When faced with issues in household equipment, having a detailed reference can make all the difference. This guide aims to equip users with essential information and troubleshooting techniques that can assist in diagnosing and resolving common problems encountered in advanced laundry machines. Understanding the mechanics of these devices is crucial for maintaining their performance and longevity.

In this section, we will explore various symptoms that may arise during operation, providing practical insights on how to identify the underlying causes. By delving into common malfunctions, users can gain a better understanding of their equipment and learn effective strategies for addressing these challenges. From unusual noises to ineffective cleaning cycles, this guide will cover a wide range of scenarios.

Equipped with step-by-step instructions and helpful tips, users will find the process of restoring their machines to optimal functionality much more manageable. This resource is designed to empower individuals, enabling them to take control of their appliance maintenance while fostering a deeper appreciation for the technology that simplifies their daily lives.

Understanding Common Washer Issues

Household cleaning devices can encounter a variety of complications that disrupt their functionality. Recognizing these frequent problems is essential for effective troubleshooting and maintaining optimal performance.

One common difficulty involves issues with drainage. A machine that fails to remove excess water may be hindered by clogged hoses or malfunctioning pumps. Ensuring proper drainage is crucial for effective cleaning.

Another prevalent concern is unusual noises during operation. Sounds such as banging, grinding, or squeaking can indicate loose components or worn-out parts. Addressing these noises promptly can prevent further damage and enhance longevity.

Additionally, inconsistent cycles can be frustrating. Machines that do not complete their programmed settings may be experiencing electrical issues or faulty timers. Regular checks and adjustments can help restore proper functioning.

Understanding these typical complications allows users to take proactive measures, ensuring their cleaning appliances operate efficiently and effectively.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing common issues encountered with a specific home appliance. By following the outlined steps, users can efficiently identify problems and implement solutions, ensuring optimal functionality.

Common Issues and Solutions

Below is a table summarizing frequent problems along with their potential causes and recommended actions.

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Unit not starting | Power supply issues | Check electrical connections and reset circuit breaker. |

| Noisy operation | Worn-out components | Inspect for loose parts and replace if necessary. |

| Poor cleaning performance | Clogged filters | Clean or replace filters as needed. |

| Water leakage | Damaged hoses | Examine hoses for cracks and replace if damaged. |

Troubleshooting Steps

To effectively resolve issues, follow these systematic steps:

- Disconnect the appliance from the power source for safety.

- Identify the symptoms and consult the table above for potential causes.

- Perform visual inspections and tests based on the identified issues.

- Apply the recommended actions to resolve the problems.

- Reconnect the appliance and conduct a test cycle to ensure proper operation.

