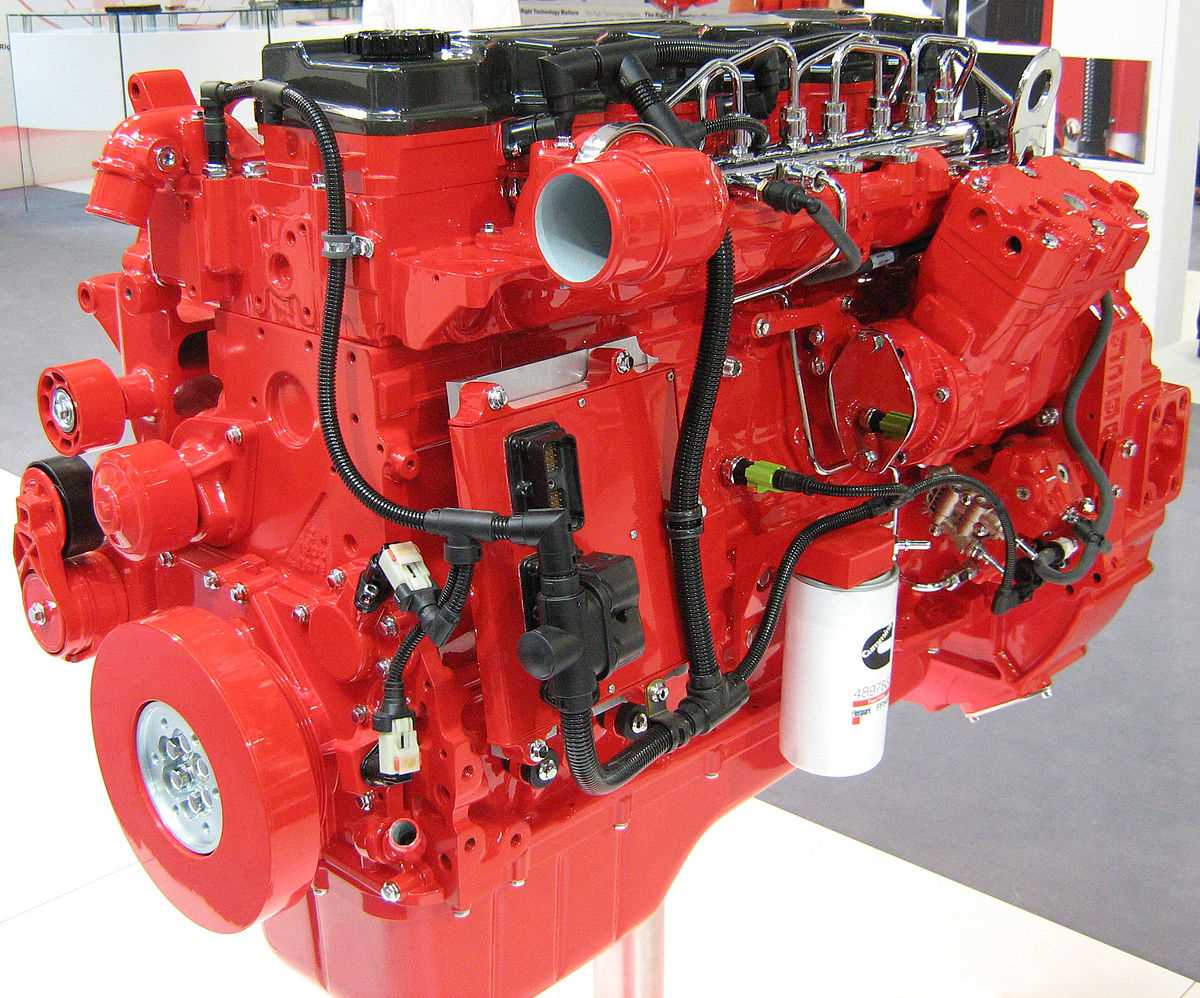

This section focuses on essential strategies for identifying and resolving issues that may arise in high-performance engines. Understanding common challenges and their solutions can greatly enhance the efficiency and longevity of these powerful machines.

Proper maintenance practices play a crucial role in ensuring optimal functionality. By following systematic approaches, users can effectively address a range of operational problems, enhancing performance and reliability.

Moreover, familiarity with specific components and their interactions enables individuals to make informed decisions. This knowledge not only aids in timely interventions but also empowers users to maintain their engines in peak condition.

