Winter equipment can be an invaluable asset during the cold months, ensuring that pathways and driveways remain clear of snow. Understanding the intricacies of these machines is essential for optimal performance and longevity. This section delves into the essential aspects of upkeep and common issues that may arise, equipping users with the knowledge to keep their equipment in peak condition.

Regular examination and appropriate attention can significantly enhance functionality, making it easier to tackle the harshest of winter conditions. By familiarizing oneself with key components and their operation, individuals can identify potential problems early and take proactive measures to address them.

Moreover, a comprehensive understanding of troubleshooting techniques can empower users to resolve minor challenges without the need for professional assistance. This guide provides insights that are not only practical but also aimed at fostering confidence in handling equipment during the snowy season.

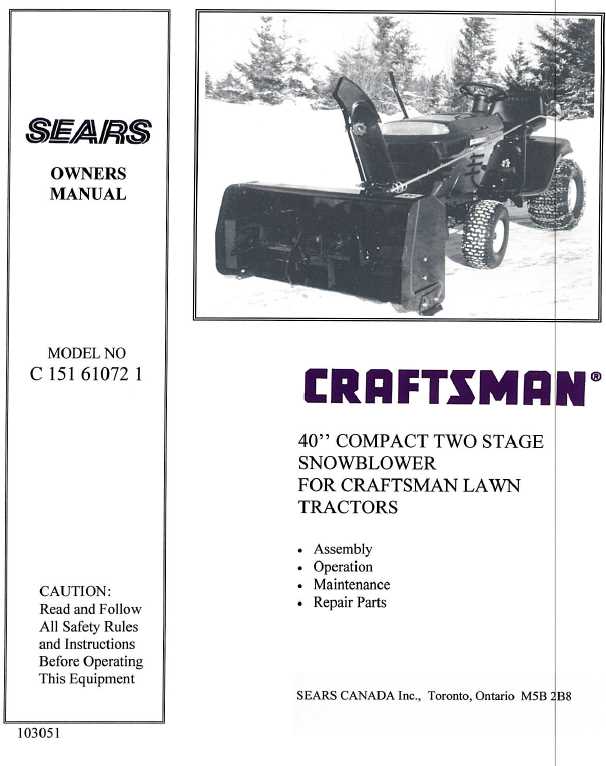

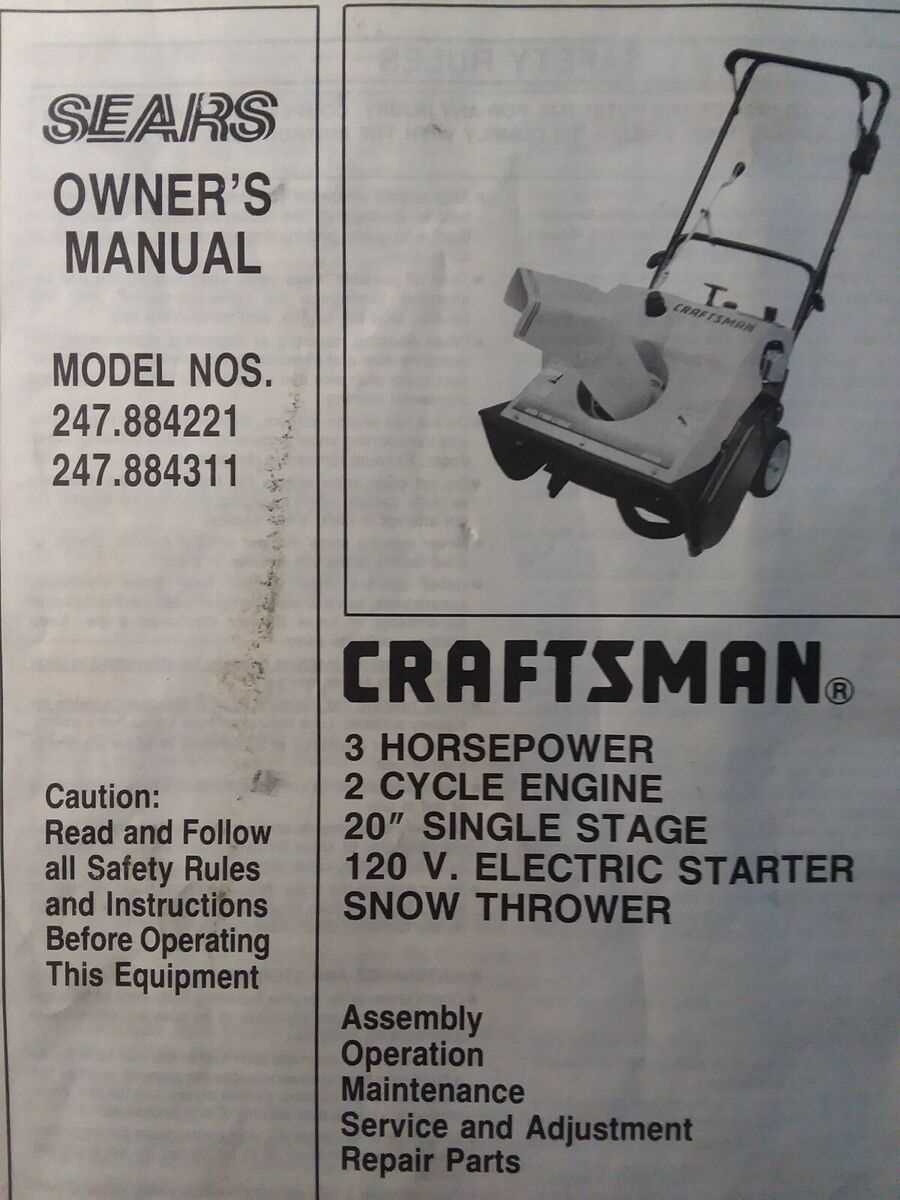

Understanding Your Craftsman Snowblower

When tackling winter’s challenges, familiarity with your machine is essential. Gaining insight into its components and functionalities can significantly enhance your experience and efficiency. This section aims to equip you with the knowledge necessary to navigate the intricacies of your device, ensuring optimal performance during snowy conditions.

Key Components: Each element of your apparatus plays a crucial role in its operation. From the engine to the auger, understanding how these parts interact will allow you to maximize their potential. Familiarize yourself with the throttle, chute, and controls to gain confidence in your usage.

Operational Features: Different models may offer unique functionalities, such as varying speeds and adjustment capabilities. Recognizing these features will enable you to tailor your approach to specific conditions, making the task of clearing snow more manageable.

