Understanding the nuances of engine upkeep is essential for any enthusiast or professional. This comprehensive guide delves into the intricacies of maintaining a specific type of air-cooled engine, focusing on its unique design and functionality. Through careful examination, one can ensure optimal performance and longevity.

Engine mechanics can seem daunting, but with the right knowledge and approach, they become manageable tasks. This resource aims to equip users with vital information regarding troubleshooting, component replacement, and general upkeep practices. By mastering these techniques, users can confidently address common issues and enhance their machinery’s efficiency.

Moreover, a well-maintained engine not only extends its lifespan but also improves fuel efficiency and overall productivity. The insights provided herein will empower individuals to undertake maintenance with precision, ensuring that their engines operate smoothly and reliably. Whether you are a novice or seasoned mechanic, this guide serves as an invaluable reference for all your maintenance needs.

Understanding Briggs and Stratton Engines

This section explores the fundamental characteristics and functionality of these widely used power units. Known for their reliability and efficiency, these machines have become a staple in various applications, from lawn care to industrial tasks. A deeper comprehension of their components and operation can significantly enhance maintenance practices and longevity.

Key Components

These engines consist of several essential parts that work harmoniously to deliver optimal performance. Understanding these elements is crucial for effective upkeep.

| Component | Function |

|---|---|

| Crankshaft | Converts linear motion into rotational force. |

| Piston | Moves up and down within the cylinder to compress the fuel-air mixture. |

| Camshaft | Controls the opening and closing of the intake and exhaust valves. |

| Flywheel | Stabilizes engine speed and helps in starting the engine. |

Operational Principles

The operational cycle of these power units generally follows a four-stroke process. Each stroke plays a vital role in transforming fuel into mechanical energy. Recognizing this cycle can aid in troubleshooting and improving efficiency.

Common Issues in Single Cylinder Models

Understanding typical problems encountered in these engine types is essential for effective maintenance and troubleshooting. Many users may face challenges that can impact performance, efficiency, and overall reliability. Recognizing these issues early can prevent more significant damage and ensure optimal functionality.

Fuel System Complications

One prevalent issue relates to the fuel system. Clogged filters and carburetor problems can lead to poor engine performance. Over time, debris can accumulate, obstructing fuel flow and causing the engine to run unevenly or not start at all. Regular inspections and cleanings are recommended to maintain a steady fuel supply.

Electrical Failures

Another frequent concern involves the electrical components. Faulty spark plugs or ignition systems can prevent proper starting and may lead to misfires during operation. Testing connections and ensuring the spark plug is in good condition can resolve these issues. Routine checks of the electrical system are vital for maintaining consistent engine performance.

Essential Tools for Engine Repair

Working on engines requires a set of vital instruments to ensure efficiency and effectiveness. Having the right equipment not only simplifies tasks but also enhances safety and precision. Understanding which tools are essential can significantly impact the success of your maintenance efforts.

Wrenches are fundamental for loosening and tightening fasteners. A variety of sizes, including both metric and imperial, is recommended to accommodate different bolts. Socket sets are particularly useful for reaching tight spaces, providing leverage that enhances torque application.

Screwdrivers in various types–flathead and Phillips–are necessary for manipulating screws throughout the engine assembly. It’s important to select high-quality options to avoid stripping screws, which can lead to further complications.

Additionally, a Torque wrench is crucial for applying the correct amount of force to bolts. Ensuring proper torque prevents damage and maintains structural integrity, especially in high-stress components.

Another indispensable item is a multimeter, which aids in diagnosing electrical issues. Understanding the electrical systems of an engine can prevent unnecessary replacements and improve troubleshooting accuracy.

Finally, an oil filter wrench simplifies the process of changing filters, ensuring that maintenance tasks can be performed smoothly. By assembling a comprehensive toolkit, you can enhance your engine maintenance and repair experience.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring the longevity and efficient performance of your engine. This section outlines a series of straightforward procedures designed to maintain optimal functionality. By following these steps diligently, you can enhance the reliability and extend the life of your machinery.

Routine Inspection

The first step in the maintenance process is conducting a thorough inspection. This includes checking for leaks, wear, and any signs of damage. It is advisable to perform this check before each use.

