Maintaining a sewing device can significantly enhance its longevity and performance. Understanding the intricacies of its components and mechanisms allows users to address issues proactively. This section aims to provide essential insights into troubleshooting, upkeep, and optimizing the functionality of your beloved crafting companion.

Whether you’re a novice or an experienced enthusiast, familiarizing yourself with the inner workings of your equipment is crucial. This resource outlines common challenges and their solutions, equipping you with the knowledge needed to tackle minor malfunctions and keep your machine in peak condition. By mastering these techniques, you can enjoy a seamless sewing experience and achieve the best results in your projects.

In addition to practical solutions, we will explore preventive measures that can be implemented to avoid potential problems. Regular maintenance routines and the correct handling of your device can make all the difference, ensuring that you continue to create beautiful pieces with ease. Dive into this guide to unlock the full potential of your sewing apparatus.

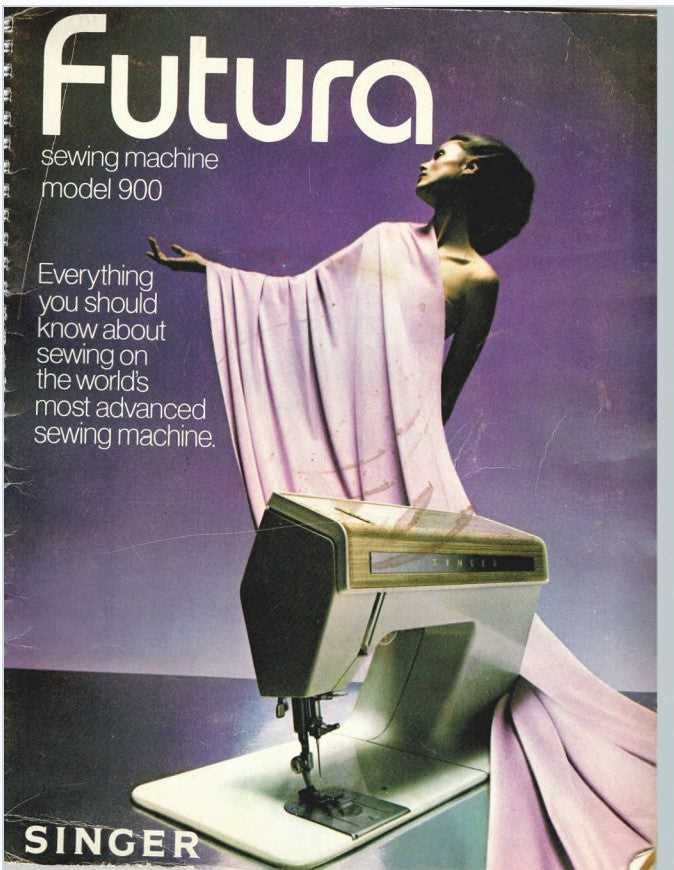

Overview

This section provides a comprehensive understanding of a versatile sewing machine designed for creativity and innovation. It caters to both beginners and experienced users, offering a blend of advanced features and user-friendly interfaces.

Equipped with cutting-edge technology, this model supports a wide range of stitching techniques, enabling users to explore their artistic potential. The machine’s intuitive design simplifies the process of sewing and embroidery, making it accessible to everyone.

Users can enjoy a seamless experience with numerous built-in patterns and customizable options, allowing for personalized projects. The combination of functionality and style makes it a valuable addition to any sewing enthusiast’s toolkit.

Common Issues with the Futura 900

Many users encounter a variety of challenges when operating their sewing machines. Understanding these common problems can help in troubleshooting and maintaining optimal performance. Below are some frequently reported issues that may arise during use.

- Thread Tension Problems:

Improper tension can lead to loose or tight stitches, affecting the quality of the final product.

- Needle Issues:

Using the wrong type or size of needle can cause skipping stitches or fabric damage.

- Stitch Malfunctions:

Skipped or uneven stitches may occur due to various factors including dirty parts or misalignment.

- Bobbin Complications:

A bobbin that is improperly wound or inserted can lead to threading issues and interruptions in sewing.

- Motor Problems:

Occasional motor malfunctions can result in a lack of power or unusual noises during operation.

- Software Glitches:

Users may experience software-related issues that can affect the machine’s functionality or settings.

Being aware of these common issues can empower users to address problems effectively and maintain their equipment in good working order.

Essential Tools for Repairs

Having the right equipment at your disposal can significantly enhance the effectiveness and efficiency of any maintenance task. This section highlights the fundamental items that every enthusiast should consider for successful interventions. From basic instruments to specialized gear, being well-prepared can make a world of difference.

First and foremost, a reliable set of screwdrivers is essential. These should include both flathead and Phillips variations, as they are crucial for loosening or tightening screws found in various components. Additionally, a pair of pliers is invaluable for gripping, twisting, and cutting tasks that may arise during your work.

