Maintaining high-performance two-wheeled machines is essential for ensuring their longevity and optimal functionality. This section provides invaluable insights into the various aspects of upkeep that every enthusiast should be familiar with. From understanding engine components to addressing common mechanical issues, a well-rounded approach to maintenance can significantly enhance the riding experience.

Regular inspections and timely interventions can prevent minor problems from escalating into costly repairs. Whether you are a seasoned rider or a newcomer to the world of off-road biking, having a reliable source of information is crucial. This guide aims to equip you with the knowledge necessary to keep your vehicle in peak condition.

Additionally, this resource emphasizes the importance of following manufacturer guidelines and utilizing the right tools for specific tasks. With a focus on practical solutions and best practices, you will find step-by-step instructions designed to facilitate effective maintenance and troubleshooting. Embrace the journey of bike care, and enjoy the thrill of riding with confidence.

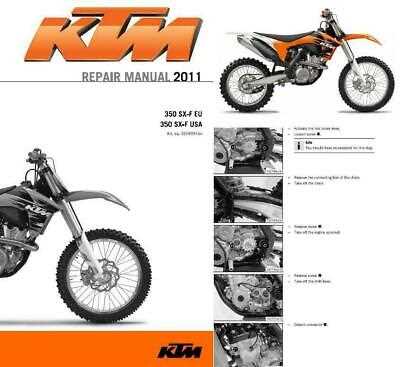

KTM 350 SX-F Repair Manual Overview

This section provides a comprehensive overview of essential information and guidance necessary for maintaining and servicing a specific off-road motorcycle model. The goal is to equip owners and enthusiasts with the tools and knowledge to ensure optimal performance and longevity of their vehicle. By following detailed procedures and instructions, users can perform various tasks effectively, from routine checks to more complex repairs.

Key Components Covered

The documentation outlines various critical components and systems that require attention during maintenance. This includes engine diagnostics, suspension tuning, brake adjustments, and electrical system checks. Understanding these elements is vital for any rider aiming to keep their motorcycle in peak condition.

Maintenance Schedule

Regular upkeep is crucial for performance. A well-structured timeline helps ensure that every part is addressed at the appropriate intervals, minimizing wear and potential failures.

| Service Type | Frequency |

|---|---|

| Oil Change | Every 15 hours |

| Filter Replacement | Every 30 hours |

| Chain Adjustment | Every ride |

| Brake Inspection | Every 20 hours |

By adhering to this schedule and understanding the intricacies of their machine, riders can enhance both safety and enjoyment while navigating various terrains.

Essential Tools for Maintenance

Proper upkeep of your motorcycle requires a selection of key implements that ensure efficient performance and longevity. Having the right tools not only simplifies the maintenance process but also enhances safety and reliability on the road. Below are some of the fundamental tools you should consider for effective maintenance tasks.

Basic Tool Kit

A well-rounded tool kit is the foundation of any maintenance effort. Here are some essential items:

| Tool | Purpose |

|---|---|

| Socket Set | For tightening and loosening bolts and nuts |

| Wrenches | Used for various sizes of fasteners |

| Phillips and Flathead Screwdrivers | To adjust and secure different components |

| Torque Wrench | Ensures correct tightness of bolts |

Specialized Maintenance Tools

In addition to the basic toolkit, certain specialized tools are invaluable for specific maintenance tasks:

| Tool | Purpose |

|---|---|

| Chain Breaker | For adjusting or replacing the chain |

| Brake Bleeder Kit | To maintain proper brake fluid levels |

| Compression Gauge | For checking engine compression |

| Oil Filter Wrench | Facilitates easy removal of the oil filter |

Step-by-Step Engine Repair Guide

This section provides a comprehensive approach to overhauling a high-performance engine. Each step is designed to ensure that enthusiasts can methodically address issues, improve performance, and enhance longevity. By following this guide, individuals will gain a clearer understanding of their engine’s intricacies and maintenance needs.

Preparation and Disassembly

Before diving into the process, gather all necessary tools and components. Ensure a clean workspace to facilitate the disassembly. Begin by draining fluids, disconnecting the battery, and removing the outer casing. Carefully document each step with notes or photographs to ease reassembly. Labeling parts during disassembly is crucial for maintaining organization.

