Off-road adventures bring both excitement and challenges, and having a dependable vehicle is essential for a successful journey. Understanding the inner workings and upkeep of your ATV ensures a smoother, safer experience on all terrains. This guide provides insights into essential upkeep steps, troubleshooting techniques, and important safety tips to keep your machine in top condition.

Whether you’re an experienced technician or a newcomer to ATV care, the following sections cover all the fundamentals of handling engine checks, system adjustments, and component replacements. Regular attention to these details helps prevent unexpected breakdowns and extends the lifespan of your vehicle.

Through this guide, you’ll learn practical skills and strategies for diagnosing performance issues, performing essential tune-ups, and maintaining every aspect of your vehicle’s systems. With the right knowledge, you can ensure your off-road companion is always ready for the next adventure.

Polaris Magnum 325 Repair Guide

In this guide, we explore the methods for maintaining and troubleshooting this specific model, focusing on ensuring longevity and optimal function. This section provides practical insights into identifying common issues, performing essential adjustments, and implementing routine upkeep to enhance the machine’s resilience over time.

Whether you’re a seasoned mechanic or a new enthusiast, this guide offers a range of techniques tailored for various mechanical challenges. By familiarizing yourself with these core strategies, you can tackle both frequent and unexpected technical hurdles confidently.

Maintenance Essentials: Begin by understanding the key parts and systems that require regular care. Frequent checks of elements like filters, belts, and wiring can prevent larger issues from arising, making it easier to maintain consistent performance.

Diagnostics and Adjustments: Pinpointing problems early can save time and costs. Learn methods for diagnosing the primary systems and adjusting components, helping to resolve minor issues before they escalate. This section covers essential checks for areas like fuel lines, engine settings, and electrical contacts.

Implementing these strategies will keep your machine in peak condition and ready for any challenge, ensuring a smoother, more reliable experience on the trails.

Essential Tools for Effective Repairs

Having the right equipment on hand is crucial to ensure smooth and precise maintenance. Quality tools can make a significant difference, helping to address mechanical issues efficiently and with greater accuracy. Here, we outline some of the most useful instruments to assist in a well-prepared and organized approach.

Basic Mechanical Tools

- Socket and Wrench Set: These are indispensable for loosening and tightening bolts and nuts of various sizes, essential in most adjustments and part replacements.

- Screwdrivers: Both flat-head and Phillips screwdrivers are necessary for handling screws in multiple parts of the assembly, ensuring all components are tightly secured.

- Torque Wrench: This tool helps apply precise force to bolts, ensuring they are neither over- nor under-tightened, which can affect the longevity of parts.

Specialized Equipment

- Multimeter: A vital device for diagnosing electrical issues, allowing you to measure voltage, current, and resistance to ensure electrical systems function correctly.

- Compression Tester: This tool evaluates the engine’s internal pressure, an essential step for understanding cylinder performance and diagnosing potential issues.

- Oil Filter Wrench: Especially useful for clean and easy removal of the oil filter during maintenance, saving time and preventing unnecessary spillage.

Safety and Utility Items

- Safety Glasses and Gloves: Protect your eyes and hands from debris and sharp edges during various repair tasks.

Step-by-Step Engine Troubleshooting

Effective engine diagnostics can greatly improve the performance and longevity of any off-road vehicle. By systematically analyzing each component, one can identify potential issues before they escalate, ensuring smoother operation and reduced downtime. Below is a detailed approach for examining common engine problems and resolving them efficiently.

1. Preliminary Checks

Start with basic assessments to rule out minor issues before delving into more intricate engine components.

- Battery Condition: Ensure the battery is fully charged and connected properly, as low power can impact performance and mimic engine faults.

- Fuel Supply: Check that the fuel tank is adequately filled and inspect for any blockages in fuel lines that may restrict flow.

- Oil Levels: Confirm that oil levels are within the recommended range, as insufficient lubrication can lead to engine wear and overheating.

2. Diagnosing the Ignition System

The ignition system plays a crucial role in engine startup and performance. By testing each part, you can identify potential malfunctions.

- Spark Plug Inspection: Remove and examine the spark plug for signs of wear, damage, or buildup. Replace if necessary, as a faulty spark plug can prevent proper ignition.

