Understanding the intricacies of small engine systems is essential for any enthusiast or professional seeking to maintain optimal performance. This section delves into the critical aspects of service and upkeep, offering valuable insights into common issues and solutions. With proper knowledge, users can enhance the longevity and reliability of their machinery.

Every engine, regardless of its brand or model, requires regular attention to ensure it runs smoothly. From routine checks to more complex repairs, a comprehensive understanding of the components involved is vital. This guide provides step-by-step instructions and tips, designed to assist individuals in navigating the complexities of engine care.

By familiarizing oneself with essential techniques and diagnostic methods, operators can troubleshoot problems effectively. Whether addressing minor adjustments or significant repairs, being equipped with the right information empowers users to tackle challenges with confidence. Embracing these principles can lead to successful outcomes and improved performance.

Overview of Briggs Stratton 12H802

This section provides a comprehensive understanding of a specific small engine model, focusing on its key features, performance, and maintenance requirements. The unit is widely recognized for its reliability and efficiency, making it a preferred choice for various outdoor power equipment.

Key Features

The engine is designed with several essential characteristics that enhance its functionality and usability. These include:

| Feature | Description |

|---|---|

| Power Output | Provides ample power for demanding tasks. |

| Fuel Efficiency | Engineered to maximize fuel consumption, reducing operational costs. |

| Durability | Constructed with high-quality materials for long-lasting performance. |

| Easy Maintenance | Designed for straightforward upkeep to ensure optimal operation. |

Performance Insights

This engine is known for its robust performance in various applications, including lawn mowers and garden equipment. Its design allows for smooth operation and quick starting, contributing to efficient workflow. Regular maintenance ensures that it continues to perform at its best, extending its lifespan and reliability.

Common Issues with the Engine

Engines can encounter various challenges that affect their performance and efficiency. Understanding these common problems can help in diagnosing issues quickly and effectively, ensuring the machinery operates smoothly.

- Starting Difficulties: Many users experience trouble starting the engine, often due to fuel delivery issues, a weak battery, or spark plug malfunctions.

- Overheating: This can occur from insufficient cooling, low oil levels, or clogged air filters, leading to potential engine damage if not addressed promptly.

- Excessive Vibration: Unusual vibrations might indicate imbalances in the internal components or loose fittings, requiring immediate inspection.

- Loss of Power: A noticeable decrease in performance can stem from fuel system blockages, air intake issues, or worn-out components.

- Oil Leaks: Leaks can arise from gaskets, seals, or damaged components, necessitating quick repairs to prevent further damage.

Regular maintenance and timely identification of these issues can greatly extend the lifespan of the engine and improve overall functionality.

Step-by-Step Repair Procedures

This section provides a detailed guide to troubleshooting and restoring the functionality of your engine. Following these sequential steps will help you address common issues efficiently, ensuring optimal performance and longevity.

Gather Necessary Tools

Before beginning the process, ensure you have all required tools at hand:

- Wrench set

- Screwdrivers (flathead and Phillips)

- Socket set

- Multimeter

- Cleaning supplies (brushes, cloths)

- Replacement parts (filters, gaskets, etc.)

Step-by-Step Instructions

- Safety First: Disconnect the spark plug wire to prevent accidental starting.

- Inspect the Fuel System: Check for leaks and ensure the fuel is fresh. Replace old fuel if necessary.

- Clean the Air Filter: Remove the air filter and clean it according to manufacturer specifications. Replace it if damaged.

- Check the Oil Level: Ensure the oil is at the proper level. Change the oil if it appears dirty or is low.

- Examine the Spark Plug: Remove and inspect the spark plug for wear. Clean or replace it as needed.

- Test the Battery: Use a multimeter to check the battery voltage. Replace if it does not meet required levels.

- Assess the Ignition System: Check all wiring and connections for corrosion or damage. Repair or replace faulty components.

- Reassemble and Test: Once all checks and repairs are complete, reassemble any disassembled parts and reconnect the spark plug. Start the engine to verify that the issue has been resolved.

By following these steps systematically, you can effectively address common issues and maintain the efficiency of your engine.

Essential Tools for Repairs

When it comes to maintaining small engines, having the right equipment is crucial for effective troubleshooting and enhancement. The right assortment of instruments not only simplifies the process but also ensures that tasks are completed safely and efficiently. Below are some indispensable tools that every enthusiast should consider for optimal performance.

