Proper upkeep of marine propulsion systems is crucial for ensuring longevity and optimal performance. Understanding the intricacies of your watercraft’s engine can greatly enhance your boating experience and minimize the risk of unexpected issues. This section delves into comprehensive resources designed to aid enthusiasts in navigating the complexities of maintenance and troubleshooting.

Mastering the Art of Upkeep involves familiarizing yourself with the essential components and mechanisms that power your vessel. From routine inspections to intricate repairs, a solid grasp of these elements can empower boat owners to tackle challenges with confidence. With the right information, even novice operators can become adept at handling common difficulties that arise during regular use.

In this guide, you’ll find valuable insights and instructions aimed at simplifying the process of engine care. Whether you’re dealing with performance concerns or simply wish to enhance your understanding of engine functionality, having access to detailed, organized information can make all the difference. Prepare to dive into the world of propulsion systems, armed with the knowledge necessary for effective maintenance.

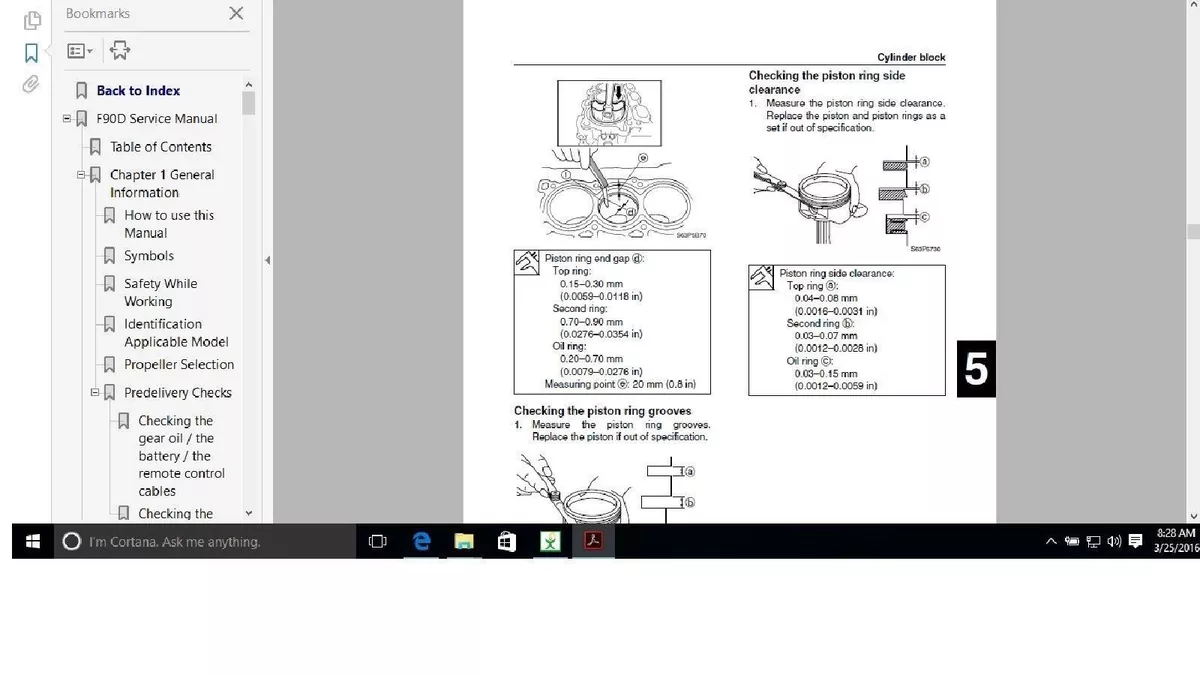

Understanding Yamaha F50 Specifications

When considering the performance and efficiency of a marine engine, it’s crucial to comprehend its specifications. These details provide insight into the capabilities, limitations, and overall functionality of the engine, ensuring optimal performance on the water.

Engine Type: This model features a four-stroke configuration, known for its reliability and fuel efficiency. The design minimizes emissions while providing consistent power delivery.

Power Output: With a robust horsepower rating, this engine is capable of propelling various types of vessels, making it suitable for both recreational and professional use.