Inspection and Component Replacement

Once the engine is fully accessible, conduct a thorough inspection of all components. Look for signs of wear, damage, or carbon buildup. Replace any faulty parts, such as gaskets, pistons, or valves, using high-quality replacements. Attention to detail during this phase can prevent future complications and ensure optimal performance. Reassemble the engine in the reverse order of disassembly, double-checking torque specifications and seal integrity.

Suspension Adjustment Techniques

Proper suspension setup is crucial for optimal performance and comfort on various terrains. Fine-tuning these systems can significantly enhance handling and stability, allowing riders to maximize their capabilities. Here, we will explore essential techniques to adjust suspension components effectively.

Key aspects to consider when adjusting suspension include:

- Preload Adjustment: This determines the initial tension on the springs. Adjusting preload can affect ride height and overall handling.

- Compression Damping: This controls how quickly the suspension compresses when encountering bumps. Proper settings can help absorb shocks without bottoming out.

- Rebound Damping: This affects how quickly the suspension returns to its original position after compression. Balancing rebound is essential to maintain tire contact with the ground.

To effectively adjust your suspension, follow these steps:

- Determine Rider Weight: Knowing your weight helps set the appropriate preload for optimal sag.

- Check Sag Measurement: Measure the distance from the axle to a fixed point on the rear fender with the bike loaded and unloaded. This helps ensure the bike is set up for your weight.

- Adjust Compression Settings: Start with the manufacturer’s recommended settings and make gradual changes to find the optimal feel.

- Tweak Rebound Settings: Adjust the rebound to ensure a smooth return after compression, preventing bouncy or sluggish behavior.

- Test Ride: After adjustments, take a test ride to evaluate handling and comfort. Make further tweaks as necessary.

By understanding and implementing these techniques, riders can achieve a suspension setup that suits their riding style and conditions, leading to improved performance and confidence on the trail.

Common Electrical Issues and Solutions

Electrical problems can often be a source of frustration for riders, affecting performance and overall enjoyment. Identifying these issues early and understanding potential fixes can make a significant difference in maintaining the functionality of your machine. This section covers common electrical malfunctions and their corresponding solutions, providing a helpful guide for troubleshooting.

1. Battery Not Holding Charge

A frequent concern is when the battery fails to retain its charge, leading to starting difficulties. This can stem from several causes, including a defective battery, poor connections, or a malfunctioning charging system. To resolve this, start by checking all connections for corrosion or looseness. If connections are secure, test the battery with a multimeter. If the voltage is below the recommended level, consider replacing the battery or examining the charging components for faults.

2. Faulty Wiring or Short Circuits

Brake System Maintenance Tips

Proper upkeep of the braking system is essential for ensuring safety and optimal performance. Regular attention to this component can significantly enhance the longevity of your vehicle and provide a more reliable riding experience. Here are some key practices to keep your brake system in excellent condition.

Routine Inspection

Frequent checks can help identify potential issues before they become serious problems. Consider the following:

- Inspect brake pads for wear and tear. Replace them if they are thinner than recommended.

- Examine brake discs for any signs of scoring or warping.

- Check brake fluid levels and top off as necessary.

- Look for leaks in the brake lines and ensure all connections are secure.

Cleaning and Lubrication

Maintaining cleanliness and proper lubrication is vital for effective braking performance. Follow these steps:

- Clean brake components regularly to remove dirt and debris.

- Use appropriate brake cleaner to avoid damaging sensitive parts.

- Apply lubricant to moving parts, such as calipers and pistons, to prevent seizing.

By adhering to these maintenance tips, you can ensure that your braking system remains responsive and effective, contributing to a safer riding experience.

How to Change the Oil

Maintaining optimal performance in your machine requires regular oil changes. This essential task not only ensures the longevity of the engine but also enhances efficiency. In this section, you will learn the step-by-step process to effectively replace the lubricant, keeping your vehicle running smoothly.

Start by gathering the necessary tools and materials: a suitable oil container, an oil filter wrench, a funnel, and the correct type of oil for your engine. Make sure the engine is warm but not hot to the touch; this helps the oil drain more easily.

Position your vehicle on a level surface and secure it with a stand. Locate the oil drain plug underneath the engine, placing your oil container beneath it. Carefully remove the plug and allow the old oil to completely drain out. Once finished, replace the drain plug securely.

Next, locate the oil filter. Using the filter wrench, remove the old filter and prepare the new one by applying a thin layer of fresh oil to its gasket. Install the new filter by hand, ensuring it’s snug but not over-tightened.