Lastly, maintenance practices are vital for ensuring longevity. Regular checks and basic upkeep will not only extend the life of your machine but also enhance its reliability when you need it most. Embrace these insights to transform your winter experiences into effortless tasks.

Common Issues and Solutions

Maintaining optimal performance of your equipment can sometimes be challenging. Users often encounter specific problems that require attention and effective strategies to resolve. Understanding these common challenges and their corresponding fixes can significantly enhance the longevity and functionality of your machine.

Problem 1: Engine Won’t Start

This is a frequent issue that can stem from various causes. First, ensure that there is sufficient fuel and that it is fresh. If the fuel is old or contaminated, replace it. Additionally, check the spark plug for any signs of wear or damage; cleaning or replacing it can often solve the problem.

Problem 2: Uneven Snow Clearing

If your unit is not clearing snow evenly, inspect the blades for any damage or obstruction. Clearing any debris and sharpening the blades can improve performance. Also, check the height adjustment settings to ensure they are set correctly for the current snow conditions.

Problem 3: Excessive Vibrations

Vibrations during operation can indicate imbalances. Begin by examining the auger and impeller for any foreign objects. If everything appears clear, inspect the mounting bolts to ensure they are tight. Loose components can lead to increased vibration and potential damage over time.

Problem 4: Fuel Leaks

Leaks can pose safety risks and indicate a need for immediate attention. Inspect all fuel lines for cracks or damage, and replace any worn components. Tightening loose fittings can also help eliminate leaks.