Weight: The overall weight of the unit is a significant factor, affecting the boat’s balance and handling. A lighter engine can enhance maneuverability, whereas a heavier one may provide stability in rough waters.

Fuel System: This model utilizes a sophisticated fuel delivery system that optimizes consumption and performance. Understanding the fuel type and capacity is essential for efficient operation and maintenance.

Cooling System: A reliable cooling mechanism ensures that the engine maintains an optimal operating temperature, preventing overheating and enhancing longevity. The choice between water-cooled or air-cooled systems can impact maintenance requirements and efficiency.

By familiarizing oneself with these specifications, boat owners and operators can make informed decisions, ensuring their engine performs at its best under various conditions.

Common Issues with Yamaha F50 Engine

Understanding typical problems that arise with this outboard motor can help owners maintain optimal performance and longevity. Identifying these issues early can save time and resources in the long run.

Engine Overheating

One of the frequent challenges faced is overheating. This can occur due to inadequate cooling water intake or blocked passages. Regular inspection of the cooling system is essential to prevent severe damage.

Fuel System Malfunctions

Another concern involves fuel delivery issues. Problems such as clogged filters or malfunctioning pumps can hinder performance. Ensuring clean fuel and proper maintenance of the system can enhance reliability and efficiency.

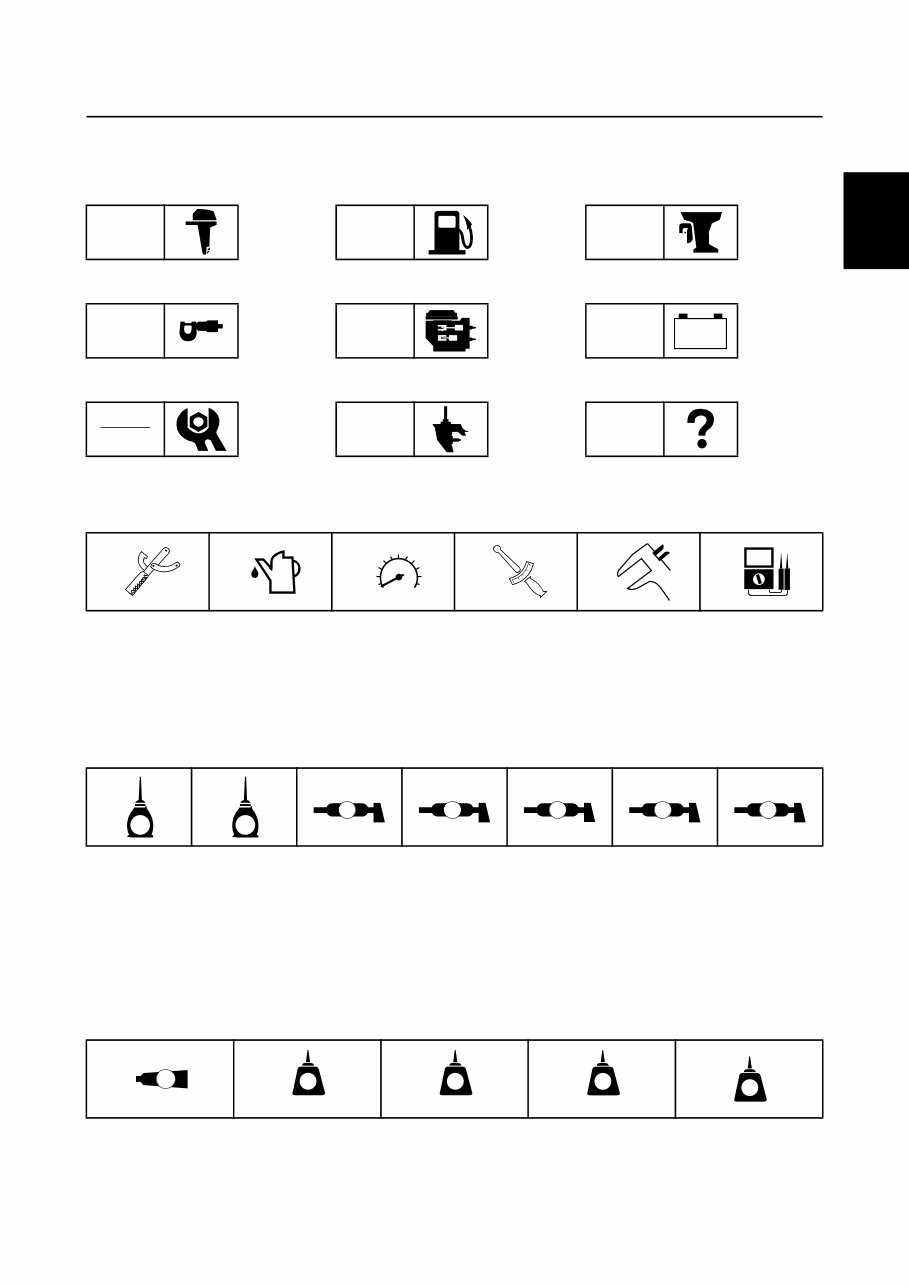

Essential Tools for Repairs

When it comes to maintaining and restoring machinery, having the right equipment is crucial. The correct set of instruments not only streamlines the process but also ensures that tasks are completed efficiently and effectively. This section outlines the fundamental tools necessary for any technician embarking on maintenance or troubleshooting tasks.

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening bolts and nuts of various sizes. |

| Screwdriver Set | Essential for driving screws, available in various types including flat and Phillips. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications, preventing damage. |

| Pliers | Used for gripping, twisting, and cutting wires or other materials. |

| Multimeter | For measuring electrical properties such as voltage, current, and resistance. |

| Oil Can | Helps in lubricating moving parts to reduce friction and wear. |

| Cleaning Supplies | Includes brushes and cloths for maintaining cleanliness and optimal functioning. |

Having these essential tools at hand prepares one for a variety of tasks, ensuring that any job can be tackled with confidence and precision. Investing in quality equipment pays off in the long run, enhancing both performance and safety during maintenance activities.