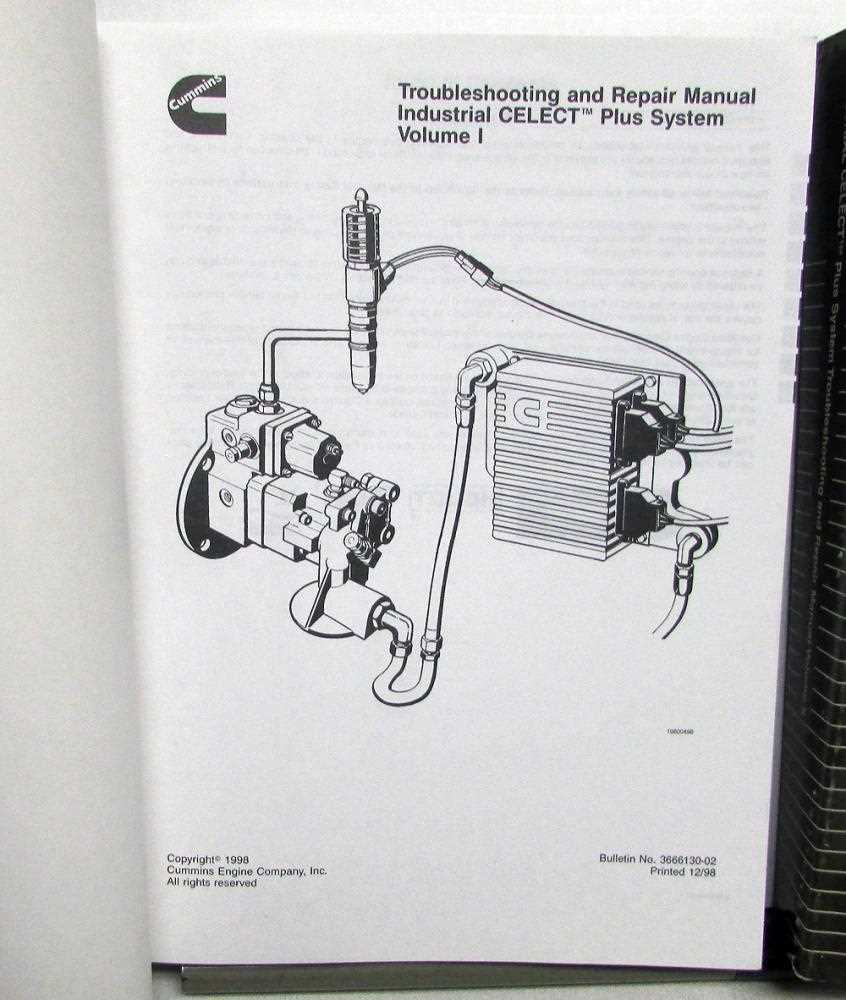

Cummins Troubleshooting and Repair Guide

This section provides essential insights into diagnosing and fixing common issues encountered with specific engines. Understanding the underlying principles and methodologies can significantly enhance maintenance practices and prolong the lifespan of the machinery.

Identifying Common Issues

Recognizing symptoms early is crucial. Common indicators of malfunction may include unusual noises, decreased performance, or warning lights. Systematic examination can help pinpoint the source of the problem.

Step-by-Step Resolution Process

Once issues are identified, following a structured approach to address them is vital. This includes gathering necessary tools, reviewing schematics, and executing repairs in a logical sequence to ensure thorough and effective solutions.

Understanding Common Engine Issues

Engine performance can be affected by various factors, leading to a range of complications. Recognizing these issues is essential for ensuring optimal operation and longevity of the machinery. Common symptoms often point to underlying problems that, if addressed promptly, can prevent significant downtime and costly repairs.

Identifying Symptoms

Common indicators of engine troubles may include unusual noises, decreased power output, or excessive emissions. Observing these signs can help in diagnosing the root cause and implementing corrective measures. Regular monitoring of engine behavior is crucial for early detection of potential malfunctions.

Preventive Measures

Implementing routine maintenance practices plays a vital role in minimizing issues. Regular oil changes, filter replacements, and thorough inspections can significantly enhance performance and reduce the likelihood of major failures. Staying proactive is key to maintaining engine efficiency.

Diagnostic Tools for Effective Repairs

Utilizing appropriate instruments is crucial for identifying issues accurately and ensuring efficient solutions. The right devices not only streamline the assessment process but also enhance the accuracy of evaluations, leading to more reliable outcomes.

Various types of diagnostic equipment play a vital role in addressing mechanical challenges. Here are some key tools that facilitate effective analysis:

| Tool Type | Description |

|---|---|

| OBD-II Scanner | Reads fault codes and provides insights into vehicle performance metrics. |

| Multimeter | Measures voltage, current, and resistance to diagnose electrical issues. |

| Pressure Gauge | Assesses fluid pressures in various systems, indicating potential leaks or blockages. |

| Oscilloscope | Visualizes electrical signals to analyze performance and detect irregularities. |

Employing these tools effectively can lead to a deeper understanding of mechanical systems, enabling swift resolution of challenges and minimizing downtime.

