Understanding the intricacies of fuel delivery systems is essential for anyone involved in engine maintenance and optimization. These mechanisms play a critical role in ensuring that the engine receives the correct amount of fuel at the right time, which is vital for performance and efficiency.

In this section, we will explore the essential steps and considerations involved in the process of overhauling these systems. Emphasis will be placed on troubleshooting common issues, ensuring proper functionality, and enhancing the longevity of the components.

By delving into the specifics of system maintenance, readers will gain valuable insights into best practices that can significantly improve operational efficiency. This guide aims to empower individuals with the knowledge needed to effectively manage and maintain their fuel delivery systems.

Having the right instruments is crucial for effectively addressing issues with fluid mechanisms. A well-equipped toolbox can significantly streamline the process, ensuring that tasks are completed efficiently and safely.

- Wrenches: Adjustable and socket types are vital for securing and loosening various components.

- Screwdrivers: A set of flathead and Phillips screwdrivers is necessary for dealing with screws of different types.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping and manipulating small parts.

- Gaskets and Seals: Having a selection of these can prevent leaks and maintain integrity during reassembly.

- Cleaning Supplies: Solvents, brushes, and cloths are important for maintaining cleanliness and ensuring optimal performance.

- Measuring Tools: Calipers and rulers help in accurately measuring components and tolerances.

- Torque Wrench: This tool ensures that all connections are tightened to the correct specifications.

Investing in these essential tools not only facilitates smoother operations but also prolongs the lifespan of the equipment being serviced.

Step-by-Step Repair Instructions

This section provides detailed guidance for addressing common issues with fuel delivery systems. Following these steps will ensure that components are properly serviced and restored to optimal functionality.

Preparation and Safety Measures

Before beginning any work, ensure the area is clean and well-lit. Gather all necessary tools and equipment, including protective gear to prevent accidents. Familiarize yourself with the system layout and identify key components that require attention.

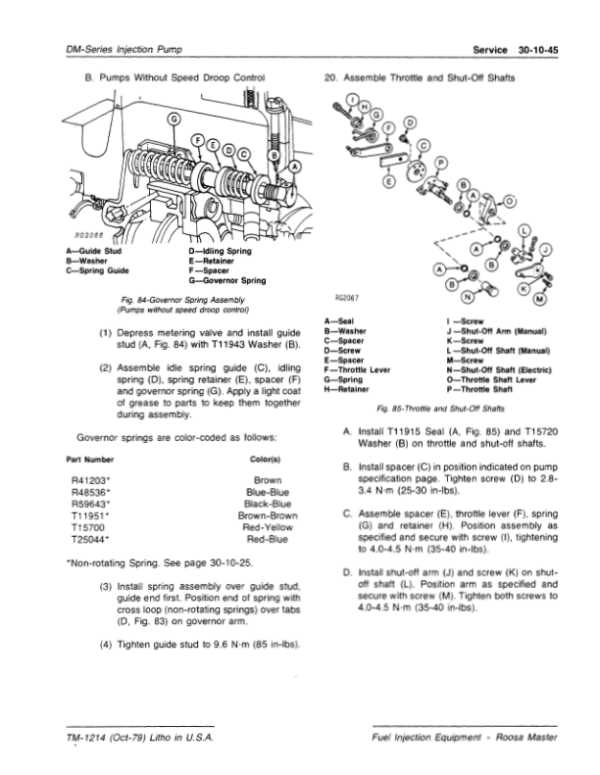

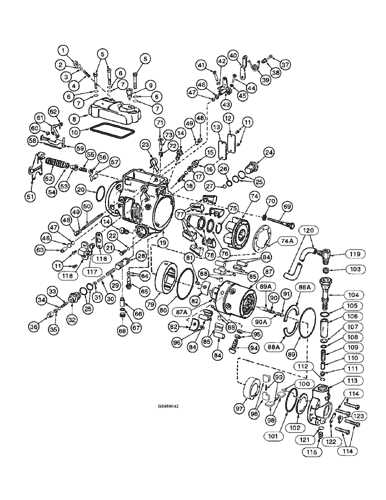

Disassembly and Inspection

Carefully disassemble the unit, taking note of the order of components. Inspect each part for wear, damage, or blockage. Document any findings to assist with reassembly and identify parts that may need replacement.

Maintenance Tips for Longevity

Ensuring the extended lifespan of mechanical systems involves adhering to a set of essential care practices. These practices not only enhance performance but also mitigate the risk of unexpected failures. By implementing routine checks and maintenance strategies, users can significantly prolong the operational life of their equipment.

Regular Inspections

Conducting frequent evaluations of the system is crucial. Pay attention to the following aspects:

- Check for any signs of wear or damage.

- Inspect connections and seals for leaks.

- Ensure that all components are securely fastened.

Optimal Operating Conditions

Maintaining ideal working conditions is vital for performance. Consider these guidelines:

- Operate within recommended temperature ranges.

- Avoid overloading the system beyond its capacity.

- Use high-quality fluids and lubricants suited for the application.

By following these practices, users can enhance reliability and ensure the long-term efficiency of their systems.

Troubleshooting Common Problems

Identifying and resolving issues in fuel delivery systems can significantly enhance performance and efficiency. This section provides guidance on common challenges that may arise, along with practical solutions.

