The intricate world of automotive machinery often necessitates a deeper understanding of its components and systems. Among these, the 4Y power unit stands out as a robust choice, favored for its reliability and performance. This guide aims to illuminate the essential aspects of maintaining and revitalizing this particular type of propulsion system.

Understanding the nuances of such machinery can empower enthusiasts and technicians alike, enabling them to tackle common issues and optimize performance. Whether addressing minor hiccups or undertaking significant enhancements, familiarity with the inner workings of the 4Y unit is crucial for ensuring longevity and efficiency.

This resource will provide a comprehensive overview, equipping readers with the knowledge and techniques necessary to navigate the complexities of the 4Y powerplant. From troubleshooting methods to practical tips, it is designed to be an invaluable companion for anyone seeking to enhance their skills in automotive maintenance and restoration.

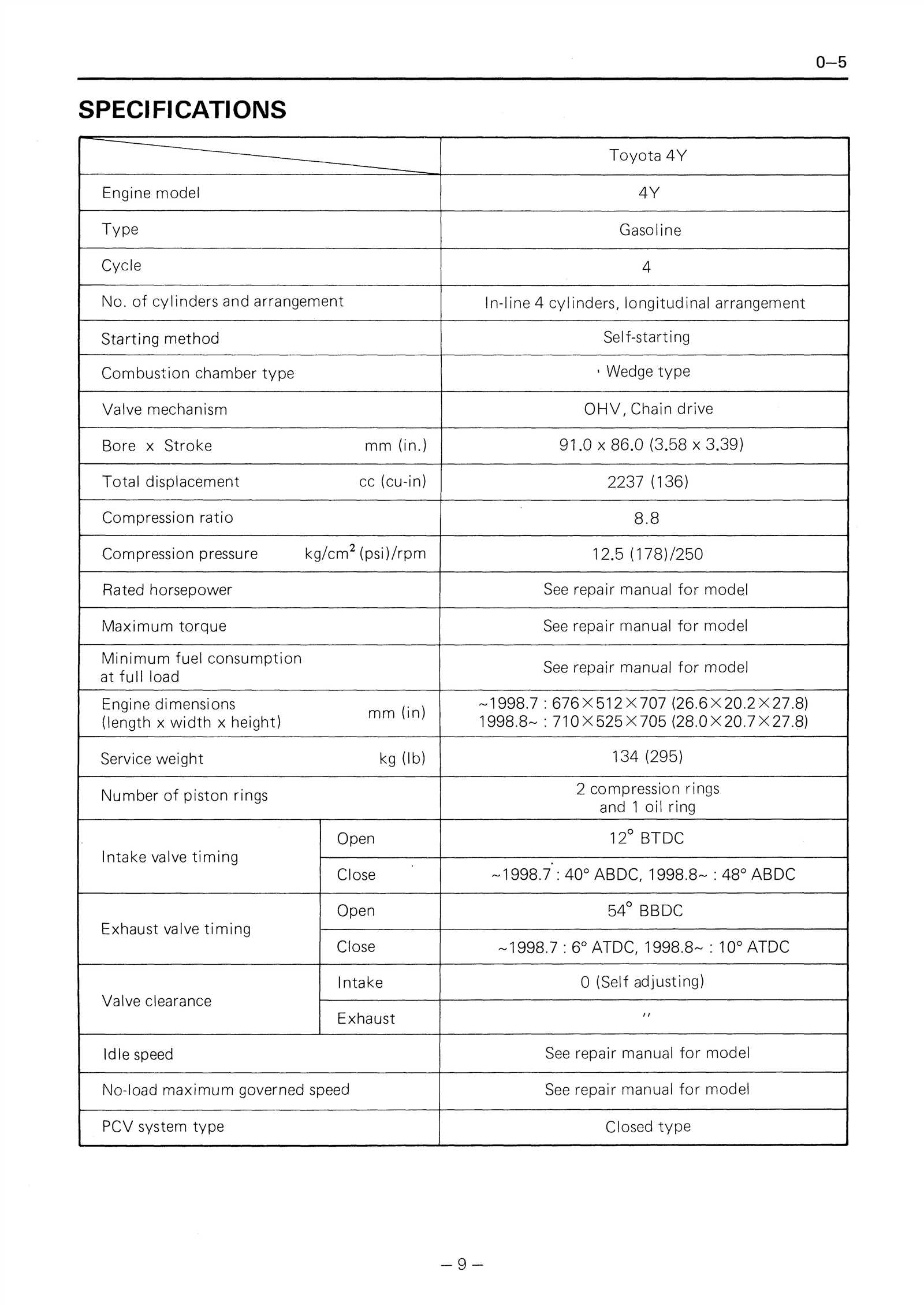

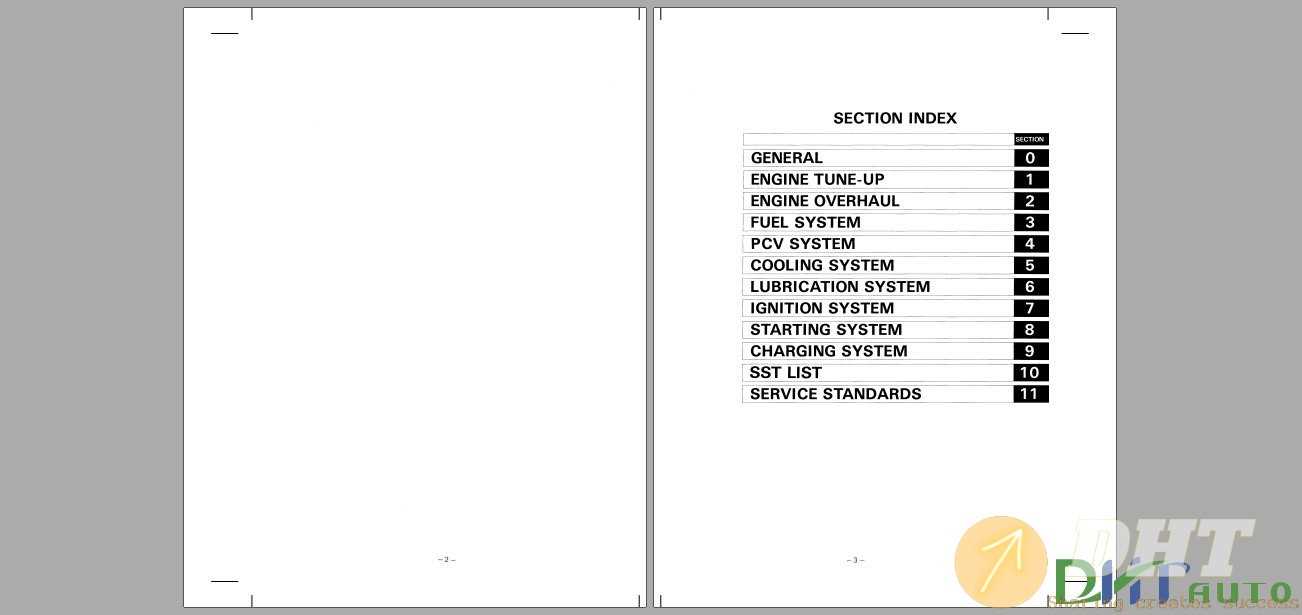

Toyota 4Y Engine Overview

This section provides a comprehensive insight into a specific four-cylinder power unit renowned for its robustness and reliability. Designed for a variety of applications, this unit is celebrated for its efficient performance and ease of maintenance, making it a preferred choice among enthusiasts and professionals alike.

The architecture of this powerplant incorporates advanced engineering principles, resulting in a balance between power output and fuel efficiency. With a displacement that suits both light-duty and heavier tasks, it showcases versatility that caters to diverse operational needs.

