Ensuring the optimal functionality of specialized tools is essential for any operational setting. This segment delves into the intricacies of servicing a specific model, providing users with the knowledge needed to maintain peak performance. Understanding the mechanisms behind these devices can significantly enhance their longevity and efficiency.

With detailed instructions and insights, this guide aims to equip users with practical solutions for troubleshooting common issues. It emphasizes the importance of routine upkeep and offers step-by-step processes that simplify complex tasks. By familiarizing oneself with the inner workings of the equipment, users can confidently address challenges as they arise.

Additionally, this resource highlights best practices for maintenance, ensuring that individuals are well-prepared to tackle any obstacles. By adhering to the guidelines presented here, operators can not only preserve the functionality of their tools but also extend their service life, leading to reduced downtime and increased productivity.

Understanding Orgapack ort-250 Overview

This section provides a comprehensive examination of a specific tool designed for efficient packaging solutions. Its innovative features and robust design cater to various industrial applications, ensuring reliability and performance in demanding environments.

The device is engineered to streamline the strapping process, utilizing advanced technology to enhance productivity. Its user-friendly interface allows operators to quickly familiarize themselves with the functionality, resulting in minimal downtime during operations.

Key characteristics include its lightweight construction and ergonomic design, which facilitate ease of use and maneuverability. Additionally, the tool is compatible with a variety of materials, offering versatility for different packaging needs.

Maintenance is straightforward, with essential components easily accessible for routine checks. Understanding these features not only aids in optimizing the use of the equipment but also contributes to prolonging its lifespan and ensuring consistent performance.

Common Issues with Orgapack ort-250

When utilizing strapping equipment, users may encounter a variety of challenges that can hinder performance and efficiency. Understanding these common problems is essential for maintaining optimal operation and prolonging the lifespan of the device. Below are some frequently observed issues that operators may face, along with potential solutions.

Frequent Problems

| Issue | Description | Possible Solution |

|---|---|---|

| Jamming | Straps may become stuck in the feed mechanism, preventing proper operation. | Check for debris and ensure correct strap loading. |

| Weak Seals | Inadequate sealing can lead to loose straps, compromising package integrity. | Adjust tension settings or replace worn components. |

| Poor Tensioning | Insufficient tension can result in ineffective bundling. | Calibrate the tension settings based on strap type. |

| Electrical Failures | Power issues may cause the device to malfunction or not start. | Inspect power connections and fuses for damage. |

Maintenance Tips

Regular maintenance can help mitigate many of the issues mentioned above. Ensure to clean the machine frequently, check for wear and tear, and follow the manufacturer’s guidelines for servicing. By staying proactive, users can enhance the reliability and functionality of their strapping equipment.

Step-by-Step Repair Instructions

This section provides a detailed approach to restoring functionality to your equipment. Following a systematic process ensures that each component is addressed effectively, minimizing the risk of future issues and maximizing performance.

Begin by gathering all necessary tools and materials. Having everything on hand will streamline the procedure and reduce interruptions. A clean, well-lit workspace is essential for safety and efficiency.

Next, disconnect the power source to prevent accidents. Carefully remove any coverings or panels to access the internal parts. Take note of how components are arranged, as this will assist in reassembly.

Inspect each part for wear or damage. Replace any faulty components with suitable alternatives. Ensure all connections are secure and free from corrosion. Lubricate moving parts as necessary to enhance functionality.

Once all adjustments are made, reassemble the equipment in reverse order of disassembly. Double-check that all screws and fasteners are tightened properly.

Finally, reconnect the power source and conduct a thorough test. Monitor the equipment’s performance to confirm that the issues have been resolved. Regular maintenance checks can prevent future complications and prolong the lifespan of your machine.

Tools Needed for Effective Repairs

Having the right instruments is essential for accomplishing tasks efficiently and with precision. Proper tools not only enhance the quality of the work but also save time and reduce frustration.

Essential Instruments

- Wrenches

- Screwdrivers

- Pliers

- Utility knife

- Measuring tape

Specialized Equipment

- Calibration tools

- Diagnostic devices

- Replacement components

- Protective gear

Utilizing the correct selection of tools ultimately leads to more effective and lasting solutions, ensuring that tasks are completed to a high standard.

Safety Precautions During Repairs

Ensuring a safe environment while performing maintenance tasks is crucial for both personal safety and the longevity of the equipment. Adhering to established safety guidelines helps prevent accidents and injuries, allowing for a more efficient working process.