- Inconsistent Fuel Flow:

This can be caused by blockages or faulty components. Check filters and lines for any obstructions.

- Difficulty Starting:

When starting issues occur, examine the fuel source and ensure proper priming. Inspect seals and connections for leaks.

- Unusual Noises:

Strange sounds may indicate mechanical wear or damage. Listen for irregular sounds and investigate accordingly.

- Low Power Output:

If power seems diminished, verify fuel quality and check for air leaks in the system.

- Excessive Smoke:

Smoke can indicate incomplete combustion. Review fuel settings and consider potential injector issues.

Regular monitoring and maintenance can help prevent many of these issues, ensuring reliable operation over time.

Replacing Pump Components Safely

When undertaking the task of component replacement in a fuel delivery system, safety should always be a primary concern. Proper procedures and precautions are essential to ensure a successful and hazard-free experience. This section outlines important steps and guidelines to follow when handling sensitive parts.

Preparation Steps

Before beginning the replacement process, it is crucial to gather all necessary tools and materials. Ensure the work area is clean and well-lit, minimizing the risk of accidents. Additionally, make sure to wear appropriate personal protective equipment (PPE) such as gloves and goggles to safeguard against potential hazards.

Component Handling Guidelines

Handling the parts with care is vital to avoid damage. Follow these guidelines:

| Step | Action |

|---|---|

| 1 | Disconnect the system from power sources. |

| 2 | Carefully remove the components, taking note of their arrangement. |

| 3 | Inspect all parts for wear or damage before installation. |

| 4 | Install the new or serviced components, ensuring a secure fit. |

| 5 | Reconnect all connections and verify that everything is in order. |

Testing the Injector Pump Functionality

Evaluating the operational efficiency of fuel delivery systems is crucial for ensuring optimal engine performance. This section outlines essential methods for assessing the functionality of these vital components, focusing on their ability to maintain proper pressure and flow rates.

To begin the evaluation, it is important to ensure that all connections are secure and that there are no leaks in the system. A thorough inspection of the components should be conducted, paying particular attention to any signs of wear or damage. Next, utilizing diagnostic tools can help in measuring the output pressure and flow rate, which are key indicators of performance.

In addition, conducting a visual inspection during operation can reveal issues such as irregular vibrations or abnormal sounds, which may indicate underlying problems. Regular testing not only prolongs the life of the system but also enhances overall efficiency, leading to improved fuel economy and reduced emissions.

By adhering to these testing procedures, one can ensure that the fuel delivery mechanism operates smoothly and effectively, contributing to the reliable performance of the engine.

Understanding Fuel System Interactions

Effective operation of an engine heavily relies on the seamless interplay of various components within the fuel system. Each element plays a critical role, influencing overall performance and efficiency. This section explores the dynamics of these interactions and their significance in maintaining optimal functionality.

Key Components and Their Functions

- Fuel Supply: Responsible for delivering the necessary fuel to the engine.

- Delivery Mechanisms: Ensure that fuel reaches the combustion chamber at the right pressure and timing.

- Filtration Systems: Protect the engine by removing impurities from the fuel.

- Control Units: Manage fuel flow and optimize combustion based on varying operating conditions.

Impact of Interactions on Engine Performance

The synergy between these components can significantly impact engine efficiency. For instance, inadequate fuel delivery may lead to poor combustion, resulting in increased emissions and reduced power output. Conversely, optimal coordination enhances responsiveness and fuel economy, illustrating the importance of maintaining each part in good working condition.

Expert Recommendations for Repairs

When dealing with the intricacies of fuel delivery systems, following professional advice can significantly enhance the effectiveness of your maintenance efforts. Understanding the essential aspects of troubleshooting and adjustments can lead to improved performance and longevity of your equipment.

Here are some key insights that experts suggest:

| Recommendation | Details |

|---|---|

| Regular Maintenance | Implementing a schedule for routine checks can prevent minor issues from escalating into significant problems. |

| Quality Components | Using high-quality parts and materials is crucial to ensure reliability and optimal functionality. |

| Professional Guidance | Consulting with specialists for complex issues can save time and resources, ensuring effective solutions. |

| Documentation Review | Referencing detailed guides and specifications helps in understanding the system’s requirements and functions. |

Resources for Further Learning

For those looking to deepen their understanding of fuel delivery systems and maintenance techniques, there are numerous valuable resources available. Engaging with expert literature, instructional videos, and specialized courses can significantly enhance knowledge and practical skills in this field.

Books and Publications: Explore various technical books that cover fundamental concepts, troubleshooting, and servicing techniques. These texts often provide in-depth insights and are written by industry professionals.

Online Courses: Many platforms offer courses tailored to fuel systems and their components. These courses typically include interactive elements, allowing learners to engage actively with the material and test their understanding.

YouTube Channels: Numerous channels focus on automotive and mechanical topics, featuring step-by-step guides and demonstrations. Watching experienced technicians can help clarify complex processes and techniques.

Forums and Community Groups: Joining online forums dedicated to automotive mechanics provides opportunities to ask questions, share experiences, and learn from fellow enthusiasts. Participating in these communities can be invaluable for gaining practical tips and advice.

Utilizing these resources can empower individuals to enhance their skills and confidently address challenges in fuel system maintenance and service.