- Ignition Coil Check: Test

Maintaining the Electrical System

Proper upkeep of the electrical components is essential to ensure a vehicle’s functionality and longevity. An effective approach to managing these parts reduces the risk of sudden breakdowns and preserves the efficiency of all electrical connections. Regular attention to this system also helps prevent potential damage from environmental factors like moisture and dust.

Battery Care and Connections

The battery plays a vital role in powering various systems, so keeping it in optimal condition is crucial. Start by checking the battery terminals for corrosion or loose connections, as these can hinder performance. Clean any buildup carefully and tighten connections as needed. Maintaining a fully charged battery will also contribute to smooth system operation.

Inspecting Wires and Connectors

Frequent inspection of wires and connectors can reveal wear or damage early on, preventing major issues. Look for cracks, frays, or exposed wiring, especially in areas subject to movement or vibration. Ensure all connectors are securely fastened and free from corrosion to maintain reliable conductivity. Applying a protective coating on vulnerable areas can extend the lifespan of these components.

Fixing Suspension and Steering Issues

Addressing challenges in the suspension and steering systems is essential for maintaining smooth control and stability. Over time, various components in these systems can wear down, resulting in reduced performance and potential safety concerns. Proper diagnosis and regular maintenance ensure a smoother ride and greater confidence in handling.

Identifying Common Symptoms

Common signs of wear in suspension and steering parts include unusual vibrations, clunking noises, and difficulties in maneuvering. These symptoms may indicate worn-out shocks, loose joints, or misaligned steering, all of which can impact overall ride quality and safety. A thorough inspection can reveal specific areas that require attention.

Steps to Correct Suspension Issues

Shock absorbers and springs are among the primary components that need inspection. Start by examining shocks for leaks or signs of wear, which often manifest as poor damping and excessive bouncing. Springs should also be checked for sagging or cracks. Replacing worn-out parts promptly restores stability and improves ride comfort.

When handling steering issues, check the tie rods, bushings, and ball joints for wear or looseness. These parts are critical for accurate handling and must be in good condition. Replacing damaged components and ensuring correct alignment will restore precise steering control, improving safety and overall driving satisfaction.

Inspecting and Replacing Brakes

Ensuring the effectiveness of your stopping system is vital for safe operation. Regular evaluations help identify wear and tear, preventing potential failures. This section outlines the key steps for assessing and renewing these essential components.

Start by inspecting the brake pads and discs for any signs of damage or excessive wear. Look for cracks, uneven surfaces, or thinning materials. If the pads are worn down to a certain level, they must be replaced immediately to maintain optimal performance.

Next, check the brake fluid level and condition. If the fluid appears dark or contaminated, it is advisable to replace it to ensure efficient hydraulic operation. Bleeding the brakes may also be necessary to remove any air bubbles that could compromise braking force.

Once the assessment is complete, gather the required tools and new parts. Remove the wheel to access the braking system, then carefully detach the old pads or discs. Follow the manufacturer’s guidelines for installing new components, ensuring everything is secured properly before reassembling the wheel.

After replacing the brakes, it is crucial to conduct a test to confirm their effectiveness. Take the vehicle for a short drive, applying the brakes at various speeds to ensure proper functionality. If any issues arise, revisit the installation steps or consult a professional for assistance.

Understanding Fuel System Maintenance

Proper upkeep of the fuel mechanism is essential for ensuring optimal performance and longevity of the vehicle. Regular attention to this system not only enhances efficiency but also prevents potential issues that could lead to costly repairs. Understanding the components and their functions is crucial for effective maintenance.

Key aspects of maintaining the fuel system include:

- Inspecting Fuel Lines: Regularly check for leaks, cracks, or wear that could affect fuel delivery.

- Cleaning Fuel Filter: Ensure the filter is clean to prevent impurities from reaching the engine.

- Monitoring Fuel Quality: Use high-quality fuel to avoid contamination and deposits that can hinder performance.

- Checking Fuel Pump: Ensure the pump is functioning correctly to maintain proper pressure.

- Examining Injectors: Regular inspection and cleaning of fuel injectors can enhance efficiency and performance.

By following these maintenance practices, vehicle owners can ensure that their fuel system operates efficiently, leading to a smoother and more reliable ride.

Cooling System Inspection and Repair

Ensuring the efficient functioning of the cooling mechanism is vital for optimal performance and longevity of the vehicle. Regular assessment of this system can help identify potential issues before they escalate, thus maintaining the engine’s temperature within a safe range. This section will explore essential procedures for evaluating and addressing common problems within the cooling apparatus.

