Oil: Essential for keeping moving parts functioning smoothly and preventing wear.

- Replacement Needles: Keeping a variety of needles on hand is important for different fabric types and projects.

Gathering these tools will prepare you for most minor adjustments and upkeep tasks, allowing you to maintain your equipment in optimal condition.

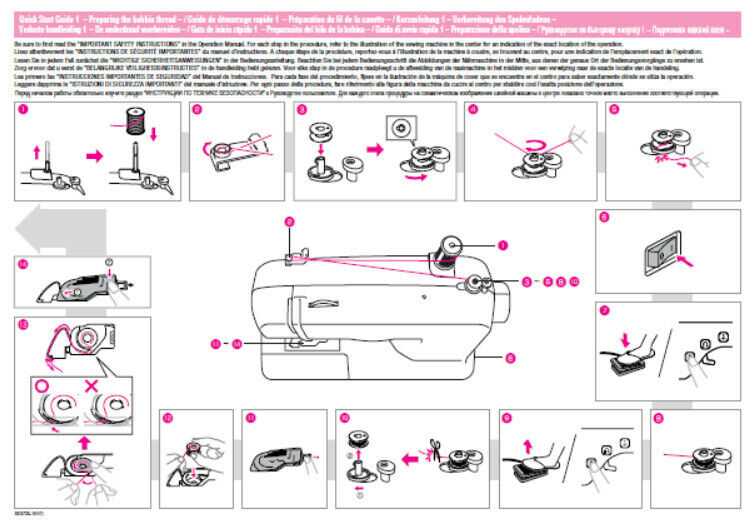

Step-by-Step Guide to Threading

Properly setting up the threading mechanism is crucial for achieving optimal sewing results. This guide will walk you through the process of threading your sewing device, ensuring smooth operation and beautiful stitches.

Step 1: Prepare the Thread

Start by placing the spool of thread onto the spool pin. Ensure that the thread unwinds smoothly from the spool. If you are using a new spool, remove any packaging that might obstruct the thread’s movement.

Step 2: Guide the Thread

Pull the end of the thread and guide it through the designated thread path. Most devices will have clear markings indicating the route. Follow these markings closely to avoid tangling.

Step 3: Thread the Tension Mechanism

Pass the thread through the tension discs. This step is essential for regulating the thread’s tension during sewing. Make sure it is seated correctly to prevent any issues.

Step 4: Insert the Thread Through the Take-Up Lever

Guide the thread into the take-up lever. This component helps maintain consistent tension as you sew. Ensure the thread is fully engaged within the lever.

Step 5: Thread the Needle

Finally, thread the needle by passing the end of the thread through the needle’s eye. Some may find it easier to use a needle threader if available. Make sure there is a tail of thread extending from the needle.

Step 6: Pull the Bobbin Thread

To complete the threading process, hold the needle thread and turn the handwheel towards you.. This action will draw the bobbin thread up through the needle plate. Gently pull both threads towards the back of the machine.

Following these steps will ensure that your device is properly threaded, leading to successful and hassle-free sewing experiences.

