When it comes to ensuring the longevity and optimal performance of outdoor equipment, understanding the intricacies of maintenance is essential. This section provides valuable insights into addressing common issues that can arise with various tools designed for lawn care and landscaping tasks. Whether you are a seasoned professional or a weekend warrior, having the right information at your fingertips can make all the difference.

Regular upkeep not only enhances the efficiency of your devices but also minimizes the risk of unexpected breakdowns. By following systematic procedures and familiarizing yourself with the components involved, you can tackle problems effectively. This guide aims to equip you with practical knowledge, empowering you to take control of your equipment’s functionality.

From basic troubleshooting tips to detailed instructions on component adjustments, this resource will serve as a comprehensive reference. Whether you’re looking to resolve minor inconveniences or perform thorough inspections, the information herein will assist you in maintaining your tools in peak condition.

Mtd Yard Machine Repair Manual Overview

This section provides a comprehensive insight into the guide designed for maintenance and troubleshooting of outdoor equipment. It serves as a valuable resource for users seeking to enhance their knowledge and skills in handling various mechanical issues, ensuring optimal performance and longevity of their tools.

The guide encompasses a wide range of topics, including routine upkeep, component identification, and step-by-step instructions for addressing common faults. Whether you are a novice or an experienced operator, this resource aims to empower you with the necessary information for effective management.

| Feature | Description |

|---|---|

| Maintenance Tips | Guidelines for regular checks and upkeep to prevent major issues. |

| Troubleshooting | Detailed solutions for common problems encountered during use. |

| Parts Identification | Visual aids and descriptions to help recognize various components. |

| Safety Precautions | Important safety measures to follow during operation and service. |

By utilizing this comprehensive guide, users can enhance their proficiency in maintaining their equipment, ensuring a smooth and efficient experience. Proper understanding of the provided information will lead to more effective handling of tasks and a greater appreciation for the machinery’s capabilities.

Common Issues with Yard Machines

When working with outdoor equipment, various challenges may arise that can hinder performance and efficiency. Identifying these prevalent problems is essential for maintaining functionality and ensuring longevity. Below, we explore some of the typical concerns that users encounter.

Performance Problems

One of the most frequent issues involves the equipment failing to start or run smoothly. This can stem from a variety of causes, including fuel quality, spark plug conditions, or air filter blockages. Regular checks and maintenance can significantly mitigate these problems.

Mechanical Failures

Another area of concern includes mechanical breakdowns. Components such as belts, blades, and wheels can wear out over time, leading to diminished effectiveness. Awareness of these parts’ conditions can help prevent unexpected disruptions.

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Won’t Start | Poor fuel, faulty spark plug | Check fuel quality, replace spark plug |

| Uneven Cutting | Dull blades, incorrect height settings | Sharpen blades, adjust cutting height |

| Excessive Vibration | Loose components, worn belts | Tighten parts, replace belts |

Essential Tools for Repairs

When embarking on the journey of fixing outdoor equipment, having the right instruments at your disposal is crucial. The proper tools not only streamline the process but also enhance the efficiency and effectiveness of the task at hand.

Wrenches and screwdrivers are fundamental components of any toolkit. A variety of sizes ensures you can tackle different fasteners with ease. Socket sets are also indispensable, allowing for quick adjustments in tight spaces.

Additionally, a multimeter is essential for diagnosing electrical issues, while pliers are useful for gripping and manipulating small components. For more intricate tasks, consider a torque wrench to achieve the ultimate precision.

Finally, don’t overlook the importance of safety gear, such as gloves and goggles, to protect yourself during the process. Equipping yourself with these essential items will ensure a smoother and safer experience.

Step-by-Step Repair Techniques

This section provides a detailed approach to addressing common issues with outdoor equipment. Following a systematic process not only enhances the likelihood of successful troubleshooting but also ensures that each step is thoroughly understood. By breaking down the procedures into manageable parts, users can effectively resolve problems and maintain optimal functionality.

Initial Assessment

The first step involves evaluating the unit to identify visible signs of damage or wear. Check for any leaks, cracks, or loose components. Documenting these findings will help streamline the repair process. Understanding the nature of the malfunction is crucial for determining the necessary actions.

