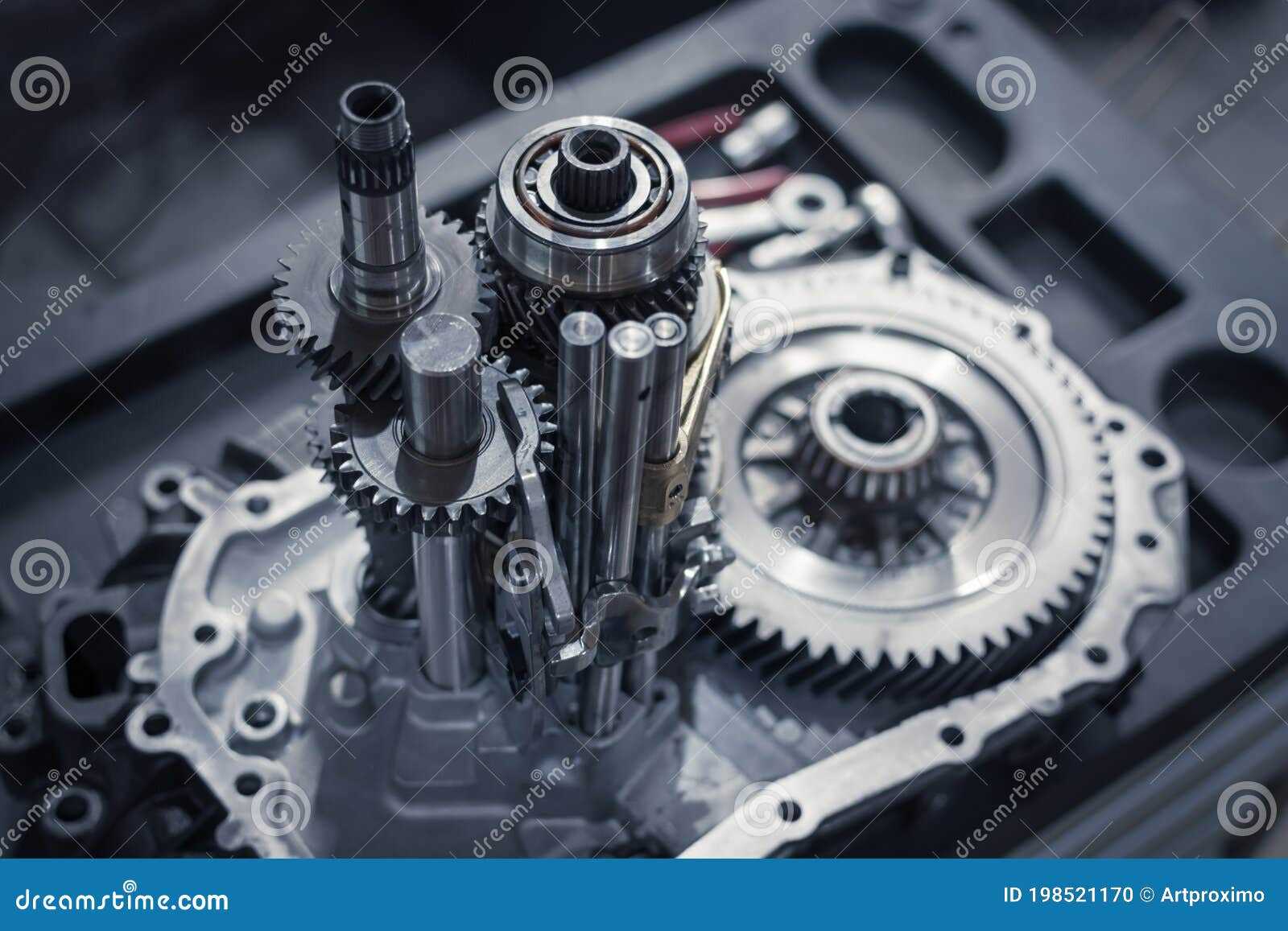

The intricate world of gear mechanisms plays a vital role in the performance and functionality of many vehicles. Understanding the components and their interactions is essential for anyone looking to maintain their automobile’s efficiency. This journey into the realm of gear systems will unveil the nuances that often go unnoticed, yet are critical for a smooth ride.

