Understanding the intricacies of power tools is essential for maintaining their performance and longevity. This section delves into the essential techniques and strategies for ensuring optimal functionality of your equipment. From basic upkeep to addressing common issues, having a solid grasp of these concepts can significantly enhance your experience and effectiveness during use.

Comprehensive insights will equip you with the knowledge needed to navigate potential problems and implement solutions efficiently. Whether you are facing minor hiccups or more complex challenges, being informed is your best ally. Regular maintenance practices not only prolong the lifespan of your tools but also ensure safety and reliability in their operation.

By following a systematic approach to troubleshooting, you can tackle issues as they arise, allowing you to focus on your tasks without unnecessary interruptions. This guide aims to empower you with the information and confidence to manage your equipment effectively, enhancing both your skills and your enjoyment of your projects.

Proper maintenance of cutting equipment requires a specific set of instruments to ensure effective functioning and longevity. Having the right tools on hand not only simplifies the process but also enhances safety during the servicing of the device. This section highlights the fundamental implements necessary for effective upkeep.

Basic Tools Needed

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening various components. |

| Wrench | To adjust nuts and bolts securely. |

| File | For sharpening the cutting elements and maintaining edges. |

| Oil Can | To lubricate moving parts and reduce friction. |

| Protective Gear | Ensures safety during the maintenance process. |

Additional Recommended Instruments

Beyond the basics, certain specialized tools can enhance the efficiency of the maintenance process. These tools cater to more intricate tasks, facilitating thorough checks and adjustments.

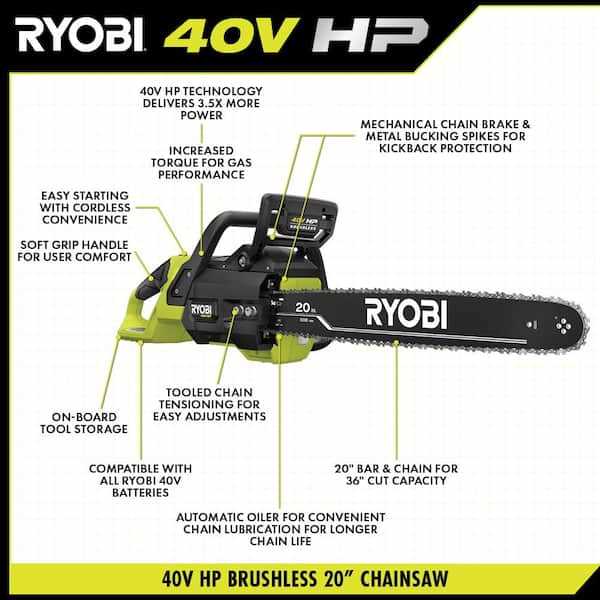

Understanding Your Chainsaw Model

When it comes to operating and maintaining a cutting tool, knowing its specific features and components is essential for optimal performance. Each model has unique characteristics that influence how it functions and how best to care for it. Understanding these elements will not only enhance your efficiency but also extend the lifespan of your tool.

Key Features to Recognize

Familiarize yourself with the primary aspects of your device, such as the power source, cutting capacity, and safety mechanisms. Each feature plays a critical role in how the tool handles various tasks. For instance, the type of motor can determine the energy efficiency and cutting speed, while the bar length affects the range of operations you can perform.

Regular Maintenance Considerations

To ensure longevity, regular upkeep is vital. This includes inspecting and replacing wear parts, maintaining sharpness, and checking fluid levels. Awareness of these maintenance tasks will help prevent breakdowns and enhance functionality. Additionally, being aware of the specific requirements for your model can prevent mishaps and improve safety during use.