Basic Toolkit

- Wrenches: A variety of sizes for different fasteners.

- Screwdrivers: Both flat-head and Phillips types are essential.

- Pliers: Useful for gripping, twisting, and cutting wire.

- Socket set: For easier access to nuts and bolts in tight spaces.

Specialized Instruments

- Compression tester: To check engine compression levels.

- Multimeter: For diagnosing electrical issues.

- Carburetor cleaning kit: To ensure optimal fuel flow.

- Torque wrench: For applying precise torque to fasteners.

Equipping yourself with these essential tools will pave the way for successful maintenance and enhancement, keeping your equipment running smoothly for years to come.

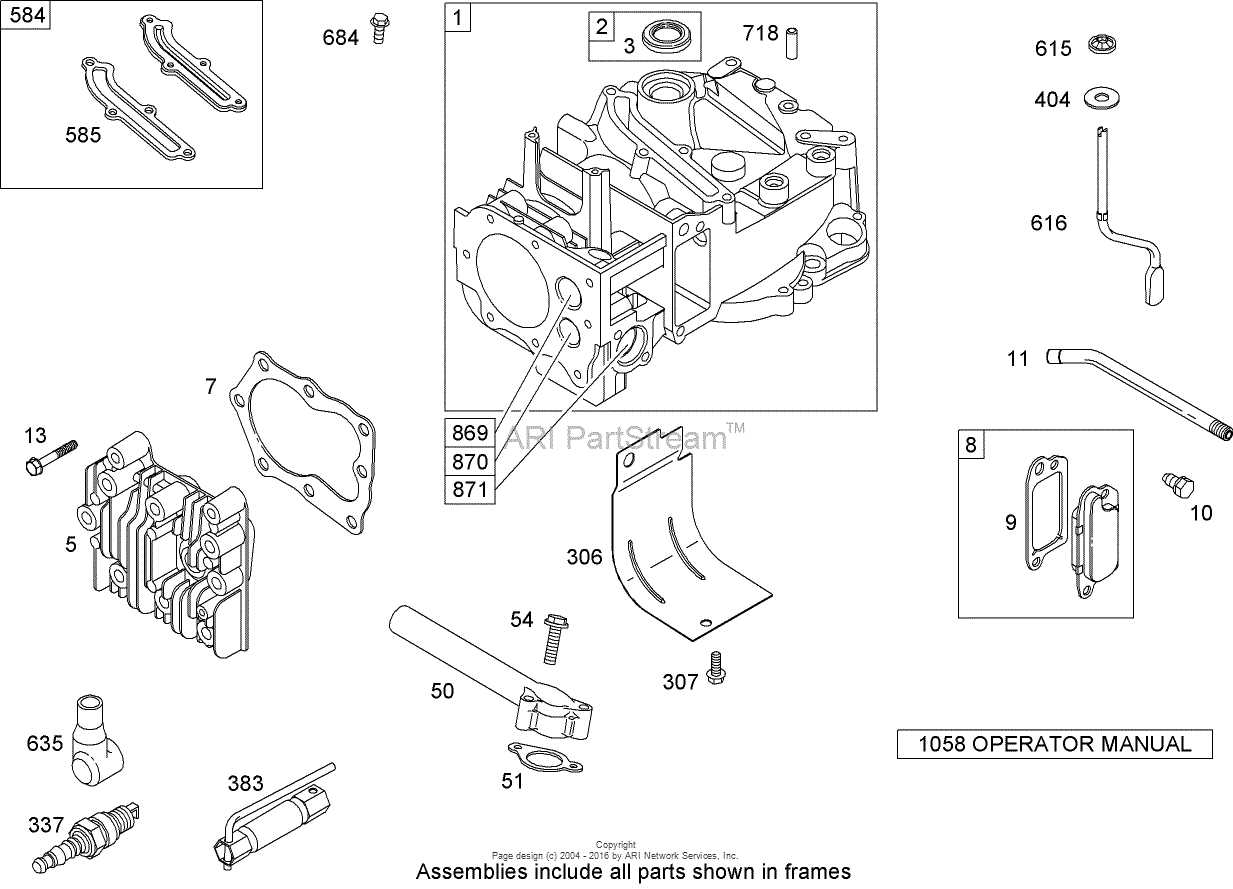

Understanding Engine Specifications

Engine specifications provide essential information that helps users comprehend the capabilities and limitations of their power equipment. By examining these details, one can ensure optimal performance and longevity of the machine. This section delves into the critical components and metrics that define an engine’s functionality.