In many instances, drivers may encounter challenges that disrupt the seamless operation of their vehicles. These complications can arise from wear and tear, lack of maintenance, or simply the passage of time. Addressing these issues requires not just knowledge but also a hands-on approach, as well as the right tools to bring back the vitality of the system.

Exploring the various aspects of these intricate assemblies allows enthusiasts and professionals alike to restore functionality and enhance performance. With patience and dedication, anyone can learn the necessary techniques to troubleshoot and overcome common hurdles, ensuring that their vehicle continues to deliver an enjoyable driving experience.

Understanding Manual Transmission Basics

Grasping the fundamentals of a vehicle’s gear-shifting system is essential for any enthusiast or mechanic. This intricate assembly plays a crucial role in the performance and efficiency of an automobile, facilitating the connection between the engine and wheels. A solid comprehension of its components and functionality lays the groundwork for further exploration and practical applications.

Key Components

Several essential elements comprise this system, each contributing to its overall operation. Understanding these parts helps in recognizing their individual roles and interconnections.

| Component | Description |

|---|---|

| Clutch | Engages and disengages the engine from the gear system, allowing for smooth shifting. |

| Gear Selector | Allows the driver to choose the desired gear, controlling the vehicle’s speed and power. |

| Synchromesh | Ensures smooth engagement of gears by matching their speeds before connection. |

| Input Shaft | Transfers power from the engine to the gear assembly. |

| Output Shaft | Delivers power from the gear assembly to the wheels. |

Operational Principles

The operation of this system revolves around shifting gears to match the speed and load conditions. Engaging a gear alters the engine’s power output, enabling the vehicle to accelerate or decelerate efficiently. Understanding the relationship between gear ratios and engine performance is vital for optimizing driving experience.

Common Symptoms of Transmission Issues

Recognizing potential complications in the vehicle’s gear system is crucial for maintaining optimal performance. Certain signs can indicate that the mechanism may not be functioning correctly, often requiring attention to prevent further damage.

Unusual Noises

Strange sounds while changing gears can be a clear indicator of trouble. These noises may vary and include:

- Grinding or shaking sounds during shifts

- Clunking noises when engaging gears

- Whining or buzzing when accelerating

Difficulty Shifting

Experiencing challenges while changing gears can signal underlying issues. Pay attention to the following:

- Resistance when moving the gear lever

- Unexpected jumps or slips between gears

- Inability to engage specific gears

Being aware of these indicators can help in addressing problems early, ensuring a smoother driving experience.

Essential Tools for the Repair Process

Embarking on a journey to restore a vehicle’s gear system requires a well-equipped arsenal. Having the right implements can significantly streamline the task, ensuring efficiency and precision throughout the project.

Below is a curated list of indispensable tools that will aid in this intricate endeavor:

- Socket Set: A comprehensive set of sockets is crucial for loosening and tightening various fasteners.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Screwdrivers: Both flathead and Phillips varieties are necessary for removing screws from different components.

- Pliers: Useful for gripping, bending, and cutting wires or small components.

- Pick Set: Helpful for removing seals and O-rings without causing damage.

- Oil Pan: Essential for collecting fluids that may spill during disassembly.

- Fluid Pump: Aids in transferring oil and other fluids with ease.

Equipping yourself with these tools lays a solid foundation for a successful project, allowing you to tackle the intricacies of the system confidently.

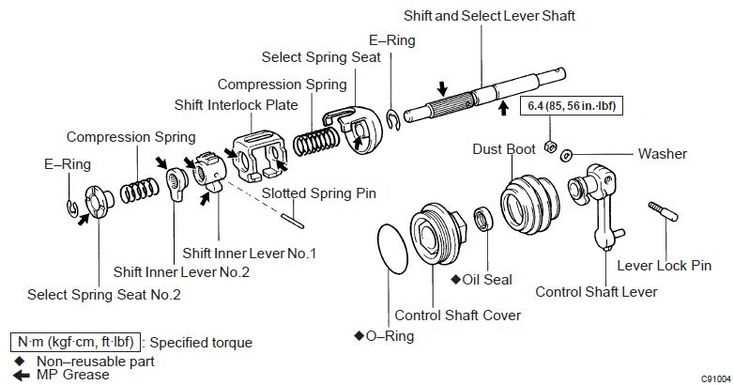

Step-by-Step Disassembly Guide

This section provides a systematic approach to taking apart a complex mechanical system, ensuring that each stage is clear and manageable. Following these steps will help you maintain organization and prevent any loss of components during the process.