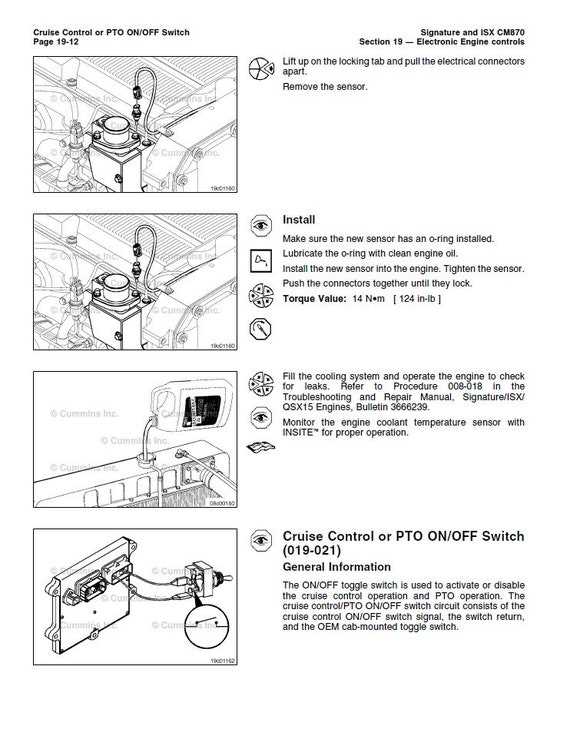

Step-by-Step Repair Procedures

This section outlines a structured approach to address common issues that may arise in various systems. By following these outlined phases, individuals can efficiently resolve problems and enhance the overall functionality of their equipment.

1. Identify the Issue

Begin by observing the symptoms presented by the machinery. Gather information on any error codes or unusual behaviors, which will help in narrowing down potential causes.

2. Gather Required Tools

Before proceeding, ensure you have all necessary tools and components at hand. This may include wrenches, screwdrivers, diagnostic devices, and replacement parts.

3. Perform Initial Checks

Conduct preliminary assessments, such as checking fluid levels, inspecting for leaks, and ensuring electrical connections are secure. These initial steps can often reveal simple issues.

4. Follow Systematic Procedures

Refer to the recommended procedures for the specific system. This may involve disassembly, testing components, and replacing faulty parts according to established guidelines.

5. Reassemble and Test

Once repairs are completed, carefully reassemble all components. After reassembly, run tests to ensure the system operates correctly and efficiently.

6. Document the Process

Record all findings, actions taken, and any parts replaced. Documentation aids in future maintenance and provides valuable insights for troubleshooting.

Preventive Maintenance Best Practices

Implementing effective upkeep strategies is crucial for maximizing equipment longevity and performance. By adhering to a systematic approach, operators can significantly reduce the risk of unexpected failures and enhance operational efficiency. This section highlights essential practices that contribute to maintaining optimal functionality.

Regular Inspections

Conducting frequent evaluations of machinery is vital. These assessments allow for early identification of wear and tear, enabling timely interventions. Visual checks and thorough examinations of critical components can uncover potential issues before they escalate, ensuring smoother operations.

Scheduled Lubrication

Consistent application of suitable lubricants is essential for minimizing friction and heat generation within moving parts. Establishing a lubrication schedule tailored to specific operational conditions can greatly enhance the reliability of equipment. Proper lubrication not only extends the lifespan of components but also improves overall efficiency.

Interpreting Error Codes and Signals

Understanding diagnostic messages is essential for effective maintenance of engine systems. These signals provide crucial insights into the operational status and potential issues that may arise. By analyzing these codes, one can identify specific problems, ensuring timely intervention and optimal performance.

Error codes are typically generated by onboard monitoring systems. Each code corresponds to a specific fault or anomaly, allowing technicians to focus their efforts on the areas requiring attention. Proper interpretation of these codes can significantly streamline the maintenance process.

| Error Code | Description | Possible Causes |

|---|---|---|

| 001 | Engine Overheat | Coolant leak, faulty thermostat, or blocked radiator |

| 002 | Low Oil Pressure | Oil pump failure, low oil level, or clogged oil filter |

| 003 | Fuel System Error | Clogged fuel filter, faulty injector, or low fuel pressure |

By familiarizing oneself with common error codes and their implications, operators can enhance their ability to address issues effectively. This proactive approach not only improves engine longevity but also ensures safety and efficiency during operation.

Fuel System Troubleshooting Techniques

Understanding the complexities of a fuel delivery system is crucial for ensuring optimal engine performance. Various issues can arise within this system, necessitating a systematic approach to identify and address them effectively. This section outlines essential strategies for diagnosing common challenges related to fuel supply.

