In the realm of automotive engineering, the intricacies of specific mechanisms often necessitate detailed guidance. This section aims to provide comprehensive insights into the upkeep of a particular gear system. Such knowledge is essential for enthusiasts and professionals alike, ensuring optimal performance and longevity.

Addressing common challenges and procedures, the following content will delve into essential techniques and considerations. By breaking down complex processes into manageable steps, users will be better equipped to tackle issues with confidence and precision.

Whether you’re a seasoned technician or a curious learner, this exploration will enhance your understanding of vital maintenance practices. Emphasizing clarity and accessibility, the information presented will serve as a valuable resource in navigating the nuances of this sophisticated machinery.

Overview of the ZF 6HP19 Transmission

The ZF 6HP19 represents a sophisticated piece of engineering designed for seamless power transfer in modern vehicles. This unit combines advanced technology and precision manufacturing to deliver optimal performance and efficiency.

Characterized by its innovative multi-gear layout, this system enhances driving dynamics while ensuring smooth gear shifts. Engineered to cater to a variety of vehicle types, it is notable for its adaptability and reliability under diverse operating conditions.

One of the key features of this assembly is its ability to manage power effectively, allowing for responsive acceleration and fuel efficiency. This performance is further supported by advanced electronic controls, which monitor various parameters to optimize functionality and enhance driver experience.

Common Issues and Symptoms

Understanding the frequent problems associated with automatic gearboxes is essential for maintaining optimal vehicle performance. Identifying the signs of potential malfunctions can help in addressing them promptly, preventing further complications.

- Slipping Gears: This occurs when the system unexpectedly shifts from one gear to another, causing a noticeable loss of power.

- Delayed Engagement: A hesitation before the vehicle moves forward or backward can indicate internal issues.

- Noisy Operation: Unusual sounds, such as grinding or whining, often signal that something is amiss within the mechanism.

- Fluid Leaks: Puddles of fluid under the vehicle may suggest a significant leak, which can lead to inadequate lubrication.

- Warning Lights: Illuminated dashboard indicators related to the drivetrain should not be ignored, as they often point to underlying problems.

Being aware of these common issues can aid in early detection and facilitate timely interventions, ensuring a smoother driving experience.

Tools Required for Repairs

Undertaking maintenance tasks for complex machinery necessitates a specific set of instruments. Having the appropriate tools ensures efficiency and accuracy during the process, minimizing the risk of errors. Below is a comprehensive overview of essential equipment that will facilitate successful interventions.

Essential Hand Tools

The following hand tools are crucial for effective servicing:

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening various fasteners. |

| Wrenches | To access and manipulate bolts in confined spaces. |

| Screwdrivers | For handling screws of different types and sizes. |

| Torque Wrench | To apply precise torque to fasteners. |

Specialized Equipment

In addition to standard tools, certain specialized instruments are necessary for specific operations:

| Tool | Purpose |

|---|---|

| Fluid Pump | To facilitate the transfer of lubricants and fluids. |

| Diagnostic Scanner | For identifying issues through electronic analysis. |

| Gear Puller | To safely remove gears and components without damage. |

| Cleaning Kit | To ensure all parts are free from contaminants before reassembly. |

