In the realm of off-road vehicles, understanding the intricacies of maintenance is crucial for longevity and performance. This section aims to provide essential insights into the upkeep and troubleshooting of a popular model that many enthusiasts cherish. By delving into the specifics of care and restoration, owners can ensure their machines remain in optimal condition.

Knowledge about the mechanics and best practices can significantly enhance the user experience. Whether addressing routine tasks or more complex issues, having access to structured guidance is invaluable. This resource not only simplifies the maintenance process but also empowers users to tackle challenges with confidence.

Through detailed descriptions and practical tips, this guide offers a pathway to mastering the essentials of vehicle care. As you embark on this journey, you will gain the tools necessary to enhance performance and extend the lifespan of your beloved ride.

Overview of Yamaha Timberwolf 250

This section provides insights into a renowned all-terrain vehicle designed for both leisure and utility. With a blend of robust engineering and versatile features, this model has established itself as a favorite among enthusiasts and practical users alike.

Key Features

Highlighting the essential characteristics, this vehicle is equipped with a powerful engine, ensuring reliable performance across diverse terrains. The ergonomic design enhances comfort during extended use, making it suitable for various applications.

Specifications

| Feature | Details |

|---|---|

| Engine Type | Four-stroke, single-cylinder |

| Displacement | Various options available |

| Transmission | Automatic |

| Brakes | Front and rear disc brakes |

| Weight | Lightweight for easy handling |

Common Issues with Timberwolf 250

Many users encounter various challenges with their all-terrain vehicles over time. Understanding these common problems can help in troubleshooting and maintaining optimal performance.

- Engine Performance: Issues such as poor starting, stalling, or reduced power can arise from fuel system blockages or ignition malfunctions.

- Transmission Difficulties: Users may experience shifting problems, which can often be traced back to worn gears or inadequate lubrication.

- Electrical Failures: Problems with the battery, wiring, or electrical components can lead to starting issues or malfunctioning lights.

- Suspension Concerns: Excessive wear on shocks or springs can result in a rough ride and poor handling.

- Braking System: Reduced stopping power or strange noises during braking often indicate worn brake pads or issues with the hydraulic system.

Regular maintenance and inspections can mitigate many of these issues, ensuring a smoother and more reliable experience.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended life and optimal performance of your vehicle. By following a few simple yet effective practices, you can enhance reliability and reduce the likelihood of unexpected issues.

Routine Inspections

Performing frequent checks on various components can help identify potential problems early. This proactive approach can save time and money in the long run. Key areas to inspect include:

| Component | Inspection Frequency | Notes |

|---|---|---|

| Fluids | Every 500 miles | Check levels and quality; top up or replace as needed. |

| Air Filter | Every 1,000 miles | Clean or replace to ensure proper airflow. |

| Tires | Monthly | Inspect for wear and maintain proper pressure. |

Proper Storage

Storing your vehicle correctly can significantly impact its longevity. Always choose a dry, cool place and consider using a protective cover to shield it from dust and moisture. Additionally, ensure that it is parked on a stable surface to avoid unnecessary strain on the suspension components.

Tools Required for Basic Repairs

When it comes to performing essential maintenance on your vehicle, having the right instruments is crucial. A well-equipped toolkit can simplify tasks, enhance efficiency, and ensure safety during the process. This section outlines the fundamental tools needed to carry out basic upkeep effectively.

Essential Hand Tools

Basic hand tools are indispensable for any maintenance task. Here are some key items to include in your collection:

| Tool | Purpose |

|---|---|

| Wrenches | Used for tightening and loosening bolts and nuts. |

| Screwdrivers | Ideal for driving screws of various types and sizes. |

| Pliers | Helpful for gripping, twisting, and cutting wires. |

| Socket Set | Facilitates easy removal and installation of fasteners. |

Additional Equipment

In addition to hand tools, some specialized equipment can be beneficial for specific tasks. Consider adding the following items to your toolkit:

| Equipment | Function |

|---|---|

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

| Multimeter | Useful for diagnosing electrical issues. |

| Oil Filter Wrench | Makes changing the oil filter easier and cleaner. |

| Jack and Stands | Essential for safely lifting the vehicle for maintenance. |

Step-by-Step Engine Diagnostics

Effective engine diagnostics is essential for identifying and resolving issues that may affect performance. This process involves a systematic approach to evaluating the internal components and overall functionality of the power unit.

