In the realm of all-terrain vehicles, understanding the intricacies of upkeep and troubleshooting is essential for enthusiasts and casual riders alike. This section serves as a vital resource, focusing on the various aspects of maintaining your machine to ensure optimal performance and longevity. With the right knowledge, you can tackle common issues and perform routine checks with confidence.

Regular attention to your vehicle can prevent minor inconveniences from escalating into significant problems. This guide provides insights into common procedures, essential tools, and helpful tips that empower you to take charge of your vehicle’s health. Whether you are dealing with engine issues or suspension adjustments, having a reliable reference can make all the difference.

By familiarizing yourself with the necessary steps and techniques, you can enhance your riding experience while saving time and money on professional services. This resource not only highlights standard practices but also addresses troubleshooting methods to resolve frequent complications efficiently. Equip yourself with the information you need to keep your ATV in peak condition and ready for any adventure.

Overview of Yamaha Grizzly 600

This section provides an insight into a versatile all-terrain vehicle known for its rugged performance and reliability. Designed to tackle a variety of terrains, this model has gained popularity among outdoor enthusiasts and workers alike. With a balance of power and agility, it is well-suited for both recreational and practical applications.

Key Features

- Robust engine providing ample power for various tasks

- Durable chassis designed for stability on rough surfaces

- Advanced suspension system enhancing comfort during rides

- Versatile storage options for tools and gear

- Reliable braking system ensuring safety on all terrains

Applications

- Recreational riding and exploration

- Utility work on farms or construction sites

- Outdoor sports and adventure activities

- Search and rescue missions in challenging environments

- Transportation of goods across difficult landscapes

Common Issues and Solutions

When operating an all-terrain vehicle, various challenges may arise that can hinder performance and enjoyment. Identifying these frequent problems and understanding their remedies is crucial for maintaining optimal functionality. Below are some common difficulties faced by riders, along with effective solutions to address them.

-

Starting Difficulties:

If the engine fails to start, consider the following solutions:

- Check the battery for charge and corrosion.

- Inspect the fuel level and ensure it is fresh.

- Examine the ignition switch for proper operation.

-

Overheating:

Overheating can lead to significant damage. To prevent this:

- Ensure the coolant level is adequate.

- Clean the radiator and check for blockages.

- Inspect the cooling fan for functionality.

-

Transmission Issues:

Shifting difficulties can disrupt riding experience. To resolve:

- Check the transmission fluid level and quality.

- Inspect the shift linkage for damage or misalignment.

- Ensure the clutch is properly adjusted.

-

Brake Problems:

If brakes feel spongy or unresponsive, consider:

- Inspect brake fluid levels and replace if low.

- Examine brake pads for wear and tear.

- Check brake lines for leaks or damage.

By addressing these common issues proactively, riders can enhance their experience and prolong the lifespan of their vehicle.

Importance of a Repair Manual

A comprehensive guide for vehicle maintenance and troubleshooting is essential for any owner. It serves as a valuable resource that facilitates understanding of various components, aiding in effective handling and care of the machine.

- Knowledge Empowerment: Owners gain insights into their vehicle’s structure, enabling informed decisions during maintenance.

- Cost Efficiency: A detailed guide helps in identifying issues early, potentially saving money on repairs and professional services.

- Safety Assurance: Proper understanding of operational procedures reduces the risk of accidents and enhances overall safety.

- Longevity of the Vehicle: Regular upkeep based on informed practices contributes to extended lifespan and improved performance.

- Self-Sufficiency: Owners can perform basic repairs and adjustments, fostering a sense of independence and confidence.

In summary, having access to a thorough instructional resource is crucial for maintaining the functionality and reliability of any vehicle. It not only empowers the owner but also ensures that the machine remains in optimal condition for years to come.