Start by examining the coolant levels and the condition of the liquid. Insufficient or contaminated coolant can lead to overheating and engine damage. Additionally, check for any leaks in the hoses, radiator, and connections that could compromise the cooling efficiency.

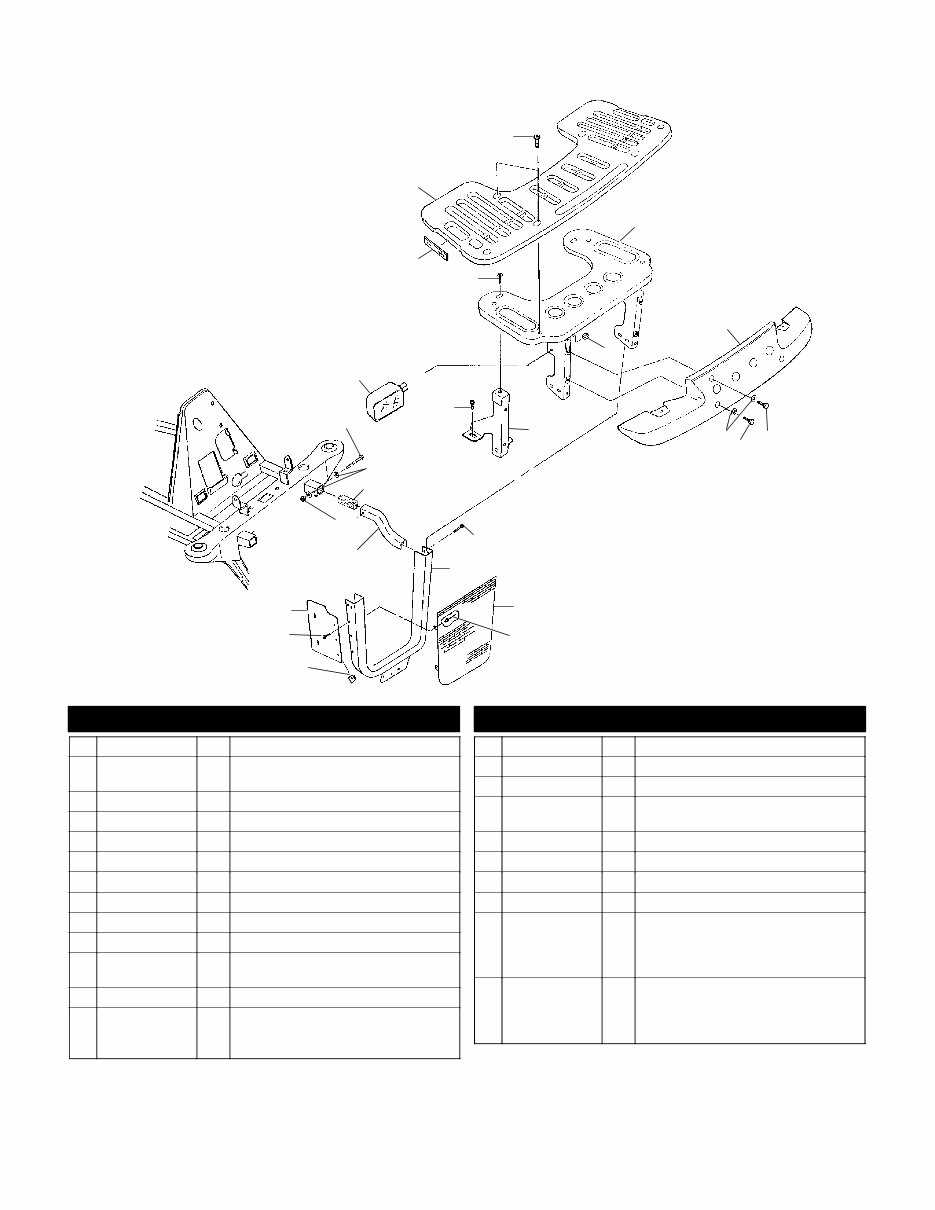

Component Inspection Steps Common Issues Solutions Coolant Reservoir Check levels and fluid quality Low levels, contamination Top up with appropriate fluid Radiator Inspect for leaks and blockages Corrosion, clogs Clean or replace as necessary Hoses Examine for cracks or wear Leaks, brittleness Replace damaged hoses Thermostat Test for proper operation Stuck open or closed Replace faulty thermostat Following these guidelines will help maintain the cooling system in excellent working condition, preventing overheating and ensuring the vehicle runs smoothly.