Start by gathering the necessary tools, including a multimeter, compression gauge, and basic hand tools. Ensure the vehicle is on a stable surface and the engine is cool before proceeding.

Begin with a visual inspection, checking for any obvious signs of damage or leaks. Examine the wiring harness and connections for wear or corrosion. Next, conduct a compression test to evaluate the engine’s ability to maintain pressure, which is critical for optimal operation.

Following the compression assessment, inspect the fuel system. Verify that fuel is reaching the engine properly by checking the fuel lines and filter for clogs or restrictions. Additionally, ensure the fuel pump is functioning effectively.

Next, assess the ignition system. Test the spark plugs and ignition coils for proper operation. Replace any faulty components to ensure reliable starting and performance. Afterward, review the air intake system for obstructions that could hinder airflow.

Finally, utilize diagnostic tools to read any error codes from the engine control unit. This data can provide valuable insights into potential malfunctions. By following these steps, you can effectively diagnose and address issues, ensuring smooth and efficient engine performance.

Electrical System Troubleshooting Guide

This section aims to provide a comprehensive approach to diagnosing issues within the electrical framework of your vehicle. Understanding the common symptoms and their potential causes can significantly aid in resolving problems efficiently.

Common Symptoms

- Dim or flickering lights

- Unresponsive ignition system

- Electrical components not functioning properly

- Frequent blown fuses

Diagnostic Steps

- Visual Inspection:

- Check for damaged wiring or connections.

- Inspect fuses for any signs of burning or breakage.

- Battery Check:

- Measure voltage using a multimeter.

- Ensure terminals are clean and securely connected.

- Component Testing:

- Test each electrical component for functionality.

- Replace any faulty parts as necessary.

- Wiring Continuity:

- Use a multimeter to check for continuity in the wiring.

- Identify any breaks or shorts in the circuit.

Following these steps can help isolate and resolve issues effectively, ensuring optimal performance of the electrical system.

Transmission Inspection Procedures

This section outlines essential practices for evaluating the functionality and condition of the gear shifting mechanism in all-terrain vehicles. Regular assessment is crucial to ensure optimal performance and longevity.

Visual Examination

Begin by conducting a thorough visual check of the transmission components. Look for signs of wear, damage, or corrosion. Key areas to inspect include:

- Seals and gaskets for leaks

- Gear teeth for chipping or excessive wear

- Housing for cracks or deformities

Operational Testing

Next, perform operational tests to evaluate shifting performance. This includes:

- Engaging gears while stationary to ensure smooth operation.

- Testing under load to assess responsiveness and accuracy.

- Listening for unusual noises during operation that may indicate internal issues.

Document all findings for further analysis and necessary adjustments. Consistent inspections will enhance vehicle reliability and performance.

Handling Fuel System Problems

Addressing issues within the fuel delivery framework is essential for optimal performance and reliability of any off-road vehicle. A well-functioning fuel system ensures that the engine receives the correct mixture of air and fuel, which is crucial for efficient operation. Problems can arise from various components, including the fuel pump, filters, and injectors, each requiring careful inspection and troubleshooting.

Common Symptoms of Fuel System Issues

Owners may notice several signs indicating a malfunctioning fuel system. These can include difficulty starting the engine, reduced power during acceleration, or irregular engine performance. Additionally, a vehicle may produce unusual noises or exhibit fuel leaks. Recognizing these symptoms early can prevent more significant damage and costly repairs.

Troubleshooting Steps

To diagnose fuel-related problems, begin by inspecting the fuel supply. Check for blockages in the filters and ensure the fuel pump is operational. Utilize a pressure gauge to verify that the system maintains appropriate pressure levels. If necessary, examine the fuel injectors for clogs or leaks. Regular maintenance of the fuel system is key to preventing these issues from arising in the first place.