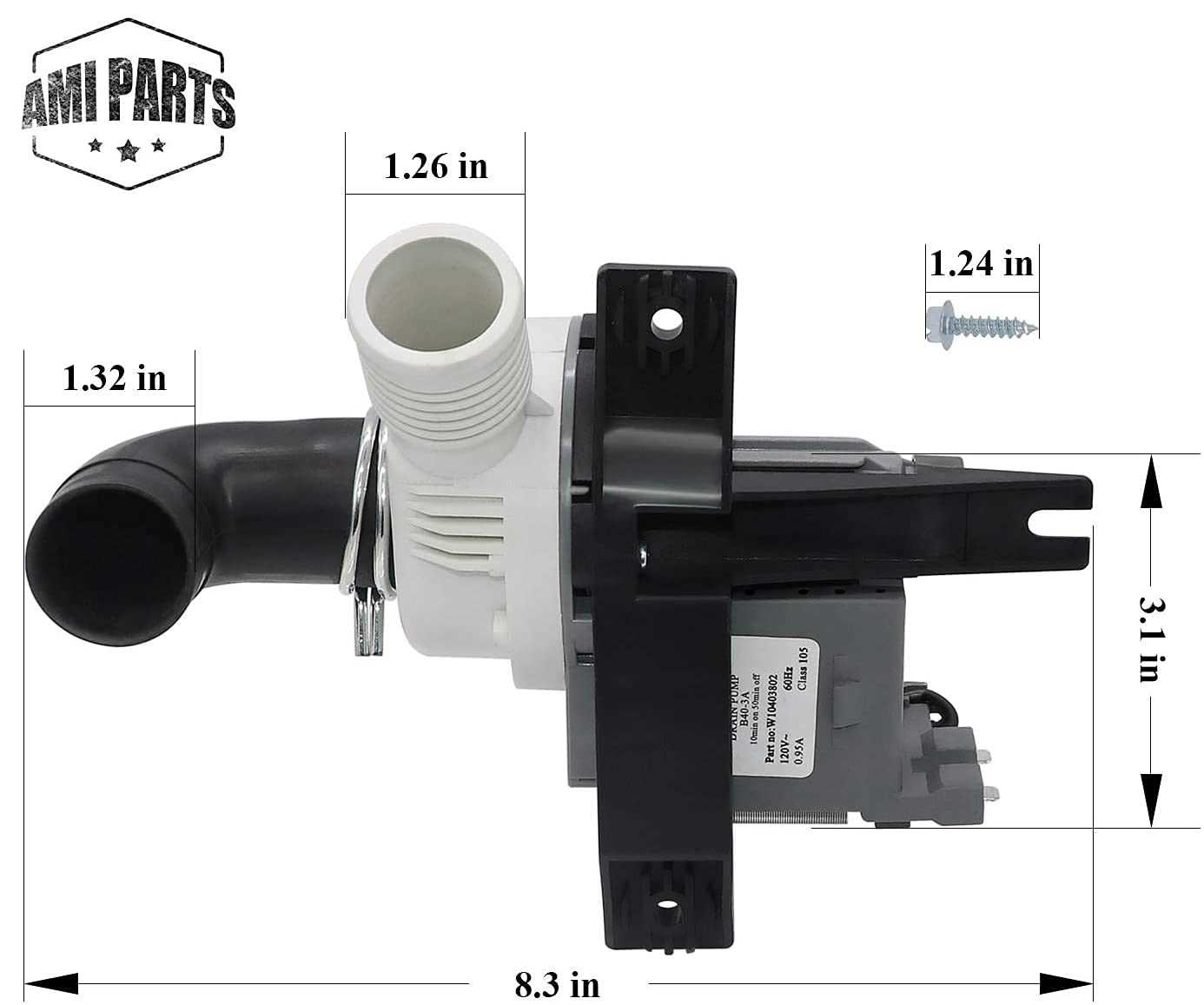

Parts Replacement Overview

This section provides a comprehensive look at the process of substituting components in a domestic appliance. Understanding the various parts and their functions is essential for effective maintenance and ensuring optimal performance. Regular updates and replacements can significantly extend the lifespan of the unit and improve its efficiency.

Identifying Components for Replacement

Recognizing which parts require attention is crucial. Commonly replaced elements include seals, belts, and motors, among others. Regular inspections can help detect wear and tear early, allowing for timely action to prevent more extensive damage.

Step-by-Step Replacement Process

Once the necessary components have been identified, the replacement process typically involves several straightforward steps. This includes disconnecting the appliance from power, removing any panels as needed, and carefully replacing the defective parts. Following the manufacturer’s guidelines ensures that the installation is done correctly and safely.

Essential Tools for Repairs

Having the right equipment is crucial for addressing issues effectively and efficiently. A well-equipped toolkit can make the process smoother, ensuring that you can tackle various tasks without unnecessary delays. Whether you are performing minor adjustments or more complex fixes, specific items can enhance your experience and outcomes.

Basic Hand Tools: A set of screwdrivers in various sizes is fundamental for loosening and tightening screws. Pliers are also essential for gripping and twisting, while wrenches can assist with nuts and bolts. These tools form the backbone of any toolkit, allowing for versatile handling of components.