Now, it’s time to add fresh oil. Using the funnel, pour the new lubricant into the designated fill cap. Check the owner’s guide for the correct amount needed. After filling, start the engine and let it run for a few minutes to circulate the oil. Finally, turn off the engine and check the oil level with the dipstick, adding more if necessary.

Dispose of the old oil and filter responsibly by taking them to a recycling center. Regularly changing the oil is crucial for maintaining the health and performance of your machine, so keep track of when the next change is due!

Air Filter Cleaning Process

Maintaining optimal performance of your off-road motorcycle requires regular attention to the air filtration system. A clean air filter is crucial for ensuring that the engine receives the right amount of clean air, which directly impacts power output and efficiency. The following steps outline the cleaning procedure for the air filter, ensuring longevity and reliability.

| Step | Description |

|---|---|

| 1 | Remove the air filter from the intake system, ensuring to follow the manufacturer’s guidelines to avoid any damage. |

| 2 | Inspect the filter for any visible damage or excessive wear. If necessary, consider replacing it. |

| 3 | Use a soft brush or compressed air to remove loose dirt and debris from the filter surface. |

| 4 | Soak the filter in a specialized cleaning solution designed for air filters, allowing it to dissolve contaminants effectively. |

| 5 | Rinse the filter gently with clean water to remove the cleaning solution, taking care not to damage the filter material. |

| 6 | Allow the filter to air dry completely before reinstallation to prevent moisture from entering the engine. |

| 7 | Once dry, apply an appropriate oil specifically formulated for air filters to enhance filtration efficiency. |

| 8 | Reinstall the filter back into the intake system, ensuring it is seated correctly for optimal performance. |

By following these steps, you can ensure that your air filtration system remains effective, contributing to the overall performance and longevity of your motorcycle. Regular maintenance will also help to prevent potential engine issues caused by poor airflow.

Importance of Regular Inspections

Conducting routine examinations of your vehicle is crucial for maintaining optimal performance and safety. These assessments help identify potential issues before they escalate into significant problems, ultimately prolonging the lifespan of the machine.

Proactive maintenance is key. By regularly checking various components, such as the engine, suspension, and braking system, you can ensure that everything functions correctly. This vigilance not only enhances the reliability of your vehicle but also provides peace of mind when riding.

Moreover, routine inspections can lead to cost savings in the long run. Early detection of wear and tear allows for timely repairs, which are often less expensive than extensive fixes required after a breakdown. Investing time in these checks fosters a safer riding experience and minimizes the risk of accidents caused by mechanical failures.

Lastly, keeping a detailed record of inspections can be beneficial for both personal tracking and potential resale value. Prospective buyers often prefer vehicles with a documented maintenance history, making regular examinations an integral part of responsible ownership.

Transmission Troubleshooting Guide

Ensuring smooth operation of your vehicle’s gearbox is crucial for optimal performance. This section provides guidance on identifying and resolving common issues that may arise within the transmission system. By following systematic troubleshooting steps, you can diagnose problems effectively and maintain the longevity of your machine.

Common Symptoms and Their Causes

There are several signs indicating that something may be amiss with your transmission. These include unusual noises, difficulty shifting gears, and unexpected slipping. Each symptom can stem from various underlying issues, such as low fluid levels, worn components, or misaligned parts. Paying close attention to these indicators can help you pinpoint the source of the problem.

Troubleshooting Steps

To effectively address transmission problems, follow these steps:

- Check Fluid Levels: Ensure that the fluid is at the appropriate level and free from contaminants.

- Inspect for Leaks: Look for any signs of fluid leakage around seals and connections.

- Test the Clutch: If applicable, check the clutch for proper engagement and adjustment.

- Listen for Noises: Pay attention to any grinding or whining sounds that could indicate wear.

- Seek Professional Help: If problems persist, consider consulting a specialist for a thorough examination.

By following these guidelines, you can effectively troubleshoot and address transmission issues, ensuring your vehicle remains reliable and performs at its best.