Key Components of Engine Specifications

Several factors play a vital role in determining an engine’s efficiency. Displacement refers to the total volume of the engine cylinders, influencing power output and fuel consumption. Additionally, horsepower measures the engine’s capability to perform work, while torque indicates the rotational force available for tasks. Understanding these parameters allows for better matching of the engine to specific applications.

Importance of Maintenance Standards

Regular adherence to maintenance standards is crucial for preserving engine performance. Specifications often include recommended oil types, filter changes, and service intervals. Following these guidelines ensures the engine operates smoothly and efficiently, ultimately extending its lifespan. Familiarity with these aspects empowers users to maintain their equipment effectively and tackle any issues that may arise.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular upkeep and attention to detail. By following a few essential practices, you can significantly extend the lifespan and performance of your machinery. Here are some valuable tips to keep in mind.

- Regular Cleaning: Keep the exterior and components free from dirt and debris. Accumulation can lead to overheating and inefficient operation.

- Oil Changes: Change the lubricant as recommended by the manufacturer. Fresh oil reduces friction and prevents wear.

- Inspect Filters: Clean or replace air and fuel filters periodically. Clogged filters can restrict airflow and reduce performance.

- Check Spark Plug: Inspect and clean the spark plug regularly. A well-functioning spark plug ensures optimal ignition and fuel efficiency.

- Examine Belts and Cables: Look for signs of wear or damage. Replace any frayed belts or corroded cables to maintain safe operation.

By adhering to these simple yet effective maintenance practices, you can ensure that your equipment operates efficiently and remains in peak condition for years to come.

Troubleshooting Electrical Problems

Identifying and resolving electrical issues is crucial for ensuring the optimal performance of your small engine. This section provides a systematic approach to diagnose common faults that may arise, allowing you to restore functionality effectively.

Common Symptoms

Typical signs of electrical problems include difficulty starting, intermittent operation, or complete power failure. Pay close attention to any unusual sounds or smells, as these can indicate deeper issues.

Diagnostic Steps

Begin by checking the battery voltage and connections. Ensure that all wires are intact and securely attached. Next, inspect the ignition system for faults, including the spark plug and ignition coil. Utilizing a multimeter can help measure voltage and continuity, guiding you in pinpointing the source of the malfunction.

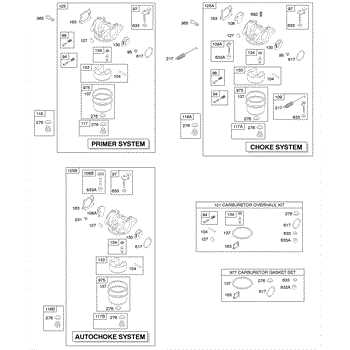

Fuel System Diagnostics and Fixes

Ensuring optimal performance of small engines often hinges on the efficiency of the fuel system. Proper diagnostics can identify issues that lead to poor combustion, starting difficulties, or erratic operation. This section delves into common problems associated with fuel delivery and offers straightforward solutions to enhance engine reliability.

One of the primary indicators of fuel system trouble is inconsistent engine performance. Symptoms such as stalling or sputtering may suggest clogged fuel lines or a dirty filter. Inspect these components regularly, and replace them if any obstructions are found. Ensuring a clear pathway for fuel flow is crucial for maintaining engine health.

Another frequent culprit is the fuel quality itself. Stale or contaminated fuel can lead to various operational issues. If the engine exhibits rough idling or fails to start, consider draining the fuel tank and refilling it with fresh, high-quality gasoline. Additionally, incorporating a fuel stabilizer can help prolong the shelf life of the fuel, preventing similar issues in the future.

Furthermore, the carburetor plays a vital role in the overall fuel system. If you notice excessive fuel consumption or an inability to maintain a steady idle, cleaning the carburetor may be necessary. Disassembling it and removing any debris can significantly improve performance. Be sure to check the float and needle valve for proper operation as well.

Lastly, pay attention to the fuel pump. A malfunctioning pump may not deliver the required pressure, leading to starting problems. Testing the pump’s output with a pressure gauge can provide insights into its condition. If it falls below specifications, replacement is recommended to restore proper fuel delivery.

