Maintaining your gardening apparatus is essential to ensure its longevity and optimal performance. Understanding the intricacies of your equipment can enhance its efficiency and make your outdoor tasks much easier. This section aims to provide valuable insights into troubleshooting and upkeep practices that can help you address common issues.

Familiarity with your device is the first step toward effective care. Knowing the components and their functions can assist you in identifying problems early on. Regular inspections and basic knowledge can save time and effort in the long run.

In addition to understanding the parts, following structured procedures for maintenance will keep your machinery in excellent condition. This guide covers various aspects, from routine checks to more detailed assessments, helping you tackle potential challenges proactively.

The internal workings of an engine are crucial for its overall performance and functionality. Each part plays a significant role in ensuring smooth operation, and understanding these elements can enhance maintenance practices and troubleshooting skills.

Main Parts of the Engine

The primary sections include the cylinder, where combustion occurs, and the crankshaft, which converts the linear motion into rotational energy. Additionally, the camshaft controls the timing of valve openings and closings, ensuring optimal airflow and fuel intake.

Regular upkeep of these components is vital for prolonging the lifespan of the engine. Ensuring that parts are clean and functioning properly can prevent larger issues from developing, leading to a more efficient and reliable power source.

Maintenance Tips for Longevity

Proper care and routine upkeep are essential to ensure the extended lifespan of your equipment. By implementing a few simple strategies, you can significantly enhance its performance and reliability, ultimately leading to more efficient operation and reduced need for interventions.

Regular Cleaning

Keeping the exterior and interior components free from debris is crucial. After each use, remove grass clippings, dirt, and other residues to prevent build-up that can affect functionality. Regularly inspect the blades and housing, ensuring they remain clear for optimal performance.

Scheduled Inspections

Conduct periodic assessments of the key parts, including belts, filters, and spark plugs. By identifying wear and tear early, you can address potential issues before they escalate, promoting a smoother operation and extending the life of your equipment.

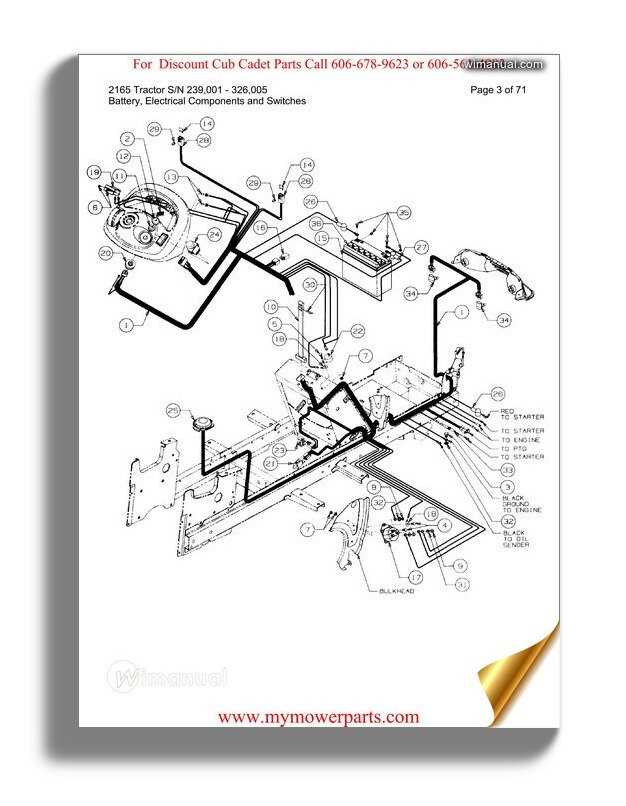

Troubleshooting Electrical Failures

Electrical issues can be frustrating and challenging to identify. Understanding common problems can help you diagnose and resolve these complications effectively. This section aims to provide insights into recognizing and addressing typical electrical malfunctions that may arise during operation.

Check the Power Source: The first step in diagnosing electrical complications is to ensure that the power source is functioning correctly. Examine the outlet or battery connections for any signs of damage or loose connections. A stable power supply is essential for proper functionality.

Inspect Wiring and Connections: Damaged or frayed wires can lead to interruptions in power flow. Carefully inspect all wiring and connections for signs of wear or corrosion. If any issues are found, replacing or repairing the affected components may resolve the problem.

Test the Circuitry: Utilizing a multimeter can help test the electrical circuit for continuity. This device can identify whether current is flowing properly through the system. If there are breaks in the circuit, further investigation into the wiring may be necessary.

Evaluate Fuses and Switches: Fuses and switches play a critical role in the electrical system. Check for blown fuses or malfunctioning switches that could disrupt operation. Replacing faulty components can restore normal function.

Seek Professional Assistance: If troubleshooting does not yield results, consulting a professional may be necessary. Experienced technicians can provide expert guidance and ensure that all electrical components are functioning optimally.

Proper Blade Installation Techniques

Ensuring correct attachment of cutting components is crucial for optimal performance and safety. This section outlines effective practices for achieving secure and precise installation, contributing to the longevity of your equipment.

Follow these steps for a successful installation:

- Gather Necessary Tools: Before starting, ensure you have all required tools, including a wrench and safety gloves.

- Disconnect Power: Always disconnect the power source to prevent accidental activation while working.

- Remove Old Blade: Carefully detach the existing cutting component, taking note of how it is mounted.

- Inspect Mounting Area: Check the attachment area for any damage or debris that could affect the new installation.

- Align New Blade: Position the new component accurately, aligning it with the mounting holes as per the manufacturer’s specifications.

- Secure with Fasteners: Use the appropriate fasteners to attach the blade, ensuring they are tightened evenly for stability.

- Check for Movement: Once installed, gently shake the component to ensure there is no excessive movement or looseness.