Common Issues and Their Solutions

In the realm of outdoor power tools, various challenges can arise during operation, impacting performance and efficiency. Understanding these frequent problems and their corresponding remedies can significantly enhance user experience and prolong the lifespan of the equipment.

| Issue | Description | Solution |

|---|---|---|

| Difficulty Starting | The device fails to ignite or run smoothly. | Check the fuel level and quality, clean or replace the spark plug, and inspect the air filter for blockages. |

| Stalling During Use | Engine cuts out unexpectedly while in operation. | Ensure there is adequate fuel supply and that the air filter is clean. Additionally, examine the ignition system. |

| Excessive Vibration | Unusual shaking during operation can be uncomfortable and concerning. | Inspect the chain tension and guide bar alignment. Tighten any loose components and check for wear. |

| Poor Cutting Performance | Inability to cut effectively through materials. | Sharpen or replace the cutting chain and ensure proper lubrication is being applied to the bar. |

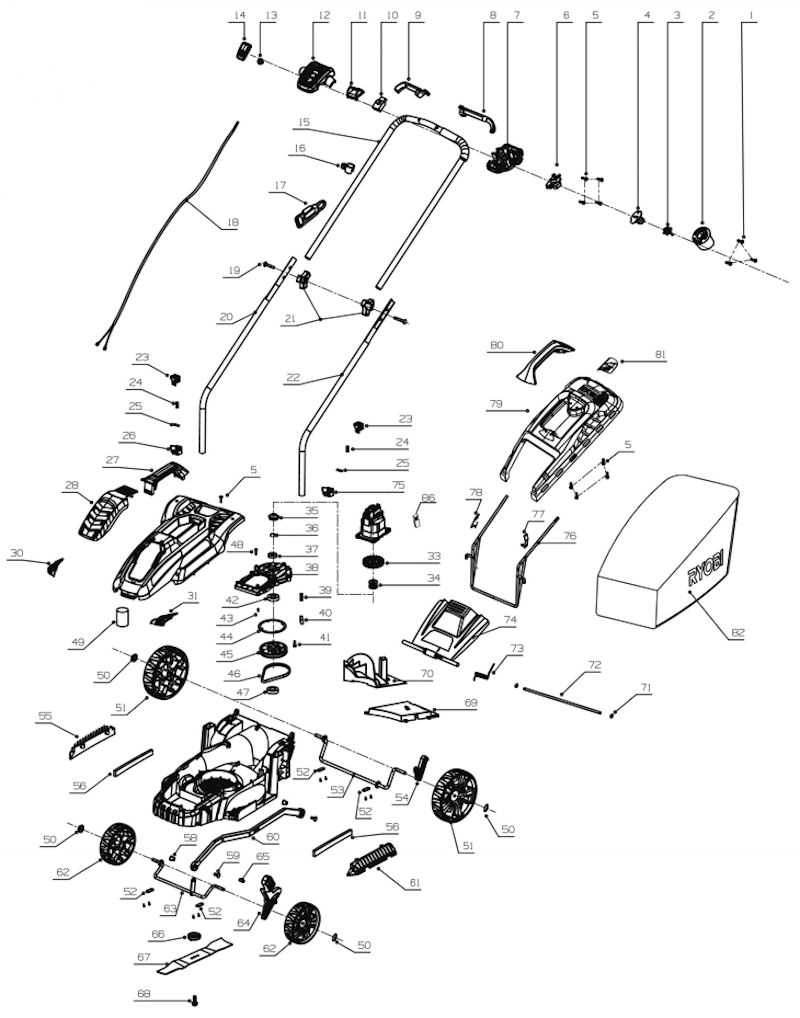

Step-by-Step Maintenance Procedures

Proper upkeep of your cutting tool is essential for optimal performance and longevity. By following a systematic approach, you can ensure that all components function efficiently and reduce the likelihood of malfunctions. This section outlines a series of tasks that, when performed regularly, will help maintain your equipment in peak condition.