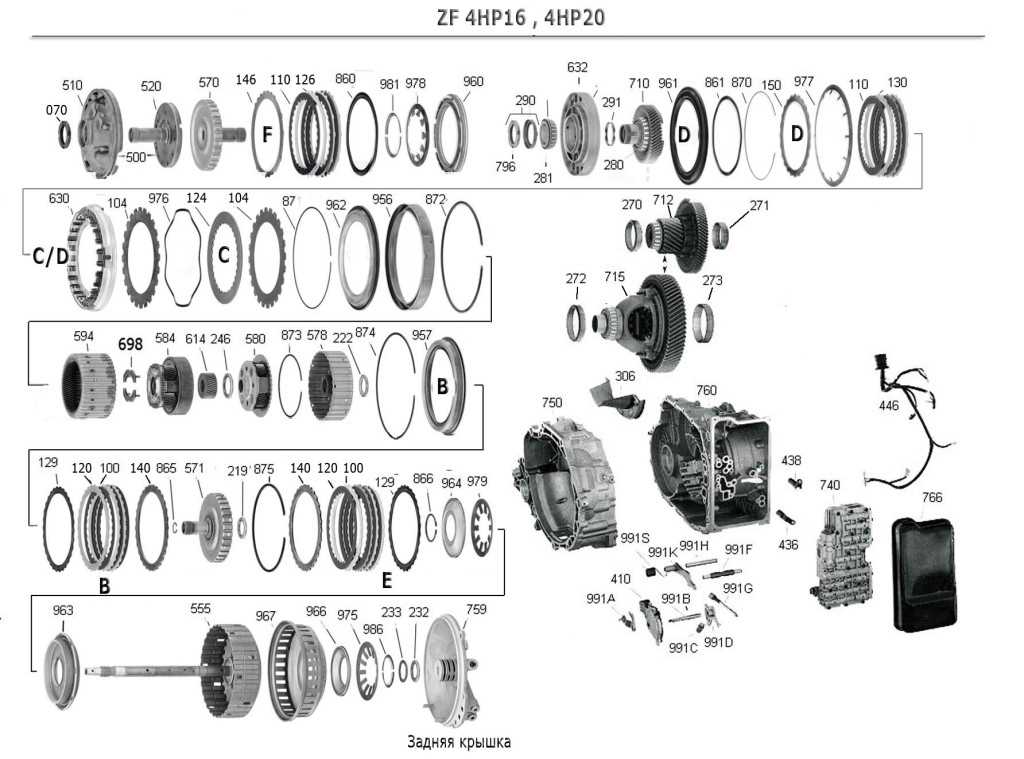

Step-by-Step Disassembly Process

This section outlines a comprehensive approach to methodically taking apart the complex assembly for maintenance or inspection. Following these steps ensures that each component is carefully removed and documented for reassembly.

Begin by preparing your workspace, ensuring all necessary tools and materials are readily available. Clear a sufficient area to lay out components as they are removed.

Next, detach the outer casing. This involves unscrewing all fasteners and gently prying apart sections without damaging the interior parts. Maintain an organized collection of screws and small components to facilitate later reassembly.

Once the outer shell is off, proceed to remove internal components. Start with larger parts, working your way towards smaller assemblies. Use a systematic approach, taking notes or labeling items as you go to keep track of their arrangement.

After all significant elements are removed, focus on intricate assemblies that may require special attention. Use caution when handling delicate parts to avoid any damage that could complicate the reassembly process.

Finally, inspect all components for wear or damage, documenting any issues that may need addressing before reassembly. This careful disassembly process sets the stage for effective evaluation and future reinstallation.

Inspecting Key Components

Careful evaluation of essential parts is crucial for ensuring optimal performance and longevity of the system. Identifying wear, damage, or irregularities can prevent further complications and costly replacements. This section outlines the primary elements to focus on during the inspection process.

- Housing: Check for cracks or signs of corrosion that may compromise integrity.

- Gears: Examine the teeth for wear patterns or chips, which can affect efficiency.

- Seals and Gaskets: Inspect for leaks or deterioration, as these can lead to fluid loss and operational issues.

- Fluid Levels: Ensure that the fluid is at the recommended level and appears clean, indicating proper function.

- Electrical Connectors: Verify the condition of wiring and connections to prevent electrical failures.

Regular checks of these components contribute to a smoother functioning system and can significantly extend its lifespan.

Reassembly Guidelines and Tips

When putting together complex machinery, following precise protocols is essential to ensure optimal performance. The process requires attention to detail and adherence to systematic approaches to avoid errors and enhance reliability. By understanding the key principles of reassembly, you can significantly improve the longevity and efficiency of your unit.

Preparation and Organization

Before beginning the reassembly process, it is crucial to organize all components and tools effectively. Create a clean workspace and lay out parts systematically, referencing diagrams if available. Ensure that all items are free from debris and damage, and replace any worn-out components as needed. Proper labeling and categorization will streamline the process and reduce the risk of missing critical elements.

Step-by-Step Assembly

Follow a methodical approach while reassembling each section. Start with the largest components, gradually working towards smaller parts. Apply appropriate lubricants where specified, ensuring that surfaces are adequately coated without excess. Double-check connections and alignments at each stage, as inaccuracies can lead to performance issues. After completing the assembly, conduct a thorough inspection to confirm that everything is correctly positioned before finalizing the process.

Fluid Types and Maintenance Practices

Proper selection of liquid substances and regular upkeep are vital for ensuring optimal performance and longevity of automotive systems. Understanding the different types of fluids available and the recommended maintenance routines can significantly impact efficiency and reliability.

Fluid Selection: The choice of liquid is crucial, as it affects lubrication, cooling, and overall functionality. Manufacturers often specify particular types to maximize effectiveness. Always refer to guidelines when choosing fluids, as using the wrong type can lead to severe consequences.

Regular Maintenance: Consistent monitoring and timely replacement of fluids are essential practices. Establishing a routine schedule for checks can prevent issues from arising and help maintain optimal working conditions. It is advisable to examine fluid levels and quality periodically, ensuring they meet the necessary standards.

Additional Practices: Beyond fluid management, consider other maintenance tasks such as inspecting seals and gaskets for leaks. Keeping components clean and addressing minor issues promptly can enhance overall system performance and prevent costly repairs down the line.

