Understanding the intricacies of automotive systems is essential for maintaining optimal vehicle performance. This section provides insights into effective practices for addressing complex issues that may arise within the drivetrain components. By exploring these methods, enthusiasts and technicians alike can enhance their knowledge and skill set.

Detailed examination of drivetrain components is crucial for diagnosing problems accurately. In this discussion, we will delve into various techniques that aid in identifying the underlying causes of issues, thereby ensuring a thorough approach to vehicle maintenance. Proper assessment not only extends the lifespan of the system but also contributes to overall safety on the road.

Furthermore, equipping oneself with a comprehensive understanding of the necessary procedures can significantly reduce repair times. Emphasis will be placed on step-by-step approaches that facilitate efficient troubleshooting and resolution of common concerns. This guidance serves as a valuable resource for those seeking to improve their proficiency in automotive care.

A4AF3 Transmission Repair Guide

This section provides essential information for addressing issues related to the automatic gear mechanism commonly found in various vehicle models. Understanding the key components and processes involved in maintaining optimal functionality can significantly enhance performance and longevity.

Common Issues and Solutions

Identifying frequent problems such as slipping, unusual noises, or fluid leaks is crucial for timely intervention. Regular inspection and maintenance can prevent minor issues from escalating into major failures. Solutions often involve checking fluid levels, replacing worn parts, and ensuring proper alignment.

Maintenance Tips

To ensure reliable operation, routine care is recommended. This includes regular fluid changes, checking for leaks, and monitoring performance during operation. Keeping the system clean and free of debris can also contribute to smoother functionality.

Understanding the A4AF3 Transmission

The design and function of this specific gear system play a crucial role in ensuring smooth vehicle operation. By comprehending its components and mechanics, one can appreciate the intricate balance required for optimal performance.

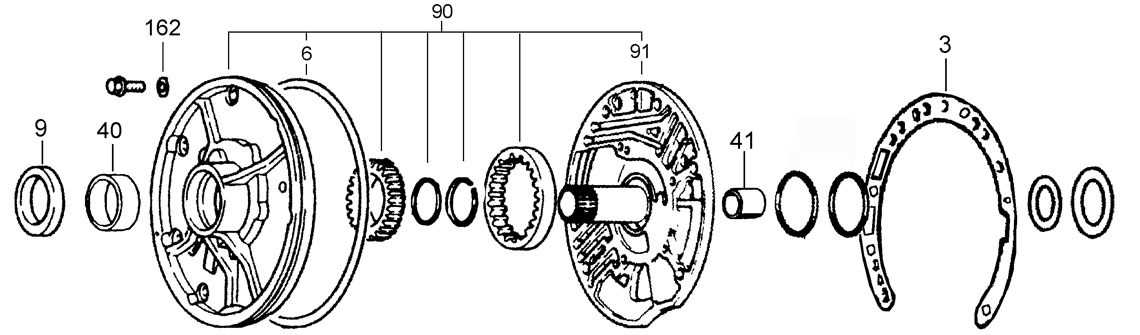

Key Components

This mechanism comprises several essential parts, including clutches, gears, and hydraulic systems. Each element interacts seamlessly to facilitate efficient power transfer, highlighting the complexity of its architecture.

Functionality Overview

At its core, this assembly is responsible for modulating engine power and enhancing driving experience. By adjusting the gear ratios, it allows for responsive acceleration and improved fuel efficiency, making it a vital aspect of modern vehicles.

Common Issues with A4AF3 Units

Understanding the frequent challenges encountered with specific automotive components is essential for maintaining optimal performance. These issues can lead to various operational difficulties, affecting overall vehicle functionality.

Typical Problems Faced

Several common complications may arise during the use of these units. Identifying these problems early can save time and resources in the long run.

| Issue | Description |

|---|---|

| Fluid Leaks | Leaks can occur due to worn seals or gaskets, leading to low fluid levels and potential overheating. |

| Shifting Difficulties | Problems with smooth shifting can arise from various factors, including linkage issues or internal wear. |

| Noises | Unusual sounds during operation may indicate internal damage or misalignment of components. |

| Overheating | Excessive heat can result from insufficient lubrication or cooling system failures, risking serious damage. |

Preventive Measures

Regular maintenance and prompt attention to symptoms can significantly mitigate these common issues. Implementing scheduled checks and addressing minor problems swiftly can prolong the lifespan of these systems.

Essential Tools for Repairing Transmissions

When undertaking the task of restoring complex gear systems, having the right equipment is crucial. These specialized instruments not only enhance efficiency but also ensure precision throughout the process. Understanding the necessary tools can significantly improve the overall outcome of the work.

Wrenches and Sockets: A diverse set of wrenches and sockets is fundamental. They allow for the loosening and tightening of bolts in tight spaces, providing the leverage needed for stubborn fasteners.

Torque Wrench: This tool is vital for applying the correct amount of force when fastening components. It helps prevent damage caused by over-tightening, ensuring the integrity of the assembly.

Fluid Pump: Managing fluids effectively is essential in any mechanical system. A dedicated pump simplifies the process of filling and draining various liquids, maintaining optimal levels for smooth operation.

Diagnostic Tools: Utilizing diagnostic equipment helps identify issues before they escalate. These tools provide insights into performance, aiding in quick assessments and timely interventions.

Specialty Gear Pullers: Extracting gears can be a delicate task. Specialty pullers make this process safer and more effective, reducing the risk of damaging surrounding components.

Equipped with these essential instruments, the task of maintaining and restoring complex systems becomes more manageable and effective.

Step-by-Step Disassembly Process

This section outlines a comprehensive approach to disassembling a complex mechanical system. By following a structured procedure, individuals can effectively separate components for thorough examination or maintenance. A methodical breakdown ensures that all parts are handled with care, reducing the risk of damage and simplifying reassembly.