Troubleshooting Stitching Problems

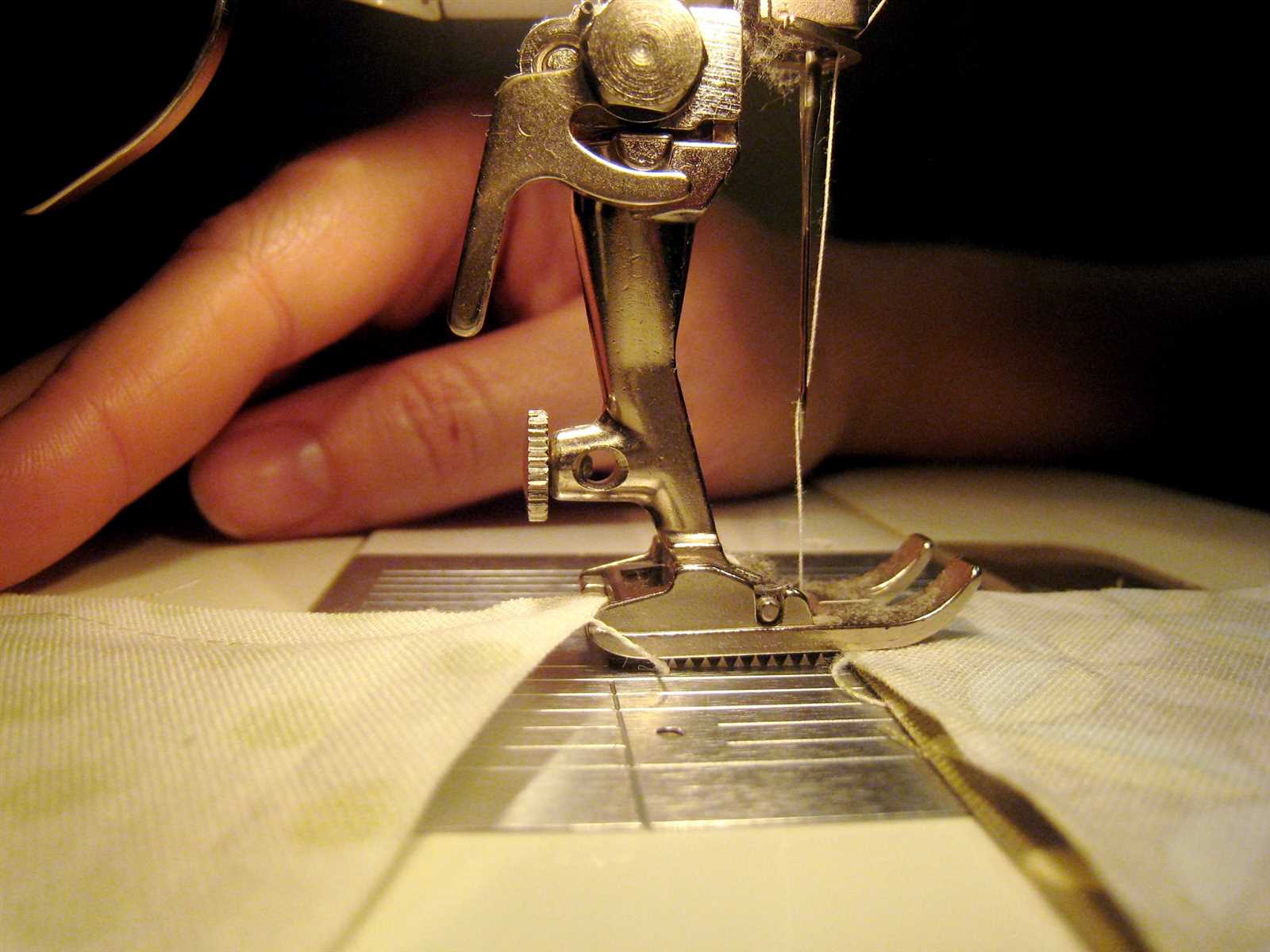

Encountering issues with your sewing can be frustrating, but understanding common stitching problems can help you quickly identify and resolve them. By examining various factors, you can enhance the quality of your work and ensure smoother operation.

Common Issues and Their Causes

- Uneven Stitching: This may result from incorrect tension settings or the use of incompatible thread and fabric types.

- Skipped Stitches: Often caused by a dull needle, incorrect needle type, or improper threading.

- Thread Bunching: Usually occurs when the upper thread tension is too tight or if the bobbin is incorrectly inserted.

- Loose Stitches: This can be a result of poor thread tension or using the wrong needle size for the fabric.

Steps to Resolve Stitching Issues

- Check and adjust the tension settings according to the fabric type.

- Replace the needle with a new one suitable for your material.

- Ensure that the machine is threaded correctly, following the user guide.

- Examine the bobbin case and ensure the bobbin is wound evenly and inserted properly.

- Test different thread types and sizes to find the best match for your project.

By systematically troubleshooting these common problems, you can achieve better results in your sewing projects and enjoy a more efficient experience.

Cleaning and Maintaining Your Machine

Proper upkeep of your sewing device is essential for ensuring optimal performance and longevity. Regular cleaning and maintenance not only enhance its functionality but also prevent potential issues that may arise from neglect. This guide outlines key practices to keep your equipment in top shape.

- Daily Cleaning: Remove any lint or debris from the feed dogs and needle area after each use. A soft brush can help dislodge any particles.