Key components include a durable block, precision-crafted cylinder head, and a well-designed intake and exhaust system that work in harmony to optimize performance. Regular maintenance of these elements is crucial for ensuring longevity and optimal functioning, reinforcing the importance of understanding its design intricacies.

Overall, this power unit stands out in its class, offering a reliable solution for various automotive and industrial applications. Its solid reputation is built on years of performance, making it a staple in the market for those seeking dependability and efficiency.

Common Issues with the 4Y Engine

The 4Y power unit is known for its robust performance; however, like any mechanical system, it is not without its challenges. Understanding the prevalent issues can help in maintaining optimal functionality and prolonging its lifespan.

One frequent concern is overheating. This can result from a malfunctioning cooling system or a clogged radiator. Overheating can lead to severe damage if not addressed promptly.

Another issue that users may encounter is poor fuel efficiency. This can be attributed to various factors, including worn-out components or improper tuning. Regular checks and adjustments are essential to ensure economical operation.

Additionally, oil leaks are a common problem. These can arise from deteriorating gaskets or seals, which may lead to reduced lubrication and increased wear. Early detection is crucial to prevent further complications.

Lastly, starting difficulties can occur, often linked to issues with the ignition system or fuel delivery. Identifying these problems early can facilitate smoother operation and reliability.

By being aware of these typical challenges, users can take proactive measures to maintain performance and reliability.

Essential Tools for Repair

Having the right equipment is crucial for effective maintenance and restoration tasks. Proper tools not only enhance efficiency but also ensure safety and precision in your work. Below is a curated list of necessary instruments that will aid you in your undertaking.

- Socket Set: A versatile socket set is vital for loosening and tightening various fasteners.

- Wrenches: Both open-end and adjustable wrenches are essential for reaching different types of bolts.

- Screwdrivers: A variety of flathead and Phillips screwdrivers will be needed for multiple applications.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping and bending components.

- Torque Wrench: This tool ensures that bolts are tightened to the correct specifications.

- Jack and Stands: A sturdy jack paired with stands provides safe access to lower areas.

In addition to the basic tools, consider these specialized items:

- Multimeter: For electrical diagnostics, a multimeter can help you measure voltage and continuity.

- Compression Tester: This instrument assesses the health of various systems by measuring pressure.

- Oil Filter Wrench: A specific tool designed to remove oil filters easily.

Investing in high-quality tools will not only make your tasks more manageable but also improve the longevity of your work. Always ensure that your toolbox is stocked with the essentials to tackle any challenge that arises.

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to carefully dismantling your mechanical assembly. Following a systematic procedure ensures that all components are handled properly and can be reassembled effectively later. Adhering to these guidelines will help avoid any damage and facilitate a smoother rebuilding process.

| Step | Description |

|---|---|

| 1 | Begin by gathering all necessary tools and workspace materials to ensure a tidy and organized environment. |

| 2 | Disconnect any electrical connections and remove external components that may hinder disassembly. |

| 3 | Loosen and remove any fasteners securing the main unit, taking care to keep them organized. |

| 4 | Gently separate the primary components, observing how each part is connected to avoid confusion during reassembly. |

| 5 | Inspect each component for wear or damage, documenting any findings for future reference. |

| 6 | Store disassembled parts in labeled containers to maintain organization and facilitate easy access. |

| 7 | Finalize the process by cleaning the workspace and reviewing the gathered components, ensuring all parts are accounted for. |

Inspecting Engine Components

Careful examination of various mechanical parts is crucial for maintaining optimal performance and longevity. This process involves assessing each component for signs of wear, damage, or any irregularities that may affect overall functionality.

Begin by evaluating the surface integrity of critical components, looking for cracks, corrosion, or other forms of deterioration. It’s essential to check tolerances and clearances to ensure proper fit and operation, as even minor deviations can lead to significant issues.

Next, focus on the seals and gaskets, as these elements play a vital role in preventing leaks and maintaining pressure. Inspecting their condition can help avoid costly repairs down the line. Additionally, ensure that all connections and fittings are secure and free from any obstructions.