Before beginning any work, it’s essential to gather the necessary tools and materials. Verify that the workspace is clean and well-lit, and remove any potential hazards. Always use the appropriate personal protective equipment to safeguard against injuries.

| Safety Measure | Description |

|---|---|

| Personal Protective Equipment (PPE) | Wear gloves, goggles, and masks as needed to protect against debris and harmful substances. |

| Power Source Isolation | Disconnect the power supply to avoid accidental activation during maintenance. |

| Tool Inspection | Check tools for defects or damage before use to prevent malfunction. |

| Clear Work Area | Remove clutter and obstacles to minimize risks of tripping or falling. |

| Follow Instructions | Adhere to provided guidelines to ensure proper handling and maintenance of the equipment. |

By prioritizing safety and being vigilant during the maintenance process, individuals can significantly reduce risks and ensure a successful outcome.

Maintaining Your Orgapack ort-250

Regular upkeep of your packaging equipment is essential for ensuring optimal performance and longevity. By following a structured maintenance routine, you can prevent potential issues, enhance efficiency, and prolong the lifespan of your device. This section outlines best practices for caring for your machinery effectively.

Routine Inspections

Conducting frequent checks is crucial. Inspect all components for signs of wear, damage, or loose connections. Ensure that the mechanical parts are clean and free from debris. Pay attention to the belts and rollers, as any misalignment or dirt buildup can affect functionality.

Lubrication and Cleaning

Regularly lubricate moving parts to reduce friction and prevent premature wear. Use appropriate lubricants as specified by the manufacturer. Additionally, keep the equipment clean; wipe down surfaces and remove any packaging residues that may accumulate during operation. A clean machine runs more smoothly and reduces the risk of malfunctions.