Preparation

- Gather necessary tools: wrenches, screwdrivers, pliers, and a torque wrench.

- Ensure a clean, well-lit workspace free from distractions.

- Have a container for small parts to avoid misplacement.

Disassembly Steps

- Remove the housing cover by unscrewing all retaining bolts.

- Take out the shift fork assembly carefully, noting its orientation.

- Disconnect any linkages or cables attached to the assembly.

- Extract the gear sets, ensuring that you document their arrangement.

- Inspect the bearings and seals for wear before removing them.

- Store each component in a labeled container for easy reassembly.

By following these steps methodically, you will ensure that the process is efficient and all parts are accounted for, making future assembly straightforward.

Identifying Worn or Damaged Parts

Recognizing components that have experienced wear or damage is crucial for maintaining optimal functionality. This process involves thorough inspection and attention to detail, ensuring that any issues are identified early to prevent further complications.

Key signs to look for include:

- Unusual Noises: Grinding, whining, or clunking sounds can indicate problems with gears or bearings.

- Difficulty Shifting: Resistance or stiffness when changing gears may suggest worn linkage or internal issues.

- Fluid Leaks: Puddles or stains beneath the vehicle often point to seal failures or damaged gaskets.

- Excessive Vibration: Noticeable shaking while operating can be a sign of imbalanced components.

To conduct a thorough examination, follow these steps:

- Start by inspecting the fluid condition; look for discoloration or metallic particles.

- Examine the external casing for cracks or signs of impact.

- Check all linkage and cables for fraying or disconnections.

- Remove the cover to visually inspect gears, synchronizers, and bearings for wear patterns.

Documenting findings will aid in determining the necessary actions and ensure that all affected areas are addressed effectively.

Replacing Gaskets and Seals

In the maintenance of mechanical systems, ensuring the integrity of components is crucial for optimal performance. Gaskets and seals play a vital role in preventing leaks and maintaining pressure within the assembly. Over time, these elements can wear out, leading to potential complications if not addressed promptly.

When approaching the replacement of these critical parts, it is essential to begin by carefully disassembling the affected sections. Cleaning surfaces thoroughly is necessary to remove old materials and ensure a proper fit for the new components. Inspecting the surrounding areas for damage is also important, as any imperfections can compromise the effectiveness of the new gaskets and seals.

Once the surfaces are prepared, applying the correct adhesive or sealant, if required, can enhance the sealing process. It is vital to follow the manufacturer’s specifications regarding torque settings when reassembling to maintain even pressure across the newly installed components. Regular monitoring after replacement can help detect any early signs of wear or failure, ensuring long-term reliability.

Reassembling the Transmission Properly

Successfully putting together a complex mechanical assembly requires precision and attention to detail. Each component must be aligned correctly to ensure smooth operation and longevity. Proper techniques and methods will contribute to the overall effectiveness of the unit once it is back in service.

Before starting the reassembly process, ensure that all parts are clean and free from debris. It’s also essential to have a well-organized workspace to prevent misplacing any components. Following a systematic approach will facilitate the process and help avoid potential mistakes.

| Step | Description |

|---|---|

| 1 | Begin with the main casing and ensure all sealing surfaces are intact and clean. |

| 2 | Insert gears and shafts, paying attention to alignment marks. |

| 3 | Carefully position synchronizers and retainers to ensure proper engagement. |

| 4 | Install the shifting mechanism, checking for smooth operation before securing. |

| 5 | Secure the casing with bolts to the manufacturer’s specified torque settings. |

After completing the assembly, conduct a thorough inspection of the unit. Testing the mechanism before installation will help identify any issues early on. Following these guidelines will help ensure reliable functionality and performance in the long run.

Fluid Types and Their Importance

The choice of liquids used in the drivetrain plays a crucial role in ensuring optimal performance and longevity of the system. Different formulations offer varying characteristics that can significantly affect how components interact, leading to smoother operation and reduced wear over time. Understanding the nuances of these fluids is essential for maintaining peak efficiency and functionality.