Finally, a thorough inspection of lubricating systems is necessary to guarantee adequate flow and protection against friction. Regular monitoring of these elements will aid in identifying potential problems before they escalate, ultimately enhancing reliability and performance.

Reassembly Tips for Efficiency

When putting components back together after disassembly, efficiency is key to ensuring a smooth process and optimal performance. Proper planning and organization can save time and reduce the likelihood of errors. Here are some strategies to enhance your reassembly workflow.

Preparation Steps

- Gather all necessary tools and parts before starting the reassembly.

- Clean all components thoroughly to remove any dirt or residue.

- Review any relevant documentation to familiarize yourself with the assembly order.

Reassembly Techniques

- Start with the larger components, ensuring a solid foundation.

- Use new gaskets or seals where applicable to prevent leaks.

- Apply a small amount of lubricant to moving parts to facilitate smooth operation.

- Double-check that all bolts and screws are tightened to the specified torque.

- Keep a checklist to track the completion of each step.

Following these tips can lead to a more efficient reassembly process, reducing the risk of mistakes and enhancing the longevity of the components involved.

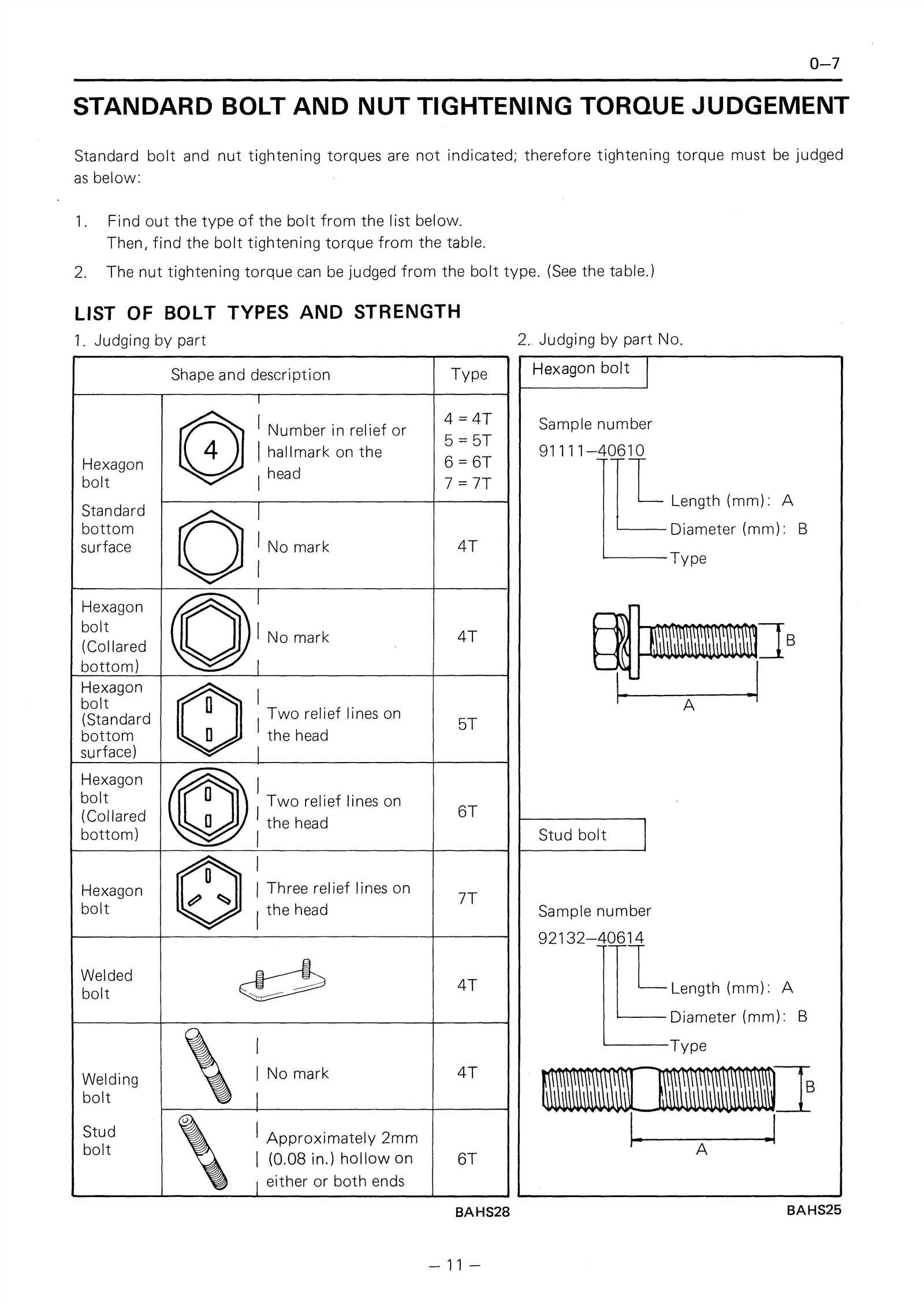

Torque Specifications and Requirements

This section provides essential details regarding the proper tightening values and conditions necessary for various components. Adhering to these specifications is crucial for ensuring optimal performance and longevity of the machinery involved. Precise torque application prevents issues such as over-tightening or loosening over time, which can lead to serious malfunctions.

Importance of Accurate Torque Settings

Maintaining the correct torque settings is vital for the stability and efficiency of parts. Each component has specific requirements, which are often dictated by factors such as material composition and intended function. Under-tightening can result in parts becoming loose, while over-tightening can lead to deformation or breakage. It is important to consult detailed specifications for each component to ensure adherence to these standards.

Common Torque Values

While exact values may vary, there are general ranges that can serve as a guideline. For example, smaller fasteners typically require lower torque settings, while larger ones may demand significantly higher values. Always refer to the designated specifications to ensure accurate application. Using a calibrated torque wrench is recommended to achieve the necessary precision when tightening bolts and nuts.

Common Maintenance Practices

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle’s power unit. Implementing a series of routine tasks can significantly enhance reliability and prevent costly breakdowns. This section outlines key practices that should be part of every vehicle owner’s checklist.