Problem 5: Electrical Issues

If your equipment’s electric start is malfunctioning, begin by checking the battery connections for corrosion or looseness. Ensure the battery is charged and functioning correctly. If issues persist, the ignition system may require further investigation.

By addressing these common challenges promptly, you can ensure your equipment operates smoothly and efficiently throughout the winter season.

Essential Tools for Repairs

Having the right equipment is crucial when addressing issues with outdoor machinery. A well-equipped workspace allows for efficient troubleshooting and maintenance, ensuring longevity and optimal performance of your device.

Basic Equipment Needed

- Wrenches: Adjustable and socket types for various fasteners.

- Screwdrivers: Both flat-head and Phillips to tackle different screws.

- Pliers: Needle-nose and standard for gripping and bending tasks.

- Fuel Container: For safe storage and transport of necessary liquids.

- Work Gloves: To protect your hands while handling components.

Specialized Tools

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Compression Tester: Evaluates the engine’s performance.

- Multimeter: Assesses electrical systems for faults.

- Oil Filter Wrench: Simplifies the removal of filters.

- Diagnostic Software: Helps identify complex issues through advanced analysis.

Step-by-Step Maintenance Guide

Keeping your equipment in optimal condition is essential for ensuring efficient performance and longevity. This guide outlines a systematic approach to caring for your machinery, helping you prevent issues and maintain functionality.

-

Gather Necessary Tools and Supplies

- Wrenches

- Screwdrivers

- Oil

- Fuel

- Clean cloths

-

Inspect Fuel and Oil Levels

Check the fuel tank and ensure it is filled with the appropriate gasoline. Inspect the oil level, and if necessary, add high-quality oil as specified in the equipment guidelines.

-

Examine Belts and Cables

Look for signs of wear and tear on belts and cables. Replace any damaged components to ensure smooth operation.

-

Clean the Air Filter

Remove the air filter and clean it according to the manufacturer’s recommendations. A clean filter promotes better airflow and efficiency.

-

Check the Spark Plug

Inspect the spark plug for signs of wear or buildup. Clean or replace it as needed to maintain proper ignition.

-

Lubricate Moving Parts

Apply lubricant to all moving components, including wheels, levers, and joints, to ensure smooth operation and reduce friction.

-

Store Properly

When not in use, store the equipment in a dry, sheltered area to protect it from the elements. Consider using a cover for additional protection.

Following these steps regularly will enhance performance and extend the lifespan of your machinery, ensuring reliable service whenever you need it.

How to Change the Oil

Regular maintenance is essential for optimal performance and longevity of your outdoor equipment. One critical aspect of this upkeep is the replacement of the lubricant, which ensures smooth operation and reduces wear on internal components. Following a few straightforward steps can help you effectively carry out this task.

| Step | Action |

|---|---|

| 1 | Gather necessary tools: an oil catch pan, wrench, funnel, and fresh lubricant. |

| 2 | Ensure the unit is on a flat surface and has cooled down. |

| 3 | Locate the oil drain plug, usually situated at the base of the engine. |

| 4 | Remove the drain plug and allow the used lubricant to fully drain into the catch pan. |

| 5 | Replace the drain plug securely after draining. |

| 6 | Use the funnel to pour in the new lubricant through the fill hole. |

| 7 | Check the oil level using the dipstick and add more if necessary. |

| 8 | Dispose of the used oil responsibly, following local regulations. |

By routinely changing the lubricant, you ensure that your machine runs smoothly and efficiently, ultimately enhancing its performance and extending its lifespan.

Replacing the Spark Plug

Maintaining optimal performance in your equipment often involves simple yet crucial tasks. One of these is ensuring that the ignition component is in good condition. A worn-out or malfunctioning part can lead to starting issues or poor efficiency. This guide outlines the steps necessary for replacing this essential component to keep your machine running smoothly.

Tools and Materials Needed

- New spark plug

- Spark plug socket

- Ratchet wrench

- Torque wrench

- Dielectric grease

Steps to Replace the Ignition Component

- Ensure the equipment is turned off and cool.

- Remove the spark plug wire by gently pulling it off the terminal.