Cleaning and Lubrication

Proper cleaning and lubrication can prevent unnecessary wear and tear. Ensure all moving parts are free of debris and adequately lubricated to enhance performance.

| Task | Frequency | Tools Required |

|---|---|---|

| Inspect for leaks | Before each use | Visual inspection |

| Clean air filter | Every 10 hours | Brush, cloth |

| Change oil | Every 50 hours | Wrench, oil container |

| Check spark plug | Every 25 hours | Socket wrench |

Following these procedures can significantly enhance the performance and reliability of your engine. Always consult your specific guidelines for any additional recommendations or specifications. Regular attention to maintenance ensures efficient operation and minimizes potential issues.

Diagnosing Engine Performance Problems

Identifying issues affecting engine efficiency is crucial for maintaining optimal functionality. Various symptoms may indicate underlying complications, and understanding these signs can facilitate timely interventions. This section outlines common performance problems and diagnostic approaches to effectively address them.

Common Symptoms

- Difficulty starting the engine

- Uneven or rough idling

- Poor acceleration or power loss

- Excessive smoke from the exhaust

- Unusual noises during operation

Diagnostic Steps

- Check the fuel system:

- Inspect fuel quality and cleanliness

- Examine fuel lines for leaks or blockages

- Examine the ignition system:

- Test spark plugs for wear or fouling

- Verify ignition timing accuracy

- Assess the air intake:

- Inspect the air filter for obstructions

- Check for intake leaks

- Evaluate the exhaust system:

- Look for signs of restriction or blockage

- Ensure proper muffler function

By systematically evaluating these components, one can diagnose performance issues and implement necessary repairs, ultimately enhancing engine reliability and efficiency.

Disassembling the L-Head Engine

Disassembling a small engine requires careful attention to detail and a systematic approach. This process allows for thorough cleaning, inspection, and replacement of worn components. Understanding the sequence of disassembly is crucial to ensure that each part is handled correctly and can be reassembled without issues.

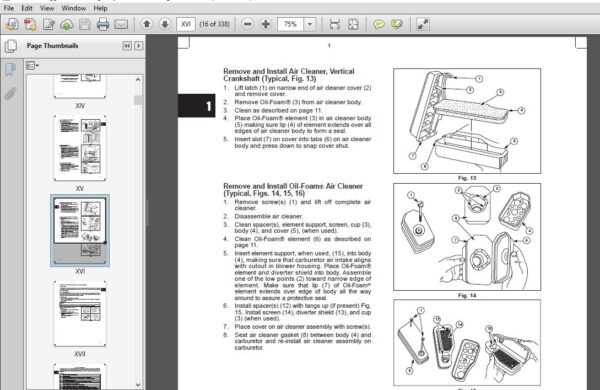

Begin by removing the engine from its mounting, ensuring that all connections are detached. Drain any fuel and oil to prevent spills. Once free, take off the outer casing and any attached accessories. Document each step, as this will assist in the reassembly phase.

Next, focus on the head assembly. Remove the bolts securing it, carefully lifting it away from the block. Inspect the gasket for wear, as replacing it will be essential during reassembly. After the head is off, take out the pushrods and valve springs, noting their arrangement for later reference.

Proceed to detach the piston assembly by removing the connecting rod cap. Gently push the piston out of the cylinder, taking care not to damage the walls. Examine the rings for wear, as they may need replacement. Clean all parts thoroughly, removing carbon buildup and debris.

Finally, inspect the crankshaft and bearings. Remove any remaining components with precision, ensuring that no pieces are lost. Keeping everything organized will simplify the rebuilding process, enabling a smooth transition from disassembly to reassembly.

Repairing Common Engine Components

Maintaining the functionality of engine elements is crucial for optimal performance. Understanding the common issues that can arise with these components allows for effective troubleshooting and restoration. This section delves into typical repairs and adjustments necessary to keep engines running smoothly, ensuring longevity and efficiency.

One of the most frequent problems involves the ignition system. Issues such as faulty spark plugs or damaged wires can hinder starting and overall performance. Regular inspection and replacement of these parts can significantly improve engine reliability.

Fuel delivery systems also require attention. Clogs in the carburetor or fuel lines can lead to inadequate fuel supply, resulting in poor performance. Cleaning and servicing these components periodically can prevent such blockages and maintain proper engine operation.

Additionally, wear and tear on gaskets and seals can lead to leaks, affecting both performance and efficiency. Replacing these components as needed will help preserve the integrity of the engine and prevent unnecessary damage.

Finally, keeping an eye on the cooling system is essential. Overheating can cause severe issues, so checking for blockages in the cooling passages and ensuring the cooling fan operates effectively are vital maintenance steps. By addressing these common concerns, you can ensure your engine remains in top condition.