Measuring Instruments: A multimeter is invaluable for diagnosing electrical issues, enabling you to test voltage and continuity. Additionally, a measuring tape is beneficial for ensuring proper dimensions and alignments during the process, which can prevent further complications.

Specialty Equipment: Depending on the tasks at hand, specific tools like a socket set or a torque wrench may be necessary. These tools help ensure that fasteners are tightened to the appropriate specifications, reducing the risk of damage due to improper assembly.

By assembling a comprehensive toolkit, you set yourself up for success in troubleshooting and enhancing your appliance’s performance. Each tool serves a distinct purpose, contributing to a more streamlined and effective process.

Electrical System Diagnostics

This section delves into the evaluation and troubleshooting of the electrical framework in home appliances. Understanding how to identify faults within the system can significantly enhance the functionality and longevity of the equipment. By systematically analyzing various components, users can pinpoint issues that may lead to operational failures.

Identifying Common Electrical Issues

Common problems within the electrical system can manifest as power failures, inconsistent performance, or unusual noises. Recognizing these symptoms early can facilitate a swift response, preventing further complications. Conducting a visual inspection for damaged wires, loose connections, or burnt components can often reveal the root cause of the malfunction.

Testing Electrical Components

Utilizing a multimeter is an effective method for assessing the condition of electrical parts. By measuring voltage, resistance, and continuity, users can determine whether each component is functioning within its specified parameters. This process helps in isolating defective elements that may require replacement or repair, ultimately restoring optimal performance.

Water Supply and Drainage Problems

Issues related to the flow and removal of liquid are common challenges faced by various laundry appliances. These complications can significantly affect performance and efficiency, leading to unsatisfactory results during operation. Understanding the potential causes and solutions for these problems is essential for maintaining optimal functionality.

Common Water Supply Issues

Several factors can hinder the proper flow of water to the appliance:

- Clogged Hoses: Accumulation of debris can obstruct hoses, restricting water intake.

- Low Water Pressure: Insufficient pressure from the source may prevent the appliance from filling adequately.

- Faulty Inlet Valve: A malfunctioning valve may fail to open, stopping water flow completely.

Drainage Complications

Problems with water removal can also arise from various sources:

- Blocked Drain Hose: Obstructions can prevent proper drainage, leading to overflow.

- Defective Pump: If the pump is not functioning correctly, it may not expel water effectively.

- Improper Installation: Incorrect positioning of hoses can result in backflow or insufficient drainage.

Preventive Maintenance Tips

Regular upkeep of your laundry appliance can significantly extend its lifespan and ensure optimal performance. By implementing a few straightforward practices, you can prevent common issues and maintain efficiency over time.

- Clean the Drum: Periodically run a cleaning cycle or a hot water wash without any laundry to remove residue and prevent odors.

- Check Hoses: Inspect the water supply hoses for any signs of wear or leaks. Replace them if they appear frayed or damaged.

- Level the Unit: Ensure that the appliance is properly leveled to minimize vibrations during operation, which can lead to mechanical issues.

- Maintain Seals: Wipe down door seals and gaskets regularly to prevent mold buildup and ensure a tight seal.

- Inspect Filters: Clean or replace lint and debris filters to maintain proper drainage and prevent clogs.

Incorporating these maintenance practices into your routine can help you avoid costly repairs and enhance the performance of your appliance.

Unusual Noises and Their Causes

Encounters with unexpected sounds during operation can indicate various underlying issues. Understanding these noises can help in diagnosing problems early and avoiding more significant damage. This section explores common unusual sounds and their potential causes, aiding in effective troubleshooting.

Types of Noises

- Grinding: Often suggests foreign objects caught in the drum or a malfunctioning component.

- Banging: May indicate loose parts or an unbalanced load.

- Humming: Typically associated with electrical issues or worn-out bearings.

- Clicking: Can arise from items caught in the mechanism or issues with the drive belt.

- Whining: Often points to motor problems or issues with the transmission.

Common Causes

- Foreign objects in the drum can create grinding or banging sounds.