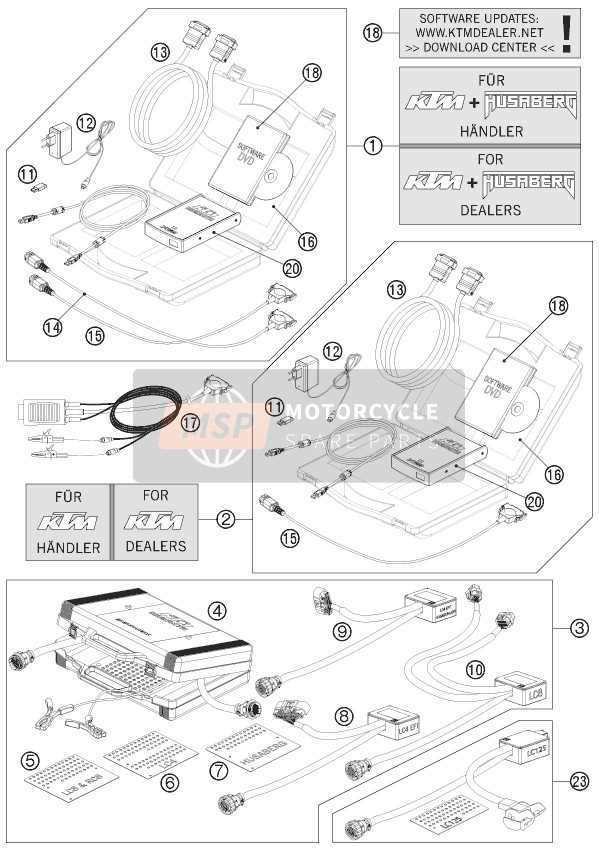

Wiring Diagrams and Schematics

This section provides essential visual representations that detail the electrical layout and connections within the vehicle. Understanding these diagrams is crucial for troubleshooting and maintaining the electrical system effectively. They serve as a guide to navigate through various components, ensuring that each connection is properly established for optimal performance.

Wiring diagrams illustrate the paths through which electrical current flows, while schematics focus on the functional aspects of the system. Both types of illustrations are invaluable for diagnosing issues, facilitating repairs, and performing modifications.

| Component | Description | Connection Type |

|---|---|---|

| Battery | Power source for the electrical system | Direct connection |

| Ignition Switch | Controls the power to the electrical system | Switching circuit |

| ECU | Electronic control unit managing various functions | Signal connections |

| Sensors | Gather data for optimal performance | Input connections |

| Lights | Provide visibility and signaling | Output connections |

Referencing these diagrams allows for a systematic approach to resolving electrical faults, making it easier to identify potential issues and implement effective solutions.

Upgrading Components for Performance

Enhancing the efficiency and capabilities of a motorcycle involves careful selection and modification of its components. Upgrades can significantly improve acceleration, handling, and overall ride quality, enabling riders to achieve better performance on various terrains.

Key Areas for Improvement

- Suspension: Upgrading the suspension system can provide improved stability and comfort. Consider options such as adjustable forks and high-performance shock absorbers.

- Exhaust System: A new exhaust system can enhance power output and improve throttle response. Look for lightweight materials and designs that optimize airflow.

- Air Intake: Upgrading the air intake system allows for better airflow to the engine, which can boost horsepower. High-performance filters and intake kits are popular choices.

- ECU Tuning: Customizing the engine control unit can optimize fuel mapping and ignition timing for enhanced performance.

Choosing the Right Components

- Research reputable brands known for quality and performance.

- Consult with experienced mechanics or riders for recommendations.

- Consider compatibility with existing components to ensure seamless integration.

- Assess your riding style and goals to choose upgrades that align with your needs.

By focusing on these areas, riders can achieve a noticeable improvement in their machine’s performance, ultimately enhancing the overall riding experience.

Safety Precautions During Repairs

When working on motorized vehicles, ensuring safety is paramount. Proper precautions can prevent accidents and injuries, creating a secure environment for both the mechanic and the machine. Adhering to guidelines and using appropriate protective gear can make the repair process not only efficient but also safe.

Essential Protective Gear

Before beginning any maintenance task, it is crucial to equip yourself with the right protective equipment. This includes gloves to shield your hands from sharp objects and chemicals, goggles to protect your eyes from debris, and sturdy footwear to prevent injuries from falling parts. Additionally, wearing long sleeves and pants can help protect your skin from cuts and burns.

Work Environment Considerations

Creating a safe workspace is just as important as personal protection. Ensure the area is well-lit and free from clutter to minimize tripping hazards. Use a stable workbench to secure the vehicle, and always have a fire extinguisher nearby when working with flammable materials. Following these practices will contribute significantly to a safer and more productive repair experience.