- Weekly Maintenance: Check and clean the bobbin case and surrounding areas. A quick wipe with a soft cloth can make a significant difference.

- Monthly Inspection: Examine the needle for wear and replace it if necessary. A dull needle can cause fabric damage and uneven stitches.

Follow these steps to ensure a smooth sewing experience:

- Unplug the device before cleaning to ensure safety.

- Use a vacuum with a brush attachment to gently remove dust and threads from the machine.

- Lubricate moving parts as indicated in the user guidelines, using appropriate oil to avoid damage.

- Store the machine in a dry place, covered to protect it from dust.

By following these maintenance tips, you can extend the life of your sewing apparatus and enjoy flawless stitching for years to come.

Replacing the Needle: A How-To

Changing the sewing needle is an essential maintenance task that can significantly enhance the performance of your sewing machine. A fresh needle ensures clean stitches and prevents potential fabric damage, making it an important step for both novice and experienced users.

Gathering the Necessary Tools

Before you begin, ensure you have the following items on hand: a new needle compatible with your machine, a screwdriver (if required), and good lighting to help you see clearly. Having these tools ready will make the process smoother and more efficient.

Steps to Replace the Needle

1. Turn off the machine: For safety, always power down your device before making any adjustments.

2. Remove the old needle: Locate the needle clamp, usually situated at the base of the needle. Loosen the clamp screw using your screwdriver, then gently pull out the old needle.

3. Insert the new needle: Take your new needle, ensuring the flat side is facing the correct direction (usually towards the back). Push it into the needle holder until it cannot go any further. Tighten the clamp screw securely.

4. Test the needle: Once the new needle is in place, manually turn the handwheel to ensure it moves freely without any obstruction.

By following these steps, you’ll ensure that your sewing machine is equipped for optimal performance, allowing you to enjoy your projects without interruptions.

Fixing Tension Issues Easily

Tension problems in sewing machines can lead to frustration, affecting the quality of your stitches. Understanding the basics of thread tension is essential for achieving optimal results. This section will guide you through simple adjustments and troubleshooting techniques to help you achieve perfect tension.

Identifying Tension Problems

Common signs of incorrect tension include uneven stitches, thread breakage, or fabric puckering. Inspecting your machine for any visible issues is the first step. Ensure the threading is correct and that the bobbin is properly installed.

Making Adjustments

To fix tension, locate the tension dial and make small adjustments. Turning it clockwise typically tightens the tension, while turning it counterclockwise loosens it. Test your machine on scrap fabric to see if the changes improve stitch quality before proceeding to your project.

Updating Machine Software and Settings

Regularly refreshing the software and configurations of your sewing device is essential for maintaining optimal performance and accessing the latest features. By keeping the machine updated, users can ensure improved functionality, resolve existing bugs, and enhance overall user experience. This process may involve downloading updates, adjusting settings, and sometimes even performing resets.

Checking for Software Updates

To begin the update process, first, check the manufacturer’s website or the accompanying application for available software updates. It is advisable to review the release notes to understand what improvements or fixes are included. Follow the instructions provided to download the necessary files to your computer or directly to the device if supported.

Adjusting Settings for Optimal Performance

After updating the software, it’s beneficial to revisit the machine’s settings. Customizing parameters such as stitch length, tension, and speed can significantly enhance your sewing projects. Experimenting with these settings allows users to tailor their experience according to specific needs. Don’t forget to save your preferred configurations to streamline future operations.

When to Seek Professional Help

Understanding the right moment to consult an expert can save you time and prevent further issues. While many common problems can be resolved with basic troubleshooting, certain situations require specialized knowledge and skills. Recognizing these scenarios is crucial for maintaining your device’s performance and longevity.

Signs of Serious Issues

If you encounter persistent problems despite following basic solutions, it may indicate a deeper underlying issue. Look out for unusual sounds, error messages, or malfunctions that happen repeatedly. Seeking professional assistance at this stage can help diagnose and address the root cause effectively.

Complex Repairs Beyond Your Skill Level

Some repairs involve intricate components that demand specialized tools and expertise. If you find yourself unsure or overwhelmed by the complexity of a problem, it’s wise to consult a technician. Trusting a professional ensures that repairs are handled safely and accurately, allowing you to avoid potential damage to your device.