- Unbalanced loads may lead to excessive vibrations, causing thumping noises.

- Worn-out bearings can produce humming or whining as they struggle to support the drum.

- Loose components can result in rattling or clicking noises during cycles.

- Electrical issues may generate unusual sounds from motors or control panels.

By recognizing and understanding these unusual sounds, users can take appropriate steps to address the issues effectively, ensuring optimal performance and longevity of the appliance.

Door Lock Mechanism Insights

The locking system is a crucial component in ensuring safety and proper functioning of the appliance. It serves as a protective barrier that prevents unintended access during operation, safeguarding both the user and the device itself. Understanding this mechanism helps in diagnosing issues and maintaining efficiency.

This system typically includes several key parts, such as the latch, actuator, and electronic control. Each element works in harmony to engage and disengage the lock based on specific conditions, such as door closure and operational status. When the door is shut, the latch secures it, allowing the appliance to start its cycle. If any part of this assembly fails, it can lead to operational interruptions or error codes.

Common issues with the locking mechanism often arise from wear and tear, misalignment, or electrical failures. Regular inspection and maintenance can prevent these problems, ensuring the system operates smoothly. Understanding the signs of malfunction, such as unusual noises or failure to engage, can aid in timely troubleshooting.

In summary, familiarity with the locking system enhances overall performance and safety. Being proactive about its care and understanding its functions can lead to a more efficient and reliable appliance experience.

Understanding Error Codes

Error codes serve as essential indicators for diagnosing issues in modern appliances. They provide valuable insights into malfunctions, allowing users to identify and address problems effectively. By interpreting these codes, users can streamline troubleshooting processes and potentially save on repair costs.

Each code corresponds to specific faults within the system. Here is a brief overview of common error codes and their meanings:

| Error Code | Meaning |

|---|---|

| F01 | Communication error between components. |

| F02 | Drain issue detected; water not removing. |

| F03 | Temperature sensor failure. |

| F04 | Door lock malfunction. |

Understanding these codes empowers users to make informed decisions regarding maintenance and repair, ensuring optimal performance of their appliances.

Cleaning and Care Procedures

Maintaining appliances in optimal condition is essential for longevity and performance. Regular cleaning and proper care not only enhance efficiency but also prevent potential issues that can arise from neglect. This section outlines essential practices to ensure your unit remains in top shape.

Routine Cleaning Steps

- Exterior Wipe Down: Use a soft cloth and mild detergent to clean the outer surfaces, removing dust and grime.

- Drum Maintenance: Periodically run a cleaning cycle using specialized cleaners to eliminate residue and odors.

- Detergent Dispenser Care: Remove and clean the detergent drawer regularly to prevent buildup that can affect performance.

Preventive Measures

- Ensure proper ventilation to avoid moisture buildup.

- Check hoses for kinks or wear, replacing them as needed.

- Inspect seals and gaskets for integrity, cleaning them to prevent mold growth.

Implementing these cleaning and care routines will enhance the efficiency and lifespan of your appliance, allowing for reliable service over the years.

Service Call Considerations

When facing issues with household appliances, evaluating the need for professional assistance is essential. Understanding the factors that influence a service visit can help ensure a smoother process and potentially save time and costs.

- Diagnosis of Symptoms: Accurately identifying the problem is critical. Before contacting a technician, take note of any unusual sounds, error codes, or performance issues.

- Age of the Appliance: Consider how long the unit has been in use. Older models may be less cost-effective to repair, while newer ones may still be under warranty.

- Accessibility: Ensure that the appliance is accessible for the technician. Clearing any obstacles around the unit can facilitate a quicker assessment and repair.

- Recent Repairs: If the appliance has undergone recent servicing, be prepared to share this information. It may impact the current issue and help the technician understand the appliance’s history.

- Warranty Status: Check if the device is still under warranty. Warranty coverage can significantly influence repair costs and options available to you.

Taking these factors into account will aid in making informed decisions regarding professional support for your appliance’s issues.