Disassembly and Component Inspection

Once the initial assessment is complete, carefully disassemble the unit according to the manufacturer’s guidelines. Keep track of all parts and fasteners. Inspect each component for signs of wear or malfunction, and replace any defective items as needed. This thorough examination is essential for restoring the equipment to optimal performance.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your outdoor equipment requires regular attention and care. By following a few essential guidelines, you can extend the life of your tools and minimize the need for extensive repairs. Proper maintenance not only enhances functionality but also contributes to safety and efficiency.

Regular Cleaning

One of the simplest yet most effective ways to maintain your equipment is through routine cleaning. Debris and residue can accumulate, affecting performance and leading to potential issues. Make it a habit to remove grass clippings, dirt, and other materials after each use.

Routine Inspections

Conducting periodic inspections is crucial. Check for wear and tear, ensuring all components are functioning correctly. Addressing minor issues before they escalate can save time and resources in the long run.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Clean after use | Every use | Prevents build-up and maintains performance |

| Inspect for damage | Monthly | Identifies issues early, preventing costly repairs |

| Check fluids | Before each use | Ensures smooth operation and prevents overheating |

| Sharpen blades | Every season | Improves cutting efficiency and reduces strain |

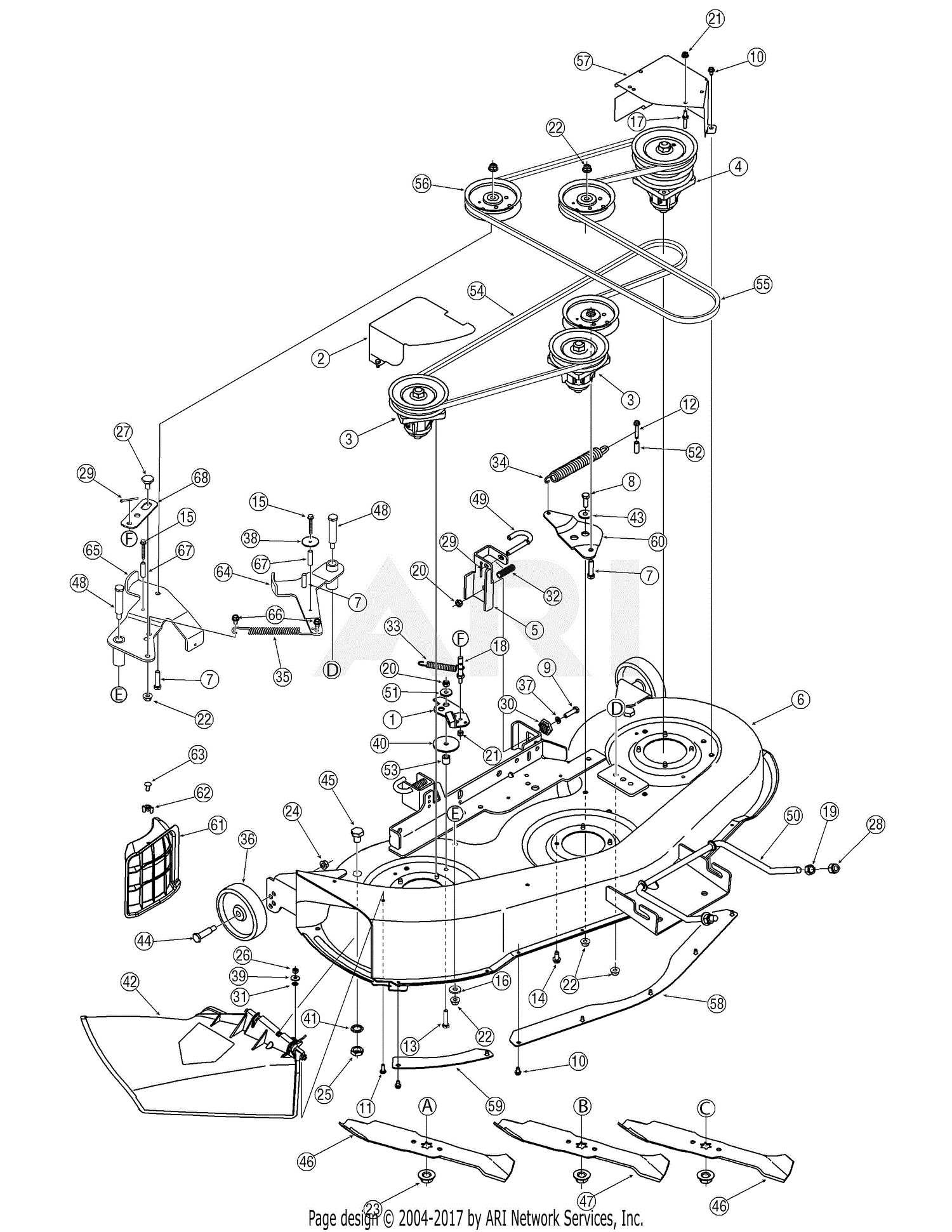

How to Identify Parts Easily

Recognizing components in equipment can often be a daunting task, but with the right approach, it becomes much simpler. Understanding the key characteristics of each part and utilizing appropriate resources can streamline the identification process, ensuring you find what you need without unnecessary frustration.

Utilizing Reference Guides

Reference guides and catalogs are invaluable tools for identifying components. They often include diagrams and part numbers that help you match the correct item with your specific model. Make sure to keep these resources handy, as they provide detailed information about sizes, shapes, and functions of various elements.

Visual Inspection Techniques

Performing a thorough visual inspection is another effective method. Look for unique markings, numbers, or shapes that can help differentiate parts. Taking clear photographs can also assist in comparing what you have with online databases or community forums, making the identification process more efficient.

DIY Troubleshooting Guide

When faced with mechanical issues, a systematic approach can save both time and money. This guide offers practical steps to diagnose and resolve common problems, empowering you to tackle difficulties confidently. With a bit of patience and observation, most challenges can be addressed without professional assistance.