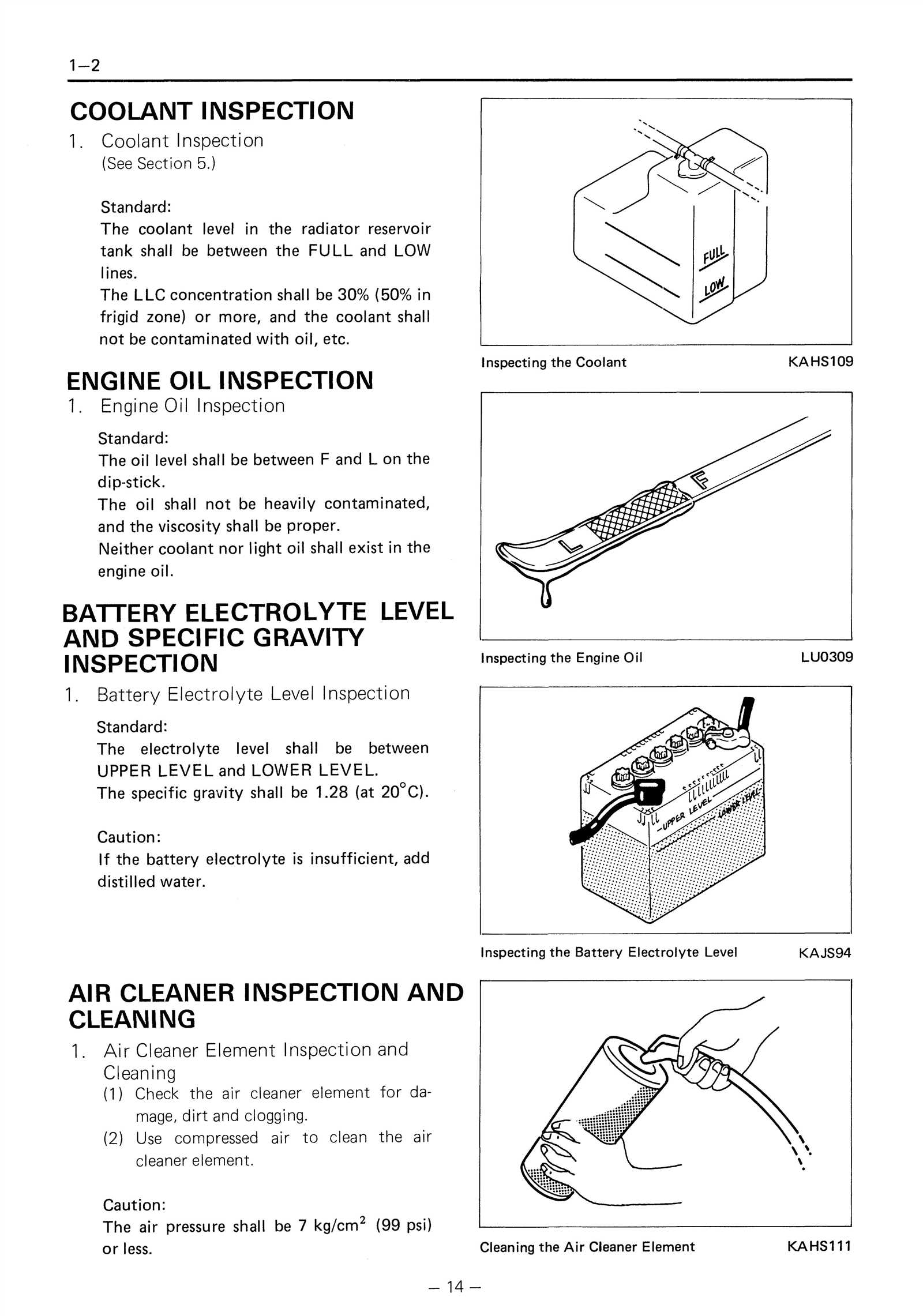

Fluid Checks and Changes

Maintaining proper fluid levels is crucial. Engine oil should be checked frequently and replaced according to the specified intervals to ensure smooth operation. Similarly, coolant, transmission fluid, and brake fluid should be inspected regularly to prevent overheating and ensure effective braking performance.

Filter Maintenance

Replacing filters is an often-overlooked aspect of upkeep. Air filters help maintain clean airflow to the combustion chamber, while fuel filters ensure the quality of fuel entering the system. Regularly changing these components can lead to improved efficiency and performance.

Diagnosing Performance Problems

Identifying issues that affect a vehicle’s efficiency can be a challenging task. Various factors can contribute to diminished power output, irregular idling, or increased fuel consumption. A systematic approach is essential for pinpointing the underlying causes and implementing effective solutions.

Common Symptoms

- Loss of acceleration

- Rough idling or stalling

- Decreased fuel economy

- Unusual noises during operation

- Excessive exhaust emissions

Diagnostic Steps

- Visual Inspection: Check for obvious signs of wear or damage, such as leaks, cracks, or loose connections.

- Diagnostic Tools: Utilize scanning devices to retrieve error codes and monitor real-time data.

- Fuel System Check: Examine the fuel delivery components, including the pump, injectors, and filters.

- Air Intake Evaluation: Assess the intake system for blockages or leaks that could affect air flow.

- Ignition System Assessment: Inspect spark plugs, wires, and coils for proper functioning.

By following these steps, you can gain insights into the factors affecting performance and take corrective actions to restore optimal functionality.

Upgrades and Modifications Available

Enhancing performance and efficiency is a common goal for enthusiasts seeking to elevate their vehicle’s capabilities. Various upgrades and modifications can significantly improve power output, responsiveness, and overall driving experience. These enhancements not only boost performance but also allow for personalization according to individual preferences.