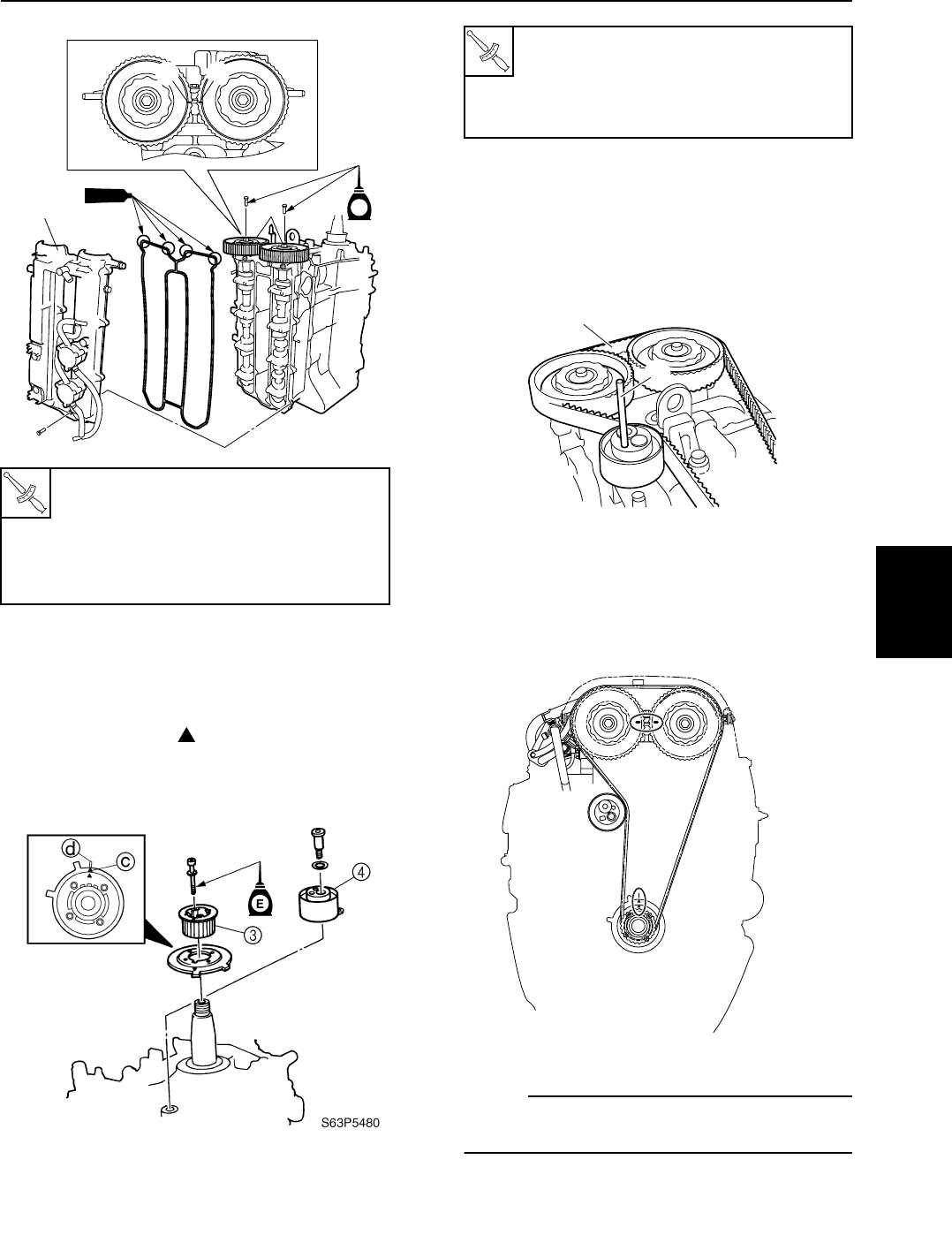

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your outboard motor. This section outlines systematic approaches to maintain your engine, helping to prevent issues and enhance its reliability. Following these procedures will enable you to keep your equipment in peak condition with minimal hassle.

Below are key maintenance tasks presented in a clear, step-by-step format:

| Task | Description | Frequency |

|---|---|---|

| Check Oil Level | Inspect the oil level using the dipstick and top up if necessary. | Every 10 hours of operation |

| Inspect Fuel System | Examine fuel lines for leaks and ensure fuel filters are clean. | Every 25 hours of operation |

| Clean Air Filter | Remove and clean the air filter to prevent debris from entering the engine. | Every 50 hours of operation |

| Examine Propeller | Check for damage, wear, or obstructions on the propeller. | Every 25 hours of operation |

| Flush Cooling System | Use fresh water to flush the cooling system after use in saltwater. | After each use in saltwater |

By adhering to these outlined steps, you can ensure your motor remains in excellent working condition, enhancing performance and reliability on the water.