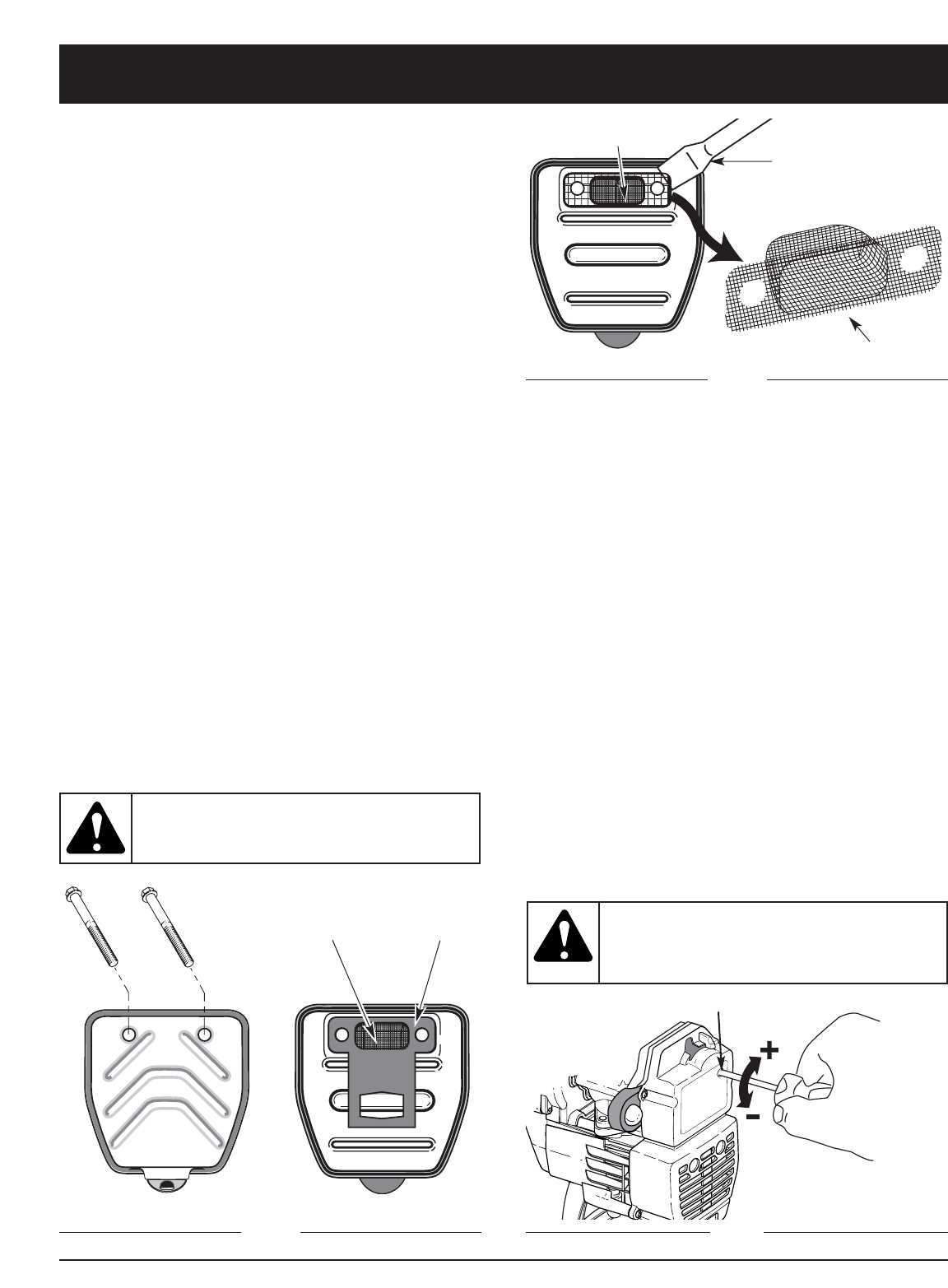

1. Cleaning the Air Filter

Start by removing the air filtration unit. Gently tap it to dislodge loose debris, and then wash it with warm, soapy water. Allow it to dry completely before reinstalling it. A clean air filter enhances airflow, improving engine efficiency.

2. Inspecting and Sharpening the Cutting Edge

Next, examine the cutting edge for any signs of wear or damage. Use a file or a sharpening tool to restore its sharpness. Maintaining a keen edge not only facilitates smoother cuts but also reduces strain on the engine, prolonging its life.