Diagnostic Procedures for Transmission Problems

Identifying issues within a vehicle’s power transfer system is crucial for ensuring optimal performance and longevity. Proper diagnostics allow for early detection of faults, which can prevent more severe damage and costly repairs. This section outlines key procedures to effectively assess and troubleshoot common concerns.

| Symptoms | Possible Causes | Recommended Actions |

|---|---|---|

| Unusual noises during operation | Worn components, insufficient lubrication | Inspect fluid levels and condition; check for damaged parts |

| Slipping gears | Low fluid levels, faulty sensors | Examine fluid levels; perform sensor tests |

| Delayed engagement | Contaminated fluid, mechanical failure | Change fluid; inspect for mechanical issues |

| Warning lights illuminated | Electrical issues, sensor malfunctions | Use diagnostic tools to read fault codes; check wiring |

By following these diagnostic steps, you can systematically address potential issues. This proactive approach not only enhances vehicle reliability but also contributes to a safer driving experience.

Upgrading and Enhancing Performance

Improving vehicle efficiency and responsiveness can significantly enhance the driving experience. By focusing on key areas of performance modification, enthusiasts can achieve noticeable gains in power delivery and overall functionality.

Software Optimization: Updating the vehicle’s control software can lead to better calibration of engine parameters. This adjustment can enhance throttle response and fuel efficiency, resulting in a smoother and more powerful driving experience.

Component Upgrades: Replacing factory components with high-performance alternatives can make a substantial difference. For example, upgraded fluid pumps and cooler systems can maintain optimal operating temperatures, which helps in sustaining performance during demanding conditions.

Regular Maintenance: Ensuring that all parts are in top condition is essential for longevity and reliability. Regular inspections and timely replacements of wear items contribute to maintaining optimal performance levels.

By focusing on these areas, owners can maximize their vehicle’s potential and enjoy improved performance on the road.

Common Mistakes to Avoid

When dealing with complex machinery, it’s crucial to be aware of frequent pitfalls that can lead to significant issues. Many individuals overlook key steps or misinterpret guidelines, resulting in setbacks or even permanent damage. Understanding these common errors can help ensure a smoother process and successful outcomes.

Here are some prevalent mistakes to watch out for:

| Mistake | Description |

|---|---|

| Ignoring Manufacturer Specifications | Failing to adhere to the specific guidelines provided by the manufacturer can lead to incompatible parts or improper assembly. |

| Using Incorrect Tools | Utilizing inappropriate tools may damage components or hinder the overall function of the system. |

| Neglecting Regular Maintenance | Overlooking routine upkeep can result in premature wear and tear, leading to costly repairs. |

| Rushing the Process | Being hasty can lead to missed steps or errors, ultimately affecting performance and longevity. |

Cost Considerations for Repairs

When addressing issues related to vehicle components, understanding the financial implications is crucial. The overall expenditure can vary significantly based on the complexity of the problem, required parts, and labor rates.

Parts Costs: The price of replacement components can fluctuate widely. High-quality or OEM parts generally come at a premium, while aftermarket options may offer savings but could compromise longevity or performance.

Labor Charges: Professional service fees can add substantially to the total cost. Rates differ based on the location and the expertise of the technicians. Opting for a well-regarded shop might ensure better service but could also increase expenses.

Additional Expenses: Often, there are hidden costs associated with the process. These may include diagnostics, fluid replacements, or unexpected repairs that arise during the assessment. Setting aside a budget for unforeseen issues is advisable.

Ultimately, careful planning and thorough research can help mitigate costs while ensuring effective resolution of vehicle issues.

Frequently Asked Questions

This section addresses common inquiries related to the service and maintenance of specific vehicle components. Here, you will find answers to typical concerns that users often have, enhancing your understanding and facilitating smoother operations.

What are the signs of issues with the component?

Common indicators of potential problems include unusual noises, fluid leaks, and changes in performance. Monitoring these signs can help identify when further inspection is needed.

How often should I conduct maintenance checks?

Regular inspections are recommended, ideally following the manufacturer’s guidelines. Consistent checks help ensure optimal functionality and prevent unexpected failures.

Resources for Further Learning

Expanding your knowledge in the field of automotive mechanics can greatly enhance your skills and understanding. Whether you are a beginner or a seasoned professional, various resources are available to help you deepen your expertise in vehicle systems and their complexities.

| Resource Type | Description | Link |

|---|---|---|

| Books | Comprehensive guides that cover a range of topics related to vehicle systems and diagnostics. | Visit Here |

| Online Courses | Interactive learning platforms offering courses on automotive technology and maintenance. | Visit Here |

| Forums | Community-driven platforms where enthusiasts and experts share insights and solutions. | Visit Here |

| Videos | Tutorials and demonstrations available on platforms like YouTube that visually explain various procedures. | Visit Here |