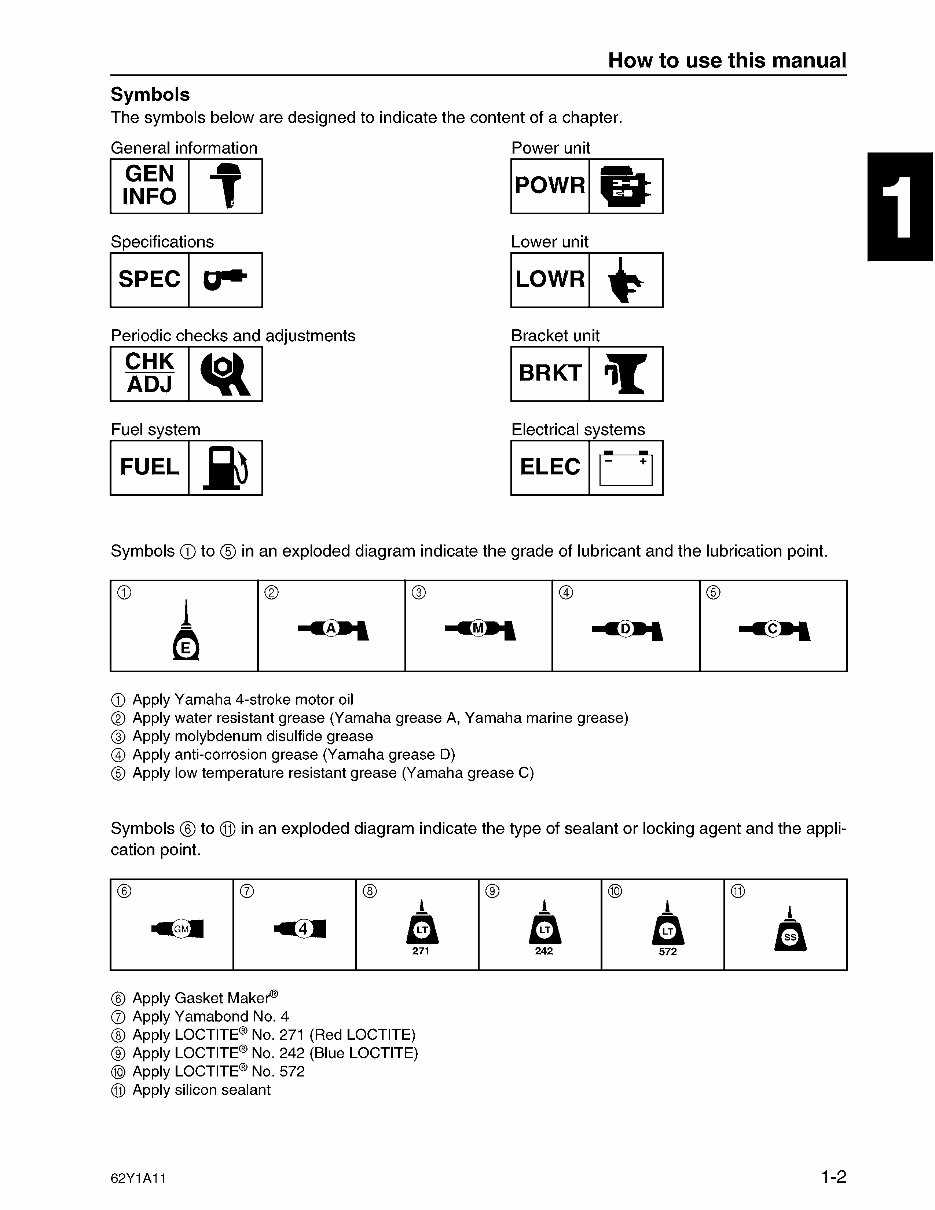

Electrical System Troubleshooting Guide

This section provides a comprehensive overview for diagnosing and resolving issues within the electrical framework of marine engines. Understanding the common problems that can arise in the electrical components is essential for ensuring optimal performance and safety on the water.

Begin by checking the battery’s condition, as it serves as the primary power source. Ensure that terminals are clean and connections are secure. A weak or dead battery can lead to various operational failures, so testing voltage levels is crucial.

Next, inspect the wiring harness for any signs of wear, fraying, or damage. Loose or corroded connections can disrupt electrical flow, leading to malfunctioning systems. Pay close attention to grounding points, as poor grounding can result in erratic behavior of electrical components.

Examine switches and circuit breakers for functionality. Faulty switches can prevent systems from receiving power, while tripped breakers may indicate underlying electrical issues. Testing these components can help identify the source of the problem.

Finally, consult the schematic diagrams to trace circuit paths. Understanding the layout will assist in pinpointing where faults may occur, facilitating a systematic approach to troubleshooting. By methodically addressing each component, one can effectively resolve electrical discrepancies and restore reliable operation.

Fuel System Inspection Techniques

Proper examination of the fuel delivery system is essential for ensuring optimal performance and efficiency of the engine. A systematic approach helps in identifying potential issues that could affect functionality. Various techniques can be employed to assess the condition and operation of the components involved in fuel handling.

Key aspects to consider during the inspection include checking for leaks, verifying fuel pressure, and assessing the condition of filters and injectors. Regular maintenance and timely checks can prevent more significant problems down the line.

| Inspection Technique | Description | Tools Required |

|---|---|---|

| Visual Inspection | Check for visible leaks or damage in fuel lines and connections. | Flashlight, Safety goggles |

| Pressure Testing | Measure fuel pressure to ensure it meets specifications. | Pressure gauge |

| Filter Examination | Inspect fuel filters for clogs or contamination. | Wrench, Cleaning solvent |

| Injector Check | Assess injectors for proper spray pattern and flow. | Multimeter, Test bench |

By following these techniques, one can effectively diagnose and maintain the fuel system, ensuring reliable operation and longevity of the engine components.