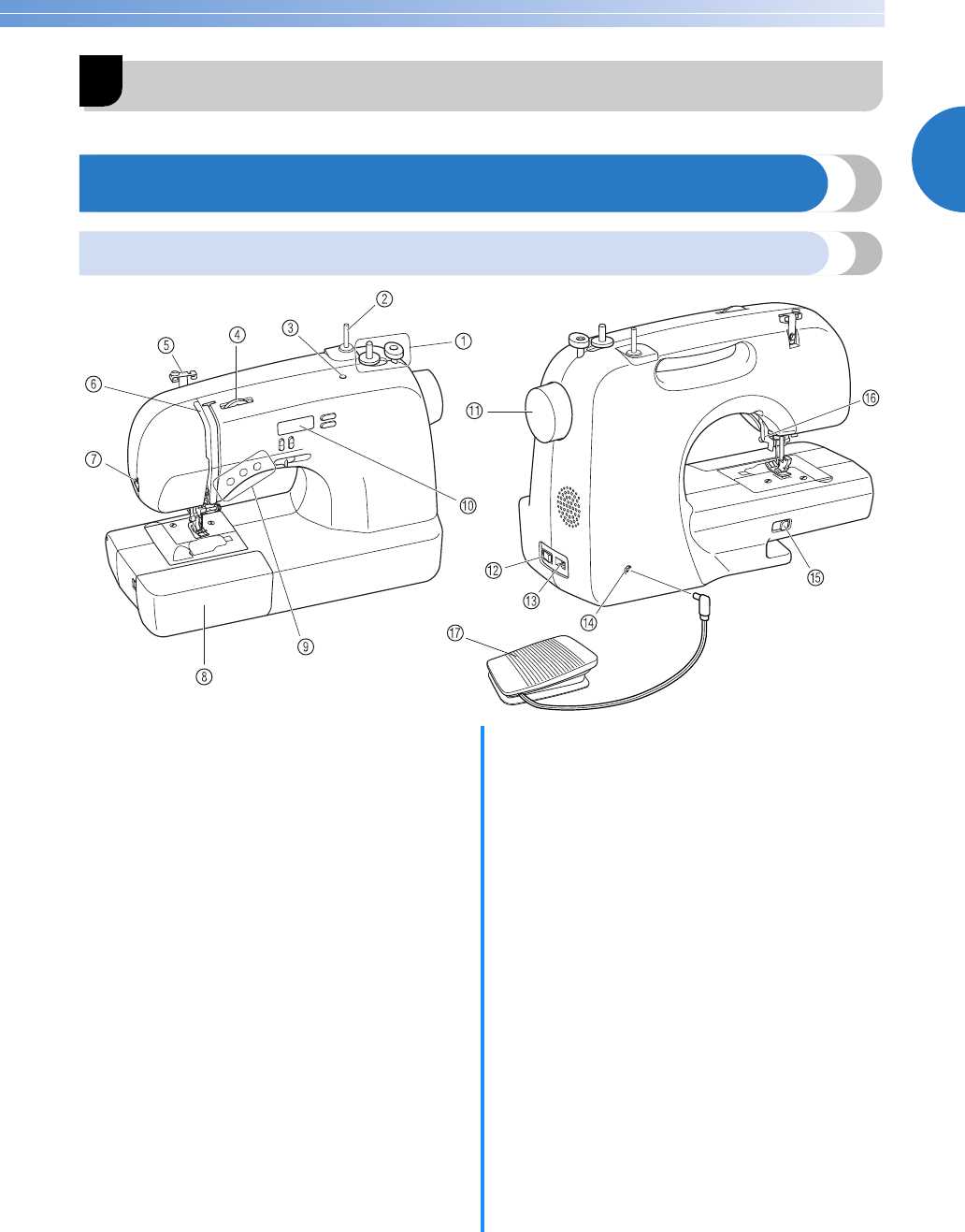

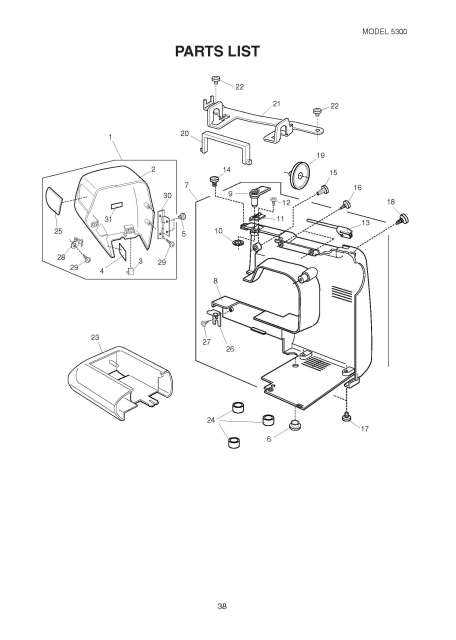

Parts Identification and Replacement

Understanding the components of your sewing machine is essential for maintaining its functionality and ensuring optimal performance. Each part plays a crucial role in the overall operation, and being able to identify them will facilitate troubleshooting and replacement when necessary.

Begin by familiarizing yourself with the key elements, such as the needle, presser foot, feed dogs, and bobbin assembly. These components often wear out or become damaged over time. When it’s time to replace any of these parts, it’s important to select the correct items that match your specific model for seamless compatibility.

To ensure successful installation, consult the user guide for detailed instructions on how to access and remove the worn parts. Make sure to keep track of any screws or small pieces during the disassembly process. After replacing the component, test the machine with scrap fabric to confirm that everything is functioning as intended.

Regular maintenance and timely replacement of worn parts not only extend the lifespan of your machine but also enhance the quality of your sewing projects. Being proactive about parts management will save time and resources in the long run.

DIY Projects to Test Your Repair Skills

Engaging in hands-on projects is an excellent way to hone your technical abilities and boost your confidence. These activities can help you understand the inner workings of devices and improve your troubleshooting techniques. Below are some creative ideas to challenge your skills and expand your knowledge.

-

Upcycling Household Items

Transform old furniture or appliances into something new and functional. Consider these options:

- Refurbish a wooden chair with fresh paint and upholstery.

- Convert an old dresser into a stylish TV stand.

- Turn glass jars into decorative storage containers.

-

Electronics Projects

Dive into electronics to enhance your circuit knowledge. Try these projects:

- Build a simple LED circuit and experiment with different designs.

- Create a homemade speaker using everyday materials.

- Assemble a basic radio from a kit.

-

Textile Creations

Explore the world of fabrics and stitching. Consider these textile-based projects:

- Sew your own tote bag using repurposed fabric.