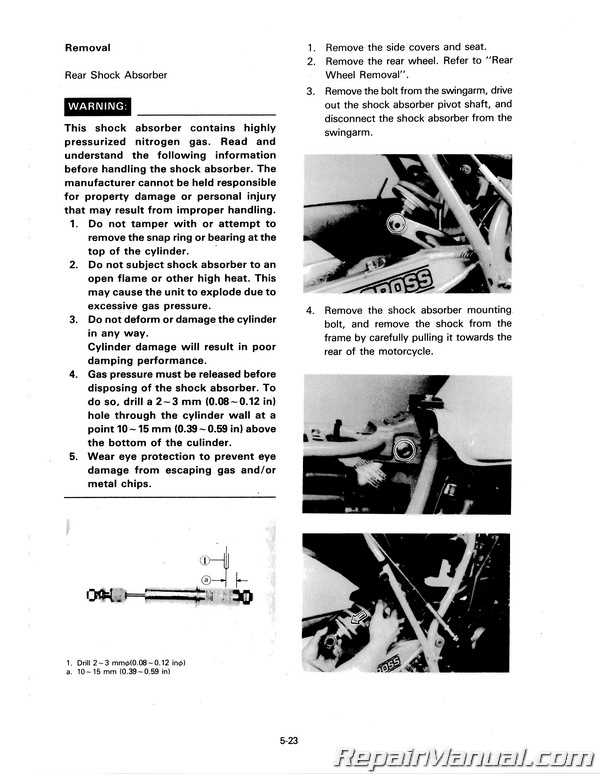

Suspension and Brake Adjustments

Maintaining optimal performance in any vehicle requires regular attention to its suspension and braking systems. Proper adjustments not only enhance ride comfort but also ensure safety during operation. Understanding the nuances of these systems is essential for effective maintenance and improvement of overall handling.

Suspension components play a critical role in absorbing shocks and providing stability. Regular inspection of the springs, shocks, and linkage is crucial. Adjustments may involve changing the preload settings or replacing worn parts to restore functionality. Keeping these elements in top condition allows for a smoother ride and better control over varied terrains.

Equally important are the braking systems, which require periodic checks to ensure they respond effectively. This includes inspecting brake pads, fluid levels, and lines for any signs of wear or leaks. Adjustments can often involve aligning calipers or replacing pads to enhance stopping power and responsiveness, contributing to a safer driving experience.

By focusing on both suspension and braking adjustments, owners can significantly improve the performance and longevity of their vehicles. Regular maintenance and timely adjustments will lead to a more enjoyable and safer ride.

Parts Replacement and Upgrades

Maintaining and enhancing the performance of your vehicle often involves replacing components and considering upgrades. Understanding which parts can be swapped out or improved is essential for ensuring optimal functionality and longevity.

Regularly inspecting critical components can help identify worn or damaged parts that may need attention. Upgrading certain elements not only improves performance but can also enhance safety and efficiency. Below is a summary of common replacements and potential upgrades:

| Component | Replacement Options | Upgrade Suggestions |

|---|---|---|

| Engine Oil | Regular oil change with recommended grade | High-performance synthetic oil |

| Brake Pads | Standard friction material | Performance-grade pads for better stopping power |

| Air Filter | OEM replacement filter | High-flow aftermarket filter for improved airflow |

| Battery | Standard lead-acid battery | Lithium-ion battery for weight reduction and efficiency |

By proactively addressing replacements and considering upgrades, you can significantly enhance the overall experience and reliability of your vehicle.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is essential for preventing accidents and injuries. A well-prepared environment and adherence to specific guidelines can significantly enhance the safety of the process.

Essential Guidelines

Before commencing any work, familiarize yourself with the tools and components involved. Proper knowledge helps in anticipating potential hazards and allows for informed decision-making.

Protective Equipment

Using appropriate protective gear is crucial. Items such as gloves, goggles, and sturdy footwear can mitigate risks associated with various tasks. Always ensure that your workspace is organized and free of unnecessary clutter.

| Type of Equipment | Purpose |

|---|---|

| Gloves | Protect hands from sharp edges and chemicals |

| Goggles | Shield eyes from debris and splashes |

| Steel-Toed Boots | Provide foot protection against heavy objects |

| Ear Protection | Minimize noise exposure during loud tasks |