Tools Needed for Repairs

Effective maintenance of your all-terrain vehicle requires a well-equipped toolkit. Whether you’re conducting routine checks or addressing specific issues, having the right instruments at your disposal can significantly simplify the process. This section outlines essential tools that will enhance your repair experience and ensure that your vehicle remains in optimal condition.

Essential Hand Tools

Among the most important items in your toolkit are hand tools. These include wrenches, screwdrivers, and pliers, which are indispensable for various tasks. A comprehensive set of metric and standard sizes will allow you to tackle different components efficiently. Additionally, having a reliable torque wrench ensures that all fasteners are tightened to the manufacturer’s specifications, preventing potential damage.

Specialized Equipment

In addition to standard tools, certain specialized equipment can prove invaluable. A mechanic’s creeper can make working underneath the vehicle more comfortable, while a multimeter is essential for diagnosing electrical issues. Furthermore, a jack and jack stands are critical for safely lifting the vehicle during maintenance. Having these tools on hand will facilitate a thorough and effective service process.

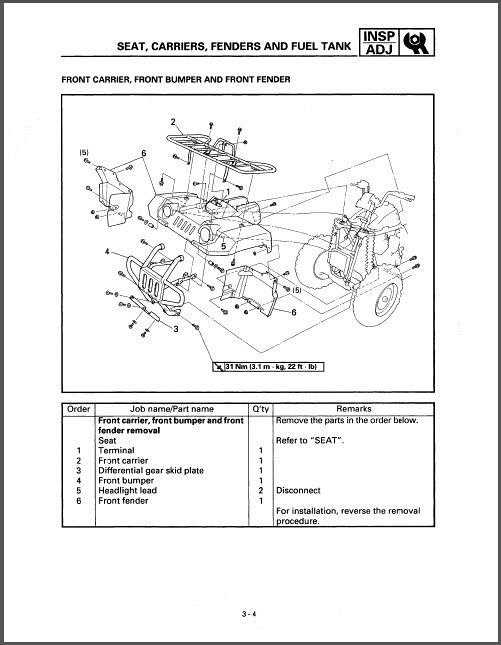

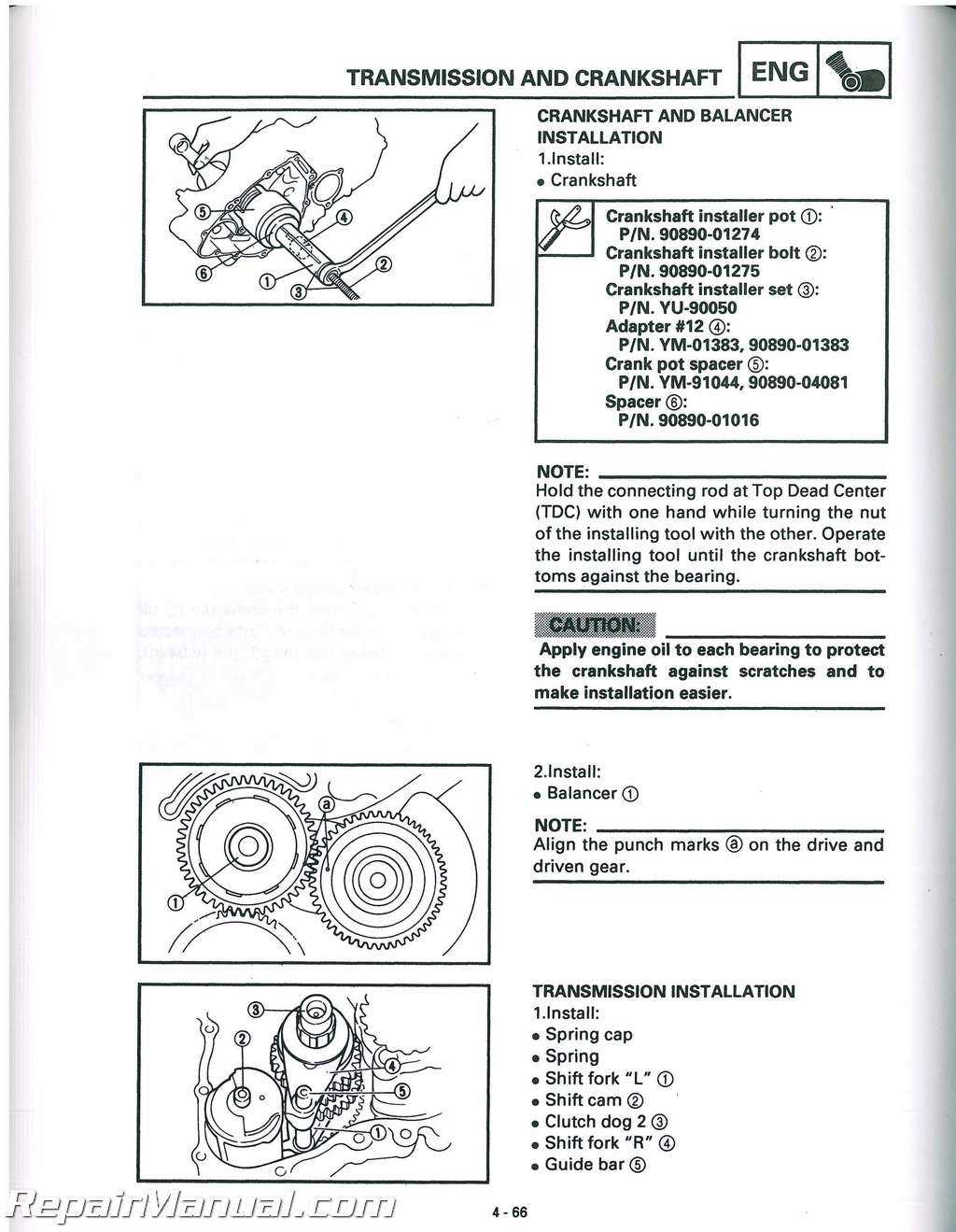

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing mechanical issues effectively. By following a structured method, one can systematically diagnose and rectify problems, ensuring that the vehicle returns to optimal functioning. Each stage of the procedure is crucial for achieving a thorough resolution.

Begin with a detailed assessment of the vehicle’s condition. Identify any visible signs of wear or damage, and take note of any unusual sounds or behaviors during operation. Documenting these observations will aid in diagnosing the underlying issues.

Next, gather all necessary tools and replacement components. Having everything on hand before starting the work streamlines the process and minimizes interruptions. Ensure that all tools are in good condition and appropriate for the tasks ahead.