A precision tool kit can be a game-changer, especially when dealing with intricate parts. Look for kits that offer a variety of tiny tools, as they allow for detailed adjustments and are particularly useful in tight spaces. Furthermore, a good pair of scissors is indispensable for trimming threads and materials as needed.

Don’t forget about cleaning supplies. A soft brush and lint-free cloth can help maintain the cleanliness of parts and ensure smooth operation. Lastly, a magnifying glass or head-mounted magnifier can greatly assist in focusing on small details, making the overall process smoother and more accurate.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving common issues that may arise with your sewing machine. By following a systematic method, you can effectively diagnose problems and implement solutions to enhance performance and ensure smooth operation.

Identify the Problem

The first step in addressing any malfunction is to clearly define the issue. Is the machine not stitching properly, making unusual noises, or displaying error messages? Take note of any specific symptoms, as this information will be crucial in diagnosing the root cause. Documenting these observations will guide you through the troubleshooting process.

Systematic Diagnosis

Once the problem is identified, proceed with a methodical examination. Start by checking the basics: ensure that the machine is properly threaded and the bobbin is correctly installed. Next, inspect for any blockages or debris in the feed dogs and check the needle for damage. If necessary, refer to the user guide for detailed instructions on maintenance tasks. Regular cleaning and oiling can often prevent many issues from occurring.

Replacing the Needle and Presser Foot

Changing the needle and presser foot is essential for maintaining optimal sewing performance and achieving high-quality results. These components play a crucial role in the machine’s functionality, and ensuring they are in good condition can significantly affect your sewing projects.

Steps to Change the Needle

Begin by turning off the machine and disconnecting it from the power source for safety. Locate the needle clamp, usually found on the side of the machine. Loosen the clamp screw using a screwdriver or your fingers, and gently pull the old needle out. Take your new needle, ensuring it is compatible, and insert it into the needle holder with the flat side facing the back. Tighten the clamp screw securely to hold the needle in place.

Steps to Replace the Presser Foot

To change the presser foot, first raise the foot lifter to elevate the current foot. Locate the presser foot release button or lever, which will allow you to detach the foot easily. Once removed, align the new presser foot with the shank, ensuring it snaps into place. Lower the foot lifter, and check that the new foot is secured properly before resuming your sewing tasks.

Threading the Machine Correctly

Properly threading your sewing device is crucial for achieving optimal performance and high-quality stitches. This process ensures that the thread flows smoothly through the various components, preventing jams and uneven tension. By following the correct procedure, you can enhance your sewing experience and prolong the life of your equipment.

To facilitate the threading process, it is helpful to understand the basic components involved. Below is a table that outlines the main parts of a sewing device and their roles in the threading sequence.

| Component | Function |

|---|---|

| Spool Pin | Holds the thread spool in place. |

| Tension Disc | Controls the thread tension for balanced stitches. |

| Take-Up Lever | Moves the thread up and down to create stitches. |

| Needle | Injects the thread into the fabric. |

| Bobbin Case | Holds the lower thread and allows it to feed into the stitch. |

By understanding these components and their functions, you can confidently navigate the threading process, ensuring that your device operates smoothly and effectively. Always refer to your specific equipment’s guidelines for any additional steps or unique requirements.

Maintaining the Futura 900

Regular upkeep of your sewing machine is essential for ensuring its longevity and optimal performance. By following some simple maintenance steps, you can prevent common issues and keep your device running smoothly. This guide will provide useful insights into caring for your machine effectively.

Here are key maintenance tasks to incorporate into your routine:

| Task | Frequency | Description |

|---|---|---|

| Clean the machine | After each project | Remove lint and debris from the feed dogs, bobbin area, and needle plate. |

| Oil moving parts | Every 3-6 months | Apply lubricant to designated areas to reduce friction and wear. |

| Check needle | Before each project | Inspect for dullness or damage, and replace as necessary to ensure clean stitching. |

| Test stitches | Before major projects | Run a few test stitches on scrap fabric to ensure proper tension and stitch quality. |

| Store properly | After use | Cover the machine with a dust cover and store in a dry place to prevent dust accumulation. |

By consistently following these guidelines, you can significantly enhance the efficiency and lifespan of your sewing equipment, making every crafting session a pleasure.

Cleaning the Bobbin Area

Maintaining the cleanliness of the bobbin compartment is essential for ensuring optimal performance and longevity of your sewing machine. A clean workspace allows for smooth operation and minimizes the risk of thread jams or uneven stitching. Regularly removing lint and debris from this area helps prevent mechanical issues that can disrupt your sewing experience.

To begin the cleaning process, first, turn off the machine and unplug it for safety. Carefully remove the needle plate, which provides access to the bobbin case. Use a small brush or a soft cloth to gently sweep away any accumulated dust, fabric fibers, or thread remnants. Pay special attention to the corners and crevices, as these areas tend to collect the most debris.