- Make a decorative pillow cover with a unique pattern.

- Create a quilt from old clothes, showcasing memories.

-

Gardening and Outdoor Upgrades

Enhance your outdoor space with practical projects:

- Build a compost bin from reclaimed wood.

- Create vertical planters to save space.

- Install a birdhouse to attract local wildlife.

These projects not only test your skills but also provide a sense of accomplishment and creativity. Embrace the challenge, learn from each attempt, and watch your expertise grow!

Resources for Further Learning

Exploring the world of sewing machines can be both exciting and daunting. To enhance your knowledge and skills, it is essential to tap into various educational materials and platforms. This section aims to provide valuable resources that will support your journey in mastering sewing techniques and troubleshooting common issues.

Online Tutorials and Videos: Numerous websites and video platforms offer step-by-step tutorials that cover everything from basic operations to advanced techniques. Engaging with visual content can significantly improve your understanding and practical skills.

User Communities and Forums: Joining online communities or forums can be incredibly beneficial. Here, enthusiasts share their experiences, tips, and tricks, allowing you to learn from others’ successes and challenges. Participating in discussions can also provide answers to specific queries you may have.

Books and Guides: There are many informative books dedicated to sewing and machine maintenance. These texts often include illustrations and comprehensive instructions that can deepen your grasp of the subject matter. Consider checking your local library or online bookstores for recommended titles.

Workshops and Classes: Look for local workshops or classes where you can receive hands-on instruction. These settings provide a great opportunity to interact with experienced professionals who can offer personalized guidance and tips tailored to your needs.

Manufacturer Resources: Often, manufacturers provide extensive resources, including troubleshooting guides and FAQs on their official websites. These documents can be invaluable for understanding specific features and maintenance practices relevant to your machine.

By utilizing these resources, you can cultivate your sewing skills and gain the confidence needed to tackle any project that comes your way.