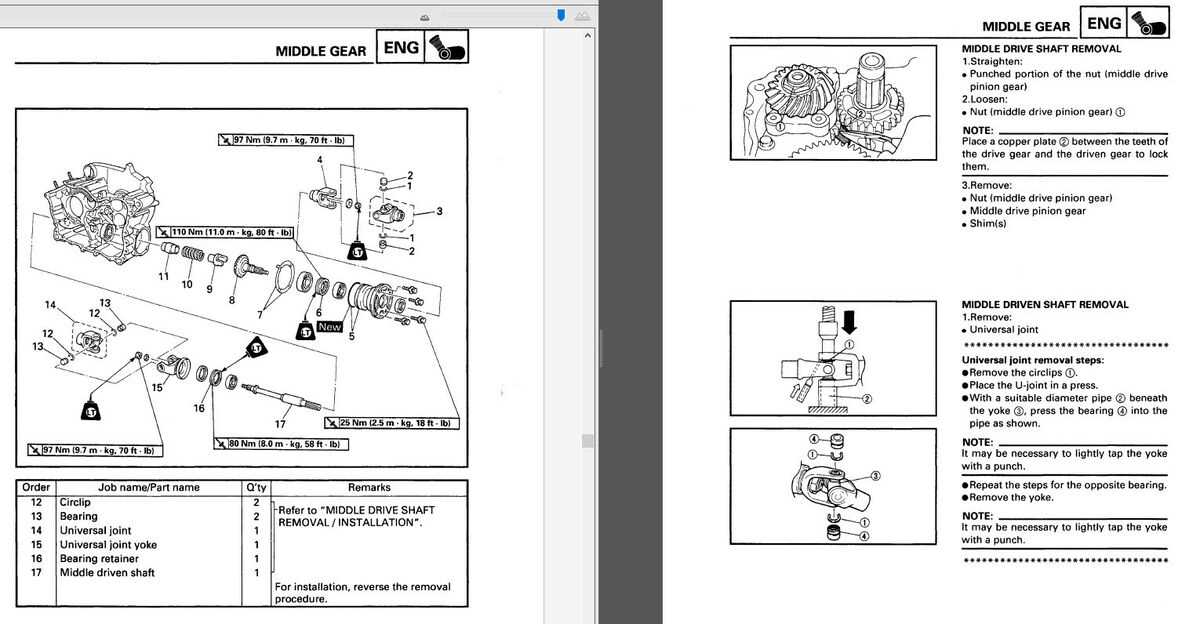

Once preparations are complete, proceed to disassemble the relevant parts carefully. Keep track of each component and fastener to ensure proper reassembly later. Use labeled containers or a magnetic tray to avoid losing small items during this stage.

After disassembly, conduct a thorough inspection of each part. Look for signs of wear, cracks, or corrosion that may require replacement. Compare damaged components with new ones to ensure compatibility before proceeding.

With the inspection complete, replace any faulty components and clean all parts meticulously. Proper cleaning prevents contaminants from causing further issues and extends the lifespan of the assembly.

Reassemble the vehicle, following the reverse order of disassembly. Ensure that all connections are secure and that any necessary adjustments are made for proper alignment and function.

Finally, conduct a test run to verify that all repairs have been successful. Monitor the vehicle for any lingering issues, and make additional adjustments as necessary to ensure peak performance. This systematic approach not only resolves the current issues but also enhances the overall reliability of the machine.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your all-terrain vehicle requires regular upkeep and attention to detail. Following some essential maintenance practices can significantly enhance performance and extend the lifespan of your machine.

- Regular Inspections: Periodically check all essential components, including the engine, brakes, and suspension. Look for signs of wear or damage that may need addressing.

- Fluid Changes: Change the oil and coolant as recommended by the manufacturer. Fresh fluids keep the engine running smoothly and prevent overheating.

- Air Filter Maintenance: Clean or replace the air filter regularly to ensure optimal airflow and prevent engine strain.

- Tire Care: Inspect tires for proper inflation and tread wear. Rotate them as necessary to promote even wear and better traction.

- Chain and Belt Care: Keep drive chains and belts clean and properly lubricated to prevent slippage and wear.

- Battery Maintenance: Check battery connections and ensure terminals are clean. Charge or replace the battery as needed to avoid starting issues.

- Storage Practices: When not in use, store your vehicle in a dry, covered area to protect it from the elements. Consider using a cover for additional protection.

By incorporating these practices into your routine, you can ensure that your vehicle remains reliable and ready for any adventure.

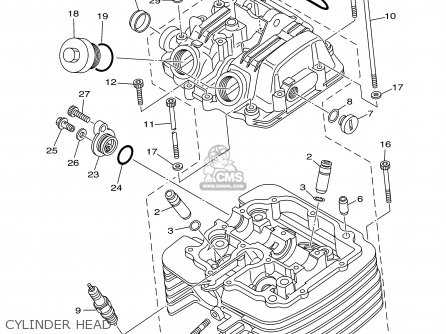

Understanding the Engine Components

Engines are complex machines composed of various elements that work together to convert fuel into motion. Each component plays a critical role in ensuring optimal performance, efficiency, and longevity. Understanding these parts is essential for anyone looking to maintain or troubleshoot their vehicle effectively.