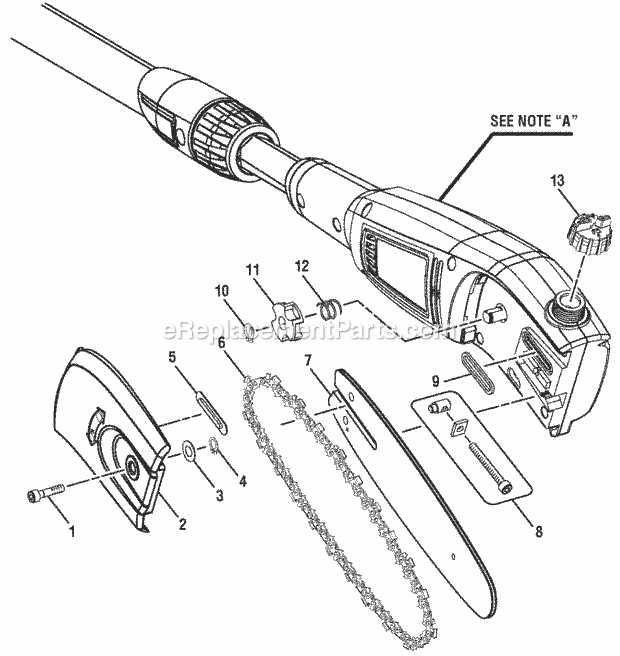

Replacing the Chain and Bar

Maintaining the cutting components of your tool is essential for optimal performance and safety. This section covers the process of changing the cutting loop and guide structure, ensuring that your device operates smoothly and efficiently.

Step 1: Before starting, ensure that the equipment is powered off and disconnected from any energy source. Safety gear, including gloves and eye protection, is highly recommended.

Step 2: Locate the tensioning mechanism, typically found on the side or top of the apparatus. Loosen the tension to relieve pressure on the cutting loop, allowing for easier removal.

Step 3: Remove the fasteners securing the guide structure to the housing. Carefully detach the guide piece from the tool, followed by the cutting loop.

Step 4: Install the new cutting loop onto the guide piece, ensuring it is correctly oriented. Align the guide structure with the housing and secure it using the fasteners.

Step 5: Adjust the tension of the cutting loop according to the manufacturer’s specifications. A properly tensioned loop enhances cutting efficiency and minimizes wear.

Final Step: Once everything is in place, conduct a brief inspection to ensure all components are secure. Power on the tool and perform a test run to verify smooth operation.