Reassembly Tips for L-Head Engines

Reassembling a small engine requires careful attention to detail and a systematic approach. Ensuring that each component is properly aligned and secured is crucial for optimal performance and longevity. This section provides essential advice to facilitate a smooth reassembly process, making your task more manageable and efficient.

Before starting, organize all parts systematically. Group similar items together and ensure that you have all necessary tools at hand. It’s advisable to refer to any notes or diagrams made during disassembly to guide the reassembly steps accurately.

Begin by inspecting all components for wear or damage. Replace any parts that show signs of deterioration. Clean surfaces thoroughly to ensure a good seal between components. Lubricating moving parts before assembly can prevent premature wear and make the engine run more smoothly.

As you assemble, follow a logical order. Start with the lower end, ensuring that the crankshaft and bearings are in place before moving to the upper section. Pay special attention to torque specifications for bolts, as improper torque can lead to significant issues down the line.

Don’t rush the process. Take breaks if needed to maintain focus. Once fully assembled, double-check all connections, bolts, and seals to ensure everything is in its correct position. Proper reassembly not only enhances performance but also contributes to the engine’s reliability.

Testing Engine After Repair

After completing maintenance or fixes on a motor, it is crucial to verify its functionality to ensure reliability and performance. This process helps identify any lingering issues that may not have been addressed during the service. Conducting a thorough assessment can prevent future complications and enhance the longevity of the unit.

The testing procedure should encompass several key aspects to guarantee that the engine operates smoothly. Below is a table outlining the essential steps involved in this evaluation process:

| Step | Description |

|---|---|

| 1 | Visual Inspection: Check for any leaks, loose components, or signs of wear. |

| 2 | Fluid Levels: Ensure that oil and fuel levels are adequate before starting. |

| 3 | Start-Up: Turn on the motor and observe its initial performance and sounds. |

| 4 | Idle Check: Allow the engine to idle and monitor for stability and vibrations. |

| 5 | Load Testing: Apply a load to the engine to assess its performance under pressure. |

| 6 | Final Inspection: Conduct a thorough check after testing for any new issues that may arise. |

By following these steps, one can ensure that the motor is in optimal working condition, ready for reliable operation. Proper testing not only safeguards against potential problems but also enhances the overall efficiency of the machine.

Safety Precautions During Repairs

When working on engines, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual performing the maintenance but also ensure that the equipment remains in good working condition. Below are key safety measures to follow during engine service tasks.

- Wear Appropriate Personal Protective Equipment (PPE): Always use safety goggles, gloves, and sturdy footwear to shield against potential hazards.

- Work in a Well-Ventilated Area: Ensure that the workspace has adequate airflow to disperse harmful fumes and prevent inhalation of toxic substances.

- Disconnect the Power Source: Before beginning any work, disconnect the battery or unplug the unit to eliminate the risk of accidental starts.

- Keep a Clean Workspace: Maintain a tidy area free of clutter to avoid tripping hazards and to easily locate tools and parts.

Additionally, it is important to stay focused and avoid distractions during the maintenance process. Taking regular breaks can help maintain concentration and prevent fatigue.

- Read the Manufacturer’s Instructions: Familiarize yourself with the guidelines specific to the engine to ensure safe and effective handling.

- Use the Right Tools: Always utilize appropriate tools designed for the task to avoid damaging components or injuring yourself.

- Handle Fluids Carefully: Be cautious when working with fuels and oils; clean up any spills immediately to prevent slips or fires.

- Seek Help if Needed: Don’t hesitate to ask for assistance or consult a professional if unsure about a procedure.

By adhering to these safety guidelines, you can minimize risks and ensure a successful engine service experience.

Resources for Further Learning

Expanding your knowledge on engine maintenance and troubleshooting can greatly enhance your skills. There are numerous resources available that cover a wide range of topics related to small engine mechanics. Whether you’re a beginner or looking to deepen your expertise, these materials will provide valuable insights and practical advice.

| Resource Type | Description | Link |

|---|---|---|

| Online Courses | Comprehensive courses focusing on engine mechanics, offering video tutorials and interactive content. | Coursera |

| Books | In-depth literature covering various aspects of engine repair and maintenance, suitable for all skill levels. | Amazon |

| YouTube Channels | Channels dedicated to hands-on demonstrations and expert tips for small engine upkeep. | YouTube |

| Forums | Online communities where enthusiasts share experiences, troubleshooting tips, and advice. | Reddit Small Engines |

| Workshops | Local classes offering hands-on experience with engine repair under the guidance of professionals. | Local Community Colleges |