Restoring the Transmission Functionality

Ensuring the optimal performance of a vehicle’s drive system is crucial for a smooth and efficient ride. This section outlines the essential steps required to restore the functionality of the transmission, addressing common issues that may arise due to wear and tear or improper maintenance.

Identifying Common Issues

Before diving into the restoration process, it’s important to recognize the typical problems that can affect transmission performance:

- Delayed shifting or slipping gears

- Unusual noises during operation

- Fluid leaks beneath the vehicle

- Overheating of the transmission

Steps to Restore Functionality

Follow these steps to effectively restore the drive system’s functionality:

- Begin by inspecting the fluid level and condition; replace any contaminated fluid.

- Check for any visible leaks and repair damaged seals or gaskets.

- Examine the shift cables and linkage for proper adjustment.

- Assess the internal components for wear; replace any faulty parts as necessary.

- Test the system under various driving conditions to ensure proper operation.

By systematically addressing these areas, you can enhance the performance of the drive system, ensuring a reliable and enjoyable driving experience.

Tire and Wheel Care Basics

Maintaining the longevity and performance of your vehicle’s wheels and tires is essential for a smooth and safe ride. Regular attention to these components not only enhances safety but also improves fuel efficiency and driving comfort. This section provides fundamental practices for proper upkeep.

Regular Inspections

Conducting frequent checks on your tires and wheels can prevent larger issues down the line. Here are key aspects to focus on:

- Examine tread depth to ensure sufficient traction.

- Look for signs of uneven wear, which may indicate alignment problems.

- Check for cracks or bulges in the sidewalls.

- Inspect wheel rims for any damage or corrosion.

Inflation Maintenance

Proper tire pressure is crucial for optimal performance. Follow these guidelines for effective management:

- Use a reliable gauge to check pressure regularly.

- Adhere to manufacturer specifications for inflation levels.

- Adjust pressure based on load and weather conditions.

- Monitor pressure more frequently during extreme temperature changes.

Battery Testing and Replacement Tips

Ensuring the longevity and performance of your vehicle’s energy source is crucial for reliable operation. Proper evaluation and timely replacement can prevent unexpected failures and extend the overall lifespan of the power unit. This section offers essential guidance on how to effectively assess and replace your power source.

Evaluating Battery Health

To determine the condition of the energy unit, start with a visual inspection. Look for any signs of corrosion, leakage, or damage. Utilize a multimeter to measure the voltage; a fully charged unit should typically read around 12.6 volts or higher. If the reading is below 12.4 volts, it may be time to recharge or replace the unit. Regular maintenance can also enhance performance and reliability.

Replacement Process

When it’s time to replace the power unit, ensure you choose a compatible model for your vehicle. Begin by disconnecting the negative terminal followed by the positive terminal to avoid any electrical short. Remove the old energy source and install the new one by reversing the process. Finally, reconnect the terminals, ensuring a snug fit to facilitate optimal performance.

Preventative Care for Long-Term Performance

Maintaining the optimal functioning of your all-terrain vehicle involves a proactive approach to upkeep. Regular attention to various components can significantly enhance the lifespan and reliability of the machine. By adopting a systematic routine, you can prevent minor issues from escalating into major repairs.

Key Maintenance Practices

- Regular Inspections: Check for wear and tear on critical components such as brakes, tires, and the suspension system.

- Fluid Levels: Ensure that oil, coolant, and other fluids are topped off to maintain engine efficiency and prevent overheating.

- Air Filter Care: Clean or replace the air filter periodically to ensure proper airflow and engine performance.

- Battery Maintenance: Inspect battery terminals for corrosion and ensure secure connections to avoid starting issues.

Seasonal Preparations

- Winterizing: Prepare your vehicle for cold weather by draining fuel lines and using appropriate antifreeze solutions.

- Pre-ride Checks: Conduct a thorough examination before each outing to identify potential hazards or necessary repairs.

- Storage Tips: Store the vehicle in a dry, sheltered environment during off-seasons to protect it from harsh weather conditions.