Replacing Spark Plugs Effectively

Changing ignition components is a vital task for maintaining optimal engine performance. Over time, these components can wear out, leading to misfires, reduced efficiency, and difficulties in starting. Regularly checking and replacing them ensures smooth operation and longevity of the engine.

Preparation is key before beginning the replacement process. Gather the necessary tools, including a socket wrench, torque wrench, and anti-seize compound. Ensure the engine is cool to prevent burns and damage. Always consult the specifications for the correct type and gap of the ignition components.

To begin, disconnect the battery to avoid any electrical issues. Remove any covers obstructing access to the components. Carefully unscrew the old parts, taking care not to damage surrounding areas. Inspect the condition of the old components to identify any underlying issues.

Next, install the new components by applying a small amount of anti-seize to the threads. This prevents seizing in the future and makes future replacements easier. Hand-tighten the new parts before using the torque wrench to ensure they are secured to the manufacturer’s specifications.

Finally, reassemble any covers and reconnect the battery. Start the engine and listen for smooth operation, indicating a successful replacement. Regular maintenance of these essential components can greatly enhance the performance and reliability of your engine.

Cooling System Care and Repair

Maintaining the cooling apparatus of your vessel is essential for optimal performance and longevity. Regular inspection and maintenance can prevent overheating and ensure that the engine operates smoothly under various conditions. Understanding the components involved and their functionality is crucial for effective upkeep.

Regular Inspection

Routine checks of the cooling system should include examining hoses for wear, ensuring that clamps are secure, and verifying that the water intake is free from debris. Any signs of leaks or corrosion should be addressed immediately to prevent further damage. Monitoring the coolant level and quality is equally important, as it directly impacts heat dissipation efficiency.

Maintenance Procedures

Flushing the cooling circuit periodically helps remove buildup and contaminants that can impede performance. It is advisable to replace any worn components such as thermostats and impellers to maintain proper flow rates. Following the manufacturer’s guidelines for fluid types and change intervals will further enhance the reliability of the cooling system.

Identifying Propeller Problems

Proper functionality of the propulsion system is essential for optimal performance on the water. Any issues with the rotating blade can lead to significant reductions in efficiency, control, and safety. Recognizing the signs of malfunction early can prevent costly repairs and enhance the overall boating experience.

Common Symptoms of Propeller Issues

Understanding the typical indicators of propeller-related problems is crucial. Here are some common symptoms to watch for:

| Symptom | Description |

|---|---|

| Vibration | Excessive shaking during operation may indicate damage or misalignment. |

| Loss of Speed | Noticing a decrease in top speed could suggest a bent or damaged blade. |

| Unusual Noise | Strange sounds, such as rattling or grinding, often point to a problem with the propeller or its components. |

| Handling Issues | Poor steering response or difficulty maintaining a straight course may stem from propeller faults. |

Inspection Techniques

Regular examination of the propeller can help identify issues before they escalate. Look for visible damage, such as dents or chips, and check for any signs of corrosion. Additionally, ensure the propeller is securely attached and free of debris. Maintaining a proactive approach will ensure safe and efficient operation on the water.

Best Practices for Storage

Proper storage of your equipment is essential to ensure its longevity and optimal performance. By following a few key guidelines, you can protect your investment from potential damage caused by environmental factors and improper handling.

Clean Before Storage: Always clean your unit thoroughly before storing it. Remove any debris, salt, or contaminants that may have accumulated during use. This will prevent corrosion and other forms of deterioration.

Choose an Appropriate Location: Select a dry, temperature-controlled environment for storage. Avoid places with extreme temperatures or high humidity, as these conditions can adversely affect the materials.

Drain Fluids: Before putting your equipment away, make sure to drain all fluids, including fuel and oil. This minimizes the risk of leaks and chemical reactions that can damage internal components.

Cover and Protect: Use a high-quality cover to shield your equipment from dust and moisture. Ensure the cover is breathable to prevent condensation buildup, which can lead to mold or rust.

Regular Checks: Periodically inspect your stored equipment to ensure it remains in good condition. Look for signs of wear or damage, and address any issues promptly to avoid more extensive repairs later.

By adhering to these best practices, you can significantly enhance the lifespan and reliability of your equipment, ensuring it is ready for use when you need it most.