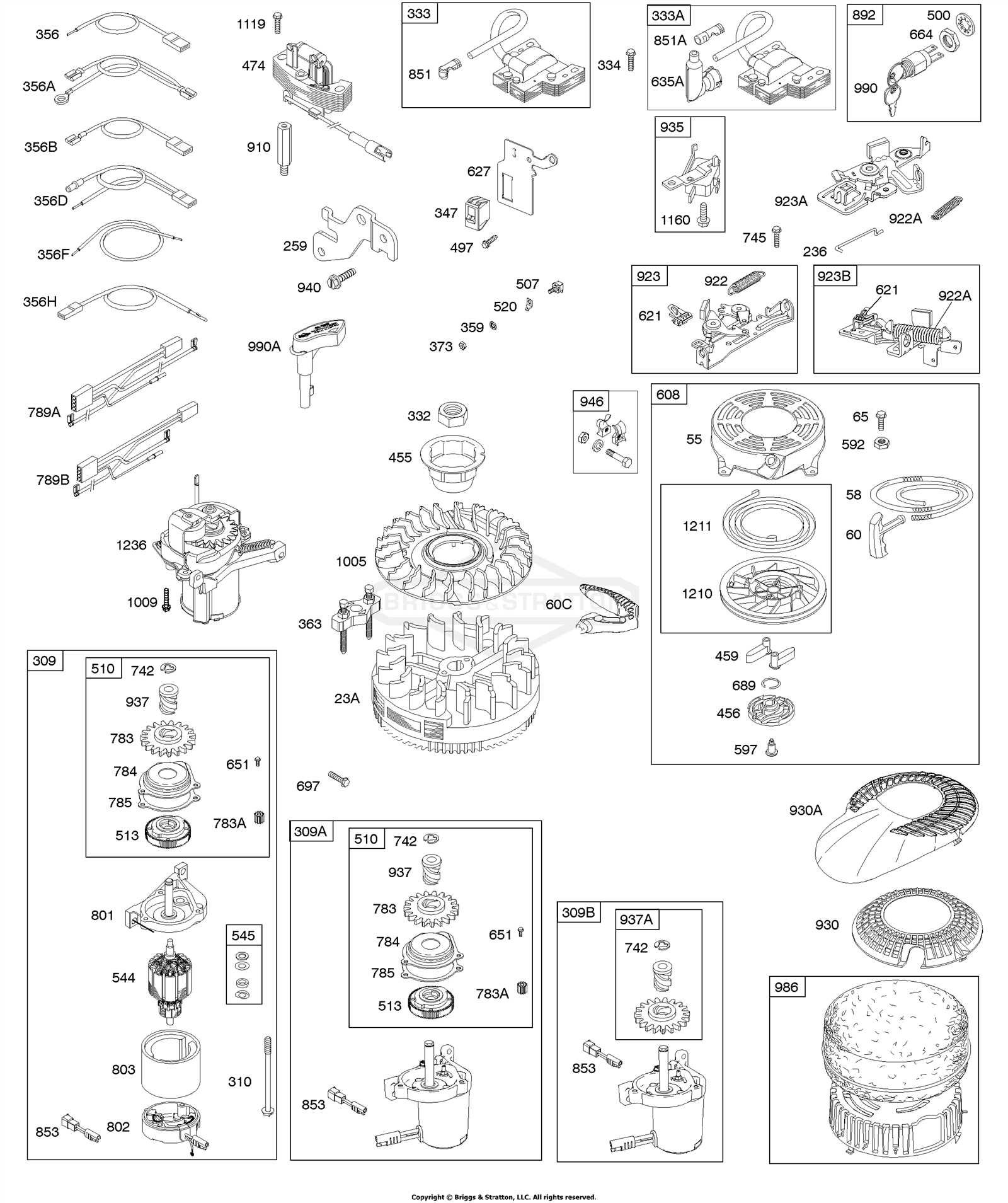

Replacement Parts and Compatibility

Ensuring optimal performance of small engines often necessitates the replacement of various components. Understanding the compatibility of these parts is crucial for maintaining efficiency and longevity. This section explores essential components and guidelines for selecting appropriate replacements.

Essential Components for Replacement

- Air Filters

- Fuel Filters

- Oil Filters

- Spark Plugs

- Carburetors

- Gaskets and Seals

- Ignition Coils

Selecting Compatible Parts

When choosing replacement components, consider the following factors:

- Model Number: Always refer to the specific model to find compatible parts.