Types of Fluids

There are several types of fluids available, each designed for specific applications. Conventional gear oils are commonly used due to their ability to provide adequate lubrication and protection against wear. Synthetic fluids, on the other hand, offer enhanced stability under extreme conditions, reducing the risk of breakdown and providing superior lubrication at varying temperatures. Additionally, specialized additives can improve performance by minimizing friction and preventing corrosion.

Significance of Fluid Maintenance

Regular maintenance of these liquids is vital for ensuring the reliability of the system. Over time, fluids can become contaminated or lose their protective properties, which can lead to increased friction and overheating. Monitoring fluid levels and quality helps to identify issues before they escalate, ensuring a longer lifespan for the entire assembly. Proper fluid management is not just about performance; it’s an investment in the overall health of the vehicle.

Testing the Transmission Functionality

Assessing the performance of the gear-shifting system is crucial for ensuring smooth operation and identifying potential issues. This process involves a series of evaluations that focus on various aspects of the mechanism, ensuring that all components function harmoniously.

Initial Observations

Begin by conducting a visual inspection. Check for any signs of leaks, wear, or damage to the surrounding parts. Listening for unusual noises during operation can also provide insight into potential malfunctions. If any irregularities are detected, further examination may be necessary.

Functional Tests

Next, engage the system under different conditions. Test the engagement of gears, paying attention to the smoothness of transitions. Acceleration and deceleration should be consistent without any hesitation or grinding sounds. Shifting should feel precise and responsive, indicating that the internal components are functioning as intended.

Preventive Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your vehicle’s drivetrain system. Implementing simple yet effective practices can greatly enhance performance and extend lifespan, preventing costly issues down the line.

First, check and maintain fluid levels consistently. Clean, high-quality lubricants reduce friction and wear, allowing components to function smoothly. Adhering to the manufacturer’s recommendations for fluid changes is crucial.

Next, monitor the condition of the linkage and cables. Keeping these components well-adjusted and free from debris will ensure smooth operation and prevent premature wear. Inspect them periodically for signs of damage or looseness.

Additionally, avoid aggressive driving habits. Gentle acceleration and smooth gear changes reduce stress on the system, enhancing overall performance. Being mindful of engine speed and load can lead to a more enjoyable driving experience.

Lastly, schedule regular inspections with a qualified technician. Professional assessments can identify potential issues before they escalate, allowing for timely intervention. Establishing a routine maintenance schedule will contribute to long-lasting reliability.

When to Seek Professional Help

Determining the right moment to call in an expert can save time, money, and frustration. While some issues can be addressed by an enthusiast, others require specialized knowledge and tools that only professionals possess.

- If you encounter persistent grinding noises or difficulty engaging gears, it may indicate deeper issues that warrant expert assessment.

- In cases where fluid leaks are evident, professional diagnosis is essential to prevent further damage to surrounding components.

- If any warning lights on your dashboard illuminate, it’s crucial to consult a specialist for accurate diagnostics.

- Complex disassembly or reassembly tasks should be left to trained technicians to avoid potential errors that could lead to more significant problems.

Ultimately, trusting your instincts is vital. If the situation feels overwhelming or outside your expertise, seeking professional assistance is a wise choice.

Resources for Further Learning

Expanding your knowledge on vehicle systems and their intricate workings is essential for anyone interested in automotive mechanics. A variety of materials and platforms are available to enhance your understanding and skills in this area. Below are some valuable resources to consider for deepening your expertise.

Books

| Title | Author | Overview |

|---|---|---|

| Automotive Engineering Fundamentals | John Doe | An introduction to the core principles of automotive mechanics, focusing on various systems. |

| Advanced Gear Systems | Jane Smith | Dive into complex gear mechanisms and their applications in modern vehicles. |

Online Courses

| Course Name | Platform | Description |

|---|---|---|

| Introduction to Automotive Systems | Coursera | A comprehensive overview of automotive technologies with interactive content. |

| Transmission Dynamics | Udemy | Focused training on the principles governing vehicle power transfer mechanisms. |

By utilizing these resources, you can effectively broaden your comprehension and proficiency, paving the way for hands-on experience in the field.