Main Components

- Engine Block: The core structure that houses the cylinders and various internal components.

- Cylinders: Chambers where fuel and air mix and ignite to produce power.

- Pistons: Moving parts that transfer the force from combustion to mechanical motion.

- Crankshaft: Converts the linear motion of the pistons into rotational motion.

- Valvetrain: Manages the intake and exhaust of gases in and out of the cylinders.

Supporting Systems

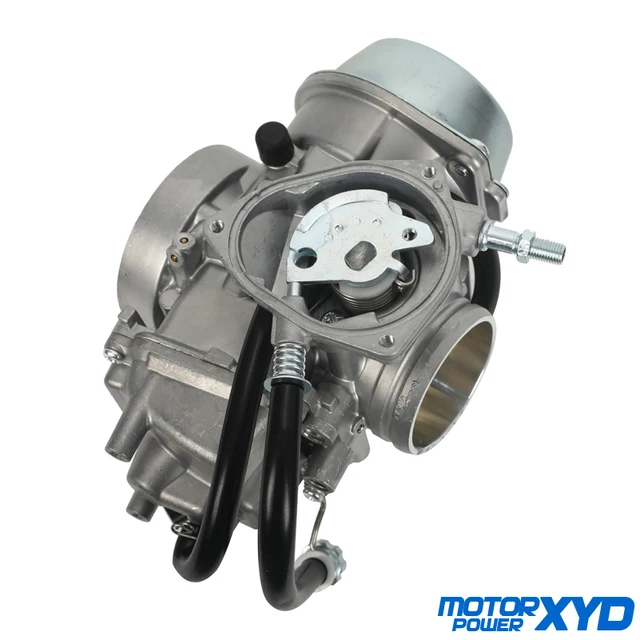

- Fuel System: Delivers fuel to the engine, often including a fuel pump, injectors, and filters.

- Cooling System: Regulates engine temperature to prevent overheating, utilizing a radiator and coolant.

- Lubrication System: Reduces friction between moving parts, ensuring smooth operation and minimizing wear.

- Electrical System: Powers the ignition and various sensors, playing a vital role in overall engine functionality.

By familiarizing oneself with these components and their functions, individuals can better appreciate the intricacies of engine operation and address any issues that may arise during usage.