Identifying Common Issues

Begin by examining the fuel source and ensuring there is an adequate supply. Inspect filters for clogs that may restrict flow, and check for leaks in the lines that could lead to pressure loss. Additionally, evaluate the fuel pump functionality, as any malfunction here can severely impact engine operation.

Testing Fuel Quality

Assessing the quality of the fuel is also vital. Contaminated or degraded fuel can lead to performance issues. Conduct tests to determine the presence of water or particulate matter. Implementing a regular maintenance schedule for the fuel system can help prevent these problems and ensure consistent performance.

Cooling System Performance Checks

Assessing the efficiency of a vehicle’s temperature regulation mechanism is crucial for optimal operation. Regular evaluations help identify potential issues that could lead to overheating or other malfunctions.

Initial Observations

Start by examining the coolant level in the reservoir. Ensure it meets the recommended mark to prevent inadequate cooling. Additionally, inspect for any signs of leaks around hoses and fittings, as these can lead to coolant loss and affect system functionality.

Thermostat Functionality

Verify the operation of the thermostat. A malfunctioning thermostat can hinder coolant flow, resulting in temperature irregularities. Testing can involve monitoring the temperature gauge during engine operation to ensure it reaches the appropriate levels.

Radiator Condition

Inspect the radiator for obstructions or damage. A clean and functional radiator is vital for effective heat dissipation. Check for debris accumulation on the fins and ensure proper airflow is maintained.

Water Pump Performance

Evaluate the water pump’s operation. Listen for unusual noises that may indicate wear or malfunction. Ensure that the pump is circulating coolant effectively, as inadequate flow can lead to overheating.

Conclusion

Conducting these performance checks helps maintain the efficiency of the cooling system, ultimately extending the lifespan of the engine and enhancing overall vehicle reliability.

Electrical Systems Diagnostics Methods

Identifying issues within electrical systems requires a systematic approach that incorporates various techniques. These methods enable technicians to pinpoint faults effectively, ensuring optimal functionality of the components involved.

One common approach involves utilizing diagnostic tools to measure voltage, current, and resistance throughout the circuit. By gathering these metrics, professionals can determine the integrity of the system and identify areas that may require attention.

| Method | Description | Tools Required |

|---|---|---|

| Visual Inspection | Examine wiring, connectors, and components for physical damage or wear. | Flashlight, magnifying glass |

| Multimeter Testing | Measure voltage, current, and resistance to assess component functionality. | Digital multimeter |

| Oscilloscope Analysis | Visualize electrical signals to diagnose waveform issues. | Oscilloscope |

| Scan Tool Usage | Retrieve error codes and data from the control unit for analysis. | OBD-II scanner |

Employing a combination of these techniques allows for a comprehensive evaluation of the electrical systems, facilitating prompt and effective maintenance actions.

Overcoming Performance Limitations

Addressing performance constraints is crucial for maximizing engine efficiency and reliability. Various factors can contribute to reduced functionality, and understanding these can lead to effective solutions.

- Fuel Quality: Ensure that the fuel used meets the required standards. Contaminated or low-quality fuel can significantly affect performance.

- Air Intake System: Regularly inspect the air filters and intake paths. Blockages can restrict airflow, leading to decreased power output.

- Exhaust System: Evaluate the exhaust for obstructions. A compromised exhaust flow can result in increased back pressure and reduced engine efficiency.

- Engine Load: Monitor the load on the engine. Operating outside the recommended load limits can lead to overheating and premature wear.

Implementing regular maintenance schedules can preemptively identify potential issues, ensuring optimal functionality. Moreover, using diagnostic tools can assist in pinpointing specific areas requiring attention.

- Conduct routine inspections.

- Replace filters and fluids as needed.

- Utilize performance monitoring systems to track operational parameters.

By addressing these aspects systematically, one can enhance overall performance and extend the service life of the engine.

Resourceful Repair Parts Selection

Choosing the right components is essential for ensuring optimal performance and longevity of machinery. A thoughtful approach to sourcing parts can lead to significant improvements in efficiency and reliability. This section explores effective strategies for selecting the most suitable items for your needs.

- Identify Specific Requirements: Assess the exact specifications needed for your equipment. Consider factors such as size, material, and compatibility.

- Quality Over Cost: Prioritize high-quality items over lower-priced alternatives. Investing in durable components can reduce the frequency of replacements.

- Vendor Research: Evaluate potential suppliers by examining their reputation, customer reviews, and product offerings. Reliable vendors can provide valuable support and information.

- Cross-Referencing Parts: Utilize cross-reference tools to find equivalent components from different manufacturers. This can expand your options and potentially lower costs.

- Inventory Management: Keep a well-organized inventory to track parts usage and availability. This helps in making timely purchases and avoiding delays.

By following these strategies, one can effectively navigate the selection process and ensure that the right components are chosen to maintain operational excellence.