Once you have cleared away the excess lint, inspect the bobbin case for any signs of wear or damage. If necessary, consult the manufacturer’s guidelines for replacement or adjustment. After cleaning, reassemble the components securely to ensure proper alignment and function. Regular maintenance of the bobbin area will contribute to a more efficient and enjoyable sewing experience.

Updating Machine Firmware

Keeping your device’s software up to date is essential for optimal performance and access to new features. Regular updates can enhance functionality, improve compatibility with various materials, and resolve existing bugs. This process is crucial for ensuring that your equipment runs smoothly and efficiently.

To initiate the firmware upgrade, begin by checking the manufacturer’s website for the latest version available. It is vital to download the correct update file that matches your device model. Additionally, ensure that your machine is connected to a reliable power source to prevent any interruptions during the update process.

Once the file is downloaded, transfer it to a compatible storage medium, such as a USB drive. Insert the drive into the designated port on your device and navigate to the settings menu. Look for an option related to system updates or firmware management. Follow the on-screen instructions carefully to complete the installation.

After the update is installed, it is advisable to restart the device to ensure that all changes take effect. Perform a quick functionality check to confirm that everything is operating as intended. Regularly updating your equipment will not only extend its lifespan but also enhance your overall experience.

Understanding Error Codes

Error codes serve as a vital communication tool between a device and its user, providing essential insights into operational issues. These codes can be perplexing, yet they are designed to facilitate troubleshooting by pinpointing specific malfunctions or irregularities. Familiarizing oneself with these codes is crucial for effective problem resolution and maintaining optimal performance.

Common Error Indicators

Each device may present unique error messages, often accompanied by a numerical or alphanumeric code. These indicators usually correspond to common issues such as threading problems, motor malfunctions, or sensor failures. Understanding the meaning behind each code can significantly streamline the troubleshooting process and help prevent potential damage.

Interpreting Error Messages

When encountering an error code, the first step is to consult the accompanying documentation, which typically offers a comprehensive explanation. It is important to approach each message systematically, assessing the potential causes and solutions. Keeping a log of recurring errors can also be beneficial, as it may reveal patterns that require further investigation or professional assistance.

Where to Find Replacement Parts

Locating suitable components for your sewing machine can be a straightforward process if you know where to look. Various sources are available, ranging from official retailers to online marketplaces, ensuring that you can find the parts needed to keep your device running smoothly.

Official Dealers and Service Centers

One of the most reliable ways to obtain parts is through authorized dealers and service centers. These establishments often carry a comprehensive selection of components specifically designed for your model. Contacting them directly can provide you with valuable information on availability and pricing.

Online Marketplaces and Specialty Websites

Another excellent option is to explore online marketplaces such as eBay or Amazon, where you can find both new and used parts. Additionally, specialized websites dedicated to sewing equipment often feature a wide range of components, ensuring that you can locate exactly what you need. Always verify the seller’s reputation to ensure you receive quality products.

Using the Manual Effectively

To maximize the utility of any instructional guide, understanding its structure and content is essential. A well-organized document can serve as a valuable resource, offering insights and step-by-step guidance for various tasks. Familiarizing yourself with the layout and key sections will enhance your overall experience and ensure that you can quickly find the information you need.

Understanding the Layout

Most guides will have a table of contents that outlines the main topics covered. Spend some time reviewing this section to identify relevant chapters or subsections. This approach allows you to locate specific information without having to read through the entire text. Look for diagrams and charts, as visual aids can often clarify complex concepts more effectively than text alone.

Utilizing Features

Pay attention to special features like troubleshooting tips, frequently asked questions, and maintenance checklists. These sections can provide quick solutions to common issues and help you avoid potential pitfalls. Additionally, highlighting or taking notes on important points can create a personalized reference that will be useful for future tasks.

Incorporating these strategies will significantly improve your ability to navigate and utilize the resource, empowering you to achieve your goals with confidence.

Getting Help from Online Communities

In today’s digital age, seeking assistance through virtual forums can be incredibly beneficial. Engaging with like-minded individuals who share similar interests allows for the exchange of knowledge and experiences. Whether you’re facing a specific issue or looking for general advice, online platforms provide a wealth of resources and support.

Benefits of Online Communities

Participating in these groups offers numerous advantages:

| Advantage | Description |

|---|---|

| Expert Insights | Access to tips and tricks from seasoned users who have encountered similar challenges. |

| Networking | Opportunities to connect with enthusiasts and professionals in the field. |

| Resource Sharing | Members often share useful links, tutorials, and other helpful materials. |

How to Engage Effectively

To maximize your experience in these communities, consider the following strategies:

- Be specific in your inquiries to receive targeted assistance.

- Contribute your own knowledge and experiences to help others.

- Respect the community guidelines and foster a positive environment.