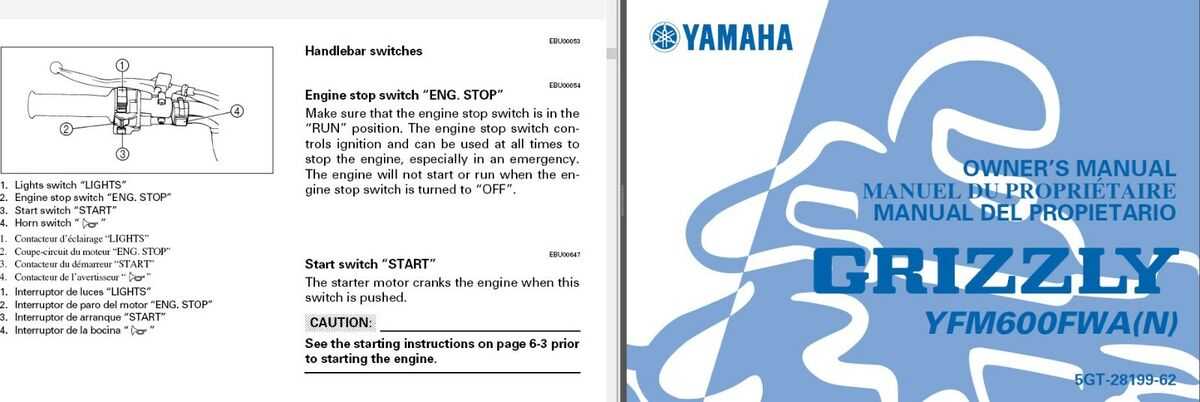

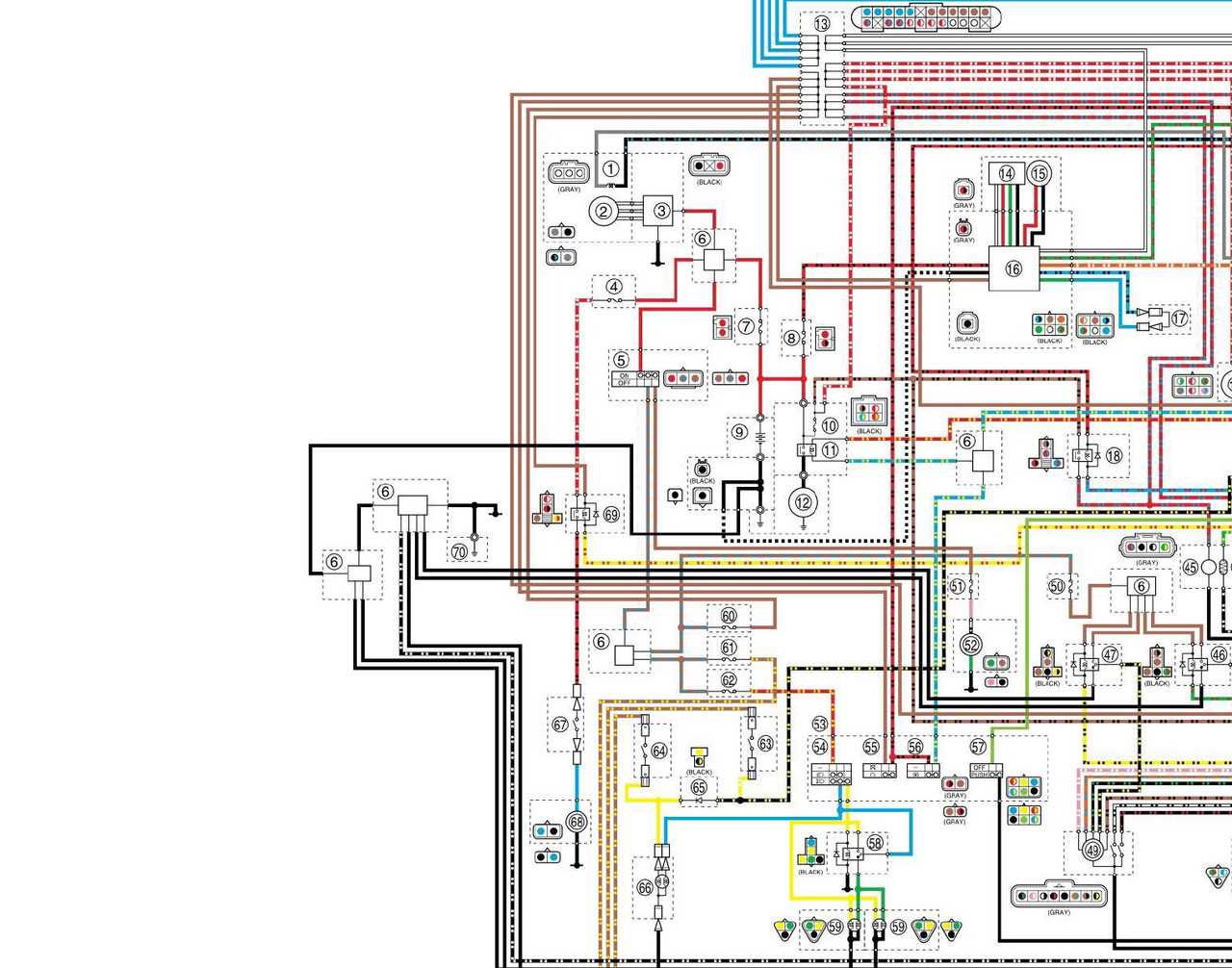

Troubleshooting Electrical Problems

Electrical issues can be one of the most challenging problems to diagnose in any vehicle. Understanding the fundamental components and their interactions is essential for effective troubleshooting. This section will guide you through identifying common symptoms and potential solutions to electrical malfunctions, ensuring a smoother experience with your machine.