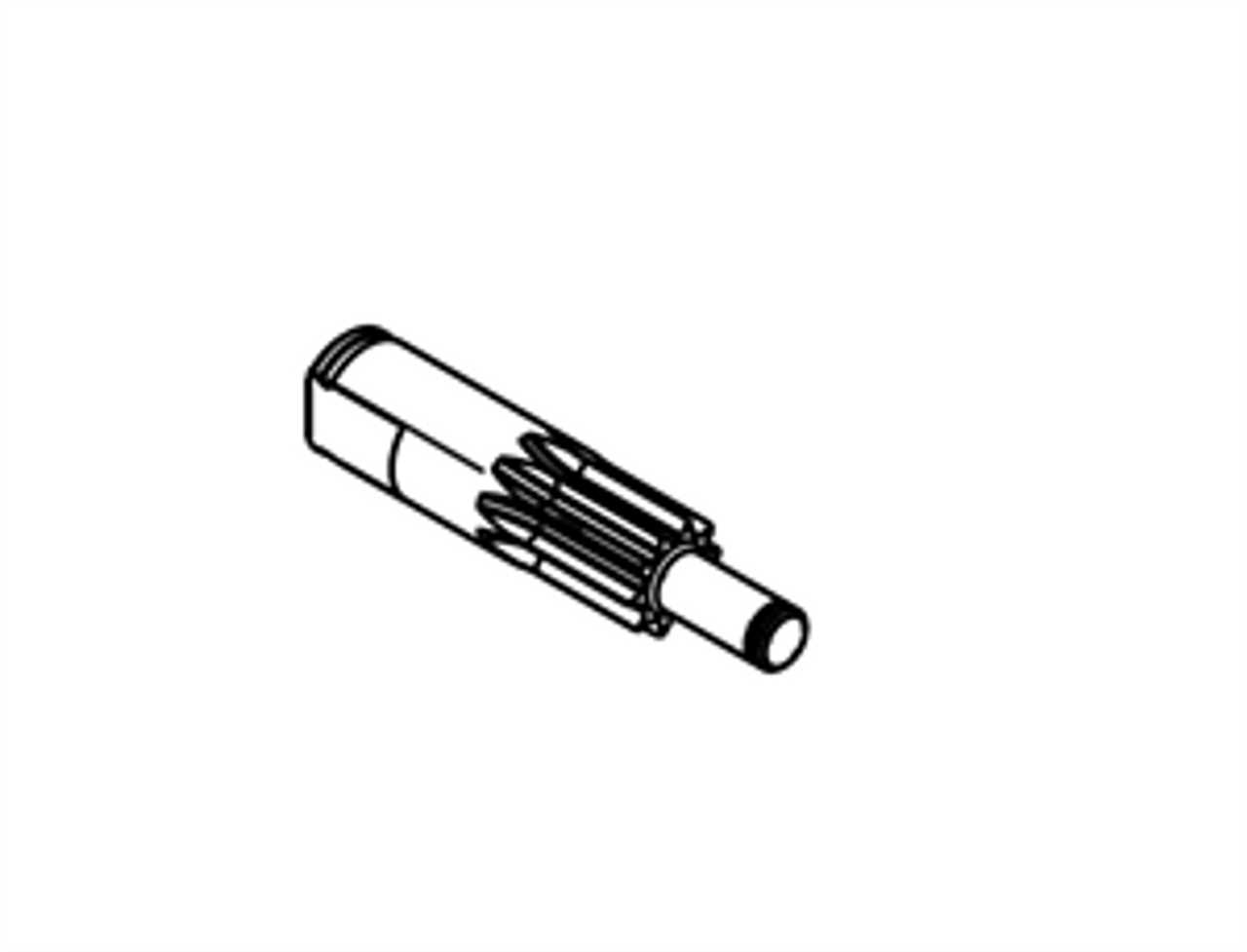

Replacing Key Components Easily

Maintaining machinery often requires the timely replacement of essential parts to ensure optimal performance. Understanding how to efficiently swap out these components can save time and reduce downtime.

Here are some steps to follow for a seamless replacement process:

- Identify the Component:

- Refer to your device’s specifications to locate the part that needs attention.

- Check for any signs of wear or damage that may indicate the need for a replacement.

lessCopy code

- Ensure you have the right tools on hand, such as wrenches, screwdrivers, and pliers.

- Consider having a replacement component ready to minimize interruptions.

- Power off the machine and disconnect it from any power source to ensure safety.

- Carefully remove the old component, taking note of how it is installed for reference.

- Install the new part, ensuring it fits securely and correctly.

- Reconnect the power and test the machinery to confirm the replacement was successful.

- Monitor the operation for any unusual sounds or behaviors.

By following these straightforward steps, you can ensure that key components are replaced with ease, maintaining the efficiency of your equipment.

Troubleshooting Common Operational Problems

In any machine or device, encountering operational issues is not uncommon. Identifying and resolving these problems promptly can enhance performance and prolong lifespan. This section outlines frequent challenges that users may face, along with practical solutions to rectify them.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Device not powering on | Dead battery, faulty power supply, loose connections | Check battery status, ensure proper power connection, inspect all cables for damage |

| Inconsistent performance | Worn components, incorrect settings, environmental factors | Examine parts for wear, verify settings are correct, assess surrounding conditions |

| Strange noises during operation | Foreign objects, lack of lubrication, damaged parts | Remove any debris, apply appropriate lubricant, check for and replace damaged components |

| Overheating | Blocked vents, prolonged usage, faulty cooling system | Clear any obstructions, allow device to cool down, inspect cooling mechanisms for functionality |

| Intermittent functionality | Electrical issues, software glitches, connectivity problems | Test electrical connections, reset device, troubleshoot any software or network issues |

By following these guidelines, users can effectively address and resolve common operational problems, ensuring their device functions smoothly and efficiently.

Finding Replacement Parts Online

Locating components for machinery can be a straightforward process when you know where to look. The internet offers a variety of platforms and resources to help users find the necessary parts efficiently. Whether you need a specific component or a complete assembly, understanding how to navigate these online spaces is essential.

Here are some effective strategies for sourcing components online:

- Manufacturer Websites: Start with the official website of the manufacturer. They often provide a list of parts, specifications, and even a direct purchasing option.

- Online Retailers: Websites like Amazon, eBay, or specialized machinery retailers frequently stock various components. Check customer reviews to ensure reliability.

- Parts Distributors: Some companies specialize in distributing parts. They may have a broader selection and can offer assistance in finding the right item.

- Forums and Communities: Join online forums or communities related to machinery. Users often share recommendations and links to where they found parts.

- Comparison Websites: Use comparison shopping sites to find the best prices and availability across different vendors.

When searching, it’s crucial to have the part number or specifications ready. This information will help narrow down results and ensure compatibility. Additionally, consider checking return policies and warranties to safeguard your purchase.

Resources for Professional Help

When facing challenges with specialized equipment, seeking assistance from qualified professionals is crucial. This section highlights various avenues available for obtaining expert support, ensuring that users can address their issues effectively and efficiently.

Authorized Service Centers

Engaging with authorized service centers guarantees that your equipment is handled by trained technicians who possess in-depth knowledge of its intricacies. These centers often utilize genuine parts and follow manufacturer guidelines, ensuring optimal performance post-service. Always check for certifications and reviews to select a reputable provider.

Online Communities and Forums

Digital platforms can be invaluable resources for troubleshooting and advice. Participating in online communities allows users to share experiences and solutions. Many forums host discussions led by seasoned professionals who can offer insights and support, making it easier to resolve common problems.