1. Identify the Problem: Start by noting any unusual sounds, smells, or behaviors. Pay attention to when the issue occurs–whether during startup or while in operation. This information is crucial for pinpointing the root cause.

2. Check the Basics: Ensure all components are securely attached and in good condition. Look for loose wires, damaged belts, or clogged filters. Simple maintenance tasks often solve the most frustrating issues.

3. Consult the Resources: Refer to online forums, videos, or community groups for insights from others who have faced similar challenges. This collective knowledge can provide effective solutions and tips.

4. Conduct Systematic Tests: Use a process of elimination to test different components. Start with the easiest fixes, such as changing batteries or replacing filters, before moving on to more complex systems.

5. Document Findings: Keep a record of what you observe and any changes made. This log can help track progress and assist in future troubleshooting efforts.

6. Know When to Seek Help: If the problem persists after thorough investigation, it may be time to consult a professional. Recognizing your limits is essential for safety and efficiency.

Understanding the Engine Components

Engines are intricate systems comprised of various parts that work in harmony to convert fuel into mechanical energy. Grasping the role of each component is essential for effective maintenance and troubleshooting. Below, we explore the fundamental elements that contribute to the overall functionality of an engine.

- Fuel System: Responsible for storing and delivering fuel to the combustion chamber.

- Air Intake: Supplies the necessary air for the combustion process, mixing with the fuel.

- Combustion Chamber: The area where fuel and air mix and ignite, generating power.

- Piston: A moving component that compresses the air-fuel mixture and transfers energy to the crankshaft.

- Crankshaft: Converts the linear motion of the piston into rotational motion, powering the output.

- Valves: Regulate the intake of air and fuel, as well as the expulsion of exhaust gases.

- Ignition System: Initiates combustion by producing a spark at the right moment.

- Exhaust System: Channels away the byproducts of combustion, ensuring optimal engine performance.

Each component plays a vital role in the engine’s operation, and understanding their functions can significantly enhance the efficiency and longevity of the equipment.

Electrical System Maintenance Practices

Ensuring the longevity and reliability of an electrical system requires consistent attention and proactive measures. Regular maintenance helps identify potential issues before they escalate, ultimately enhancing performance and safety. This section outlines essential practices for maintaining the electrical components of your equipment.

Routine Inspections: Conducting periodic checks of all electrical parts is crucial. Look for signs of wear, corrosion, or loose connections. Regular visual inspections can prevent unexpected failures and ensure optimal operation.