Common Symptoms

When electrical systems fail, certain indicators often arise. These may include flickering lights, a non-starting engine, or unresponsive accessories. Each symptom points to a different underlying issue, whether it’s a faulty battery, a damaged wiring harness, or a malfunctioning switch. Observing these signs closely will help narrow down the problem.

Basic Diagnostic Steps

To effectively diagnose electrical issues, follow these basic steps:

- Check the battery voltage to ensure it is charged.

- Inspect all wiring connections for signs of corrosion or damage.

- Test fuses and relays to confirm they are functioning correctly.

- Utilize a multimeter to check for continuity in circuits.

By systematically following these steps, you can identify the root cause of the electrical issue and implement appropriate solutions.

Replacing Key Parts Effectively

When it comes to maintaining the longevity and performance of your vehicle, understanding how to effectively replace essential components is crucial. This process not only enhances functionality but also prevents potential issues that can arise from worn or damaged parts. By approaching replacements with the right techniques and tools, you can ensure a smoother operation and extend the life of your machine.

First, it’s important to identify the components that require attention. Regular inspections can reveal signs of wear, such as unusual noises, decreased efficiency, or visible damage. Once identified, sourcing high-quality replacements is paramount. Using original or reputable aftermarket parts guarantees compatibility and reliability.

Preparation is key before commencing the replacement. Gather all necessary tools and create a clean workspace to facilitate the process. Following a systematic approach, refer to a reliable resource that outlines the steps specific to the component being replaced. This ensures you do not overlook any critical stages and maintain safety throughout the procedure.

During the actual replacement, take your time to ensure that each step is executed properly. Double-check connections and secure fittings to prevent future issues. After installation, conducting a thorough test run is essential to confirm that everything operates as intended. This final step allows for early detection of any irregularities, providing an opportunity for immediate corrections.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is paramount. Proper precautions help prevent accidents and injuries, creating a secure environment for both the technician and the equipment. Familiarity with safety guidelines enhances overall effectiveness during the process.

Essential Safety Measures

- Always wear appropriate protective gear, including gloves and goggles.

- Ensure the workspace is well-lit and organized to avoid hazards.

- Disconnect the power source before starting any disassembly.

- Use tools that are in good condition and suited for the job.

Environmental Considerations

- Keep flammable materials away from the work area.

- Dispose of waste materials properly to prevent contamination.

- Be aware of your surroundings and potential hazards, such as slippery surfaces.

Where to Find Replacement Parts

Locating components for your vehicle can be a crucial aspect of maintenance and longevity. Whether you’re conducting routine upkeep or addressing specific issues, knowing where to source these parts is essential for ensuring optimal performance.

Online Resources

The internet is a valuable tool for finding parts quickly and efficiently. Consider exploring the following platforms:

- Official manufacturer websites: These often provide a comprehensive catalog of components.

- Online marketplaces: Websites like eBay and Amazon can have a variety of options from different sellers.

- Specialty parts retailers: Websites dedicated to specific types of vehicles frequently carry hard-to-find items.

Local Outlets

If you prefer to see components in person before purchasing, local options can be beneficial:

- Automotive supply stores: Many local shops stock a range of parts for various models.

- Salvage yards: These can be a treasure trove for used components at reduced prices.

- Dealerships: Authorized dealers usually carry OEM parts, ensuring compatibility and reliability.

By utilizing both online and local resources, you can effectively locate the necessary components to keep your vehicle running smoothly.