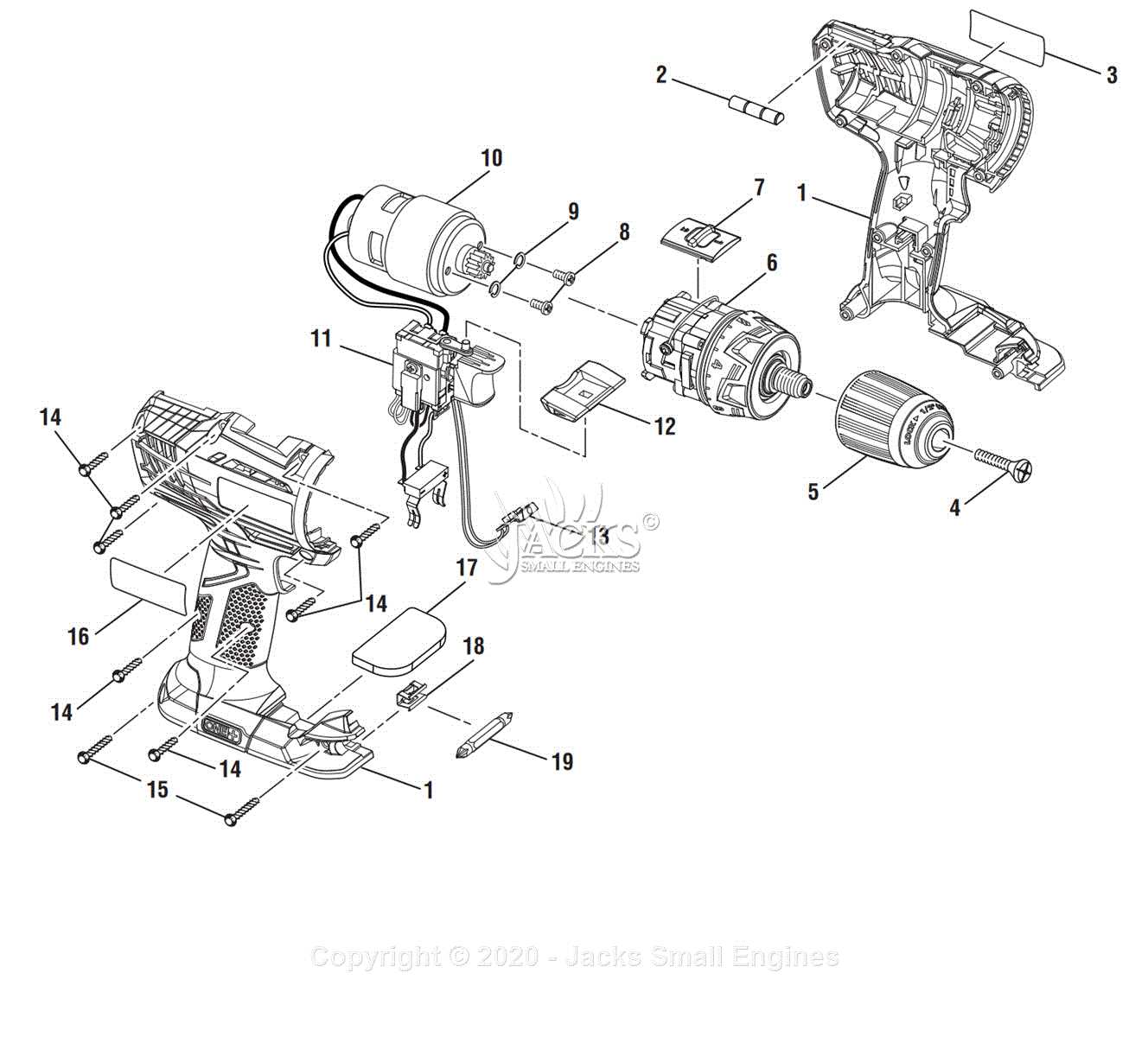

Inspecting the Engine Components

Examining the internal mechanisms of a cutting tool is crucial for maintaining optimal performance. Proper inspection ensures that each part functions harmoniously, preventing unexpected breakdowns and enhancing longevity.

Begin by gathering the necessary tools for inspection:

- Screwdriver set

- Torque wrench

- Flashlight

- Cleaning materials

Follow these steps to thoroughly assess the engine components:

- Remove the cover: Carefully detach the outer casing to expose the engine.

- Inspect the spark plug: Check for signs of wear or carbon buildup. A clean plug ensures efficient ignition.

- Examine the fuel system: Look for leaks or cracks in fuel lines. Ensure the filter is clean and unobstructed.

- Check the air filter: A dirty filter can impede airflow, affecting performance. Clean or replace if necessary.

- Assess the piston and cylinder: Look for scratches or scoring, which can indicate a need for replacement or repair.

Regular inspections will help identify potential issues before they escalate, ensuring the tool operates safely and efficiently.

Cleaning and Air Filter Care

Maintaining optimal performance of your cutting tool requires regular attention to the air filtration system. This vital component ensures that the engine receives clean air, preventing dirt and debris from causing damage. Neglecting proper upkeep can lead to reduced efficiency and increased wear on the internal parts.

Regular Inspection

Frequent checks of the air filter are essential. Remove the filter periodically to assess its condition. Look for signs of clogging, such as dirt accumulation or discoloration. A clean filter promotes better airflow, which is crucial for engine performance.

Cleaning Process

To clean the filter, use compressed air to blow out any trapped particles. If the filter is excessively dirty, consider washing it with soapy water. Ensure it is completely dry before reinserting it into the unit. This process not only extends the filter’s lifespan but also enhances overall functionality.