- Use the spark plug socket and ratchet wrench to unscrew the old part from the engine.

- Inspect the old component for wear and damage.

- Prepare the new spark plug by applying a small amount of dielectric grease to the threads.

- Screw the new component into the engine by hand, then tighten it with the torque wrench to the manufacturer’s specifications.

- Reconnect the spark plug wire securely.

By following these steps, you can ensure that your ignition system is functioning optimally, leading to improved performance and reliability.

Troubleshooting Starting Problems

When facing difficulties with ignition, it’s essential to methodically identify potential causes. A systematic approach can help in diagnosing the issue effectively and ensuring your equipment operates smoothly.

Common Causes

- Insufficient fuel levels

- Old or contaminated gasoline

- Faulty spark plug

- Clogged air filter

- Battery issues (if applicable)

Steps to Diagnose

- Check fuel levels and ensure they are adequate.

- Inspect the quality of gasoline; replace if stale or contaminated.

- Examine the spark plug for wear or damage and clean or replace as necessary.

- Ensure the air filter is clean and unobstructed.

- If equipped with a battery, confirm it is charged and in good condition.

By systematically assessing these elements, you can often pinpoint the reason for starting difficulties and take appropriate corrective actions.

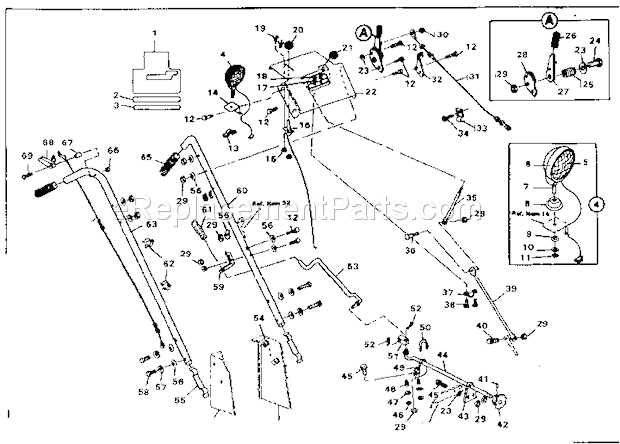

Adjusting the Auger Belt

Ensuring optimal performance of your machine often requires fine-tuning its components. One crucial aspect is the adjustment of the belt that drives the auger. Proper alignment and tension not only enhance functionality but also prolong the lifespan of the equipment.

To begin, disconnect the power source to guarantee safety during the process. Once secured, inspect the belt for any signs of wear or damage. If the belt appears in good condition, you can proceed with the adjustment.

Locate the tensioning mechanism, which is typically situated near the auger assembly. Loosen the mounting bolts slightly to allow for movement. Adjust the belt tension by either tightening or loosening the adjustment screw, depending on the current tension level. A well-tensioned belt should have a slight deflection when pressed but remain firm enough to engage without slipping.

After achieving the desired tension, re-tighten the bolts to secure the adjustment. Finally, conduct a test run to verify that the auger operates smoothly without any unusual noises or performance issues. Regular checks and adjustments can significantly enhance the efficiency of your equipment.

Winter Preparation Tips

As the cold season approaches, ensuring that your outdoor equipment is ready for the challenges ahead is essential. Proper preparation can make a significant difference in efficiency and performance during heavy snowfall. Here are some valuable suggestions to help you get your gear in optimal condition.

Inspect and Maintain Your Equipment

Before the first snowfall, take the time to thoroughly check your machinery. Look for any signs of wear and tear, and ensure that all components are functioning correctly. Change the oil and replace any worn belts to avoid unexpected breakdowns when you need your tools the most. Clean any debris and check fuel lines for leaks to ensure smooth operation.

Stock Up on Essential Supplies

Prepare for the winter by gathering necessary supplies. Keep an adequate amount of fuel on hand, as well as any additives that may enhance performance in low temperatures. Additionally, having a supply of shovels, ice melt, and sand will help you manage snow and ice around your property effectively.