Preparation and Safety Measures

Before beginning the disassembly, it is crucial to prepare the workspace and gather necessary tools. Ensure that the area is clean and well-lit. Wearing appropriate safety gear, such as gloves and goggles, is essential to protect against potential hazards. Identifying and organizing components beforehand will facilitate a smoother process.

Disassembly Steps

Start by carefully removing any external coverings or shields. This initial step allows access to the inner mechanisms. Proceed by systematically loosening fasteners and separating components in a logical order. Documenting each step, including the placement of parts, can aid in reassembly. Take special care with delicate elements, as they may require gentle handling to avoid damage.

Inspecting Components for Damage

Regular examination of various parts is crucial for maintaining optimal performance and longevity. Identifying signs of wear or damage can prevent further complications and ensure smooth operation. This section outlines key considerations when assessing the integrity of components.

| Component | Signs of Damage | Recommended Action |

|---|---|---|

| Seals | Cracks or tears | Replace immediately |

| Gears | Chipping or excessive wear | Inspect for replacement |

| Housings | Cracks or deformities | Consider repair or replacement |

| Shafts | Bending or scoring | Realign or replace |

Reassembly Tips for A4AF3

When putting components back together, it’s essential to follow a systematic approach to ensure everything fits perfectly and functions as intended. This section offers guidance on achieving a seamless reassembly process, minimizing the risk of errors that could lead to operational issues.

First, carefully organize all parts and tools before starting. Keeping everything accessible will streamline the process and help prevent any missing components. It is also advisable to reference any previous notes or diagrams taken during disassembly, as they can provide crucial insights into the correct positioning of each element.

Another key aspect is to apply appropriate lubrication where necessary. Ensuring that moving parts are adequately greased will facilitate smoother operation and enhance overall performance. Additionally, double-checking torque specifications for bolts and fasteners is vital to maintain structural integrity and avoid future complications.

Finally, take your time during reassembly. Rushing through can lead to oversights that may compromise the functionality of the entire assembly. A meticulous approach will ultimately yield a more reliable outcome and extend the lifespan of the unit.

Fluid Requirements and Maintenance

Maintaining optimal performance in automotive gear systems relies heavily on the correct selection and upkeep of fluids. Understanding the specific requirements for lubricants and hydraulic substances is crucial for ensuring longevity and efficiency.

Regular checks and changes of these fluids can prevent wear and tear, contributing to smoother operation. Here are key aspects to consider:

- Fluid Types: Use the recommended lubricant that meets the manufacturer’s specifications to ensure compatibility.

- Fluid Levels: Regularly monitor the fluid levels to prevent overheating and maintain effective lubrication.

- Change Intervals: Adhere to the suggested intervals for fluid replacement to avoid contamination and degradation.

By prioritizing these maintenance practices, vehicle owners can enhance the durability of their systems and improve overall driving experiences.

Testing Transmission Performance Post-Repair

After completing any service on a vehicle’s power transfer system, it is crucial to assess its functionality to ensure optimal operation. This evaluation not only confirms that the necessary adjustments have been made but also identifies any potential issues that may arise during regular use.

Key Assessment Steps

Begin by conducting a thorough visual inspection of the components involved. Look for any signs of leakage, unusual wear, or misalignment that could affect performance. Following this, engage in a series of operational tests to evaluate responsiveness and smoothness during gear changes.

Performance Evaluation Techniques

Utilize diagnostic tools to monitor performance metrics during various driving conditions. Pay attention to factors such as shifting speed and overall responsiveness. Driving tests in different scenarios will provide valuable insights into the system’s behavior, helping to ensure everything functions as intended.

Identifying Signs of Failure

Understanding the indicators of malfunction in your vehicle’s drivetrain is essential for maintaining optimal performance. Recognizing these early warning signs can prevent more significant issues down the line and ensure a smoother driving experience.

Common Symptoms to Watch For

Drivers should be attentive to several common symptoms that may indicate a problem. Unusual noises, such as grinding or whining, can signal that components are not functioning correctly. Additionally, slipping sensations during gear changes or difficulty engaging gears may suggest underlying issues.

Visual and Sensory Cues

In addition to auditory warnings, visual inspection can reveal important clues. Leaks beneath the vehicle or warning lights on the dashboard are critical indicators that should not be ignored. Furthermore, any noticeable changes in vehicle responsiveness or performance may necessitate further investigation.

Upgrades and Modifications to Consider

When it comes to enhancing performance and reliability, there are several options available that can significantly improve the functionality of your vehicle’s drivetrain. These enhancements not only boost efficiency but also contribute to a smoother driving experience.

Performance Enhancements

- Upgrading to a high-performance fluid for better lubrication.

- Installing a cooler to manage temperatures effectively during heavy use.

- Utilizing a tuning module to optimize engine and drivetrain parameters.

Durability Improvements

- Reinforcing components with stronger materials to withstand higher stress.

- Adding a protective shield to guard against debris and damage.

- Implementing regular maintenance schedules to prolong lifespan.

Safety Precautions During Repairs

Ensuring a secure environment is paramount when conducting maintenance on automotive components. Adhering to safety measures not only protects the individual performing the work but also prevents damage to the vehicle and surrounding areas.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is essential. This includes gloves to safeguard against sharp edges and chemicals, goggles to protect the eyes from debris, and sturdy footwear to minimize the risk of injury from heavy parts. Always prioritize your safety when engaging in any mechanical tasks.

Workspace Organization

Maintaining an orderly workspace contributes significantly to safety. Ensure that all tools and materials are neatly arranged and easily accessible. This reduces the likelihood of accidents caused by tripping or misplaced equipment. A well-organized area enhances efficiency and keeps the focus on the task at hand.