Engine Performance Kits are among the most sought-after modifications. These kits typically include components such as high-flow air intakes, upgraded exhaust systems, and optimized tuning software. By improving airflow and adjusting fuel delivery, these kits can unlock additional horsepower and torque.

Suspension Upgrades are another popular choice. Upgrading shocks, springs, and sway bars can enhance handling and stability, making the vehicle more agile on the road or track. This not only improves performance but also contributes to a more comfortable driving experience.

Brake Enhancements should not be overlooked. High-performance brake pads, larger rotors, and upgraded calipers can significantly improve stopping power and reduce brake fade during demanding driving conditions. Safety and control are paramount, making these modifications essential for high-performance builds.

Additionally, wheel and tire upgrades can dramatically impact both aesthetics and performance. Lightweight alloy wheels paired with high-performance tires can reduce unsprung weight, improve traction, and enhance the overall look of the vehicle.

Ultimately, a combination of these modifications allows for a tailored driving experience, ensuring that the vehicle meets the specific desires and needs of its owner.

Cost Estimates for Repair Services

Understanding the financial implications of maintenance work is crucial for vehicle owners. Accurate cost projections can help individuals budget appropriately and make informed decisions regarding necessary services. This section provides an overview of typical expenses associated with various types of vehicle maintenance and restoration, allowing owners to prepare financially for their vehicle’s needs.

| Service Type | Estimated Cost ($) | Time Required (Hours) |

|---|---|---|

| Basic Tune-Up | 150 – 300 | 2 – 4 |

| Complete Overhaul | 2,500 – 4,500 | 10 – 20 |

| Cooling System Service | 100 – 250 | 1 – 3 |

| Fuel System Cleaning | 80 – 200 | 1 – 2 |

| Transmission Check | 150 – 400 | 2 – 5 |

These estimates serve as a guideline and can vary based on location, vehicle condition, and specific service requirements. It is advisable to consult multiple service providers to obtain accurate quotes tailored to individual circumstances.

Finding Quality Replacement Parts

When it comes to maintaining and enhancing your vehicle, sourcing high-quality components is crucial for ensuring optimal performance and longevity. Quality parts not only improve functionality but also enhance safety and reliability. The challenge lies in distinguishing genuine items from inferior alternatives in a market flooded with options.

Research and Recommendations

Start by conducting thorough research to identify reputable suppliers. Online forums, enthusiast groups, and automotive websites can provide valuable insights and recommendations. Listening to the experiences of fellow vehicle owners can guide you toward trustworthy vendors. Additionally, consider seeking advice from professional mechanics who often have firsthand knowledge of reliable parts sources.

Evaluating Suppliers

Once you have a list of potential suppliers, evaluate them based on several criteria. Look for customer reviews and ratings, which can provide insight into the quality of their offerings. Ensure that the seller provides warranties or guarantees for their products, as this indicates confidence in their merchandise. Furthermore, consider the availability of technical support or resources that can assist you in making informed choices.

Resources for Further Learning

Expanding your knowledge in automotive maintenance and enhancement can significantly benefit both enthusiasts and professionals alike. Various materials and platforms provide invaluable insights, ensuring a deeper understanding of mechanical systems and their functions. Below are some recommended resources to help you advance your skills and expertise.

| Resource Type | Description | Link |

|---|---|---|

| Online Courses | Interactive courses covering various aspects of vehicle systems and troubleshooting techniques. | Coursera |

| Books | Comprehensive guides that detail both basic and advanced topics in automotive mechanics. | Amazon |

| YouTube Channels | Visual tutorials and demonstrations that illustrate practical skills and problem-solving approaches. | YouTube |

| Forums | Community-driven platforms where enthusiasts share experiences, tips, and solutions. | |

| Workshops | Hands-on sessions that provide real-world experience under the guidance of experienced professionals. | Local Workshops |