- OEM vs. Aftermarket: Original Equipment Manufacturer parts generally offer better fit and reliability.

- Specifications: Verify dimensions and specifications to ensure proper functionality.

- Customer Reviews: Check feedback on aftermarket parts to assess their reliability and performance.

By following these guidelines, you can ensure that your engine remains in top condition through the use of suitable replacement components.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Adopting appropriate measures not only protects the individual performing the work but also safeguards the equipment involved. Awareness of potential hazards and following specific guidelines can create a secure environment for effective servicing.

Personal Protective Equipment

Wearing the right protective gear is essential. This includes items such as safety goggles, gloves, and steel-toed boots. Such equipment helps shield against flying debris, sharp edges, and heavy components. Ensuring that clothing is snug and free from loose ends can further reduce the risk of entanglement in machinery.

Work Area Safety

Maintaining a clean and organized workspace significantly minimizes the chance of accidents. Keep tools and materials well-arranged to prevent tripping hazards. Ensure proper ventilation if working with chemicals or fuel, and always store flammable substances away from sources of ignition. Regularly checking for any potential risks in the area will enhance overall safety during the task.

Proper Storage Techniques for Engines

Storing engines correctly is essential to ensure their longevity and optimal performance. Implementing suitable practices during the off-season or when not in use can prevent deterioration and mechanical issues. Proper preparation before storage can significantly reduce the likelihood of rust, fuel degradation, and other damaging factors.

Begin by thoroughly cleaning the engine and removing any debris, dirt, or grease. This step not only helps in maintaining the appearance but also prevents contaminants from causing corrosion during storage. After cleaning, consider applying a protective coating or rust inhibitor to vulnerable metal parts.

Fuel management is another critical aspect. If possible, drain the fuel system or add a stabilizer to the remaining fuel. This helps in preventing varnish buildup and ensures that the engine starts smoothly when it’s time to use it again. Additionally, running the engine for a few minutes after adding the stabilizer allows it to circulate throughout the system.

Before storing, check and change the oil if necessary. Fresh oil contains additives that help protect internal components from wear and corrosion. Ensuring that the oil is at the correct level and clean will provide better protection during idle periods.

Finally, choose a suitable storage environment. Keeping the engine in a dry, temperature-controlled area will further minimize risks of rust and damage. If possible, cover the engine with a breathable tarp to protect it from dust and moisture while allowing air circulation.

Resources for Further Assistance

When encountering challenges with your small engine equipment, having access to reliable resources can make a significant difference. Whether you are a novice or an experienced technician, utilizing available tools and communities can enhance your troubleshooting process and provide valuable insights.

Online forums and discussion groups dedicated to small engine maintenance are excellent platforms for sharing experiences and obtaining advice from fellow enthusiasts. These communities often feature detailed guides, troubleshooting tips, and answers to common questions that can help you navigate various issues.

Additionally, instructional videos on platforms like YouTube can visually guide you through repair processes, offering step-by-step demonstrations. These resources can be particularly helpful for those who prefer a hands-on approach to learning.

Manufacturer websites typically provide comprehensive documentation, including diagrams and parts lists, which can assist in identifying components and understanding how they function together. Exploring these official resources can ensure that you have accurate information at your fingertips.

Finally, local repair shops often serve as a valuable resource. Engaging with professionals who have hands-on experience can lead to practical advice and tips tailored to your specific equipment needs. Networking with these experts can also open doors to future support and recommendations.

Owner Experiences and Testimonials

This section delves into the insights and reflections shared by users of small engine equipment. Their stories provide a rich perspective on performance, maintenance, and overall satisfaction. By examining real-life encounters, potential buyers can gain valuable knowledge and understanding.

Many owners appreciate the reliability of their machines, often highlighting key aspects such as:

- Ease of starting, even in challenging weather conditions.

- Durability during heavy usage, making them ideal for various tasks.

- Cost-effectiveness in fuel consumption.

Furthermore, users frequently share their thoughts on maintenance practices:

- Regular oil changes significantly enhance engine longevity.

- Replacing air filters is crucial for optimal performance.

- Staying ahead with seasonal check-ups prevents unexpected breakdowns.

Feedback often emphasizes community support, with many owners exchanging tips and troubleshooting advice. These interactions foster a sense of belonging among enthusiasts, contributing to an enriched ownership experience.

Ultimately, the testimonials reflect a blend of satisfaction and practical insights, guiding new users toward informed decisions and successful operations.