Replacement Guidelines

Even with diligent cleaning, filters have a limited lifespan. If cleaning does not restore its performance, replacement is necessary. Refer to the specifications for compatible options, ensuring you maintain the integrity of your equipment.

Regular maintenance of the air filtration system is vital for longevity and performance. By incorporating these care practices, you can ensure optimal operation and efficiency of your equipment.

Fuel System Troubleshooting Tips

When dealing with performance issues in gas-powered tools, the fuel system is often a critical area to examine. A well-functioning fuel system ensures the engine receives the right mixture for optimal operation. Here are some effective strategies for diagnosing common problems within this system.

Inspecting Fuel Lines and Filters

Start by examining the fuel lines for any signs of damage, such as cracks or leaks. Clogged filters can restrict fuel flow, so ensure they are clean and replace them if necessary. A thorough check can prevent minor issues from escalating into more significant failures.

Evaluating Fuel Quality

Always consider the quality of the fuel being used. Old or contaminated fuel can lead to performance degradation. If the fuel has been stored for an extended period, it is advisable to drain it and refill with fresh gasoline. Additionally, check for the presence of water or sediment, as these can significantly impair engine function.

Safety Precautions During Repairs

When undertaking maintenance tasks on power tools, ensuring personal safety is paramount. It is essential to be aware of potential hazards and to take necessary precautions to mitigate risks while working with machinery.

Before beginning any work, it is advisable to familiarize yourself with the specific equipment and its components. This knowledge can help prevent accidents and ensure efficient handling. Below are key safety measures to consider:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use appropriate safety equipment such as gloves, goggles, and hearing protection to shield yourself from debris and noise. |

| Work in a Well-Lit Area | Ensure that your workspace is adequately illuminated to see all parts clearly and avoid mistakes. |

| Disconnect Power Source | Before starting any maintenance, make sure to disconnect the power supply to prevent accidental activation. |

| Keep Workspace Organized | Maintain a clean and clutter-free area to avoid tripping hazards and misplacing tools. |

| Follow Manufacturer Guidelines | Adhere to the guidelines provided by the manufacturer for safe handling and maintenance practices. |

By implementing these safety measures, you can create a secure environment that reduces the likelihood of accidents and injuries while performing essential maintenance tasks on your equipment.

Identifying Electrical Problems

Recognizing issues related to electrical components is crucial for maintaining optimal performance of your equipment. These problems can manifest in various ways, including inconsistent operation, sudden failures, or erratic behavior during use. Understanding the symptoms and common causes will help in diagnosing the underlying issues effectively.

Common Symptoms of Electrical Issues

Several signs can indicate that there are electrical troubles. Look for symptoms such as flickering lights, unusual sounds, or failure to start. Additionally, a loss of power during operation or overheating components may suggest electrical malfunctions. Observing these behaviors can provide valuable clues for troubleshooting.

Diagnosis Techniques

To diagnose electrical concerns, start by visually inspecting connections and components for wear or damage. Use a multimeter to check voltage levels and continuity, ensuring that circuits are functioning as intended. Testing each component systematically will help isolate the problem and guide necessary repairs.

When to Seek Professional Help

In certain situations, it may be wise to enlist the assistance of a trained expert. Recognizing the limits of your own abilities is crucial to ensure safety and the longevity of your equipment. Professional technicians possess specialized knowledge and tools that can effectively address complex issues that may arise.

Signs of a Major Issue

If you encounter persistent problems despite your efforts, it may indicate a more serious underlying fault. Unusual noises, excessive vibrations, or difficulty starting can all signal that professional intervention is necessary. Ignoring these symptoms could lead to further damage or unsafe operating conditions.

Time Constraints and Safety Concerns

When time is of the essence, seeking expert help can often save you significant hassle. Additionally, if you feel uncertain or uneasy about tackling a problem, it’s better to rely on a professional. Prioritizing safety should always come first; if in doubt, turning to someone with expertise can provide peace of mind and ensure proper resolution of the issue.