Cleaning Connections: Over time, dust and grime can accumulate on electrical contacts. Use a suitable cleaning agent to remove any buildup, ensuring that connections are clean and secure. This practice enhances conductivity and minimizes the risk of shorts.

Checking Wiring Integrity: Inspect the wiring for any signs of damage, such as fraying or cracking. Damaged wires can lead to shorts and other electrical issues. If any wear is detected, replace the wiring promptly to maintain system integrity.

Testing Voltage and Continuity: Utilize a multimeter to regularly test voltage levels and continuity in circuits. This helps to confirm that electrical flow is consistent and that there are no interruptions in the system.

Battery Maintenance: For systems that rely on batteries, ensure they are charged and in good condition. Regularly check the terminals for corrosion and clean them as needed. Maintaining battery health is essential for reliable performance.

Consulting Professional Services: If you encounter complex issues or are unsure about performing maintenance tasks, consulting a qualified technician is advisable. Professionals have the expertise to diagnose problems accurately and ensure safe handling of electrical components.

Implementing these maintenance practices will significantly enhance the reliability and efficiency of the electrical system, reducing the likelihood of unexpected breakdowns.

Safety Precautions During Repairs

Ensuring a safe working environment is essential when undertaking any maintenance tasks. Proper precautions not only protect the individual but also help to prevent damage to the equipment. Understanding and implementing safety measures can significantly reduce the risk of accidents and injuries.

Preparation and Personal Protective Equipment

Before starting any maintenance work, it is crucial to gather all necessary tools and equipment. Ensure that the workspace is clean and organized. Wearing personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear is vital to safeguard against potential hazards. Hearing protection may also be necessary in noisy environments.

Safe Practices During Maintenance

Always disconnect the power source before beginning any service. This step is fundamental in preventing accidental startups. When working with sharp tools or heavy components, maintain a clear focus and avoid distractions. It is advisable to follow the guidelines outlined in the instruction documentation to ensure safe handling and assembly of parts.

When to Seek Professional Help

Determining the right moment to enlist expert assistance can be crucial for ensuring optimal performance and longevity of your equipment. While some tasks may be manageable for a skilled enthusiast, others may require specialized knowledge and tools to address complex issues effectively.

It’s important to recognize the signs that indicate the need for professional intervention. Whether it’s unusual noises, persistent operational failures, or the inability to diagnose the problem, these indicators suggest that expertise is necessary.

| Signs of Trouble | Recommended Action |

|---|---|

| Unusual noises or vibrations | Consult a technician to diagnose potential mechanical failures. |

| Frequent breakdowns | Consider professional assessment for underlying issues. |

| Inability to start or operate | Seek help to identify electrical or fuel system problems. |

| Visible damage or wear | Request an evaluation to determine necessary repairs. |

| Unsure of proper maintenance | Engage a specialist for advice on care and upkeep. |

Being proactive in seeking assistance can prevent minor issues from escalating into major complications, ultimately saving time and resources. Prioritize safety and efficiency by recognizing when to bring in a professional.

Resources for Further Assistance

When tackling maintenance tasks or troubleshooting equipment issues, having access to a variety of support materials can significantly enhance your experience. Whether you’re seeking visual guides, expert advice, or community forums, numerous resources are available to assist you in understanding and addressing your needs effectively.

Online Forums: Engaging with online communities can provide valuable insights and tips from fellow users. Many enthusiasts share their experiences and solutions, making these platforms a great place for knowledge exchange.

Video Tutorials: Platforms like YouTube offer a wealth of instructional videos that can guide you through specific tasks step-by-step. Visual demonstrations often make complex procedures easier to grasp.

Official Websites: Manufacturers typically provide comprehensive resources, including FAQs, troubleshooting guides, and contact information for customer support. These official channels can be invaluable for accurate information and assistance.

Local Repair Shops: Visiting a nearby service center can connect you with professionals who possess hands-on experience. They can offer advice, repairs, and maintenance services tailored to your equipment.

Instructional Books: Investing in detailed literature focused on your type of equipment can deepen your understanding and provide a reliable reference for future tasks. These books often cover a wide range of topics, from basic maintenance to advanced troubleshooting techniques.

Utilizing these diverse resources can empower you to handle your equipment with confidence, ensuring it remains in optimal condition for years to come.