By adhering to these techniques, you can enhance performance and extend the lifespan of your cutting equipment.

Adjusting Cutting Height Effectively

Achieving an optimal cutting level is essential for maintaining a healthy and visually appealing grassy area. The height at which vegetation is trimmed can significantly impact growth and overall aesthetics. This section outlines effective methods to modify cutting elevation to ensure desired results.

Understanding the Importance of Cutting Height

Proper adjustment of cutting height plays a crucial role in the health of the grass. Here are some benefits of maintaining the correct elevation:

- Promotes robust root development

- Enhances moisture retention

- Reduces weed growth

- Improves disease resistance

Steps to Adjust Cutting Height

Follow these guidelines to effectively alter the cutting height:

- Identify the desired height based on the type of vegetation.

- Locate the adjustment mechanism, usually found on the side or rear.

- Raise or lower the cutting blades to achieve the preferred level.

- Check the elevation using a ruler or measuring device for accuracy.

- Test the adjustments on a small area to confirm satisfactory results.

Cleaning and Caring for Your Mower

Maintaining the appearance and functionality of your cutting machine is essential for optimal performance and longevity. Regular cleaning and proper care not only enhance its look but also prevent potential issues that could arise from neglect. This section will guide you through effective practices to keep your equipment in prime condition.

Begin by removing any grass clippings, dirt, or debris from the surface after each use. Utilize a brush or cloth to wipe down the exterior, ensuring that all components are free of buildup. For a deeper clean, consider using water and a mild detergent, taking care to avoid electrical parts. Allow the machine to dry thoroughly to prevent rust and corrosion.

Additionally, inspect the blades regularly for sharpness and cleanliness. Dull or dirty blades can hinder performance, resulting in uneven cuts. Sharpening the blades as needed ensures an efficient operation. Finally, check all moving parts and lubricate where necessary to facilitate smooth functionality.

Identifying Fuel System Problems

Understanding the common issues within the fuel system is essential for optimal performance of your equipment. Recognizing the symptoms of these challenges can prevent further complications and ensure a smooth operation.

Here are some typical signs indicating potential fuel system issues:

- Engine difficulty starting or stalling during operation

- Poor acceleration or sluggish performance

- Unusual sounds from the engine

- Excessive exhaust emissions

- Fuel leakage around connections

To accurately diagnose these problems, consider the following steps:

- Inspect the fuel lines for cracks or damage.

- Check the fuel filter for clogs or contamination.

- Examine the fuel pump for proper functionality.

- Ensure the fuel tank is filled with clean, appropriate fuel.

Taking these steps will help in identifying issues effectively, allowing for timely action to restore functionality.

Exploring Transmission Adjustments

Proper configuration of the drivetrain is essential for optimal performance and efficiency. Fine-tuning these settings can significantly enhance the operation of the equipment, ensuring smooth engagement and responsive handling. Understanding the mechanics behind these adjustments is crucial for maintaining functionality over time.

Initial Assessment is the first step in the adjustment process. Examine the current performance and identify any discrepancies in responsiveness. Noting unusual sounds or irregular behavior during operation can provide valuable insights into potential misalignments.

After completing the assessment, fine-tuning the settings involves making incremental changes to the linkage and other components. Carefully follow manufacturer guidelines to achieve the desired outcomes. Regular checks and adjustments can lead to a more reliable experience and prolong the lifespan of the machinery.

Replacing Spark Plugs Easily

Changing the ignition components in your equipment is a straightforward task that can enhance performance and efficiency. Proper maintenance of these elements is essential for ensuring optimal functionality. In this section, we will guide you through the steps needed to perform this essential procedure effectively.

Gathering Necessary Tools

Before starting, make sure you have all the required tools at hand. You will need a socket wrench, a gap gauge, and replacement plugs. Having these items ready will streamline the process and minimize any interruptions.

Step-by-Step Process

Begin by ensuring the engine is cool and disconnecting the spark plug wire. Use the socket wrench to carefully remove the old component, taking care not to damage surrounding parts. Next, check the gap of the new plug with the gauge to ensure proper fit. Once prepared, install the new piece securely, and reattach the wire. Regularly replacing these components will significantly improve the efficiency and reliability of your equipment.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is essential to prevent accidents and injuries. Proper precautions can safeguard both the individual and the equipment being serviced. Adhering to established guidelines helps create a secure working environment.

Essential Safety Gear

Wearing appropriate protective gear is crucial when engaging in maintenance activities. This includes items that shield against physical hazards and ensure personal safety. The following table outlines the recommended equipment:

| Equipment | Purpose |

|---|---|

| Safety Goggles | Protects eyes from debris |

| Gloves | Prevents cuts and abrasions |

| Steel-Toed Boots | Safeguards feet from heavy objects |

| Ear Protection | Reduces noise exposure |

Work Area Organization

Maintaining an orderly workspace is vital to minimize risks. Clear any clutter and ensure that tools are easily accessible. A tidy area reduces the likelihood of accidents and enhances efficiency during the servicing process.

Tools Needed for Effective Repair

Having the right equipment is essential for ensuring a smooth and successful restoration process. Utilizing appropriate instruments can significantly enhance efficiency and accuracy while working on your device.

Basic Hand Tools: Start with fundamental implements such as wrenches, screwdrivers, and pliers. These items are crucial for disassembly and reassembly tasks.

Specialized Equipment: Depending on the nature of the issue, you may require specific tools, including torque wrenches or diagnostic devices, to address particular challenges effectively.

Safety Gear: Always prioritize your safety. Wearing protective eyewear, gloves, and masks will safeguard you from potential hazards encountered during the process.

Workspace Essentials: A clean, organized workspace equipped with a sturdy workbench and adequate lighting will facilitate a smoother workflow and help prevent accidents.