Cleaning the Fuel System

Maintaining optimal performance of your equipment involves ensuring that the fuel delivery system is free from contaminants and obstructions. Regular cleaning of this system helps to enhance efficiency and prolong the lifespan of your machine.

Steps to Clean the Fuel System

Follow these essential steps to effectively clean the fuel system:

| Step | Description |

|---|---|

| 1 | Shut off the fuel supply and disconnect the spark plug for safety. |

| 2 | Drain the fuel tank completely to remove old fuel and debris. |

| 3 | Inspect and clean the fuel filter, replacing it if necessary. |

| 4 | Flush the fuel lines using a suitable solvent to remove any buildup. |

| 5 | Reconnect everything and refill with fresh fuel. |

Tips for Maintenance

To ensure longevity, use high-quality fuel and consider adding a fuel stabilizer. Regularly inspect the system for leaks and damage to maintain peak performance.

Diagnosing Electrical Issues

Identifying problems in electrical systems can be crucial for ensuring proper functionality and safety. Understanding the common symptoms and using systematic approaches can greatly enhance troubleshooting efficiency. This section will guide you through essential steps to diagnose issues effectively.

Start with Visual Inspections: Begin by checking for visible signs of damage. Look for frayed wires, burnt connections, or any corrosion that may impede performance. Pay attention to the condition of the connectors, as loose or damaged terminals can lead to inconsistent operation.

Use Multimeter Tools: A multimeter is invaluable for diagnosing electrical components. Measure voltage levels, continuity, and resistance to identify faulty parts. For instance, if a circuit is open, it may indicate a break in the wiring or a defective component.

Check the Power Source: Ensure that the power supply is functioning correctly. Inspect fuses and circuit breakers for any interruptions. Sometimes, the issue may originate from the outlet or extension cord, rather than the device itself.

Systematic Component Testing: Test individual components such as switches, motors, and igniters. Isolating each part can help pinpoint the source of the malfunction. If one component fails to operate as expected, it may be the culprit for the overall issue.

Refer to Schematics: Having access to wiring diagrams can aid in understanding the electrical layout. This reference can assist in tracing circuits and identifying potential problem areas more efficiently.

By methodically assessing the electrical aspects, you can determine the underlying issues and take appropriate actions to restore functionality.

Safe Operation Practices

Ensuring a secure and efficient experience while handling outdoor equipment is essential for both the operator and the surrounding environment. Following certain guidelines can significantly reduce the risk of accidents and enhance performance, allowing for a smoother operation.

Preparation and Awareness

Before starting any machinery, it is crucial to familiarize yourself with the equipment’s features and controls. Always inspect the device for any potential hazards, such as damaged components or foreign objects in the working area. Wearing appropriate protective gear, including gloves, goggles, and sturdy footwear, is highly recommended to minimize injuries.

Operational Techniques

When using the equipment, maintain a safe distance from others to prevent injuries. Avoid operating the machine in extreme weather conditions or on steep inclines. Regularly monitor the surroundings, and be prepared to stop the operation if any unexpected situations arise. Proper handling not only enhances safety but also contributes to the longevity of the device.

When to Seek Professional Help

Understanding when to engage an expert can significantly impact the longevity and performance of your outdoor equipment. While many tasks can be handled independently, certain situations require specialized knowledge and skills to ensure optimal functionality and safety.

Here are some key indicators that suggest professional assistance may be necessary:

| Indicator | Description |

|---|---|

| Unusual Noises | If your equipment is emitting strange sounds during operation, it may indicate an underlying issue that needs expert diagnosis. |

| Reduced Performance | A noticeable drop in efficiency or power suggests that professional evaluation is warranted to identify and address potential problems. |

| Frequent Breakdowns | If your machine is experiencing repeated malfunctions, it may be time to consult a technician to prevent further damage. |

| Complex Repairs | Tasks involving intricate systems or components typically require specialized skills and tools that a professional can provide. |

| Safety Concerns | Any signs of risk to your safety or the safety of others should prompt immediate professional intervention. |

By recognizing these signs, you can make informed decisions about when to call in an expert, ultimately preserving your equipment’s efficiency and extending its lifespan.